Page is loading ...

Program Features

The DDC controller offers improved control through

easy monitoring and adjustment of unit parameters

by way of a lighted graphical display and a push-

button keypad.

Pre-Programmed Operating Sequences

The controller has been pre-programmed to offer

multiple control sequences to provide tempered

air. Factory default settings allow for easy setup

and commissioning. The sequence parameters are

fully adjustable. Refer to the Sequence of Operation

beginning on page 2 for details.

BMS Communication

With the addition of an optional BMS Communication

card, the user can remotely adjust set points, view

unit status points and alarms. The DDC controller is

capable of communicating over several protocols:

•BACnet®MSTP

•BACnet®IP/Ethernet

•LonWorks®

•Modbus

SeePointsListonpages32and33foracompletelist

of BMS points.

Internal Time Clock

The controller has an internal programmable time

clock, allowing the user to add up to seven different

occupancy schedules. The user may also add

Holidays for additional energy savings.

Alarm Management

The DDC controller will monitor the unit conditions

for alarm conditions. Upon detecting an alarm, the

controller will record the alarm description, time,

date, available temperatures, and unit status for user

review.Adigitaloutputisreservedforremotealarm

indication.AlarmsarealsocommunicatedviaBMS(if

equipped).

Occupancy Modes

The DDC controller offers three modes of determining

occupancy: a dry contact, the internal time clock

ortheBMS.IfintheUnoccupiedmodetheunitwill

either be shut down, or will cycle on to maintain an

adjustable unoccupied room temperature set point.

Remote Display Panel (Optional)

Atouchpaddisplaypanelallowsforremote

monitoring and adjustment of parameters, allowing

ease of control access without going outdoors.

Introduction

TAP v2.00

Version Date: 9/22/11

WARNING

Electricalshockhazard.Cancausepersonalinjury

or equipment damage. Service must be performed

only by personnel that are knowledgeable in the

operation of the equipment being controlled.

1

DDC Controller for Tempered Air Products

Reference Guide for the DDC Controller

Pleasereadandsavetheseinstructions.Readcarefullybeforeattemptingtooperateormaintaintheproduct

described.Protectyourselfandothersbyobservingallsafetypractices.Failuretocomplywithinstructions

couldresultinpersonalinjuryand/orpropertydamage!Retaininstructionsforfuturereference.

®

®

Part #474894

DDC Controller for

Tempered Air Products

Sequence of Operation . . . . . . . . . . . . . . . 2

General Operation . . . . . . . . . . . . . . . . 2

SetPointControl . . . . . . . . . . . . . . . . . 3

Heating . . . . . . . . . . . . . . . . . . . . . . 3

Economizer . . . . . . . . . . . . . . . . . . . . 3

Cooling . . . . . . . . . . . . . . . . . . . . . . 3

Dehumidification . . . . . . . . . . . . . . . . . 4

Reheat . . . . . . . . . . . . . . . . . . . . . . . 4

Alarms . . . . . . . . . . . . . . . . . . . . . . . 4

EnergyRecoveryWheelSequences . . . . . . . 4

OutdoorAirandRecirculated(Recirc)Air . . . . 5

ExhaustFanVFD . . . . . . . . . . . . . . . . . 5

SupplyFanVFD . . . . . . . . . . . . . . . . . . 5

Controller Overview . . . . . . . . . . . . . . . . 6-7

Display Use . . . . . . . . . . . . . . . . . . . . . 8

ExampleofParameterAdjustment . . . . . . . . . 8

ExampleofAlarms . . . . . . . . . . . . . . . . . 9

Menu Overview . . . . . . . . . . . . . . . . . 10-11

Main Menu Overview . . . . . . . . . . . . . . 12-14

Menus

A.

On/OffUnit . . . . . . . . . . . . . . . . .15

B.

Setpoin . . . . . . . . . . . . . . . . . 16-19

C.

Clock/Scheduler. . . . . . . . . . . . . .20

D.

Input/Output . . . . . . . . . . . . . . . .20

E.

DataLogger . . . . . . . . . . . . . . . . 20

F.

Board Switch . . . . . . . . . . . . . . .21

G.

Service

a.Information . . . . . . . . . . . . . . . . 21

b. Overrides . . . . . . . . . . . . . . . 21-23

c. BMS Config . . . . . . . . . . . . . . 23-25

d. Service Settings

a. Working hour set. . . . . . . . . . . .25

b.Probeadjustment . . . . . . . . . . . 26

c.Password/Defaults . . . . . . . . . .26

H.

Manufacturer

a. Configuration . . . . . . . . . . . . . 26-27

b.I/OConfiguration . . . . . . . . . . . . .27

c. Factory Settings . . . . . . . . . . . 27-31

d.Initialization . . . . . . . . . . . . . . . . 31

PointsList

LonWorks® . . . . . . . . . . . . . . . . . . . . 32

ModBus/BACnet® . . . . . . . . . . . . . . . .33

AuxiliaryI/O(pCOe) . . . . . . . . . . . . . . . . .34

Setup . . . . . . . . . . . . . . . . . . . . . . .34

Troubleshooting . . . . . . . . . . . . . . . . . . .35

NTC Temperature Sensor Chart . . . . . . . . . .35

BACnet®MSTPQuickStart . . . . . . . . . . . .36

BACnet®IP/EthQuickStart . . . . . . . . . . . . 37

MaintenanceLog . . . . . . . . . . . . . . . . 38-39

Warranty . . . . . . . . . . . . . . . . . . Backcover

Table of Contents Sequence of Operation

The DDC controller can be configured for air handler,

energyrecoveryandmake-upairapplications.Each

applicationutilizessimilartechnologiesforheating

and cooling: chilled water, hot water, indirect gas,

electric heat, packaged DX cooling, and packaged

DXcoolingwithdigitalscrolls.Allsetpoints,lockouts

and delays are user adjustable.

General Operation

UNIT START COMMAND: The DDC controller

requires a digital input to enable operation. The unit

can then be commanded on or off by this digital

input, the BMS or internal time clock.

•Initialdelay

•Factorymountedandwireddampersarepowered,

if equipped.(Outdoorair,exhaustair,and

recirculation air dampers).

•Exhaustfanstartsaftera10seconddelay,if

equipped.

•Supplyfanstarts5secondsaftertheexhaustfan.

•Heating,coolingandwheeloperation(page3).

UNIT STOP COMMAND (OR DE-ENERGIZED):

•Supplyfan,exhaustfan,tempering,andwheelare

de-energized.

•OutdoorairandExhaustairdamperdampersare

closed after a 10 second delay. Recirculation air

dampers spring open.

OCCUPIED/UNOCCUPIED MODES: The DDC

controller offers three modes of determining

occupancy: a dry contact, the internal time clock or

the BMS. When in the unoccupied mode, the unit will

either be shut down, or will cycle on to maintain the

unoccupied room temperature set point.

•Occupied Mode:

- Exhaustfanon,if equipped.

- Supply fan on.

- Heating(refertoHeatingsection).

- Cooling(refertoCoolingsection).

- Wheelcontrol(page4),if equipped.

- Dampercontrol(page5),if equipped.

•Unoccupied Mode (Unit Off): Unit remains off when

in unoccupied mode.

•Unoccupied Mode (Cycle on Room): Optional

unoccupied mode when there is a recirculation

damper and a room temperature sensor wired to

unit.

- Exhaustfanoff,if equipped.

- Supply fan off.

- Recirculation air damper open.

- OAdamperclosed.

- Unoccupied heating is enabled when the

room temperature is less than the unoccupied

heatingsetpointminusdifferential(65°F±5°F).

The supply air temperature set point will be

settothesupplymaximumresetlimit(90°F).

The unit cycles off when the room temperature

reaches the unoccupied heating set point plus

differential.

2

DDC Controller for Tempered Air Products

®

Sequence of Operation

- Unoccupied cooling is enabled when the room

temperature is greater than the unoccupied

coolingsetpointplusdifferential(85°F±5°F).

The supply air temperature set point will be

settothesupplyminimumresetlimit(55°F).

The unit cycles off when the room temperature

reaches the unoccupied cooling set point minus

differential.

Set Point Control

Supply air temperature set point can either be reset

byoutsideairtemperature,orroomtemperature.If

equipped with BMS communications, the user can

also directly set the supply temperature set point, or

roomtemperaturesetpoint(ifequippedwitharoom

temp sensor).

•Outdoor Air Temperature Reset Function:

Without a room temperature sensor, the controller

will default to supply temperature reset based

on outdoor air temperature. The controller will

monitortheOAtemperatureandresetthesupply

temperature set point based upon the outdoor air

reset function.

•RoomTemperatureReset(optional): With a

room temperature sensor, the controller will

adjustthesupplyairtemperaturesetpointup/

down accordingly to satisfy the desired room

temperature. Cooling and heating are determined

by a difference in temperature of the room

temperature sensor compared to the desired room

temperature set point.

Anoptionalroomdehumidstatcanalsobeusedfor

room humidity control for both operating sequences.

Heating

The heating is controlled to maintain the supply

temperature set point. The heating will be locked out

when the outside air temperature is above the heating

lockout(70°F).

•Indirect Gas Furnace: DDC controller will

modulate the indirect gas furnace to maintain the

supply temperature set point.

• Hot Water Coil: DDC controller will modulate a

hotwatervalve(providedbyothers)tomaintain

the supply temperature set point. Coil Freeze

protection must be provided by others in the field!

•Electric Heater: DDC controller will modulate an

electric heater to maintain the supply temperature

set point.

•Heat Pump: DDC controller will stage

compressor(s)tomaintainthesupplyairsetpoint.

This signal will come wired to the factory provided

heat pump module. All external water valves and

valve controls are provided, wired and mounted

by others in the field, including freeze protection.

Economizer

Iftheapplicationrequirescooling,andtheoutdoor

air conditions are suitable for free cooling, the

controllermayentertheeconomizerstate.Iftheunit

iseconomizingandthedischargetemperatureset

point is not being met, the controller may bring on

mechanicalcooling.Ifequippedwithamodulating

outdoor air and recirculated air damper, the dampers

willmodulateopen.Ifequippedwithanenergywheel,

seeEnergyRecoveryWheelSequencesonpage4.

•Temperature: Theeconomizerwillbelockedout

when:

- Theoutsideairislessthantheeconomizerlow

lockout(40°F).

- Theoutsideairisgreaterthantheeconomizer

highlockout(65°F).

- The unit is operating in dehumidification mode.

- There is a call for heating.

•Temperature/Dew Point:Theeconomizerwillbe

locked out when:

- Theoutsideairislessthantheeconomizerlow

lockout(40°Fdry-bulb).

- Theoutsideairisgreaterthantheeconomizer

highlockout(75°Fdry-bulb).

- Theoutsideairisgreaterthantheeconomizer

highdew-pointlockout(55°Fdew-point)

- The unit is operating in dehumidification mode.

- There is a call for heating.

Cooling

The cooling is controlled to maintain the supply

temperature set point. The mechanical cooling will be

locked out when the outside air temperature is below

thecoolinglockout(55°F).

•Chilled Water: DDC controller will modulate a

chilledwatervalve(providedbyothers)tomaintain

supply air set point. Coil Freeze protection must

be provided by others in the field!

•Packaged DX Cooling (Standard Scroll): DDC

controller will control stages of cooling to maintain

the supply air set point.

•Packaged DX Cooling (Digital Scroll): DDC

controller will modulate the digital scroll to maintain

the supply air temperature set point.

•Heat Pump: DDC controller will power the

reversing valve within the heat pump module

to direct the refrigerant flow for airside cooling.

The cooling is controlled to maintain the supply

temperature set point. All external water valves

and valve controls are provided, wired and

mounted by others in the field, including freeze

protection.

3

DDC Controller for Tempered Air Products

®

Dehumidification

The cooling is controlled to maintain the cold coil set

point. The Dehumidification sequence will be locked

outwhentheOAislessthanthedehumidification

lockout(10°F)abovethecoldcoilsetpoint.

•OptionalRoomDehumidistat: The room

dehumidistat is a field mounted sensor that

monitorstherelativehumidity(RH)oftheroom.

IftheRHexceedssetpoint,thedehumidistatwill

decrease the cold coil set point to the dehumidify

setpoint(50°F)tofurtherdrythesupplyair.

Once the room dehumidistat is satisfied, the DDC

controller will resume normal operation.

•Optional Room Relative Humidity Sensor: The

room relative humidity sensor is a field mounted

sensorthatmonitorstherelativehumidity(RH)

oftheroom.IfthemeasuredRHexceedstheset

point, the unit will decrease the cold coil set point

tothedehumidifysetpoint(50°F)tofurtherdrythe

supply air. Once the room RH has dropped below

the set point, the DDC controller will resume normal

operation.

Reheat

While the unit is in dehumidification mode, the supply

aircanbereheatedviaPrimaryHeatingSource,On/

Off Hot Gas Reheat or Modulating Hot Gas Reheat.

•Primary Heating Source: The main heating source

is enabled to reheat the air to meet the supply

temperaturesetpoint.(Exceptheatpump).

•Modulating Hot Gas Reheat (bypass damper): The

DDCcontrollerwillopentheOn/Offhotgasreheat

valve, and modulate the Hot Gas Reheat bypass

damper to maintain the supply temperature set

point.

•Modulating Hot Gas Reheat (valve): The DDC

controller will modulate the hot gas reheat valve to

maintain the supply temperature set point.

•On/Off Hot Gas Reheat: The DDC controller will

opentheOn/Offhotgasreheatvalvetomaintain

the supply temperature set point.

Alarms

The DDC controller includes a digital output for

remoteindicationofanalarmcondition.Possible

alarms include:

• Dirty Filter Alarm:Iftheoutsideairorreturn

air filter differential pressure rises above the

differential pressure switch set point, the DDC

controller will activate an alarm.

•Supply and Exhaust Air Proving Alarm: DDC

controller monitors proving switch on each blower

and displays an alarm in case of blower failure.

•Temperature Sensor Alarm: DDC controller

will send an alarm in the case of a failed air

temperature sensor.

•Supply Air Low Limit:Ifthesupplyairtemperature

dropsbelowthesupplyairlowlimit(35°F),theDDC

controllerwillde-energizetheunitandactivatethe

alarmoutputafterapresettimedelay(300s).

•Other Alarms: Wheel Rotation, High Wheel

Pressure,High/LowRefrigerantPressure.

Energy Recovery Wheel Sequences

Economizer (optional):Iftheunitisequippedwithan

energyrecoverywheel,theeconomizerwillmodulate/

stop the energy wheel to achieve free cooling.

• Stop Wheel:Wheneconomizermodeisenabled

and there is a signal for cooling, the wheel will stop

rotating to allow free cooling.

•Modulate Wheel:Wheneconomizermodeis

enabled and there is a signal for cooling, the wheel

VFDmodulateswheelspeedtomaintainthesupply

temperature set point.

• Energy Wheel Bypass Dampers (optional): During

normal operation, the dampers shall remain closed

to allow full operation of the energy wheel. During

economizersequences,thebypassdamperswillbe

open to alleviate pressure drop through the wheel,

while allowing more outdoor air to be used for

economizercooling.

Frost Control (optional): The DDC controller will

activate the frost control method when the outdoor

airtemperatureislessthanthedefrostsetpoint(5°F)

and the wheel pressure switch is closed, due to a

high wheel pressure drop.

•Electric Preheater: When frosting is occurring, the

preheaterisenergizedtodefrostthewheel.Once

the pressure drop decreases below the pressure

switchsetpoint,thepreheaterisde-energized.

•Modulate Wheel: When frosting is occurring, the

VFDslowsthewheeltoallowdefrostingtooccur.

Once the pressure drop decreases below the

pressure switch set point, the wheel returns to full

speed.

•Stop Wheel: When frosting is occurring, the

energy wheel is cycled OFF for 2 minutes and ON

for30minutes.Oncethepressuredropdecreases

belowthesetpoint,frostmodeisde-energizedand

the energy wheel is no longer cycled.

•Timed Exhaust: When frosting is occurring, the

supply fan is cycled off along with the tempering

for5minutes.Theexhaustfanwillcontinueto

run,allowingthewarmexhaustairtodefrostthe

wheel.Afterthe5minutecycle,thesupplyfanand

temperingarere-energizedtocontinuenormal

operation. The unit will continue normal operation

for30minutesbeforeallowinganotherdefrost

cycle to occur.

4

DDC Controller for Tempered Air Products

®

Outdoor Air and Recirculated (Recirc) Air

Damper Control

Ifequippedwithamodulatingoutdoorairand

recirculated air damper, the dampers will open to

aMinimumOutdoorAirPosition(MinOA)whenin

Occupied mode.

•Optional Room CO2 Sensor: The controller will

proportionallymodulatetheOA/RAdampersbased

upon a comparison of the CO2 set point to the

actualCO2levelreportedfromthesensor.As

the CO2 level rises, the outdoor air damper will

beproportionallymodulatedfromMinOAtothe

maximumdampersetting.

Exhaust Fan VFD Sequence

IfthefactoryhasinstalledaVFDandwiredittothe

controller, it is intended to operate at a constant

speed during operation. This speed needs to be set

during test and balance of the unit.

• Optional Building Static Pressure Sensor: The

exhaustfanismodulatedbaseduponthesignal

from a building static pressure sensor. The

microprocessorcontrollerwillmodulatetheexhaust

fan based upon a comparison of the building static

pressure set point to the actual building static

pressure level reported from the sensor.

•Optional Supply Fan Tracking: The controller will

proportionallymodulatetheexhaustfanbased

upon the supply fan speed.

•Optional Outdoor Air Damper Tracking: The

controllerwillproportionallymodulatetheexhaust

fan based upon the outdoor air damper position.

Supply Fan VFD Sequence

IfthefactoryhasinstalledaVFDandwiredittothe

controller, it is intended to operate at a constant

speed during operation. This speed needs to be set

during test and balance of the unit

•Optional Room CO2 Sensor: The controller will

modulate the supply fan based upon a comparison

of the CO2 set point to the actual CO2 levels

reported from the sensor. Mechanical high static

protection cutoffs must be installed by others

to protect the system and equipment from over-

pressurization.

•Optional Duct Static Pressure Sensor: The

controller will modulate the supply fan based upon

a comparison of the duct static pressure set point

to the actual duct static pressure level reported

from the sensor. Mechanical high static protection

cutoffs must be installed by others to protect the

system and equipment from over-pressurization.

The manufacturer does not assume responsibility

for this.

•OptionalBuildingStaticPressureSensor:The

supply fan is modulated based upon the signal

from a building static pressure sensor. The

microprocessor controller will modulate the supply

fan based upon a comparison of the building static

pressure set point to the actual building static

pressure level reported from the sensor.

5

DDC Controller for Tempered Air Products

®

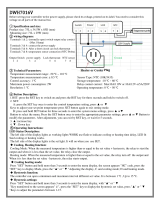

Small Controller Overview

J1J1 J24J24

J14J14

J11J11

J15J15

J2J2 J5J5J4J4J3J3

service card

Rx-/Tx-

Rx+/Tx+

GND

C1

NO1

NO2

NO3

C1

C4

NO4

NO5

NO6

C4

C7

NO7

C7

NO8

C8

NC8

G

G0

24 VAC to Controller

B1

B2

B3

GND

+VDC

+Vterm

GND

+5 VREF

B4

BC4

B5

BC5

VG

VG0

Y1

Y2

Y3

Y4

ID1

ID2

ID3

ID4

ID5

ID6

ID7

ID8

IDC1

J10J9

field card serial card

input: 24V~/ V ; 50 to 60 Hz

max. power: 40 VA/15W

J12J12 J13J13

Room RH or Dehumidistat

Room Temperature Sensor

After Cold Coil Temperature Sensor

Sensor B1, B2, B3 Commons

Supply Discharge Temperature Sensor

Outdoor Air Temperature Sensor

24 VAC for Analog Outputs

24 VAC When Unit On

Frost Control Enable

Output to Supply Fan

Output to Exhaust Fan

24 VAC from Supply Fan Proving

Heating Enable/Reversing Valve

Compressor Output 1

Compressor Output 2

24 VAC

Output to Dampers

Alarm Dry Contact

Energy Wheel Analog Output

Heating Analog Output

Cooling Analog Output

Hot Gas Reheat Analog Output

Supply Fan Proving

Wheel Pressure

Wheel Rotation Alarm

Unit On/Off

Exhaust Fan Proving

Occupied/Unoccupied Input

Dirty Filter

Compressor Limit

OptionalBACnet,LonWorksand

Modbus cards are located in

Serial Card port

Remote Display

(sixconductorRJ25cable)

6

DDC Controller for Tempered Air Products

®

Large Controller Overview

Remote Display

(sixconductorRJ25cable)

service card

Rx-/Tx-

Rx+/Tx+

GND

C1

NO1

NO2

NO3

C1

C4

NO4

NO5

NO6

C4

C7

NO7

C7

NO8

C8

NC8

NO12

C12

NC12

NO13

C13

NC13

C9

NO9

NO10

NO11

C9

G

G0

B1

B2

B3

GND

+VDC

+V

term

GND

+5 V

REF

B4

BC4

B5

BC5

VG

VG0

Y1

Y2

Y3

Y4

ID1

ID2

ID3

ID4

ID5

ID6

ID7

ID8

IDC1

B6

B7

B8

GND

ID9

ID10

ID11

ID12

IDC9

ID13H

ID13

IDC13

ID14

ID14H

J1 J24 J2 J3

J4 J5

J7

J8

J20

J21

J14

J11

J10J9

J13

J12

J22

J16 J17

J18

J15

J23

J6

J19

NO14

C14

NC14

NO15

C15

NC15

C16

NO16

NO17

NO18

C16

E-

E+

GND

ID15H

ID15

IDC15

ID16

ID16H

Y5

Y6

ID17

ID18

IDC17

B9

BC9

B10

BC10

field card serial card

input: 24V~/ V ; 50 to 60 Hz

max. power: 40 VA/15W

Wheel Frost Mode

24 VAC When Unit On

Exhaust Fan Enable

Supply Fan Enable

Heating Enable/Reversing Valve

24 VAC from Supply Fan Proving

Staged Compressor 2

Staged Compressor 1

Economizer Mode/Output to Dampers

24 VAC

Alarm Dry Contact

Wheel Pressure Limit

Supply Fan Proving

Unit On/Off Input

Wheel Rotation Alarm

Occupied/Unoccupied Input

Exhaust Fan Proving

Compressor Limit

Dirty Filter Input

Supply Fan VFD Output

Room Temperature Sensor

Exhaust Fan VFD Output

Outdoor Air Damper Analog Output

Cooling Analog Output

Heating Analog Output

Hot Gas Reheat Analog Output

24VAC for Analog Outputs

Outdoor Relative Humidity Sensor

Duct Pressure Sensor

Building Pressure Sensor

Room RH or Dehumidistat

After Cold Coil Temperature Sensor

CO2 Sensor

Sensor B1, B2, B3 Commons

Supply Discharge Temperature Sensor

Outdoor Air Temperature Sensor

24VAC to Controller

!

!

OptionalBACnet,LonWorksand

Modbus cards are located in

Serial Card port

7

DDC Controller for Tempered Air Products

®

The DDC controller is located in the unit control panel.

Thefaceofthecontrollerhassixkeys,allowingthe

user to view unit conditions and alter parameters. The

DDC controller is pre-programmed with easy to use

menus.

Tochangethedisplaycontrast,holdtheEnterand

Escapebuttonwhilepressingtheupanddownarrows.

Aremotemounteddisplayisalsoavailable,which

connects via the J10port.Asixwirepatchcableis

needed.

Keypad Description

Prg Esc

Alarm

Buttonwillblinkred,indicatinganalarmcondition.Presstoreviewcurrentalarms.To

reviewpreviousalarms,accesstheDATALOGGERthroughthemainmenu.

Prg Esc

DownArrow

The arrow keys allow the user to scroll through different screens and adjust parameters.

Prg Esc

UpArrow

Prg Esc

Enter

A.Inscreenswithadjustableparameters,pressingtheEnterkeymovesthecursorfrom

the upper left corner of the screen to the parameter. The arrow keys can then be used

to adjust the parameter.

B.Tomovetothenextparameteronthesamescreen,presstheEnterbutton.

C.Tosavethechange,presstheEnterbuttonuntilthecursormovesbacktotheupper

left corner of the screen.

Prg

Esc

Escape Allowstheusertoexitthecurrentmenu,jumpingtotheMainMenu.

Prg

Esc

Program

PressingthePrg(Program)buttonallowstheusertoentertheMainProgramMenu.

Refertopages10and11forMainProgramMenudescription.

Display Use

Example of Parameter Adjustment

The cursor always begins in the upper left corner of the display and will be

blinking.Pressthe

Prg Esc

key to move the cursor down for parameter adjustment.

Once the cursor has reached the desired parameter, press the

Prg Esc

Prg Esc

keys to

adjust the value.

When satisfied with the adjustment, press the

Prg Esc

key to save the parameter.

Whenfinished,makecertainthecursorisintheupperleftcorner.Ifthecursor

is not in the upper left corner, the changes will not be saved. The cursor must

be in the upper left corner to enable screen advancement.

Supply air low limit

Alarm when supply is

below: 35.0º F

Alarm delay: 300s

Supply air low limit

Alarm when supply is

below: 32.0º F

Alarm delay: 300s

Supply air low limit

Alarm when supply is

below: 32.0º F

Alarm delay: 300s

8

DDC Controller for Tempered Air Products

®

Examples of Alarms

Ifanalarmoccurs,the

Prg Esc

buttonwillglowredonthecontrollerandtheremotedisplay(ifinstalled).

To view alarm, press the

Prg Esc

button once. This will display the most recent

alarm.Pressthe

Prg Esc

buttonagaintoresetthealarm.Ifthealarmcannotbe

cleared,thecauseofthealarmhasnotbeenfixed.Pressthe

Prg Esc

Prg Esc

buttons to

view any additional occurring alarms.

Thisisanexampleofanoutdoorairsensorfailure.

This screen appears if there are no active alarms.

To view all saved alarms, press the

Prg Esc

buttontoentertheDATALOGGER.For

moreinformation,seetheDataLoggermenu.

Examples of Alarms

OutdoorAirTemperature

Sensor Failure

Failure of outside air temperature sensor. Alarmonly

SupplyAirTemperature

Sensor Failure

Failure of supply air temperature sensor. Alarm&Shutdown

Cold Coil Temperature

Sensor Failure

Failure of after cooling coil air temperature sensor. Alarmonly

Room Temperature Sensor

Failure

Failure of room temperature sensor.

(IfUnoccupied-CycleOnRoomisenabled)

Alarmonly

Systemhasexceededthe

set number of run hours

The unit has been operating for a period longer than the

maintenance set point.

Alarmonly

Supply airflow Indicatesalossofairflowinthesupplyfan. Alarm&Shutdown

WheelPressure

-DirtyWheel/HighCFM

Indicatesabuildupofpressureacrosstheenergywheel. Alarmonly

Energyrecoverywheel

rotation. Check wheel.

Indicatesawheelrotationfailure. Alarmonly

ExhaustAirflow Indicatesalossofairflowintheexhaustfan. Alarm&Shutdown

FilterAlarm Indicatesabuildupofpressureacrossthefilters. Alarmonly

Acompressorlimitswitch

has tripped

Indicatesahighorlowrefrigerantpressureswitchhastripped. Alarmonly

Supply temperature low

limit alarm

Indicatesasupplyairtemperaturelowerthanthesupplylowlimit

set point.

Alarm&Shutdown

pCOe Offline IndicatescommunicationwithpCOeauxiliaryI/Ohasfailed. Alarmonly

pCOe-Analoginputprobe

on channel # disconnected

or broken

IndicatesananalogprobefailureonthepCOe.Checkintegrityof

auxiliaryI/Oanalogprobes.

Alarmonly

BuildingPressureSensor

Failure

Failure of building pressure sensor

Alarm&minimumfan

speed

DuctPressureSensor

Failure

Failure of duct pressure sensor

Alarm&minimumfan

speed

Room Humidity Sensor

Failure

Failure of room RH sensor Alarmonly

OutdoorAirHumidity

Sensor Failure

Failure of outdoor air humidity sensor Alarmonly

CO2 Sensor Failure Failure of CO2 sensor

Alarm&minimumfan

speed

Alarms

Press DOWN to review

current alarm(s).

Press ESC to exit.

Press ALARM to reset.

Alarms

No active alarm

Press ENTER

to DATA LOGGER

Outside Air Temperature

Sensor B01 Failure

9

DDC Controller for Tempered Air Products

®

Menu Overview

Press

Prg

Esc

to enter menus.

Main Menu

On/Off Unit

Setpoint

Clock/Scheduler Input/Output Data Logger Board Switch Service Manufacturer

Main Status Unit On/Off Supply Set Point Clock Analog Inputs Alarms Board Switch Set Information Configuration

Sensor Status Unit On/Off Control Room Temp Scheduler Enable Digital Inputs Information Unit Code

Sched. Override Occupancy Control Room Humidity Schedule(s) Digital Outputs Information2 Expansion I/O

Supply Fan Supply Reset Limits Holiday(s) Analog Outputs Overrides pLAN Comm

Exhaust Fan Supply Reset Energy Wheel Field Card Comm

Energy Wheel Supply Set BMS Wheel Preheat I/O Config

Cooling Status Temp Set Pt Source Cooling Analog Inputs

Heating Status Cold Coil Set Pt Heating Digital Inputs

OA Damper Heat Lockout Reheat Digital Outputs

Cool Lockout Supply Fan Analog Outputs

Dehumid Lockout Exhaust Fan Factory Settings

Econ Lockout OA Damper Economizer

Supply Low Limit I/O Manual Management Defrost Cycle

Defrost BMS Config Cooling Control

Unoccupied Cycle Protocol Compressors

Supply Fan VFD Modbus Digital Scroll

Exhaust Fan VFD BACnet MSTP Comp Timers

Duct Pressure BACnet TCP/IP Comp Staging

Building Pressure BACnet TCP/IP Heat Control

CO2 Set Point BACnet R/W Heater Reheat

OA Damper Set Point Unit BMS Control Heater Reheat 2

Unit BMS Control 2 Hot Gas Flush

Service Settings Hot Gas

Working Hours SA Reset Control

Maintenance Hours Heat/Cool Delay

Working Hours Damper Delay

Probe Adjustment Air Proving

Password/Default Fan Delay

Service Password Rotation Delay

Service Restore CO2 Control

Duct Pressure

Building Pressure

Temp Scale

Initialization

Manf Restore

Manf Password

Factory Restore

NOTE

Your controller may not show all menus

depending on unit configuration.

10

DDC Controller for Tempered Air Products

®

Menu Overview

Press

Prg

Esc

to enter menus.

Main Menu

On/Off Unit

Setpoint

Clock/Scheduler Input/Output Data Logger Board Switch Service Manufacturer

Main Status Unit On/Off Supply Set Point Clock Analog Inputs Alarms Board Switch Set Information Configuration

Sensor Status Unit On/Off Control Room Temp Scheduler Enable Digital Inputs Information Unit Code

Sched. Override Occupancy Control Room Humidity Schedule(s) Digital Outputs Information2 Expansion I/O

Supply Fan Supply Reset Limits Holiday(s) Analog Outputs Overrides pLAN Comm

Exhaust Fan Supply Reset Energy Wheel Field Card Comm

Energy Wheel Supply Set BMS Wheel Preheat I/O Config

Cooling Status Temp Set Pt Source Cooling Analog Inputs

Heating Status Cold Coil Set Pt Heating Digital Inputs

OA Damper Heat Lockout Reheat Digital Outputs

Cool Lockout Supply Fan Analog Outputs

Dehumid Lockout Exhaust Fan Factory Settings

Econ Lockout OA Damper Economizer

Supply Low Limit I/O Manual Management Defrost Cycle

Defrost BMS Config Cooling Control

Unoccupied Cycle Protocol Compressors

Supply Fan VFD Modbus Digital Scroll

Exhaust Fan VFD BACnet MSTP Comp Timers

Duct Pressure BACnet TCP/IP Comp Staging

Building Pressure BACnet TCP/IP Heat Control

CO2 Set Point BACnet R/W Heater Reheat

OA Damper Set Point Unit BMS Control Heater Reheat 2

Unit BMS Control 2 Hot Gas Flush

Service Settings Hot Gas

Working Hours SA Reset Control

Maintenance Hours Heat/Cool Delay

Working Hours Damper Delay

Probe Adjustment Air Proving

Password/Default Fan Delay

Service Password Rotation Delay

Service Restore CO2 Control

Duct Pressure

Building Pressure

Temp Scale

Initialization

Manf Restore

Manf Password

Factory Restore

11

DDC Controller for Tempered Air Products

®

The DDC controller will revert to a default main menu loop. This loop includes several screens to view the

operating conditions of the unit. Scroll through the menu screens by using the

Prg Esc

Prg Esc

keys. Screens with a

dashed line border are dependent upon an optional accessory and may not always appear.

The SenSor STaTuS Screen diSplayS real Time condiTionS from The SenSorS

locaTed in The uniT and The room (if inSTalled).

Main Menu Overview

TIMEDATEUNIT##

TAP v2.00 GWY1X000XXXX

STATUS LINE

TIMEDATEUNIT##

Supply Air: 000.0°F

Outside Air: 000.0°F

OA Humidity 00.0%

Cold Coil: 000.0°F

Room Temp: 000.0°F

Room Humidity: 00.0%

STATUS LINE

®

Supply fan STaTuS. (if equipped wiTh Vfd)

IfequippedwithasupplyfanVFD,thisscreenwilldisplaythesupplyfan

rampbeingsentfromthecontrollertotheVFD.Theminimumandmaximum

speedsaresetintheVFD(SeeunitInstallationandOperationManualforVFD

programming).Thecontrollercanmodulatethefanbetweentheminandmax

speeds via an analog output. This screen also displays the method of fan

control and the parameter it is controlling.

Possiblemethodsinclude:ConstantSpeed,DuctPressureControl,Building

PressureControl,andCO2Control.

The iniTial menu Screen diSplayS The program VerSion, uniT code and STaTuS

line. The STaTuS line diSplayS which mode The uniT iS in.

Possiblemodesinclude:

• InitialDelay • SysOn-Cooling

• OpeningDampers • SysOn-Dehumidifying

• ExhaustFanStarting • SysOn-Dehumid&Reheat

• SupplyFanStarting • Unoccupied-UnitOff

• SystemOn • Unoccupied-Heating

• DefrostModelActive • Unoccupied-Cooling

• SysOn-Econ+Cooling • ManualOverride

• SysOn-Economizer • RemoteOff

• SysOn-Heating • PressAlarmButton!!!

exhauST fan STaTuS. (if equipped wiTh Vfd)

IfequippedwithanexhaustfanVFD,thisscreenwilldisplaytheexhaustfan

rampbeingsentfromthecontrollertotheVFD.Theminimumandmaximum

speedsaresetintheVFD(SeeunitInstallationandOperationManualforVFD

programming).Thecontrollercanmodulatethefanbetweentheminandmax

speeds via an analog output. This screen also displays the method of fan

control and the parameter it is controlling.

Possiblemethodsinclude:ConstantSpeed,BuildingPressureControl,

OutdoorAirDamperTracking,andSupplyFanTracking.

Supply Fan Status

Supply Fan Ramp: 0%

(0%=Min Speed by VFD)

Duct Ps Control

Duct Pressure: 0.00”wc

STATUS LINE

ExhaustFanStatus

Exhaust Fan Ramp: 0%

(0%=Min Speed by VFD)

Building Ps Control

Building Ps: +.000”wc

STATUS LINE

energy recoVery wheel STaTuS. (if equipped)

Ifselectedwithapreheater,thestatuswillalsobedisplayed.

EnergyRecovery

Wheel: 100% Speed

Wheel Differential

Pressure Is: Normal

Preheater: OFF

STATUS LINE

12

DDC Controller for Tempered Air Products

®

cooling STaTuS iS diSplayed, along wiTh compreSSor operaTion. (if equipped)

This screen appears if a cooling option is provided.

Chilled Water:TheCoolingControl%isdirectlyproportionaltothe0-10VDC

output signal.

0%Cooling=0VDC

100%Cooling=10VDC

ThecoolingcontroloutputcanbeconfiguredtoDIRECT/REVERSEacting,

alongwiththeminimumandmaximumoutputvoltagesbyenteringthe

MANUFACTURER menu.

Packaged DX Cooling: The Cooling Control displays internal cooling ramp as

a percent. Compressor operation is displayed when engaged.

•D=DigitalScrollCompressorOperation

•1=FirstStagedCompressorOperation

•2=SecondStagedCompressorOperation

Heat Pump Cooling: The Cooling Control displays internal cooling ramp as a

percent. Compressor operation is displayed when engaged.

•1=FirstStagedCompressorOperation

•2=SecondStagedCompressorOperation

Cooling Status

Cooling Control: 000%

Compressor D 1 2

STATUS LINE

Heating Status

Heater Control: 000%

Hot Gas Reheat: 000%

Staged reheat is: ON

Compressor: 1 2

STATUS LINE

heaT and reheaT operaTion iS diSplayed. (if equipped)

Heater Control displays the proportional percentage of the heater analog

output.

Electric Heater:TheHeaterControl%isproportionaltothe0-10VDCsignal

being sent to the SCR controller, located in the electric heater control center.

0%Heating=0VDC-0kWoutput

100%Heating=10VDC-MaxkWoutput

Hot Water:TheHeaterControl%isproportionaltothe0-10VDCsignalbeing

senttotheheatingcontrolvalve(BYOTHERS).Theheatingcontroloutput

canbeconfiguredtoDIRECT/REVERSEacting,alongwiththeminimumand

maximumoutputvoltagesbyenteringtheMANUFACTURERmenu.

0%Heating=0VDC

100%Heating=10VDC

Indirect Gas:TheHeaterControl%isproportionaltothe0-10VDCsignal

being sent to the indirect gas furnace controller, located in the indirect gas

control center. The first stage is on at 1% Heater Control. The furnace will then

modulateproportionallyfromminimumtomaximumcapacity.

0%=0VDC–OFF

1%=0VDC–MINIMUMTURNDOWNENABLED

1-100%=0-10VDC=FURNACEMODULATION

Heat Pump Heating: The Heater Control % displays internal heating ramp as a

percent. Compressor operation is displayed when engaged.

•1=FirstStagedCompressorOperation

•2=SecondStagedCompressorOperation

Hot Gas Reheat:

If hot gas reheat is staged control:

“Stagedreheatis:ON/OFF”willindicateoperation.

If hot gas reheat is modulating bypass damper control:

0% = OFF

1%-100%=4-10VDC=AIRFLOWDAMPERMODULATION

If hot gas reheat is modulating valve control:

0% = OFF

1%-100%=0-10VDC=HOTGASREHEATVALVEMODULATION

13

DDC Controller for Tempered Air Products

®

ouTdoor air damper STaTuS. (if equipped wiTh modulaTing ouTdoor and

recirculaTed air damperS)

This screen will display the outdoor air damper position commanded by the

controllerandwhichmethodthedamperpositionisactivelyutilizing.

Possiblemethodsinclude:ActiveonMinimumOA%,ActiveonEconomizerand

ActiveonCO2.

Outdoor Damper Status

Damper Position: 50%

Active on Minimum OA%

CO2 Level: 0

ppm

STATUS LINE

14

DDC Controller for Tempered Air Products

®

A. On/Off Unit

The controller is equipped with several menus to help guide users with altering program parameters. The

following menus can be accessed by pressing the

Prg

Esc

key. To enter the desired menu, press the

Prg Esc

key.

The On/Off UnitmenuallowstheusertoviewthedetailedOn/Offstatusofthe

controller.

The unit ships from the factory in a disabled state. To allow the unit to operate,

thecontrollermustreceivearuncommandfromdigitalinputID4.Jumper unit

terminals R - G to allow the unit to operate.

ActualState:ThecontrollermaybeinfollowingOn/Offstates:

a. Unit On - Unit is ON, functioning normally.

b. OffbyALARM-UnitisOFFduetoanalarm.Viewalarmsbypressing

ALARMbutton.

c. OffbyPLAN-UnitisOFFbypLANnetwork.

d. Off by BMS - Unit is OFF by BMS command

e. OffbySCHEDULER-UnitisOFFbyinternalClock/Scheduler.

f. OffbyDIGITALINPUT(ID4)-UnitisOFFbydigitalinput4(ID4).

g. OffbyKEYPAD-UnitiscommandedOFFbythisscreen.

Change to (Switch Off/Switch On):EnablesusermanuallyturnunitOn/Offvia

display. Unit terminal Gmusthave24VACpowertoenabletheunit.

ThiS Screen allowS The uSer To adjuST which SySTem conTrolS The uniT

on/off STaTe.

Digital Input:DefaulttoYES.UnitterminalGmusthave24VACpowerto

enable the unit.

The user can also use the BMS or internal time clock to command the unit

On/Offstate.Ifschedulingisdesired,gototheClock/Schedulermenutoset

a schedule.

BMS:YESallowsBMStocontrolunitOn/Offstate.

Scheduler:YESallowsinternalscheduler(timeclock)forunitOn/Offcontrol.

Menus

UnitOn/Off

Actual state:

Off by DIG INPUT (ID4)

Change to: SWITCH ON

*Power ID4 to start…

UnitON/OFFControl

Enable unit OnOff

By digit input: Yes

By BMS: No

By Scheduler: Yes

Occupancy Control

Type: Unit OFF

Source: Input ID6

ThiS Screen diSplayS whaT The uniT will do in unoccupied mode.

Setting the Type to CycleSupplyFan will engage the unit to maintain space

temperature. However, a room temperature sensor must be wired between

controllerterminalsB4andBC4.Ifdesired,theSourceoffersthreeoptionsto

controloccupancy.ThefactorydefaultisterminalID6onthecontroller.

InputID6: Typically used with a remote time clock, motion sensor or switch

(default).

BMS: BMScontrol(seePointsList).BMScanbeoverriddenwithID6.

Time Clock: Internaltimeclock(Scheduler).SeeClock/Schedulermenufor

more information. The Scheduler can be overridden with digital

inputID6.

Without the room temperature sensor, the Type will be Unit Off, forcing the unit

off during unoccupied mode.

15

DDC Controller for Tempered Air Products

®

B. Setpoint

The Setpoint menu allows the user to view and adjust temperature related

parameters.

ThiS Screen diSplayS The currenT Supply air SeT poinT.

This screen does not appear if a BMS is directly setting the supply air set point.

This screen displays the current supply air set point, determined by the

controller. The supply set point is reset either by outdoor air temperature, or

room temperature if installed. The user may also directly control the supply air

set point. To activate the BMS set point capability, go to the Set Point Source

screen in this menu.

Ifaroomtemperaturesensorisconnectedtothecontroller,thesupplyair

temperatureisresettoachievetheroomtemperaturesetpoint.The“local”

roomtemperaturesetpointcanbesetviathecontroller(seeRoom Set Point

screen). Otherwise, the BMS can directly input the desired room set point. To

activate the BMS set point capability, go to the Set Point Source screen in this

menu.

ThiS Screen diSplayS The room Temp SeT poinT.

This screen only appears if a room sensor is wired into the controller.

Theunitwillresetthesupplyairtemperaturetomaintainthelocalsetpoint.If

a BMS is interfaced with the controller, the user has the capability to directly

inputthedesiredRoomTempSetPointthoughtheBMS.Thescreenwill

showaBMSsetpointandanActivesetpoint.Theactivesetpointistheroom

temperature the controller is currently trying to maintain.

ThiS Screen diSplayS The room relaTiVe humidiTy SeT poinT.

This screen only appears if a room relative humidity sensor is wired into the

controller.

The unit will reset the cold coil temperature set point to maintain the local

roomhumiditysetpoint.IfaBMSisinterfacedwiththecontroller,theuserhas

thecapabilitytodirectlyinputthedesiredRoomRelativeHumiditySetPoint

thoughtheBMS.ThescreenwillshowaBMSsetpointandanActivesetpoint.

The point source must be changed to BMS to allow BMS control.

SupplySetPoint

is currently = 60°F

This set pt is reset up/down

by the DDC

RoomTempSetPoint

Local set pt: 72.0°F

BMS set pt: 70.0°F

Active set pt: 70.0°F

RoomHumiditySetPoint

Local set pt: 55.0%

BMS set pt: 55.0%

Active set pt: 55.0%

Set Pt Source: LOCAL

ThiS Screen diSplayS The minimum and maximum Supply air TemperaTure

limiTS.

This screen only appears if the unit is connected to a room temperature sensor.

The supply air temperature will be controlled within the Supply Min and Supply

Maxlimitstomaintainroomtemperaturesetpoint.

SupplyResetLimits

Supply Min: 55.0°F

Supply Max: 90.0°F

16

DDC Controller for Tempered Air Products

®

TheSe parameTerS dicTaTe The operaTion of The ouTdoor air reSeT funcTion.

This screen does not appear when a room temp sensor is wired to the controller.

The controller monitors the outdoor air temperature and adjusts the desired

supplytemperatureaccordingly.Forexample,whentheoutdoorairisbelow

60°F,thecontrollerwillchangetheSupplysetpointto72°F.Iftheoutdoor

airisabove70°F,thecontrollerwillchangetheSupplysetpointto55°F.If

theoutdoorairtemperatureisbetween60°Fand70°F,theSupplysetpoint

changesaccordingtotheoutdoorairresetfunction.Avisualrepresentationof

the outdoor air reset function is shown below.

SupplyAirReset

Outside: Supply

60.0°F - - > 72.0°F

70.0°F - - > 55.0°F

Outdoor Air Reset Function

49°

55°

61°

67°

73°

55°60° 65°70° 75°

Outside Air Temperature (°F)

Supply Air Set Point (°F)

ThiS Screen diSplayS The Supply air SeT poinT aS SeT by a bmS.

This screen appears if the unit has BMS communications and set point source is

set to BMS.

See Set Point Source screen in this menu to allow BMS to determine set point.

The conTroller will lockouT cooling when The ouTdoor air TemperaTure iS

below The cooling lockouT SeT poinT. (facTory defaulT = 55°f)

This screen only appears if the unit the unit is equipped with cooling.

Thereisabuiltinhysteresisof2°Fwhichpreventsthecoolingfromshort

cycling. The hysteresis is similar to a dead-band above and below the lockout

setpoint.(Example:IfLockout=55°F,coolingislockedoutbelow53°Fand

enabledabove57°Foutsideairtemperature.)

The conTroller will lockouT heaTing when The ouTdoor air TemperaTure iS

aboVe The heaTing lockouT SeT poinT. (facTory defaulT = 70°f)

This screen only appears if the unit the unit is equipped with heating.

Thereisabuiltinhysteresisof2°Fwhichpreventstheheatingfromshort

cycling. The hysteresis is similar to a dead-band above and below the lockout

setpoint.(Example:IfLockout=70°F,heatingislockedoutabove72°Fand

enabledbelow68°Foutsideairtemperature.)

ThiS Screen diSplayS The TemperaTure SeT poinTS for The cooling coil.

This screen only appears if the unit is equipped with cooling.

The Normal mode set point is the after coil temperature the unit will maintain

understandardoperation,whenincooling.Ifahumidistatwasprovided

with the unit, the Dehumidify set point is the temperature the cooling coil will

dischargeonacallfordehumidification.TheActivesetpointisthecoolingcoil

discharge temperature the unit is currently trying to maintain.

Supply Set From BMS

BMS interface: ##.#°F

Set pt min: 55.5°F

Set pt max: 90.0°F

ColdCoilSetPoint

Normal Mode: 55.0°F

Dehumidify: 50.0°F

Active set pt: 55.0°F

HeaterLockout

Lockout heater when outside

above: 70.0°F

Hysteresis: 2.0°F

CoolingLockout

Lockout cooling when outside

below: 55.0°F

Hysteresis: 2.0°F

17

DDC Controller for Tempered Air Products

®

economizer lockouT preVenTS The uniT from going inTo economizer mode

when The ouTdoor air condiTionS are Too cold.

This screen only appears if economizer was provided with the unit.

Thelockoutpreventsoutdoorairfrom:(1)enteringthespaceattoocoldofa

temperatureor(2)enteringheatingorcoolingcoilsatconditionsthatcould

freezethecoils.Built-inhysteresisof2°F.Thehysteresisissimilartoadead-

band above and below the lockout set point. Example:IfLockout=40°F,

economizerislockedoutbelow38°Fandenabledabove42°Foutsideair

temperature.)

ThiS Screen diSplayS The TemperaTure difference aT which The

dehumidificaTion mode iS locked ouT. (facTory defaulT = 10°f)

This screen only appears if the unit is equipped with cooling.

This setting prevents the unit from operating in dehumidification mode when the

outdoor air conditions are relatively cool. Example:Ifthecoldcoilsetpointis

55°F,dehumidificationmodecannotoperateuntiltheoutdoorairisatleast65°F.

Dehumidification lock

Lockout dehumidification until

outside air is 10.0°F above

cold coil set point.

EconomizerLockout

Lockout economizer if

outdoor air is:

Below: 40.0°F [Dry Bulb]

Above: 75.0°F [Dry Bulb]

Above: 55.0°F [Dew PT]

Differential 2.0°F

ThiS Screen diSplayS The room SeT poinTS for heaTing and cooling operaTion

during unoccupied mode.

This screen only appears if the unoccupied mode is set to “Cycle on Room”

instead of “Unit Off”. A room temp sensor must be wired into the controller. For

energy recovery units, a Night Set-Back Damper must be installed.

InunoccupiedmodewhenthetemperaturefallsbelowtheroomHeatingset

point,thesupplyfanandheatingwillturnon.IftheunitisanEnergyRecovery

unit, the Night Set-Back Damper will also open. The unit will discharge the

SupplyMaxtemperaturepertheSupplyResetLimitsscreen,untiltheroom

set point is satisfied. Unit will then shut down. When the temperature rises

above the Cooling set point, the unit will discharge the Supply Min temperature

pertheSupplyResetLimitsscreenuntiltheroomtemperaturesetpointis

satisfied. Unit will then shut down.

The differential acts as a hysteresis to keep the heating and cooling from

cyclingtoooften.Forexample,onacallforheating,theunitturnsonat60°F

andturnsoffat65°F.Forcooling,theunitturnsonat85°Fandturnsoffat80°F.

ThiS Screen diSplayS The TemperaTure aT which The uniT will enable froST

conTrol mode if neceSSary. (facTory defaulT = 5°f)

This screen only appears if the unit has an energy recovery wheel and a frost

control method was provided with the unit.

Upon sensing a high differential pressure across the energy wheel, the unit will

go into defrost if the outside air temperature is below this temperature setting.

ThiS Screen diSplayS The low Supply air TemperaTure limiT.

IftheunitsupplyairtemperaturefallsbelowSupplyAirLowLimitforaperiod

ofAlarmDelay,theunitwillshutdownandanalarmwillbesignaled.The

purpose of the supply low limit is to protect the building and contents from

coldsupplyair.ItisNOTdesignedtoprotecttheair-handlingunit.

Iftheunitdoesnothavechilledwater(CW)orhotwater(HW)coils,itshould

notneedadditionalprotectionfromfreezing.IftheunitdoeshaveCWorHW

coils,fieldprovidedcoilfreezeprotectionmaybenecessary.

Supply air low limit

Alarm when supply is

below: 35.0°F

Alarm delay: 300s

Defrost

Allow wheel defrost

mode when outside

is below: 05.0°F

UnOcc Fan Cycle Setup

Unit will energize to maintain

unocc room set points.

Heating: 65.0°F

Cooling: 80.0°F

Differential: 5.0°F

uSerS can chooSe eiTher The conTroller or The bmS To deTermine Supply

air TemperaTure SeT poinT during operaTion.

This screen only appears if the controller was supplied with BMS capability.

Localmeansthecontrollersetpointwillbeusedduringoperation.(OutdoorAir

Reset or Room Reset)

BMS means that the BMS set point will be used during operation.

TempSetPointSource

Use local set point, or BMS

interface set point? Local

18

DDC Controller for Tempered Air Products

®

ThiS Screen diSplayS The Supply fan Speed SeT poinTS.

This screen only appears if equipped with a supply fan VFD controlled by

microprocessor.

TheSpeedSetPointistheproportionalpercentageoftheanalogoutputfrom

thecontrollertotheVFD.

0%Speed=MinSpeed(determinedbyVFD)

100%Speed=MaxSpeed(determinedbyVFD)

(SeeunitInstallationandOperationManualforVFDprogramming).

Set point source must be changed to BMS to allow BMS control.

ThiS Screen diSplayS The exhauST fan Speed SeT poinTS.

This screen only appears if equipped with an exhaust fan VFD controlled by

microprocessor.

TheSpeedSetPointistheproportionalpercentageoftheanalogoutputfrom

thecontrollertotheVFD.

0%Speed=MinSpeed(determinedbyVFD)

100%Speed=MaxSpeed(determinedbyVFD)

(SeeunitInstallationandOperationManualforVFDprogramming).

Set point source must be changed to BMS to allow BMS control.

ThiS Screen diSplayS The ducT preSSure SeT poinT.

This screen only appears if equipped with a duct pressure sensor.

The unit will modulate the supply fan to maintain the local duct pressure set

point.

Set point source must be changed to BMS to allow BMS control.

ThiS Screen diSplayS The building preSSure SeT poinT.

This screen only appears if equipped with a building pressure sensor.

Dependingonunitconfiguration,theunitwilleithermodulatetheexhaustor

supply fan to maintain the local building pressure set point.

Set point source must be changed to BMS to allow BMS control.

ThiS Screen diSplayS The co2 SeT poinT.

This screen only appears if equipped with a CO2 sensor.

Depending on unit configuration, the unit will either modulate the supply fan or

outdoor air damper to maintain the CO2 set point.

Set point source must be changed to BMS to allow BMS control.

ThiS Screen diSplayS The ouTdoor air damper SeT poinT.

This screen only appears if equipped with a modulating outdoor air and

recirculating damper.

When the unit is operating in the Occupied mode, the outdoor air dampers

willremainattheOutdoorAir(OA)MinPosition.IfequippedwithCO2control

ormodulatingeconomizer,theoutdoorairdampermaymodulateopenpast

theOAMinPosition.Tolimitthemaximumopenposition,adjusttheOAMax

Positiontothedesiredlimit.

SetPtSourcemustbechangedtoBMStoallowBMScontroloftheOAMin

Position.ThedamperwillmodulateopenpasttheOAMinPositionifequipped

withCO2controlormodulatingeconomizer.

SupplyFanSpeedSetPt

Local set pt: 30%

BMS set pt: 0%

Active set pt: 30%

Set pt source: LOCAL

ExhaustFanSpeedSetPt

Local set pt: 30%

BMS set pt: 0%

Active set pt: 30%

Set pt source: LOCAL

DuctPressureSetPt

Local set pt: 0.25”wc

BMS set pt: 0.00”wc

Set pt source: LOCAL

Duct Ps: 0.00”wc

BuildingPressSetPt

Local set pt: +.050”wc

BMS set pt: +.000”wc

Set pt source: LOCAL

Building Ps: +.000”wc

CO2SetPoint

Local set pt: 1000ppm

BMS set pt: 1000

ppm

Set pt source: LOCAL

CO2 Levels: 0

ppm

OADamperSetPoint

OA Min Position: 50%

BMS set pt: 50%

Active set pt: 50%

Set pt source: LOCAL

OA Max Position: 100%

19

DDC Controller for Tempered Air Products

®

E. Data Logger

The clock Screen allowS The uSer To adjuST The Time and daTe.

ThiS Screen allowS The uSer To SeT holiday daTeS (if enabled).

This screen only appears if Holidays are enabled.

The internal time clock will go into unoccupied mode as long as the date is

equaltotheholidaydate(alwaysa24hourperiod).

ThiS Screen allowS The uSer To adjuST ScheduleS.

This screen only appears if a Schedule was added in the screen above.

Theprogramsupportsuptosevenseparateschedules.Eachschedulewill

require the user to enter a Time On, Time Off and which days the schedule is

applicable for.

ThiS Screen allowS The uSer To add The number of unoccupied ScheduleS

and holidayS.

The Number of Schedules corresponds to the number of unoccupied periods

the user wishes to add. By setting the number of schedules to a value greater

thanzero,theunoccupiedmodewillautomaticallybesettotimeclock.

Aholidayisasingleoccurrenceinwhichyouwouldliketheunittobe

unoccupiedfor24hours.Amaximumof15holidayscanbeset.Holidaysmust

be reconfigured each year.

TomanuallycontrolI/Ovalues,gototheService menu > Overrides.

Similar screens appear for all controller inputs and outputs.

Your controller may not utilize all of the inputs and outputs shown. See

unit wiring diagram for your specific configuration.

ThiS Screen iS an example of a recorded alarm.

The unit conditions are displayed for past alarm events. The date, time,

temperatures and unit status are recorded.

To clear recorded alarms, press

Prg

Esc

and

Prg

Esc

simultaneously.

Scheduler

Schedule #: #

Time On: 07:00

Time Off: 05:00

Days Enabled: MTWTFSS

Holiday #1

Month: MM

Day: DD

Unoccupied for 24 hrs

AnalogInput

Outside Temperature

Input B01: 75.0°F

13:21:04 MM/DD/YY

OA Sensor

Room T: 70.0

Discharge T: 65.0

Outside Air T: -623.3

Cold Coil T: 55.0

System Off

C. Clock/Scheduler

D. Input/Output

The Clock/Scheduler menu allows the user to view and alter the time and date.

The user can also add up to seven schedules for occupancy requirements.

Clock

Day: Monday

Date: MM/DD/YY

Hour: 15:30

Scheduler

Number of schedules: 0

Holidays

Holiday = unoccupied mode

for 24 hours.

Number of Holidays: 0

The Input/Output menu allows the user to quickly view the status of the controller

inputs and outputs.

The Data Logger menu allows the user to view past alarms.

20

DDC Controller for Tempered Air Products

®

/