Page is loading ...

09/09 506215−01

*2P0909* *P506215-01*

Page 1

Litho U.S.A.

E2009

506215−01

09/09

PRODIGYt

M2 Unit Controller

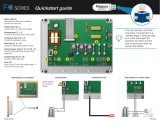

INSTALLATION & SETUP GUIDE FOR THE M2 UNIT CONTROLLER

USED WITH ENERGENCEt ROOFTOP UNITS

USB

INTERFACE

PORT

DISPLAY

USER INTERFACE NAVIGATION ARROWS

SELECT

BUTTON

ALARM

STATUS

MODE

CALLS

USB

TEST

OFFLINE

IN/OUTPUTS

REPLACE

REPORT

RUNTIMES

HISTORY

SENSORS

NETWORK

FACTORY

UNIT

SETPOINTS

CONTROL

OPTIONS

INSTALL

DISPLAY SERVICE DATA SETTINGS

M2 UNIT CONTROLLER

Push to select or enter value; then use

arrows

Use arrows to move

USB

INTERFACE

PORT

(For Flash Drive

DISPLAY

USER INTERFACE NAVIGATION ARROWS

SELECT

BUTTON

L CONNECTION ( optional

connection method for Unit

Controller software)

USB CONNECTION

(for Unit Controller

software)

SMARTWIREt

CONNECTORS

BACnet

R

t Listed

Description

The Prodigyt M2 unit controller:

S provides control functions for Energencet roof-

top unit,

S includes a user interface consisting of a dot ma-

trix display, navigation arrow buttons, a select

button, and a USB port,

S provides status & diagnostic information for trou-

bleshooting,

S allows adjustment of time delays and setpoints

that enable advanced features,

S is controlled by a standard room thermostat, di-

rect digital controller (DDC), or a zone sensor,

S can be configured as a device on the network

when daisy−chained to the L Connection

®

Net-

work,

S may be connected to a PC which has been

loaded with Unit Controller software,

S accepts add−on boards to build variations ac-

cording to application or equipment type.

S USB verification

Table Of Contents

M2 unit controller, expansion board locations,

SmartWiret connections 2. . . . . . . . . . . . . . . . . . . . . . . .

M2 unit controller LED operation indications 3. . . . . . . . . . . .

Startup 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Menu interface 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operation:

DISPLAY 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SERVICE 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TEST 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DATA 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SETTINGS 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

BACnet

®

15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Networking Controllers 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Economizer (Damper) 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

APPENDIX:

Abbreviations 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Parts List 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

USB Service Report Example 21. . . . . . . . . . . . . . . . . . . .

Alarm Codes 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Wiring Diagrams 25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

M2 unit controller signal reference diagram 30. . . . . . . . .

M2 unit controller board connections diagram 31. . . . . . .

QUICK START GUIDE (BACK COVER) 32. . . . . . . . . . . .

Page 2

M2 (A55) unit controller − location, controls, inputs/outputs

M2 unit controller board, expansion board locations, SmartWiret connections

Figure 1 shows the controller components and the locations for expansion boards.

EXPANSION

PORT

ECONOMIZER POTS

AND DIP SWITCHES

(PAGE 18)

EXPANSION

PORT

2 AMP FUSE

CONTROL

BOARD

CONTROL

BOARD

L CONNECTION ( optional

connection method for Unit

Controller software)

USB CONNECTION

(for Unit Controller

software)

Figure 1. M2 unit controller board and expansion boards

Page 3

M2 unit controller LED indicators

Some indicators on the circuit board are visible with the cover in place; others are not. The indicators and their meanings are

described in table 1.

Table 1. LED operation indications

LED Status Indication Meaning

Heartbeat green Slow Flash Normal Operation

green Fast Flash Check 24V, update

firmware, or replace

board

green Steady Off No voltage to M2 board

or defective board

green Steady On Defective Board (re-

place)

OAS

green Steady ON Outside air is suitable

green Flashing

IAQ mode or mechani-

cal cooling during free

cooling

PC

Connection

Local

(amber)

Flickering ON

Communication to PC

USB connector

Network

(green)

Flickering ON

Network communica-

tion

LED Status Indication Meaning

S−BUS BUS

(green)

Flickering ON Network traffic present

TX

(amber)

Flickering ON M2 is transmitting

BACnet RX (green) Flickering ON M2 is receiving

TX (red) Flickering ON M2 is transmitting

Thermostat

Input

amber Indicates a

thermostat de-

mand

G− Blower on

W1− 1st stage heat

W2− 2nd stage heat

Y1− 1st stage cool

Y2− 2nd stage cool

OCP−Occupied

Thermostat LEDs indicate only with incoming thermostat connection

vis SmartWire connector.

Slow Flash = 1 sec on; 1 sec off.

Fast Flash = 1 msec on; 1 msec off.

A flickering" LED flashes significantly faster than a fast flash.

NOTE − LEDs are energized by 24 vac thermostat inputs.

Startup

Connections between RTU & M2 unit controller

The M2 unit controller connects to the rooftop unit using

SmartWiret connectors. Each connector is keyed" so

that no connector can be installed in the wrong location. Be

sure all connectors are in place and completely inserted

(see figure 1).

Sensor Common Isolation

Thermostat (TSTAT) and humidity (HUM) sensor com-

mons may be isolated if they are powered remotely. Slide

switch to OPEN to isolate (see figure 1).

USB interface usage

The USB port is used for service verification and for down-

loading reports. Onsite data collection requires use of a

USB flash drive. Data written to the drive includes date,

time, serial number, catalog number, basic data, and error

code buffer. Technicians then transfer the data to a PC and

then forward encrypted files to billing personnel for service

history verification.

PC interface

The PC interface is used with unit controller software to

change programming. The M2 interface uses a USB A to B

male cable. You may also continue to use 9 pin/RS485

connection to the phone jack or S−BUS connector as be-

fore. A list of service connection kits is on Page 20.

SmartWire Field Wiring Connections

The SmartWire connectors, P297, P298 and P299, al-

low for easy field wiring connection points.

2−amp fuseThe 24VAC supply outputs, (R), on these

connectors are routed through the fuse, F1. This fuse is a

standard 2−amp, automotive−style blade fuse. This fuse

protects the Prodigy controller from field wiring mis−wires.

TSTAT COMThe switch "TSTAT COM" is located to the

left of P297. This switch is used only in unique situations

where the device supplying the thermostat signals to the

Prodigyt controller has its own power source and does

not share a common reference voltage with the Prodigyt

controller. Otherwise the TSTAT COM switch needs to be

set to the default, closed position, to the right.

HMD COMThe switch "HMD COM" is located to the right

of P299. This switch is used only in unique situations

where the device supplying the dehumidify command sig-

nal to the Prodigyt controller has its own power source

and does not share a common reference voltage with the

Prodigyt controller. Otherwise the HMD COM switch

needs to be set default, closed position, to the left.

Page 4

Startup (continued)

User interface menu

The user interface is accessed through the menu naviga-

tion arrows and the select button . The diagram

in figure 2 shows a high level overview of the main menu

options along with the next level list of selections. The low-

er level options are described later in this manual.

Home" location, DISPLAYWhen the unit is powered

on, one of the features in the DISPLAY column will be

shown (the word ’DISPLAY’ is never shown). What is dis-

played in this home" screen, is dependant on the priority

message present at the time, in priority order of top−to−bot-

tom of the left column in figure 2. For example, if an alarm is

present, that will be displayed until it has been silenced or

cleared.

To access the other three columns, first press and then

use to scroll between SERVICE, DATA, AND SET-

TINGS. Next, press to open the SERVICE (or DATA or

SETTINGS) menu. Use

until desired item is dis-

played.

To return to DISPLAY, use

(hold it down if you are deep in

the menu structure and you will be stepped back to DIS-

PLAY.

ALARM

STATUS

MODE

CALLS

USB

TEST

OFFLINE

IN / OUTPUTS

REPLACE

REPORT

RUNTIMES

HISTORY

SENSORS

NETWORK

FACTORY

UNIT

SETPOINTS

CONTROL

OPTIONS

INSTALL

DISPLAY

Dashed line for automatic

displayed messages

SERVICE DATA SETTINGS

Use arrows to move

Use arrows to move

Use arrows to move

NOTE − Use the left button during normal

operation to clear delays (hold 2 seconds)

or reset the controller (5 seconds).

Figure 2. M2 unit controller main interface menu

Page 5

Menu Interface

Table 2 shows the major levels of the menu interface.

Many of these options have more levels and are described

in the following sections that detail DISPLAY, SERVICE,

DATA, and SETTINGS.

Use rectangular button

to progress to next

lower level (i.e. Level 1 to Level 2).

Use left arrow

toback up" to the next higher level

(i.e. Level 2 to Level 1).

Use the up/down

arrows to move within a level

and change values of selected item.

Table 2. Menu Interface

Level 1 Level 2 Level 3

NOTE − Features and options not currently available are greyed out in

the manual and will show a message of N/A" on the display

(display

area)

ALARM

SILENCE (push any button to silence)

STATUS

SILENCE (push any button to silence)

MODE

BLOWER

COOLING

FREE COOLING

FRESH AIR COOL

FRESH AIR HEAT

HEATING

HVAC OFF

IDLE

MORNING

WARMUP

M2 FAILED TO

RESPOND

PRE−COOL

PRE INSTALL

REHEAT

SMOKE

TEST

CALLS

TSTAT Y1, etc

BACNET Y1, etc

LONTALK Y1, etc

LCONN Y1, etc

BUILDING Y1, etc

USB

WRITING USB

WRITING ALARM/STATUS LOG

USB COMPLETE

SER-

VICE

USE ARROWS TO MOVE

TEST

GUIDED

BLOWER

FANS

COOL

HEAT

DAMPER

REHEAT

SENSORS

OUTPUTS

CONTROLLER

OFFLINE

LOCKOUT

BLOWER ONLY

COOLING ONLY

HEATING ONLY

RESET

IN /

OUTPUTS

ZONING

SENSORS

RELAYS

NETWORK

OUTPUTS

REPLACE

FILTER

BELT

UV LAMP

FANS

BLOWER

COMPRESSOR

REPORT

MAKE REPORT

READ INSTALL

READ FACTORY

Table 2. Menu Interface (cont’d)

Level 1 Level 2 Level 3

DATA

USE ARROWS TO MOVEUSE ARROWS TO MOVEUSE ARROWS TO MOVEUSE ARROWS TO MOVE

RUNTIMES

POWER ON

FILTER: XX HRS

BELT: XX HRS

UV LAMP: XX HRS

BLOWER: XX HRS − XX CYC

COOLING

HEATING

FREE COOLING: XX HRS − XX

CYC

FANS

EXHAUST

REHEAT: XX HRS − XX CYC

HISTORY

ALARMS

STATUS

LAST USB

READ INSTALL RPT

CLEAR HISTORY

SENSORS

(also

accessible

thru In /

Outputs)

TSTAT

BRPM:XX

DPOS:XX%

OAT:XXºF

RAT:XXºF

DAT:XXºF

ZAT:XXºF

IAQ:XX PPM

SMK:OFF/ON

RH:XX%

IE:XX MA

OE:XX MA

GLO:OFF/ON

DI2:OFF/ON

DI3:OFF/ON

DI4:OFF/ON

NETWORK

LCONN ADDRESS

BACNET ADDRESS

LONTALK ADDRESS

FACTORY

READ M2 SOFTWARE

VERSION

READ DB SOFTWARE

VERSION

READ FACTORY RPT

CATALOG NO.

MODEL NO.

SERIAL NO.

SET-

TINGS

USE ARROWS TO MOVE

UNIT

UNIT NO.

DATE/TIME

UNITS F/C

SETPOINTS

COOLING

HEATING

DAMPER

REHEAT

EXHAUST

IAQ

CONTROL

GUIDED SETUP

LOCAL

THERMOSTAT

LCONN

BACNET

LONTALK

MSAV

REHEAT

OPTIONS

RESERVED

INSTALL

NEW M2

DAMPER

FLOAT SW

BLOWER PROVING SW

PHASE MONITOR

UV LAMP

ELECTRIC HEAT STAGES

UPDATE DISPLAY SOFTWARE

Page 6

Menu Interface DISPLAY

The display shows operating mode if in normal operation.

Alarm, status, calls and plugging in the USB will interrupt

the display. Alarm messages will stay displayed until cor-

rected or silenced using the local menu.

DISPLAY

ALARM

STATUS

MODE

CALLS

USB

Dashed line for automatic

displayed messages

ALARM Example ˘ MODE message

COOLING" is displaying when a smoke

alarm occurs; then ALARM:(XX) SMOKE

A17" displays until cleared. You must

clear all alarms and status to see normal

MODE message. Strike 3 alarms will say

ALARM(XX):STRIKE 3 COMP1 HIGH

PRESS S4" after the alarm message.

USB ˘ normal MODE message is dis-

played when USB is plugged in; message

examples:

WRITING USB"

WRITING ALARM/STATUS LOG"

USB COMPLETE"

Normal Mode Messages

The format of the message is mode and setpoint (see table

3).

Table 3. Possible MODE messages

BLOWER Blower only

COOLING Cool demand present; unit is cooling

FREE COOLING No compressor cooling

FRESH AIR COOL Cool ventilation air to neutral value

FRESH AIR HEAT Heat ventilation air to neutral value

HEATING Heat demand present; unit is heating

HVAC OFF No heat, cool, ventilation allowed

IDLE Demand satisfied; blower off

MORNING WARMUP Outdoor air damper closed

M2 FAILED TO RESPOND

Display is missing messages from

M2

PRE−COOL

No compressor allowed when free

cooling

PRE−INSTALL Must follow installation menus

REHEAT Unit is dehumidifying

SMOKE Smoke input detected

TEST Network has unit in test mode

(blank screen) Bootloader mode

Unit Operation

This section describes the display and control buttons,

how to configure the unit, and how to read stored configu-

ration data, status, and alarms.

The M2 unit controller is an input and output junction

point. If in the thermostat mode, thermostat inputs at

P297 result in an output to unit components (see table 11

on Page 30). If the heartbeat LED is not flashing, see

table 1 (Page 3) for heartbeat operation. If the display

shows an alarm, refer to table 10 (Page 22) for more in-

formation. If the thermostat input indicating lights are not

responding appropriately, check the thermostat or a

DDC control acting as thermostat inputs into P297.

Basic cooling and heating functions may be energized to

test major unit components by using the M2 unit controller

testing function or by using jumper wires on the Field Wir-

ing Termination plug P297.

To access the other three columns, first press and then

use to scroll between SERVICE, DATA, AND SET-

TINGS. Next, press to open the SERVICE (or DATA or

SETTINGS) menu. Use until desired item is dis-

played.

Alarms

Figure 3 shows a typical alarm and how the message will

scroll.

ALARM(xx): SMOKE DETECTED.

DISPLAY

WINDOW

LEFT SCROLLING

MESSAGE

(To SILENCE an alarm,

press any of these buttons.)

Figure 3. Alarm Code Readout Example

SILENCE − to silence an alarm, press any of the control

buttons while the alarm is displayed.

USB Service Verification

When the Lennox USB drive is plugged in during normal

MODE, a message will be displayed to indicate data is be-

ing written to the drive. When finished, the message USB

COMPLETE" will be displayed.

From the USB you may get the last report from the M2 unit

controller and view it using any PC text program.

Multiple units may use the same USB drive. The filename

of the service reports will be based on the unit’s serial num-

ber; for example 5608J5875.txt.

Page 7

Menu Interface SERVICE

From the DISPLAY mode, press and then use to

scroll to SERVICE. Next, press

to enter the SERVICE

menu. Use until desired item is displayed.

SERVICE

TEST

OFFLINE

IN / OUTPUTS

REPLACE

REPORT

Use arrows to move

Using SERVICE, you may run tests that

check a functional operation (e.g. HEAT-

ING) or you may run tests that single out

a system component for checking. The

diagram below shows how to navigate

through the system to access a functional

test or a component test.

When the list of tests appears, use the

up/down arrows until the test you want to

run appears. Then press the SELECT

BUTTON to begin running the test.

SERVICE > TEST

In the SERVICE menu, use until TEST is displayed.

Press to enter the TEST menu.

Use arrows to move

GUIDED

BLOWER

FANS

COOL

HEAT

DAMPER

REHEAT

SENSORS

OUTPUTS

CONTROLLER

TEST

TEST is described in

detail in table 4

[Page 8]).

Using the TEST menu, the service technician may run a

sequence of tests to gather information available while that

component is turned on. The unit will return to normal

mode when leaving the TEST menu. See table 4 for de-

tails.

Any Status/Alarm codes found during testing will be logged

to the event history.

Upon exit from TEST mode, the unit will return to normal

operation if no key is pushed for 1 hour.

SERVICE > OFFLINE

In the SERVICE menu, use until OFFLINE is dis-

played. Press to enter the OFFLINE menu.

Use arrows to move

LOCKOUT

BLOWER ONLY

COOLING ONLY

HEATING ONLY

RESET

OFFLINE

SERVICE > IN / OUTPUTS

In the SERVICE menu, use until IN / OUTPUTS is dis-

played. Press to enter the IN / OUTPUTS menu.

Use arrows to move

ZONING

SENSORS

RELAYS

NETWORK

OUTPUTS

IN/OUTPUTS

SERVICE > REPLACE

In the SERVICE menu, use REPLACE to reset the runtime

counters for the listed device when a new hardware com-

ponent has been installed in the system.

Use until REPLACE is displayed. Press to enter

the REPLACE menu. This will reset the runtime for the new

part to zero.

Use arrows to move

FILTER

BELT

UV LAMP

FANS

BLOWER

COMPRESSOR

REPLACE

Page 8

Menu Interface SERVICE (Continued)

SERVICE > TEST (Continued)

Table 4. TEST

Use arrows to move

GUIDED

BLOWER HIGH K3 HK3 OFF/ON Run blower on maximum speed

LOW K3 LK3 OFF/ON Run blower on minimum speed

PROVING SWITCH Display status of the switch with blower low speed.

FILTER SWITCH Display status of the switch with blower low speed

RPM XX RPM Shows RPM for blower and allows adjustment

FANS FAN1 FN1 OFF/ON Allow turning on fan1 individually

FAN2 FN2 OFF/ON Allow turning on fan2 individually

COOL COOL 1 (compr low) RAT Monitors return air temperature. Stage 1 compr low−speed test. Dampers are closed for

compressor tests.

DAT Monitors discharge air temperature. Blower, dampers, fans are actuated automatically

during tests.

COOL 2 (compr hi) RAT Monitors return air temperature. Stage 2 compr low−speed test. Dampers are closed for

compressor tests.

DAT Monitors discharge air temperature. Blower, dampers, fans are actuated automatically

during tests.

HEAT HEAT 1 RAT Monitors return air temperature. Stage 1 heat test; dampers automatically close and blower

comes on for heat test.

DAT Monitors discharge air temperature. Stage 1 heat test; dampers automatically close and

blower comes on for heat test.

HEAT 2 RAT Monitors discharge air temperature. Stage 2 heat test; dampers automatically close and

blower comes on for heat test.

DAT Monitors discharge air temperature. Stage 2 heat test; dampers automatically close and

blower comes on for heat test.

DAMPER POSITION OPEN: XX % Damper allows testing economizer, motorized damper, and powered exhaust. Position

allows monitoring damper position and control using arrow keys.

IEN: XX MA Monitors indoor enthalpy sensor.

OEN: XX MA Monitors outdoor enthalpy sensor.

EXHAUST EXHAUST 1 EXH1:OFF/ON Turns on stage 1 fan individually.

EXHAUST 2 EXH2:OFF/ON Turns on stage 2 fan individually.

REHEAT HUM − Y1 HUM − Y1 OK Turns on stage 1 reheat; displays report.

HUM &−Y2 HUM − Y2 OK Turns on stage 2 reheat; displays report.

SENSORS

OUTPUTS SERVICE RELAY RELAY OFF/ON Output test of service relay.

DO2 DO2 OFF/ON Output test of DO2.

DO3 DO3 OFF/ON Output test of DO3.

CONTROLLER M2 TEST M2 OK" if no errors. Checks memory and

installation of controller options.

DISPLAY TEST TEST OK" if no errors. Checks switches and screen.

SETUP SETUP OK" if no errors. Checks proper installation of controller boards,

switches, and settings

TEST

Use ar-

rows to

move

Use ar-

rows to

move

Use ar-

rows to

move

Use ar-

rows to

move

Use ar-

rows to

move

TSTAT

BRPM:XX

DPOS:XX%

OAT:XX ºF

RAT:XX ºF

DAT:XX ºF

ZAT:XX ºF

IAQ:XX PPM

SMK:OFF/ON

RH:XX%

IE:XX MA

OE:XX MA

GLO:OFF/ON

D12:OFF/ON

DI3:OFF/ON

DI4:OFF/ON

Use sensor tests to choose each sensor

and read the current sensed value.

Page 9

Menu Interface DATA

From the DISPLAY mode, press and then use to

scroll to DATA. Next, press

to enter the DATA menu.

Use until desired item is displayed.

Use DATA to view information stored in the M2 Unit Con-

troller.

DATA

RUN TIMES

HISTORY

SENSORS

NETWORK

FACTORY

Use arrows to move

DATA > RUNTIMES

In the DATA menu, use until RUNTIMES is displayed.

Press to enter the RUNTIMES menu.

View accumulated runtime hours logged against various

components and systems by the M2 unit controller.

Use arrows to move

POWER ON

FILTER: XX HRS

BELT: XX HRS

UV LAMP: XX HRS

BLOWER: XX HRS

COOLING

HEATING

FREE COOLING: XX HRS − XX CYC

FANS

EXHAUST

REHEAT: XX HRS − XX CYC

RUNTIMES

As each entry is listed, its ac-

cumulated runtime is automati-

cally displayed.

DATA > HISTORY

In the DATA menu, use until HISTORY is displayed.

Press to enter the HISTORY menu.

Read the accumulated historical data of alarms, status,

and USB reports logged by the M2 unit controller.

Use arrows to move

ALARMS

STATUS

LAST USB REPORT

READ INSTALL

CLEAR HISTORY

HISTORY

Use the up/down arrows

to scroll through a list of

ALARMS and STATUS

events

DATA > SENSORS

In the DATA menu, use until SENSORS is displayed.

Press to enter the SENSORS menu.

View the current sensed value for various systems being

sent to the M2 unit controller.

TSTAT

BRPM:XX

DPOS:XX%

OAT:XXºF

RAT:XXºF

DAT:XXºF

ZAT:XXºF

IAQ: XX PPM

SMK: OFF/ON

RH: XX%

IE: XX MA

OE: XX MA

GLO: OFF/ON

DI2: OFF/ON

DI3 OFF/ON

DI4: OFF/ON

Use arrows to move

SENSORS

As each sensor is listed, its

reading is automatically dis-

played.

Page 10

Menu Interface DATA (Continued)

DATA > NETWORK

In the DATA menu, use until NETWORK is displayed.

Press to enter the NETWORK menu.

Read the NETWORK addresses stored in the M2 unit con-

troller.

Use arrows to move

LCONN ADDRESS

BACNET ADDRESS

LONTALK ADDRESS

NETWORK

Use the up/down arrows

to scroll through a list of

device addresses

DATA > FACTORY

In the DATA menu, use until FACTORY is displayed.

Press

to enter the NETWORK menu.

Read the FACTORY information stored in the M2 unit con-

troller. Use

Use arrows to move

READ M2 SOFTWARE VERSION M2 VX.XX

READ DB SOFTWARE VERSION DB1 VX.XX

READ FACTORY REPORT

CATALOG NO. (catalog number)

MODEL NO. (model number)

SERIAL NO. (serial number)

FACTORY

Use the up/down arrows

to scroll through the read-

able entries. Use the se-

lect button to view soft-

ware versions.

Page 11

Menu Interface SETTINGS−

From the DISPLAY mode, press and then use to

scroll to SETTINGS. Next, press

to enter the SET-

TINGS menu. Use until desired item is displayed.

SETTINGS

UNIT

SETPOINTS

CONTROL

OPTIONS

INSTALL

Use arrows to move

Use SETTINGS to make changes to the

Unit Controller after initial installation.

Many of the setting changes are the same

as install. Changes are limited by the

unit’s build information. If you install new

options, you can make changes to equip-

ment settings beyond the factory values.

Load shed to include power percentage

and hard wire.

SETTINGS > UNIT

In the SETTINGS menu, use until UNIT is displayed.

Press to enter the UNIT menu.

View and change the current settings in the 2 unit control-

ler.

Use arrows

to move

UNIT NO.

DATE/TIME

TIME 15:45:00 DISPLAY TIME

DATE 01.01.00 DISPLAY DATE

SET CLK MTH: 09

DAY: 21

YR: 2009

HR: 10

MIN: 08

09:45:01

UNITS F/C

UNIT

(returns

TIME"

display)

EXAMPLE

OF TIME

AND DATE

CHANGE

SETTINGS > SETPOINTS

COOLING

HEATING

(See Page 12 for DAMPER)

REHEAT

EXHAUST

IAQ

In the SETTINGS menu, use

until SETPOINTS is dis-

played. Press

to enter the SETPOINTS menu.

View and change the current system setpoints setup in the

M2 unit controller as shown in the following diagrams for

COOLING, HEATING, REHEAT, EXHAUST and IAQ.

Use arrows to move

COOLING

OCP COOL BU STPT XX.XºF

UNOCP COOL BU STPT XX.XºF

FREE COOL TEMP STPT XX.XºF

COMP TIME OFF DELAY

COOLING OPTION

HEATING

OCP HEAT BU STPT XX.XºF

UNOCP HEAT BU STPT XX.XºF

DAMPER (SEE PAGE 12)

REHEAT

REHEAT STPT 68ºF

REHEAT DEADBAND 3%

EXHAUST

SMOKE POS 50%

EXHAUST FAN STPT 50%

IAQ

DAMPER START OPEN STPT 700PPM

DAMPER FULL OPEN STPT 1200PPM

SETPOINTS

REHEAT WILL NOT BE VISIBLE UNLESS

IT WAS INSTALLED AT THE FACTORY.

Page 12

Menu Interface SETTINGS (Continued)

SETTINGS > SETPOINTS

DAMPER

Use SETTINGS > SETPOINTS > DAMPER as shown in

the following diagram; default settings will be used. You

may adjust those settings to suit the building’s require-

ments. The following diagram shows the DAMPER menu’s

structure and how to make changes.

OAS TEMP STPT

ECONOMIZER MODE

TEMP MODE Set DIP sw1 to TMP −>

CONTROL

OAT STPT 41−70ºF 60ºF

OFFSET 0−40ºF 15ºF. . . . . . . . .

ENTH MODE Set DIP sw1 to ODE −>

GLOBAL MODE Set DIP sw1 to GLO −>

SUPPLY AIR STPT 55ºF

MIN OCP BLOWER LOW 15%

MIN OCP BLOWER HIGH MIN POS SET POT

FAH DISABLED

FAC DISABLED

Use arrows to move

DAMPER

SEE

FIGURE 6

(PAGE 19)

NOTE: FOR

DETAILS, SEE

ECONOMIZER

SECTION Page 18

SETPOINTS

SETTINGS > CONTROL

In the SETTINGS menu, use until CONTROL is dis-

played. Press to enter the CONTROL menu.

View the current system setpoints setup in the M2 unit con-

troller.

Use arrows to move

GUIDED SETUP

LOCAL

THERMOSTAT

L CONN

BACNET

LONTALK

MSAV

REHEAT

CONTROL

SETTINGS > CONTROL

LOCAL

Select SETTINGS > CONTROL > LOCAL as shown in the

following diagram; default settings will be used. You may

adjust those settings to suit the building’s requirements.

LOCAL

RETURN AIR BACKUP YES/NO

OCP HEAT BU STPT XX.XºF

UNOCP HEAT BU STPT XX.XºF

OCP COOL BU STPT XX.XºF

UNOCP COOL BU STPT XX.XºF

CONTROL

SETTINGS > CONTROL

THERMOSTAT SETUP

No setting changes are required. Simply hook up to Smart-

Wiret connections.

SETTINGS > CONTROL

CONTROL: L CONN (L Connection)

Select SETTINGS > CONTROL > L CONN as shown in

the following diagram; default settings will be used. You

may adjust those settings to suit the building’s require-

ments.

L CONN

ADDR:XX

CONTROL MODE

BACKUP MODE (1,2,3)

OCP HEAT BU STPT XX.XºF

UNOCP HEAT BU STPT XX.XºF

OCP COOL BU STPT XX.XºF

UNOCP COOL BU STPT XX.XºF

STARTUP DELAY (2 − 30) 2 MIN

OVERRIDE TIMER (0 8HR) 1 HR

BLOWER ON OCP

NETWORK COMFORT SENSOR

CONTROL

0. NONE

1. TSTAT

2. RAT

3. ZAT

CYCLES OR

CONTINUOUS

Page 13

Menu Interface SETTINGS (Continued)

SETTINGS > CONTROL

BACNET

Select SETTINGS > CONTROL > BACNET as shown in

the following diagram; default settings will be used. You

may adjust those settings to suit the building’s require-

ments. The following diagram shows the BACNET menu’s

structure and how to make changes.

Use arrows to move

MAC ADDRESS 0 − 127

BAUD RATE

CONTROL MODE

BACKUP SENSOR

OCP HEAT BU STPT 70.0ºF

UNOCP HEAT BU STPT 60.0ºF

OCP COOL BU STPT 75.0ºF

UNOCP COOL BU STPT 85.0ºF

STARTUP DELAY (2 − 30) 2 MIN

OVERRIDE TIMER (0 8HR) 1 HR

BLOWER ON OCP

NETWORK COMFORT SENSOR

BACNET

CONTROL

9.6K 19.2K

38.4K 76.8K

1. NO BACKUP

2. TSTAT

3. RET AIR SENSOR

MONITOR ONLY

ZONE

REMOTE

CYCLES OR

CONTINUOUS

SETTINGS > CONTROL

LONTALK

Select SETTINGS > CONTROL > LONTALK as shown in

the following diagram; default settings will be used. You

may adjust those settings to suit the building’s require-

ments. The following diagram shows the LONTALK

menu’s structure and how to make changes.

Use arrows to move

CONTROL MODE

BACKUP SENSOR

OCP HEAT BU STPT 70.0ºF

UNOCP HEAT BU STPT 60.0ºF

OCP COOL BU STPT 75.0ºF

UNOCP COOL BU STPT 85.0ºF

STARTUP DELAY (2 − 30) 2 MIN

OVERRIDE TIMER (0 8HR) 1 HR

BLOWER ON OCP

NETWORK COMFORT SENSOR

LONTALK

CONTROL

CYCLES OR

CONTINUOUS

1. NO BACKUP

2. TSTAT

3. RET AIR SENSOR

MONITOR ONLY

ZONE

SETTINGS > CONTROL

MSAV (Multi-stage air volume)

Select SETTINGS > CONTROL > MSAV as shown in the

following diagram; default settings will be in place. You

may adjust those settings to suit the building’s require-

ments. The following diagram shows the MSAV menu’s

structure and illustrates how to use the controls to make

changes.

MSAV HIGH SPEED 85%

MSAV LOW SPEED 55%

MSAV

CONTROL

Use arrows

to move

Actual values depend on tonnage.

SETTINGS > CONTROL

REHEAT

When you select REHEAT, default settings will be in place.

You may adjust those settings to suit the building’s require-

ments. The following diagram shows the REHEAT menu’s

structure and illustrates how to use the controls to make

changes.

SENSOR

REHEAT STPT 0−99%

REHEAT DEADBAND 1−10%

REHEAT

CONTROL

Use arrows

to move

DEHUMIDISTAT

ZONE SENSOR

NETWORK

NONE

Page 14

Menu Interface SETTINGS (Continued)

SETTINGS > INSTALL

In the SETTINGS menu, use until INSTALL is dis-

played. Press

to enter the INSTALL menu.

Use INSTALL > NEW M2 to go through the setup and

change settings as needed when installing a replacement

M2 (new M2 units have no factory pre−sets). This complete

INSTALL procedure is described earlier in this manual

(see Page 14).

Use INSTALL > DAMPER to set up motorized outdoor air

damper or economizer (see Page 12).

Use INSTALL > FLOAT SW to set up a condensate pan

overflow switch.

Use INSTALL > UPDATE DISPLAY SW is to install new

display software.

Use arrows to move

NEW M2

DAMPER

MOAD OR ECON SEE DAMPER (PAGE 12)

FLOAT SWITCH

BLOWER PROVING SW

PHASE MONITOR

UV LAMP

ELECTRIC HEAT STAGES 0, 1, 2

UPDATE DISPLAY SOFTWARE

ERS

INSTALL

EXIT BOOTLOADER BY

HOLDING BACK ARROW

FOR ~ 3 SECONDS

SETTINGS > INSTALL

INSTALL: NEW M2

Use SETTINGS > INSTALL > NEW M2 as shown in the

following diagram; default settings will be used. Use menu

to change setpoints or control mode. The unit comes facto-

ry configured for thermostat mode. An expert manual and

service software are available for more complex installa-

tions (see Table 9, Page 20).

If any alarms are present, take corrective action prior to

installation.

Use arrows to move

Use arrows to move

UNIT SERIAL NUMBER

UNIT NUMBER 1 TO 256

UNIT CATALOG NUMBER

DAMPER 0 TO 2

EXHAUST STAGES NONE,

OUTDOOR FAN 1 TO 3

NEW M2

INSTALL

Page 15

BACnet

®

Recommendations

1. Set all BACnet

®

devices on an MS/TP network to con-

secutive MAC addresses, starting at 1, so that there

are no gaps between MAC address values.

2. Set Max_Master device property on all devices to

match the largest MAC address on the network. Note,

this could be larger than existing network to allow for

adding devices to the network with out the need to ad-

just the Max_Master property in the future.

3. Use ReadPropertyMultiple service instead of Read-

Property service when reading multiple analog inputs

or values.

4. Do not exceed the maximum recommended length

(1200 M / 4000 ft.) for any MS/TP segment.

5. All MS/TP network segment ends should be termi-

nated the same way per manufacturer instructions.

6. To minimize communication compatibility problems,

BACnet gateways or BACnet devices that are NOT

BTL listed should be avoided.

Default Settings

device Max_Master = 127

device Max_Info_Frames = 1

device Object_Identifier = MAC address

device Object_Name = Lennox_M2" + MAC address

device Location = US"

device Description = Lennox HVAC Controller"

baud rate = 38.4k

(terminated)(terminated) (not terminated) (not terminated)

CONTROLLER/

ROUTER

(not termi-

nated)

(not termi-

nated)

(not terminated)

(terminated)

(not terminated)

(terminated per mfg

instructions)

The configuration shown above has terminations on the

M2 BACnet modules at both ends and ONLY at both ends

of the chain.

The configuration shown to the right has a termination at

the controller/router on one end and a termination at the

M2 BACnet module on the other end; terminations are

ONLY at the ends of the chain.

Cable type − twisted pair with shield, 22 awg minimum,

Belden #88761 or #8761 (Lennox 27M19, 94L63, 68M25).

CONTROLLER/

ROUTER

(not termi-

nated)

Figure 4. Terminating ends of daisy−chained networks

Analog Output Objects

Optional Properties Supported: Min_Pres_Value, Max_Pres_Value

Optional Writable Properties: Out_Of_Service

Analog output object’s Overridden status flag set if the equivalent setpoint in the M2 is written to by an S−BUS device.

Table 5. Analog Output Objects List

Object ID Object Name Units Min. Value Max. Value Valid Values within Range

101 Application Mode Control None 0 255 0,1,3,6,9,208,209,216,217,218,224-254,255*

102 Outdoor Air Min Pos Control Percent 0 255 all

103 Occupancy Override Control None 0 255 all

104 Occupancy Scheduler Control None 0 255 all

107 Occupancy Sensor Input None 0 255 all

108 Space Dehumidification Setpoint Percent 0 100 all

109 Temperature Setpoint (abs) Deg. F 36.25 100 all

110 Temperature Setpoint Offset Deg. F −32 31.75 all

113 Space Temperature Input Deg. F 36.25 100 all

114 Emergency Override Control None 0 255 all

115 Compressor Enable Control None 0 255 all

117 Primary Heat Enable Control None 0 255 all

119 Auxiliary Heat Enable Control None 0 255 all

123 Duct Static Setpoint In. of water 0 5 all

124 Building Static Setpoint In. of water −0.5 0.5 all

125 Discharge Air Cooling Setpoint Deg. F 40 80 −9,40-80*

126 Discharge Air Heating Setpoint Deg. F 80 140 −9,80-140*

127 Supply Fan Capacity Input Percent 33 255 all*

128 Exhaust Fan Capacity Input Percent 33 255 all

129 Set Economizer Outdoor Air Suitable None 0 255 all

Page 16

BACnet

®

(continued)

Analog Input Objects

Optional Properties Supported: None

Optional Writable Properties: Out_Of_Service (AI239 − AI252, AI274 − AI285 only)

Table 6. Analog Input Objects List

Object ID Object Name Units Data Range

198 Mac Address None 0 − 127

199 M2 Address None 1−31

200* M2 Version[4] None 0 − 127

201* M2 Version[5] None 0 − 127

202* M2 Version[6] None 0 − 127

203* M2 Version[7] None 0 − 127

204* M2 Version[8] None 0 − 127

205* M2 Version[9] None 0 − 127

206* M2 Version[10] None 0 − 127

207* M2 Version[11] None 0 − 127

231 Unit ID None 0 − 127

232 Unit Status None 0 − 255

239 Space Temperature Deg. F 63.75 − 100.00

240 Discharge Air Temperature Deg. F −8.7 – 164.4

241 Effective Occupancy None 0 − 2

242 Local Outside Air Temperature Deg. F −30.6 – 131.6

243 Local Space Temperature Deg. F 63.75 – 100.00

244 Outside Air Damper Percent 0 − 100, 255

245 Heat Primary Percent 0 – 100

246 Heat Secondary Percent 0 – 100

247 Cool Primary Percent 0 – 100

248 Economizer Enabled Percent 0, 1, 255

250 Supply Fan Status Percent 0 − 100

252 Space Temperature Set Point (Eff) Deg. F 40.0 – 95.0

253 Current Error None 0 − 255

254 Error Pointer None 0 – 83

255 Most recent Error 1 None 1 − 255

256 Most recent Error 2 None 1 − 255

257 Most recent Error 3 None 1 − 255

258 Most recent Error 4 None 1 − 255

259 Most recent Error 5 None 1 − 255

260 Most recent Error 6 None 1 − 255

261 Most recent Error 7 None 1 − 255

262 Most recent Error 8 None 1 − 255

263 Most recent Error 9 None 1 − 255

264 Most recent Error 10 None 1 − 255

274 Space CO2 Sensor (Eff) Parts−per−million 0 − 2000

275 Space CO2 Sensor (Local) Parts−per−million 0 − 2000

276 Space Humidity (Eff) Percent 0 − 100

277 Space Humidity (Local) Percent 0 − 100

278 Dehumidification Set Point (Eff) Percent 0 − 100

279 Dehumidification Status None 0 − 2

281 Return Air Temperature Deg. F −8.7 – 164.4

282 Building Static Pressure Inches of water −0.5 − 0.5

283 Duct Static Pressure Inches of water 0 – 5.00

285 Exhaust Fan Status Percent 0 − 100

* Not recommended for new installations; legacy support only

Page 17

BACnet

®

(continued)

Analog Value Objects

Optional Properties Supported: None

Optional Writable Properties: Present_Value

Table 7. Analog Value Objects List

Object ID Object Name Units

Min.

Value

Max.

Value

Valid Values

within Range

Note

1 Baud Rate Setting None 9600 76800 9600, 19200, 38400, 76800 38400 default

130 Heating Occupied Setpoint Deg. F 40 95 all

For occupied and unoc-

cupied setpoints consid-

ered separately, the

heating setpoint must be

lower than the cooling

setpoint by at least the

auto−changeover dead-

band value set in M2

(default 3 deg F). See

M2 Setup to change.

131 Cooling Occupied Setpoint Deg. F 40 95 all

132 Heating Unoccupied Setpoint Deg. F 40 95 all

133 Cooling Unoccupied Setpoint Deg. F 40 95 all

Networking Controllers

A network control panel (NCP) and NCP PC software can

be used to schedule building operation for any M2 on the

same daisy−chained l connection network.

The network thermostat controller (NTC) is an L connec-

tion direct digital controller used on units which are not

equipped with an M2 unit controller. The Building Control-

ler (BC) is used to control building functions such as lights

and signs. Use L connection specific network cable and

daisy chain as shown in figure 5.

Up to 31 controllers can be daisy chained on a single L con-

nection network. Any combination of M2, NTC, and BC

controller can be used.

SYS BUS TERMINAL

BLOCK ON LENNOX

CONTROLLERS IMC

(M1−1 TO M1−6 L

SERIES)

S−BUS TERMINAL

BLOCK ON LENNOX

PRODIGY M2 CON-

TROLLER ENER-

GENCE SERIES

SYS BUS TERMINAL

BLOCK ON LENNOX

CONTROLLERS IMC (M1−7,

M1−8, NTC, BC AND ZONE

CONTROLLERS)

DO NOT CONNECT THE CABLE SHIELD TO THE "G" TERMINAL ON M1−6 AND OLDER

CONNECT + TERMINAL OF NCP TO + TERMINALS ON ALL CONTROLLERS.

CONNECT − TERMINAL OF NCP TO − TERMINALS ON ALL CONTROLLERS.

3

2

1

SHIELD

SHIELD

SHIELD

− S + − S +

− G +

SHIELD

Cable type − twisted pair

with shield, 22 awg mini-

mum, Belden #88761 or

#8761 (Lennox 27M19,

94L63, 68M25).

CONTINUE WIRING TYP.

TO LAST CONTROLLER

ON NETWORK

Figure 5. L Connection® Network Daisy−chain Communication Wiring

Page 18

Economizer (Damper)

General

The economizer, when configured, controls

S damper position, which determines how much outdoor

air is used to meet free cooling or indoor air quality

(IAQ) requirements, and

S the optional power exhaust fans.

On a cooling demand, outdoor air is used for free cooling

instead of first−stage compressor(s) when outdoor air is

suitable (OAS).

Heartbeat LED

Flashing green LED indicates normal operation (See fig-

ure 6).

Outdoor Air Suitable (OAS) LED

A yellow LED which is labeled OAS provides economizer

status. A steady yellow LED indicates that outdoor air is

suitable for free cooling. A flashing yellow OAS light indi-

cates the IAQ sensor requires outdoor air. (A flashing yel-

low LED can also mean that the economizer dampers are

open to bring in fresh air while a compressor is on.) If the

economizer is already operating, a flashing yellow OAS

light indicates the IAQ sensor requires more outdoor air

than is suitable for free cooling.

DIP Switch Settings

The DIP switch setting determines the mode used to en-

able free cooling. The DIP switch also has a mode to set

the damper minimum position and test damper operation.

DIP switch is factory−set when the economizer is factory−

configured.

Free Cooling Discharge Air Setpoint

When outdoor air conditions are suitable and economizer

is set to provide free cooling, dampers will modulate to

achieve a discharge air temperature of 55°F (13°C) de-

fault. This setpoint is adjustable between 45° and 65°F.

The setpoint can also be automatically increased when

outdoor or return air temperatures drop. See Outdoor Air

Reset and Return Air Reset in the Discharge Air Control

section in the advanced setup instructions. These settings

are not accessible through the Prodigy display at this time.

The unit does not have to be operating in discharge air

cooling mode to adjust the setpoint, or to use setpoint re-

set.

During free cooling operation, the damper modulates to its

maximum position where it remains for at least 3 minutes.

If the damper has been continuously in this position for at

least three minutes, then a second stage cooling demand

will be allowed to turn on the first stage of mechanical cool-

ing. While the mechanical cooling is on, the damper is held

to its maximum position, and does not modulate until the

second stage demand is satisfied. On a third stage cooling

demand, the second stage of mechanical cooling will be

turned on.

Outdoor Air Suitability

There are six options available to determine outdoor air

suitability (OAS) for free cooling. See table 8. Economizer

settings are shown for each mode in figure 7.

The appropriate sensors are provided when the economiz-

er is factory−configured. When the economizer is field−con-

figured, the ODE mode requires additional field−provided

sensor(s). See table 8. The TEMP mode uses sensors pro-

vided with all units.

Table 8. Free Cooling Options

Free cooling mode

DIP SW

positions

MODE

Selection

CONTROL

Selection

OAS setpoint calc if CONTROL

is SENSIBLE

Temperature offset 1,2 to TMP TEMP OFFSET OAT<RAT−OFFSET (0 to 40 F)

Temperature setpoint 1,2 to TMP TEMP OAT STPT OAT<OAT STPT (41 to 70 F)

Remote 1,2 to TMP TEMP ANY OAS sent by network.

Enthalpy differential (Potentiometer set to DIFF) 1,2 to ODE ENTH N/A ODE<IDE

Enthalpy setpoint (Potentiometer set to A−D) 1,2 to ODE ENTH N/A ODE<POT

Global input 1,2 to GLO GLOBAL N/A GLO input

Page 19

Economizer (Damper) (Continued)

Mode Outdoor air is suitable for free cooling when:

TEMP OFFSET Outdoor air temperature (RT17) is less than return air temperature (RT16) by at least the OFFSET value.

TEMP OAT STPT Outdoor air temperature (RT17) is less than the OAT STPT value.

Remote

Either of the TEMP modes can be used when a network OAS signal is provided by an energy management or building

control system, via BACnet, LonTalk, or L Connection. The network can command OAS, NOT OAS, or AUTO. AUTO

returns to local control of OAS, which is the selected TEMP mode..

ENTH (differential) Outdoor air enthalpy* (A7) is less than return air enthalpy (A62). Enthalpy setpoint potentiometer is set to DIFF

ENTH (setpoint) Outdoor air enthalpy (A7) is less than enthalpy setpoint potentiometer position A, B, C, or D.

GLOBAL

Global input is energized by (P297−9). This setting is also used for outdoor air damper applications. Global input also

brings on the blower. (This mode is NOT used when OAS signal is provided via network connection. GLO is only used

when a 24VAC signal is used to energize the P297−9 GLO input.)

Enthalpy includes effects of both temperature and humidity.

LED FLASHING GREEN

HEARTBEAT" LED INDICATES

NORMAL OPERATION

STEADY YELLOW OUTDOOR

AIR SUITABLE" LED INDICATES

OUTDOOR AIR CAN BE USED

FOR COOLING

ECON DIP SWITCH

M2 UNIT CONTROLLER

0−100%

MINIMUM

POSITION

POTENTIOMETER

Figure 6. Economizer controls

Note−All economizer modes of operation, except DSET, will modulate dampers to 55°F (13°C) discharge air.

ODE DIFFERENTIAL

(Outdoor Enthalpy)

GLO

(Global Enthalpy)

ODE

(Outdoor Enthalpy)

Set to DIF

A

B

C

D

DIF

ENTH SET PNT

A

B

C

D

DIF

Set to A

ENTH SET PNT

TEMP OFFSET,

TEMP OAT STPT, and

Remote MODE.

Figure 7. Economizer free cooling settings

Page 20

APPENDIX

Abbreviations

A55 M2 board. Main controller board for RTU

A59 C2 board. Second compressor add−on board

A133 GP1 Board. General purpose add−on board DIP selects 3 func-

tions

AI Analog input

AO Analog output

BL Blower

BRPM Blower RPM

C2 2nd compressor add−on board (A59)

C1 1st stage cooling

C2 2nd stage cooling

C3 3rd stage cooling

C4 4th stage cooling

CAI Combustion air inducer

CAVB Constant air volume with bypass damper

COM Electrical common

CLK Clock

CP1 Compressor 1

CP2 Compressor 2

CP3 Compressor 3

CP4 Compressor 4

CSP Cooling setpoint

DAC Discharge (supply) air control

DACC Discharge (supply) air control cooling

DACH Discharge (supply) air control heating

DAP Discharge (supply) air pressure

DAT Discharge (supply) air temperature

DB Deadband

DCV Demand controlled ventilation

DDC Direct Digital Controller

DI Digital input

Diff Differential

DIP DIP switch

DPOS Damper position

DO Digital output

ECON Economizer

ECTO Electronic configure to order (control parameters)

FAC Fresh air cooling control

FAH Fresh air heating control

FAT Fresh air tempering control. See FAC & FAH

FC Free cooling

G Thermostat demand, blower

GLO Global mode or input (economizer)

GP1 General purpose board GP1−1 (A133)

H1 1st stage heating

H2 2nd stage heating

H3 3rd stage heating

H4 4th stage heating

HP1 Heat pump add−on board (A61)

HP High pressure

HSP Heating setpoint

HT Heating

IAQ Indoor air quality. Often synonymous with CO

2

level in ppm

IDE Indoor enthalpy. Depends on temperature and humidity

IE Indoor enthalpy.

w.c. Inches of water column

LCONN L Connection

LED Light emitting diode. An indicator light, found either as individual

elements or grouped together as segments to form characters

LP Low pressure

LT Limit

M2 Main M2 unit controller board (A55).

MCB1 Motor control board

MGV Modulating gas valve

MOAD Motorized outdoor air damper

MSAV Multi Stage Air Volume

OAC Outdoor air control

OAS Outdoor air suitable for free cooling

OAT Outdoor air temperature

OCP Thermostat demand, occupied mode

ODE Outdoor enthalpy. Depends on temperature and humidity

OE Outdoor enthalpy.

PID Proportional, integral and derivative based control loop

PPM Parts per million (mostly used for CO

2

measurements)

RAP Return air pressure

RAT Return air temperature

RH Relative humidity

RS Reset

RTU Roof top unit

RT6 Discharge air temperature sensor

RT16 Return air temperature sensor

RT17 Outdoor air temperature sensor

SMK Smoke detection mode (alarm)

SP Setpoint

Stg Stage

STPT Setpoint

TB Terminal block

TSTAT Thermostat

UNOCP Unoccupied

USB Universal Serial Bus, connect to PC or flash drive

W1 Thermostat demand, heat stage 1

W2 Thermostat demand, heat stage 2

W3 Thermostat demand, heat stage 3

W4 Thermostat demand, heat stage 4

VAC Alternating current voltage

VAV Variable air volume. Accomplished with a variable frequency

drive (VFD)

VDC Direct current voltage

VFD Var. frequency drive. An AC inverter used to vary motor speed

VT Ventilation

Y1 Thermostat demand, cooling stage one

Y2 Thermostat demand, cooling stage two

Y3 Thermostat demand, cooling stage three

Y4 Thermostat demand, cooling stage four

ZAT Zone air temperature

Table 9. Service parts available for Prodigyt Controller

Description

Catalog

number

Description

Catalog

number

Description

Catalog

number

M2 Unit Controller Replacement kit 59W47 M2 USB service kit tube 59W52 SmartWiret Field Termination kit 59W57

DB1−0 M2 Display Replacement kit 59W48 M2−1 Display battery (10−pack) 59W53 SmartWiret Repair Tool kit 59W58

DB1−1 M2 Display Replacement kit 59W49 M2−1 Fuse (2−Amp ATC, 5−pack) 59W54 Lennox Prodigyt USB Memory

Stick (5−pack)

59W59

MCB1 M2 Motor Control Replace-

ment kit

59W50 M2 Deluxe Training kit (suitcase,

UC, USB kit, expert manual, M2,

trainer)

59W55 Service Software & Expert Manual

on USB

59W60

M2 BACnett Replacement kit 59W51 M2 Training board (no suitcase,

USB, or M2)

59W56

/