Page is loading ...

Migmaster 300i cvcc

MIG/TIG/STICK WELDING PACKAGE

P/N 34677

INSTALLATION AND OPERATION for

Be sure this information reaches the operator.

You can get extra copies through your sup-

plier.

F-15-094-A

October, 1994

F-15-094-A

These INSTRUCTIONS are for experienced operators. If you are not fully familiar with the principles of operation and safe

practices for electric welding equipment, we urge you to read our booklet, ‘‘Precautions and Safe Practices for Arc Welding,

Cutting, and Gouging,’’ Form 52-529. Do NOT permit untrained persons to install, operate, or maintain this equipment. Do NOT

attempt to install or operate this equipment until you have read and fully understand these instructions. If you do not fully

understand these instructions, contact your supplier for further information.

ESAB Welding & Cutting Products

PO Box 100545

Florence SC 29501-0545

2

USER RESPONSIBILITY

This equipment will perform in conformity with the description thereof contained in this manual and

accompanying labels and/or inserts when installed, operated, maintained and repaired in accordance with the

instructions provided. This equipment must be checked periodically. Defective equipment should not be used.

Parts that are broken, missing, worn, distorted or contaminated should be replaced immediately. Should such

repair or replacement become necessary, the manufacturer recommends that a telephone or written request

for service advice be made to the Authorized Distributor from whom purchased.

This equipment or any of its parts should not be altered without the prior written approval of the manufacturer.

The user of this equipment shall have the sole responsibility for any malfunction which results from improper

use, faulty maintenance, damage, improper repair or alteration by anyone other than the manufacturer or a

service facility designated by the manufacturer.

3

TABLE OF CONTENTS

SECTION NO. PAGE NO.

SECTION 1 - GENERAL SAFETY RULES FOR WELDING AND CUTTING ........................... 2

GENERAL PRECAUTIONS ....................................................................................................... 2

ADDITIONAL SAFETY INFORMATION .................................................................................... 4

PRECAUTION SYMBOL DEFINITIONS .................................................................................... 5

SECTION II - INTRODUCTION

2.1 GENERAL ..................................................................................................................... 6

2.2 RECEIVING-HANDLING ............................................................................................... 6

2.3 DUTY CYCLE................................................................................................................ 6

2.4 DESCRIPTION .............................................................................................................. 6

2.5 OPTIONAL EQUIPMENT .............................................................................................. 7

2.6 SAFETY ........................................................................................................................ 8

SECTION III - INSTALLATION

3.1 LOCATION .................................................................................................................... 9

3.2 REAR WHEEL ASSEMBLY .......................................................................................... 9

3.3 PRIMARY (INPUT) ELECTRICAL CONNECTIONS ...................................................... 9

3.4 SECONDARY (OUTPUT) WELDING CONNECTIONS ................................................ 10

3.5 TORCH CONNECTIONS .............................................................................................. 10

3.6 WIRE FEEDER MECHANISM....................................................................................... 10

3.7 CONNECTION OF SHIELDING GAS SUPPLY ............................................................. 11

3.8 WELDING CABLE CONNECTIONS ............................................................................. 13

SECTION IV - OPERATION

4.1 CONTROLS .................................................................................................................. 13

4.2 OPERATING PROCEDURES ....................................................................................... 14

4.3 WELDING SETUP ....................................................................................................... 15

SECTION V - MAINTENANCE

5.1 INSPECTION AND SERVICE ....................................................................................... 28

4

SAFETY PRECAUTIONS

(TBS)

5

(TBS)

6

II. INTRODUCTION

2.1 GENERAL

This manual has been prepared for experienced weld-

ers. Do NOT permit untrained persons to install, oper-

ate or maintain this equipment. Do NOT attempt to

install or operate this equipment until you have read and

fully understand these instructions.

This manual is intended for use in familiarizing person-

nel with the design and operation of this equipment. All

information presented here should be read carefully

before installing and using this equipment.

2.2 RECEIVING-HANDLING

Upon receipt of this equipment, clean all packing mate-

rial from around the unit and immediately inspect for

any damage that may have occurred during shipment.

Any claims for loss or damage occurring in transit must

be filed with the carrier. The carrier will furnish a copy

of the bill of lading and the freight bill on request, if the

need to file a damage claim arises.

When requesting information regarding this equip-

ment, make sure that you include product name, part

number, and serial number.

2.3 DUTY CYCLE

The duty cycle of the equipment is the percentage of a

10 minute period which it can operate safely at a given

output current. The Migmaster 300i is rated at 300

amps at 40% duty cycle and 250 amps at 60% duty

cycle..

2.4 DESCRIPTION

The Migmaster 300i is a DC welding system designed

for Mig Welding(GMAW), Tig(GTAW) or Stick(SMAW).

In the Mig mode this unit is capable of operating with

short arc or spray arc transfer and handles both solid

wires and tubular cored wires. This unit is suitable for

carbon steel, stainless steel, aluminum and many other

alloys. It provides a power source with built in wire

feeder and undercarriage with provisions for one gas

cylinder.

2.4.1 AVAILABLE PACKAGES AND

CONTENTS

Each of the following packages include the power

source, with the built-in wire feeder, factory installed

19.5''

32.25''

undercarriage and cylinder rack, MT-200cc Mig Torch

(with .035" and .045" accessories), dual groove feed

rolls (.035"/.045"), regulator and adjustable flowmeter,

6' gas hose, 10' work cable and clamp, 8' primary cable

(with plug and receptacle), Mig Welding Handbook, Tig

Welding Handbook, and set-up guide.

Description Part Number

Migmaster 300i cvcc

w/12' MT-200cc Torch 604576

Migmaster 300i cvcc

w/15' MT-200cc Torch 604577

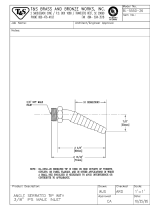

Figure 2.3 Dimensions

2.4.2 POWER SOURCE

The power source consists of an inverter DC power

source for single phase 208 or 230 primary connection.

2.4.3 WIRE FEEDER

The wire feeder is built into the power source cabinet,

housed separately from the welding machine electrical

components. Cooling air is not drawn through the wire

feeder mechanism, reducing its exposure to dirt and

dust.

The wire feeder pushes wire at speeds up to 655 ipm

(inches per minute). The purge/inch switch mounted

inside the power source cabinet allows the operator to

advance the wire without welding voltage.

40''

7

TABLE 2.1. SPECIFICATIONS

Rated DC Output...............................................

40% duty cycle..................................................300 amps @ 32 vdc

60% duty cycle (NEMA Class I).........................250 Amps @ 34 vd

c

Output Current Range.......................................

Mig (GMAW)...............................................................35 - 300 amp

s

Tig (GTAW)................................................................10 - 300 amps

Stick (SMAW)............................................................40 - 300 amps

Output Voltage (open circuit):............................

Mig (GMAW).........................................................................40 vdc

Tig (GTAW) ..........................................................................40 vdc

Stick (SMAW)...............................70 vdc (51 vdc shown on display)

Rated Primary Input @ 300 amp rated load: ...................................208/230 vac, 72/65 amps, single phase, 50/60

Wire Feed Range: ...................................................................................................................................65 - 655 ip

m

Dimensions (with cylinder rack and

wheels):.............................................................

length......................................................................40" (1016 mm)

width....................................................................19-1/2" (495 mm)

height ..................................................................32-1/4" (819 mm)

Weight (no cylinder): ...........................................................................................................................175 lbs. (80 kg

CSA..................................................................................................................................................approval pendin

g

2.4.6 RUNNING GEAR

The Migmaster 300i is equipped with a running gear

with swiveled front wheels and a gas cylinder support.

The rear wheels are packed loose for shipping but are

easily installed, as described in Section 3.8.

2.5 OPTIONAL EQUIPMENT

2.5.1 Mig 41A Push/Pull Mig Torch Assembly; includes

liner, contact tip, feed roll and nozzle.

15 ft, .035" soft wire ...................................... 604417

25 ft, 3/64" soft wire ...................................... 604578

2.5.2 Mig 41A Push/Pull Basic Mig Torch; does not

include liner, feed roll or contact tip; order separately

(see Form F-7036).

15 ft Basic ....................................................... 20506

25 ft Basic ....................................................... 20536

2.5.3 HW-17TV-2 (w/valve) Heliarc Tig Torch; 60 deg

head, 17 ft; ................................................ 33814CS

TIG weld without disconnecting the Mig torch. Includes

HW-17TV body, handle, long cap, cable cover, contactor

switch and cable, power adaptor, and gas hose.

2.4.4 MT-200cc TORCH

This air-cooled welding torch is supplied complete and

ready to weld 0.035 in. hard wire. The torch accommo-

dates 0.045 inch wire by changing the contact tip. Other

wire sizes can be used. Refer to Table 2.2 and Table 2.3

for other wire size accessories.

2.4.5 CONTROLS

The Migmaster 300i can be used to weld hard, alumi-

num, and flux cored wire . Control of the power source

and its different applications is provided by the 2 line, 32

character display screen. The operator selects the

process desired on a three position rotary switch

located on the front panel. A detailed description of the

power source controls is included in Section III (Opera-

tion) of this manual.

8

Wire

Size & Type

Standard Duty Contact Tips* Liners

Short Medium Long 10' 12' 15'

Hard Wires &

Cored Wires

-- 20543 999742 999743** -- --

.023" (.6mm)

.030" (.8mm) -- 20544 996994 948850 17717 --

.035"(.9mm) -- 996995 996996 2075237 17718 2075238

.045"(1.2mm) 999578 996999 996998 2075237 17718 2075238

.052"(1.4mm) 948340 2075349 -- 2075239 17719 2075240

1/16"(1.6mm) 948341 996997 -- 2075239 17719 2075240

Soft Wires

(aluminum)

-- 996995 996996 948862 -- --.035"(.9mm)

3/64" 999578 996999 996998 948863 -- --

* Short contact tips are generally recommended to give proper wire stick out for flux cored wire welding.

Medium contact tips are generally recommended to give proper wire stick out for spray arc Mig welding.

Long contact tips are generally recommended to give good visibility and proper wire stick out for short

arc Mig welding.

** Requires support liner for .023" wire. Order P/N 999797.

*Requires support tube. Order P/N 21169

Nozzle

Desc. I.D.

Standard

Duty

Heavy

Duty

#6 Tapered 3/8" 998895 -

#8 1/2" 998893 999471

#10 5/8" 998894 999472

#12 3/4" - 999473

#12 Spot 3/4" 17316 999625

2.5.4 HW-17cc Heliarc Tig Torch;

60 deg head, 12-1/2 ft. ........................... 16X48cc

Torch plugs into same front panel connector as the MT-

200cc; convert from Mig to Tig quickly and have gas

control through the power source. Includes body,

handle, long cap, cable cover, contactor switch and

cable “cc” connector.

2.5.5 HC-6 Hand Control; 25 ft. ..................... 21225

Attach to welding torch for remote hand control of

output and trim functions.

2.5.6 FC-6 Foot Control; 25 ft. ....................... 33517

Remote foot control of output and trim functions.

2.5.7 Stick Electrode Holder Assembly .......... 21226

Assembly includes holder, cable and twist lock connec-

tor, 15 ft.

2.5.8 Hub Adaptor .......................................... 17511

Required for 8-in. spools

Table 2.4 Slide-on Nozzles

(MT-200cc & MIG-41A)

*Uses Nozzles Adapter P/N 999452.

2.6 SAFETY

The safety section at the front of this manual should be

read completely before attempting to install and oper-

ate this equipment. Both equipment and personnel

hazards are reduced if proper safety precautions are

taken. If you are unsure of yourself in any situation, ask

your supervisor or other experienced personnel for

help.

Wire

Size & Type

Guide

Tube

Feed

Roll

Hard Wires -

"V" Groove

21163 21155

.023"(.6mm)

.030"(.8mm) 21164 21155

.035"(.9mm) 21165 21156

.045"(1.2mm) 21165 21156

Cored Wires -

Serrated

21164 21160.030"(.8mm)

.035"(.9mm) 21165 21160

.045"(1.2mm) 21165 21161

.052"(1.4mm) 21166 21161

1/16"(1.6mm) 21166 21161

Soft Wires

(aluminum)-

"U" Groove

21167" 21158

.035"(.9mm)

3/64"(1.2mm) 21168* 21158

Table 2.3 Guide Tubes and Feed Rolls

Table 2.2 Contact Tips and Liners

9

Before making electrical input connections to the

welding machine, “Machinery Lockout Procedures”

should be employed. If the connections are to be

made from a line disconnect switch, the switch

should be padlocked in the off position. If the

connection is to be made from a fusebox, remove

the fuses and padlock the cover closed. If no

locking facilities are available, attach a red tag to

warn others not to energize the circuit.

3.3.1 Input Electrical Requirements

The primary input voltage requirements are shown on

the power source nameplate. The power source is

designed to be operated from 208/230 single phase 50/

60 Hz.

Figure 3.1 Primary Connections

3.3.2 Input Conductor Connections

The input power cord is provided with an attachment

plug. The plug will mate with a 250 Volt, 50 Amp

receptacle conforming to NEMA 6-50R configuration.

The receptacle should be wired to a separately fused

disconnect or circuit breaker. This disconnect or breaker

can be wired to a single phase system or to two

conductors of a three phase system. A third conductor

for grounding should also be connected between the

disconnect and the receptacle.

The terminal labeled GRD is connected to the power

source chassis and is for ground purposes only. It

must be connected to a good electrical ground. Do

not connect a conductor from the terminal labeled

GRD to any one of the L1, L2 terminals as this will

result in an electrically hot machine chassis.

III. INSTALLATION

3.1 LOCATION

Several factors should be considered when selecting

an installation site. Adequate ventilation is necessary

to provide cooling, and the amount of dirt and dust to

which the machine is exposed should be minimized.

There should be at least 18 inches of unrestricted

space between the machine’s side and rear panels and

the nearest obstruction to provide freedom of air move-

ment through the power source.

The installation site should permit easy removal of the

machine outer enclosure for maintenance. Installing or

placing any type of filtering device will restrict the

volume of intake air, thus subjecting the power source

internal components to overheating. Warranty is void

if any type of filtering device is used.

Do not operate the machine without the running

gear installed.

3.2 ASSEMBLE REAR WHEELS

The units’ running gear is factory assembled except for

the rear wheels which are packed loose and in the

shipping carton. The rear gear consists of 2-wheels, 4

washers, 2-cotter pins, and an axle. To install the gear,

do the following:

A. Insert the axle through the holes provided at

the rear of the gear.

B. Place a washer onto each end of the axle, then

slip on the wheels, then add another washer to

the outside of each wheel, and secure the

whole assembly by inserting a pin in each end

of the axle.

C. Remove the existing shipping supports by un-

screwing from chassis. (Wooden lifting lever

provided.)

3.3 ELECTRICAL INPUT CONNECTIONS

In order to provide a safe and convenient means to

completely remove all electrical power from the ma-

chine, it is highly recommended that a line disconnect

switch be installed in the input circuit to the machine.

10

Figure 3.2 Voltage Changeover Terminal Board

3.4 SECONDARY OUTPUT CONNECTIONS

The Migmaster 300i Welding System is completely

self-contained so that the front panel torch fittings are

internally connected to the welding polarity (DC reverse

or DC straight) via the secondary output terminals. The

machine comes set up for DCRP welding.

3.5 TORCH CONNECTIONS

The MT-200cc torch is supplied as standard equip-

ment. Line up the matching holes, push on and tighten

the locking collar. As shipped from the factory, the

common connector type torches are set-up for DCRP

welding polarity.

3.6 WIRE FEEDER MECHANISM

3.6.1 DRIVE ROLLS

The drive roll has two grooves: the small groove feeds

0.035 in. diameter wire, the large groove feeds 0.045 in.

wire. The groove nearest the gear motor feeds the wire.

If the required groove is not correctly positioned, per-

form the following:

A. Release the pressure drive roll lever and lift the

assembly upward.

B. Remove the two (2) screws holding the drive

roll to the gear.

Figure 3.3 Front Panel Connections

c. Reverse the drive roll on the drive roll shaft.

d. Replace the screws and tighten.

e. Secure the pressure drive roll assembly.

3.6.2 WELDING WIRE SPOOL

As with any work area, make sure safety glasses

with side shields are worn when handling or chang-

ing wire or clipping wire off at the spool or at the end

of the torch. Hold onto the wire coming off the

spool with one hand before clipping. Serious eye

injury can result due to the resilience of the wire

which can quickly unravel, or a cut wire end which

may shoot across the room.

Install a spool of welding wire on the hub as follows:

11

A. Unscrew spool nut from hub.

B. Place wire spool on hub to rotate clockwise as

wire is unwound; hub pin must engage hole in

spool.

C. Replace nut.

3.6.3 THREADING WELDING WIRE

A.Turn off power switch.

When the power switch is on, and gun trigger is

depressed, the electrode wire becomes electrically

hot, and the wire drive rolls will run.

B. Release pressure drive roll assembly and lift

upward. Check that proper wire diameter

groove is in the inner position.

Before threading welding wire through liner, make

sure chisel point and burrs have been removed

from wire end to prevent wire from jamming in gun

or liner.

C. Feed the wire from the spool through the inlet

guide, across the drive roll groove and into gun

outlet guide.

Make sure that the proper “outlet guide tube” is inserted

into the front-panel gun fitting for the size and type of

wire being used, see Table 2.3 for wire feed accesso-

ries.

To ensure proper wire feeding, it is important that the

wire be kept clean and that the drive rolls be periodically

cleaned of any chips or scale that might be carried into

the gun liner and cause sticking.

D. Lower pressure roll assembly and secure.

Check that the gears mesh. Feed wire through

to gun tip using the inch/purge switch.

3.6.4 SPOOL BRAKE DRAG ADJUSTMENT

Spool brake disc friction should provide enough drag to

keep the wire spool or core from spinning freely after

wire feed stops. If adjustment is required, turn adjusting

screw clockwise to increase drag, counterclockwise to

decrease it. Drag should be just low enough to limit wire

overrun.

Figure 3.4 Wire Feeder Mechanism

3.7 CONNECTION OF SHIELDING GAS

SUPPLY

The R-50-FM-580 regulator is an adjustable regulator

designed for use with Argon, Helium, Nitrogen, and C-

25 (75% argon/25% CO2) gas service. The following

chart provides the recommended flow ranges for the R-

50-FM-500 regulator.

Argon 10-40 CFH

Helium 25-125 CFH

Nitrogen 10-50 CFH

C-25 10-40 CFH

TO SET UP THE GAS SHIELDING SUPPLY:

A. With the cylinder cap in place, CAREFULLY

slide the cylinder of gas onto the Migmaster

300i cylinder rack.

B. Secure the cylinder to the unit, using the chain

provided.

C. Unscrew the cylinder cap.

12

Never stand directly in front of or behind the regu-

lator when opening the cylinder valve. Always

stand to one side.

E. Open the cylinder valve SLOWLY a fraction of

a turn. This will prevent damage to gauge and

critical components in the regulator. When the

gauge needle stops moving, then open the

cylinder valve fully.

TO REGULATE FLOW:

Flow is controlled by adjusting the flowmeter valve until

desired flow is indicated by the ball float in the flowmeter

tube. Always take the reading across the TOP of the

ball.

Using a leak test solution, such as P/N 998771 (8 oz.

ctr) or soapy water, test for leakage about the cylinder

valve stem, the regulator inlet connection, and the hose

connections at the regulator and at the Migmaster 300i

for leakage. Correct any leaks before starting work.

TO STOP WORK:

If work is to be stopped for a half-hour or more, the

regulator is to be removed from the cylinder, shut down

the regulator as follows:

A. Close the cylinder valve.

B. Release gas from the regulator by closing the

torch trigger lever.

C. When pressure gauge drops to zero, the regu-

lator is depressurized and shut down.

Each regulator is equipped with a porous metal inlet

filter, P/N 71233, pressed into the regulator input

nipple. No regulator should be connected to a cylinder

or station valve unless it contains this filter. You can

replace the filter if necessary. Refer to the regulator

instruction literature for details.

Regulators in need of repair should be returned to your

welding equipment distributor or to an authorized

remanufacturing center.

For a detailed description of the regulator, refer to the

R-50-FM-580 Regulator-Flowmeter Instruction Manual,

F-14-238.

TO CONNECT:

Do not clamp regulator cap in a vise or grip it with

a pair of pliers. Distortion of cap can jam the

internal parts and cause excessively high delivery

pressure as well as weaken the threaded joint to the

regulator body. This may cause cap to fly off and

possibly injure personnel in area.

A. Open the cylinder valve slightly, for an instant,

to blow out any dust or dirt that may have

collected in the valve outlet. BE SURE to keep

your face away from the valve outlet to protect

your eyes.

B. Attach the regulator to the cylinder valve. Align

the regulator so that the flowmeter is vertical

and then tighten the connection nut with a

1-1/8 in. open end or adjustable wrench. (To

prevent damaging the O-ring seals and plastic

tube, do not use the flowmeter tube as a

'handle' when attaching the regulator.)

Figure 3.5 R-50 Regulator

C. Make sure that the flow control valve on the

flowmeter is closed.

D. Attach the gas hose from the rear of the Mig-

master 300i to the regulator outlet connection.

13

If welding is performed in a confined area, shield-

ing gas flow can displace oxygen, thereby endan-

gering personnel entering the area.

3.8 WELDING CABLE CONNECTIONS

Connect the work clamp solidly to the workpiece or

work table. Clamp onto a bare metal area.

A good electrical connection to the work is essen-

tial for proper welding operation and for prevention

of electric shock.

+

—

Migmaster 300i

REAR VIEW

FRONT VIEW

Figure 3.6 Controls and Welding Cable Connections

Welding cables should be kept as short as possible and

be of adequate current carrying capacity. Resistance

of the welding cables and connections causes a voltage

drop which is added to the voltage drop of the arc.

Excessive cable resistance may result in a reduction of

the maximum usable current output of the equipment.

The proper operation of this equipment is to a large

extent dependent on the use of welding cables and

connections which are in good condition and of ad-

equate size.

IV. OPERATION

4.1 CONTROLS

4.1.1 POWER ON/OFF SWITCH

The rotary power switch is located on the back panel in

the upper right hand corner. This switch also turns on

the fan. The twelve o’clock position is the “off” position,

the “on” is one quarter turn clockwise.

14

Figure 4.1 Control Display Screen

4.1.4 SECONDARY WELDING CONNEC-

TIONS

The secondary output welding terminals, POS (+) and

NEG (-) are located on the lower front panel, directly

beneath the common connector (see figure 3.3).

4.1.5 WIRE FEED SPEED CONTROL

Wire feed speed is controlled automatically. It can be

adjusted using the arrow keys or from a remote control

while welding (fine tuning the arc).

4.1.6 MIG-41A PUSH-PULL GUN

The MIG-41A push-pull gun combines with the Mig-

master 300i to create a high performance push-pull

system. The MIG-41A synchronizes with the wire

feeder, providing an ideal means for feeding small

diameter wires or soft wires long distance.

The MIG-41A connects to the front panel of the Mig-

master 300i. The inlet connector of the MIG-41A is

inserted into the common connector and the power lead

plugs into the MIG-41A connector in the center of the

front panel.

For a detailed description of the MIG-41A, refer to the

MIG-41A Push-Pull Gun Instruction manual, F-14-497.

4.2 OPERATING PROCEDURES

4.2.1 OPERATING SAFETY PRECAU-

TIONS

Comply with all ventilation, fire and other safety

requirements for arc welding as established in the

SAFETY Section at the front of this manual.

Also remember the following:

A. Because of the radiant energy of the welding

arc and the possibility of drawing an arc before

the helmet is lowered over the face, the opera-

tor should wear flash goggles with filter lenses

under his helmet. The helmet filter plate should

be shade number 11 (nonferrous) or 12 (fer-

rous). All those viewing the arc should use

helmets with filter plates, as well as flash

goggles. Nearby personnel should wear flash

goggles.

B. The radiant energy of the arc can decompose

chlorinated solvent vapors, such as trichloro-

ethylene and perchlorethylene to form phos-

gene, even when these vapors are present in

low concentrations. DO NOT weld where

chlorinated solvents are present in at-

mospheres in or around the arc.

C. DO NOT touch the electrode, nozzle or metal

parts in contact with them when power is on; all

4.1.2 PROCESS SELECTOR SWITCH

The three position process selector switch is on the

upper right front panel. The processor selector switch

provides the visual indication of which process (Mig, Tig

or stick) has been selected.

4.1.3 CONTROL DISPLAY SCREEN

(Figure 4.1)

Welding set-up options are controlled and monitored by

use of the Display Window and the control pushbuttons.

The screen displays the settings required for the de-

sired welding process as determined by the position of

the Process Selector Switch. The Scroll Key is used to

select functions as required to select wire speed, volt-

age, trigger type, etc. The arrow keys are used to select

options. For example, the operator would use the keys

in order to select plate size. The scroll key is depressed

several times, until SEL PLATE SIZE is displayed. The

arrow keys are then depressed until the desired plate

size appears in the display.

15

are electrically energized (HOT) and can cause

a potentially fatal shock. DO NOT allow elec-

trode to touch grounded metal, it will create an

arc flash that can injure eyes. It may also start

a fire or cause other damage.

D. When working in a confined space, be sure it

is safe to enter. The confined space should be

tested for adequate oxygen (at least 19%) with

an approved oxygen measuring instrument.

The space should not contain toxic concentra-

tions of fumes or gases. It this cannot be

determined, the operator should wear an ap-

proved air supplied breathing apparatus. DO

NOT bring gas cylinders into confined spaces.

When leaving a confined space, shut off gas

supply at the source to prevent gas from leak-

ing into the confined space.

E. Never operate the equipment at currents greater

than the rated ampere capacity; overheating

will result.

F. Never operate equipment in a damp or wet

area without suitable insulation for protection

against shock. Keep hands, feet and clothing

dry at all times.

G. Whenever the equipment is left unattended,

turn all control and power supply switches and

gas supplies off and open the main line switch.

H. Wear dark substantial clothing to protect ex-

posed skin from arcburn, sparks and flying hot

metal.

I. Turn off welding power before adjusting or

replacing electrodes.

4.2.2 PRE-WELD REQUIREMENTS

Before welding commences, with all power OFF, check

the following:

A. All safety requirements have been read and

understood.

B. All hoses and cables are in good condition,

safely insulated and securely connected.

C. Turn on gas supply by slowly opening cylinder

valve to full ON.

D. Spool of correct size wire is locked in place,

brake tension is set, and wire is properly

threaded through the inlet guide to the gun tip.

E. The wire feeding compartment cover is closed

and secure.

F. Metal to be welded is properly prepared.

4.3 SET UP FOR WELDING

Work safely and follow all safety precautions listed in

the Instruction Manual.

4.3.1 MIG WELDING: GUIDED SET-UP

MODE

The Guided Set-up mode is the quickest and simplest

way of using the Migmaster 300i. Welding conditions

for a wide variety of material types, and shielding gases

have been pre-set at the factory. All that is required to

get excellent welding performance is to answer a few

questions on the front control panel.

Table 4-1 contains the actions required to set-up the

Migmaster 300i cvcc using the Guided-Set-up mode for

Mig welding.

TO FINE TUNE ARC: Press or to increase

or decrease voltage or wire feed speed for the desired

arc characteristics. These changes can be made while

welding. Make small changes when fine tuning the arc.

Too large a change will make the arc unstable.

To return to beginning of the list: momentarily press

torch trigger or turn process selector switch to Tig and

then back to Mig.

To reset to factory default settings: turn power off.

Press center scroll key and left arrow key. While press-

ing both keys, turn the power on.

4.3.2 MIG WELDING: MANUAL SETUP

MODE

A manual set up mode is selectable if you want to use

conditions that are not pre-set or if you want to set up for

a special application or condition. In the manual mode

you can manually set wire feed speed, voltage and

power supply inductance. Table 4-2 contains the

actions required to set-up the Migmaster 300i cvcc

using the manual set-up mode for Mig Welding.

16

4.3.3 MIG WELDING: SET-UP OPTIONS

There are a variety of set-up options that are available

for Mig welding. Selecting the appropriate option can

improve productivity, convenience or operator comfort.

Table 4-3 contains a list of the various options that are

available for Mig welding.

4.3.4 TIG WELDING SET-UP

Table 4-4 contains the operator actions required to set-

up the Migmaster 300i cvcc for Tig welding.

4.3.5 STICK WELDING SET-UP

Table 4-5 contains the operator actions required to set-

up the Migmaster 300i cvcc for Stick welding.

4.3.6 DESCRIPTION OF TRIGGER TYPE

OPTIONS

A. Continuous - This is the most commonly used

trigger option. When the torch trigger is de-

pressed, welding begins. When the torch

trigger is released, welding stops. The weld is

continuous as long as the torch trigger is de-

pressed.

B. Trigger Lock - Using this mode, the welding

process begins when the torch trigger is de-

pressed. Once the welding process has started,

the torch trigger may be released without af-

fecting the welding process. To stop the weld-

ing operation, the torch trigger must be de-

pressed a second time. This allows a continu-

ous weld without having to continuously de-

press the torch trigger.

C. Spot Weld - Spot welding provides a timed

weld. When this trigger type is selected an

option is added to the setting list. This option

sets the time for the spot weld duration. If the

scroll key is pressed after spot weld is se-

lected, the option "SET SPOT TIME" is dis-

played for changing the spot time duration.

Once the torch switch is pressed the option

with the spot time is moved up in the list to be

quickly accessible to trim the parameter for the

spot welding operation.

D. Stitch Welding - Stitch weld provides for the

automatic switching between welding "on" and

welding "off" while the torch trigger is pressed.

The "on/off" time for the weld is set separately.

When stitch weld is selected two options are

added to the list. "SET ON TIME" and "SET

OFF TIME". The options are handled the same

as the spot weld options described above.

E. Dual Schedule - This selection is only available

when the active list #1 is selected. When

selected, it provides the option to switch be-

tween two welding parameters during welding.

Switching is done using a short release of the

torch trigger. The first welding parameter

(voltage and wire feed speed) is from list #1.

The welding parameter switched to (voltage

and wire feed speed) are from list #2. A short

release of the torch trigger returns the param-

eters from list #1.

The bottom row of the display will not change

to show the set value from list #2 during weld-

ing using second parameters. The measured

voltage and current will show the second weld-

ing parameters.

The two welding conditions must be set up in

list #1 and list #2 before dual schedule selec-

tion is made.

4.4 WELDING OPERATION

Never operate the machine with any portion of the

outer enclosure removed. In addition to a hazard,

improper cooling may result in damage to the

welding transformer and the welding machine

components. Warranty is void if the machine is

operated with any portion of the outer enclosure

removed.

A. Turn Power switch (on unit) to ON position -- be

careful not to operate the torch switch.

B. Before starting the weld, the welding wire should

extend about 1/2-inch beyond the end of the

nozzle. Adjust this length by either clipping off

the end of the wire with insulated cutters or by

using the torch switch.

(cont. to page 26)

17

Table 4-1. Migmaster 300i cvcc Guided Set-up for the MIG Process

Display Action

Power on unit

Select MIG on the front panel selector switch

Set shielding gas flowmeter to 35 cfh

Press

to accept active list #1

Press to accept guided set-up mode.

Press to accept mild steel or press or to

change WIRE TYPE to desired material.

Note: Wire Type Options are listed in Table 4-3.

Press to accept .035" dia or press or to

change WIRE SIZE to desired diameter.

Note: WIRE SIZE options are listed in Table 4-3.

SEL ACTIVE LIST

< active list #1 >

SEL WIRE TYPE

< mild steel >

SEL SET-UP TYPE

< guided set-up >

SEL WIRE SIZE

< .035" dia >

Press to accept 75% Ar + 25% C02 or press

or to change GAS SHIELD to desired mixture.

Note: GAS SHIELD options are listed in Table 4-3.

SEL GAS SHIELD

< 75% aR + 25% CO2 >

18

Table 4-1 Continued

TRIM WIRE SPEED

v ^

TRIM VOLTAGE

v ^

TRIM BURNBACK

v ^

SEL START TYPE

< slow run in >

SEL TRIGGER TYPE

< continuous >

SEL PLATE SIZE

< 1/4" .250" >

Display Action

Press

to accept PLATE SIZE or press or

to change PLATE SIZE.

Note: PLATE SIZE options are listed in Table 4-3.

Press to accept TRIGGER TYPE.

Press to accept START TYPE.

Press to accept BURNBACK.

Press to accept VOLTAGE.

Press to accept WIRE SPEED.

The shaded boxes are the only selections required to be modified by the operator when using the guided set-up mode.

The non-shaded boxes provide advanced settings or other special functions and are detailed under the Migmaster 300i

manual setup procedures.

19

Power on unit.

Select MIG on the front panel selector switch.

Set shielding gas flowmeter to 35 cfh.

Press to accept displayed active list or press or to

select desired active list.

Press to change to the manual set-up mode.

Press to accept displayed wire type or press or to

change WIRE TYPE to desired material.

Note: Wire Type options are listed in Table 4-3.

Press to accept displayed WIRE SIZE diameter or press

or to change WIRE SIZE to desired diameter.

Note: Wire Size options are listed in Table 4-3.

Table 4-2. Migmaster 300i cvcc Manual Set-up for the MIG Process

Display Action

SEL WIRE SIZE

< .035" dia >

SEL SET-UP TYPE

< guided set-up >

SEL WIRE TYPE

< mild steel >

SEL ACTIVE LIST

< active list #1 >

20

Display Action

SEL GAS SHIELD

< 75% Ar + 25% CO2 >

Table 4-2 Continued

Press

to accept displayed GAS SHIELD mixture or press

or to change GAS SHIELD to desired mixture.

Note: Gas Shield options are listed in Table 4-3.

Press to accept displayed TRIGGER TYPE or press or

to change to desired TRIGGER TYPE.

Note: Trigger Type options are listed in Table 4-3.

This display will appear when stitch weld is selected as TRIGGER

TYPE.

Press

to accept displayed ON TIME.

Press to decrease ON TIME.

Press to increase ON TIME.

This display will appear when stitch weld is selected as TRIGGER

TYPE.

Press to accept displayed OFF TIME.

Press to decrease OFF TIME.

Press to increase OFF TIME.

This display will appear when spot weld is selected as TRIGGER

TYPE.

Press to accept displayed SPOT TIME.

Press to decrease SPOT TIME.

Press to increase SPOT TIME.

SEL TRIGGER TYPE

< continuous >

SET ON TIME

v 1.2 seconds ^

SET OFF TIME

v 1.2 seconds ^

SET SPOT TIME

v 1.0 seconds ^

/