Page is loading ...

OperatingGuide

ECLComfort310,applicationP318

1.0TableofContents

1.0TableofContents...............................................1

1.1Importantsafetyandproductinformation.....................2

2.0Installation........................................................6

2.1Beforeyoustart.....................................................6

2.2Identifyingthesystemtype......................................18

2.3Mounting...........................................................19

2.4Placingthetemperaturesensors................................23

2.5Electricalconnections.............................................25

2.6InsertingtheECLApplicationKey..............................31

2.7Checklist............................................................37

2.8Navigation,ECLApplicationKeyP318.........................38

3.0Dailyuse.........................................................46

3.1Howtonavigate...................................................46

3.2Understandingthecontrollerdisplay..........................47

3.3Ageneraloverview:Whatdothesymbolsmean?...........48

3.4Monitoringtemperaturesandsystem

components........................................................49

3.5Manualcontrol.....................................................50

3.6Schedule............................................................51

4.0Settingsoverview............................................52

5.0Settings...........................................................54

5.1IntroductiontoSettings..........................................54

5.2Tanktemperature..................................................55

5.3Flowtemperature..................................................59

5.4Returnlimit.........................................................61

5.5Controlparameters................................................65

5.6Flowmeter..........................................................75

5.7Application.........................................................76

5.8Anti-bacteria........................................................78

6.0Event...............................................................80

6.1IntroductiontoEvent.............................................80

6.2ChargeT.............................................................81

6.3DHWowT.........................................................84

6.4Tanktemperature..................................................87

6.5SupplyT.............................................................90

6.6Anti-bacteria........................................................91

6.7Tsensordefect.....................................................92

6.8Eventoverview.....................................................93

7.0Commoncontrollersettings..............................94

7.1Introductionto‘Commoncontrollersettings’................94

7.2Time&Date.........................................................95

7.3Inputoverview.....................................................96

7.4Log...................................................................97

7.5Outputoverride....................................................98

7.6Keyfunctions.......................................................99

7.7System.............................................................101

8.0Miscellaneous................................................108

8.1ECA30/31setupprocedures.................................108

8.2Severalcontrollersinthesamesystem......................116

8.3Frequentlyaskedquestions....................................119

8.4Denitions........................................................121

8.5Type(ID6001),overview.......................................124

8.6ParameterIDoverview..........................................125

DanfossDistrictEnergy

VI.JM.Q3.02

DEN-SMT/DK1

OperatingGuideECLComfort310,applicationP318

1.1Importantsafetyandproductinformation

1.1.1Importantsafetyandproductinformation

ThisOperatingGuideisassociatedwiththeECLApplicationKey

P318(codeno.087H3835).

TheECLApplicationKeyP318containstwosubtypes:

•P318.1,whichisabuffer-basedDomesticHotWater(DHW)

application.

•P318.10,whichisanadvancedDomesticHotWater(DHW)

application.

SeetheInstallationGuideforelectricalconnections.

ThedescribedfunctionsarerealizedinECLComfort310whichalso

allowsM-bus,ModbusandEthernet(Internet)communication.

TheApplicationKeyP318complieswithECLComfort310

controllersasofrmwareversion1.11.Thermware(controller

software)isvisibleatstart-upofthecontrollerandin'Common

controllersettings'in'System'.

UptotwoRemoteControlUnits,ECA30orECA31,canbe

connected.

TheapplicationP318workswithadditionalInternalI/Omodules:

•TheextensionmoduleECA32gives0-10Voltsignalforspeed

controlofcontrolpump,chargingpumpandcirculationpump.

•TheextensionmoduleECA35gives0-10Voltsignalforspeed

controlofcontrolpump,chargingpumpandcirculationpump.

ECA35canalsogivePWM*signalforspeedcontrolofthe

abovelistedpumptypes.

Apumpcanalsobeconsideredasacirculator.

TheECLComfort310workswitheitheroneECA32oroneECA

35.TheInternalI/Omoduleinquestionisplacedinthebasepart

oftheECLComfort310.

*PWM=PulseWidthModulation

TogetherwiththeECLComfort310theadditionalInternalI/O

modulescanalsobeusedforextradatacommunicationtoSCADA:

•Temperature,Pt1000(default)

•0-10voltsignals

•Digitalinput

Theset-upofinputtypecanbedonebymeansoftheDanfoss

Software"ECLTool".

Navigation:Danfoss.com>Products&Solutions>Products>

DistrictHeatingandCooling>Documentation>Tools&Software

>ECLTool.

TheURLis:http://district-heating.danfoss.com/download/tools/

ECLComfort310isavailableas:

•ECLComfort310,230volta.c.(codeno.087H3040)

•ECLComfort310B,230volta.c.(codeno.087H3050)

•ECLComfort310,24volta.c.(codeno.087H3044)

TheB-typehasnodisplayanddial.

2

DEN-SMT/DK

VI.JM.Q3.02

DanfossDistrictEnergy

OperatingGuideECLComfort310,applicationP318

TheB-typeisoperatedbymeansoftheremotecontrolunit

ECA30/31:

•ECA30(codeno.087H3200)

•ECA31(codeno.087H3201)

InternalI/Omodules:

•ECA32(codeno.087H3202)

•ECA35(codeno.087H3205)

BasepartforECLComfort310,230voltand24volt:Codeno.

087H3230.

AdditionaldocumentationforECLComfort210and310,modules

andaccessoriesisavailableonhttp://heating.danfoss.com/.

SafetyNote

Toavoidinjuryofpersonsanddamagestothedevice,itisabsolutely

necessarytoreadandobservetheseinstructionscarefully.

Necessaryassembly,start-up,andmaintenanceworkmustbe

performedbyqualiedandauthorizedpersonnelonly.

Locallegislationsmustberespected.Thiscomprisesalsocable

dimensionsandtypeofisolation(doubleisolatedat230V).

AfusefortheECLComfortinstallationismax.10Atypically.

TheambienttemperaturerangesforECLComfortinoperationare:

ECLComfort210/310:0-55°C

ECLComfort296:0-45°C.

Exceedingthetemperaturerangecanresultinmalfunctions.

Installationmustbeavoidedifthereisariskforcondensation(dew).

Thewarningsignisusedtoemphasizespecialconditionsthatshould

betakenintoconsideration.

Thissymbolindicatesthatthisparticularpieceofinformationshould

bereadwithspecialattention.

Applicationkeysmightbereleasedbeforealldisplaytextsare

translated.InthiscasethetextisinEnglish.

DanfossDistrictEnergy

VI.JM.Q3.02

DEN-SMT/DK3

OperatingGuideECLComfort310,applicationP318

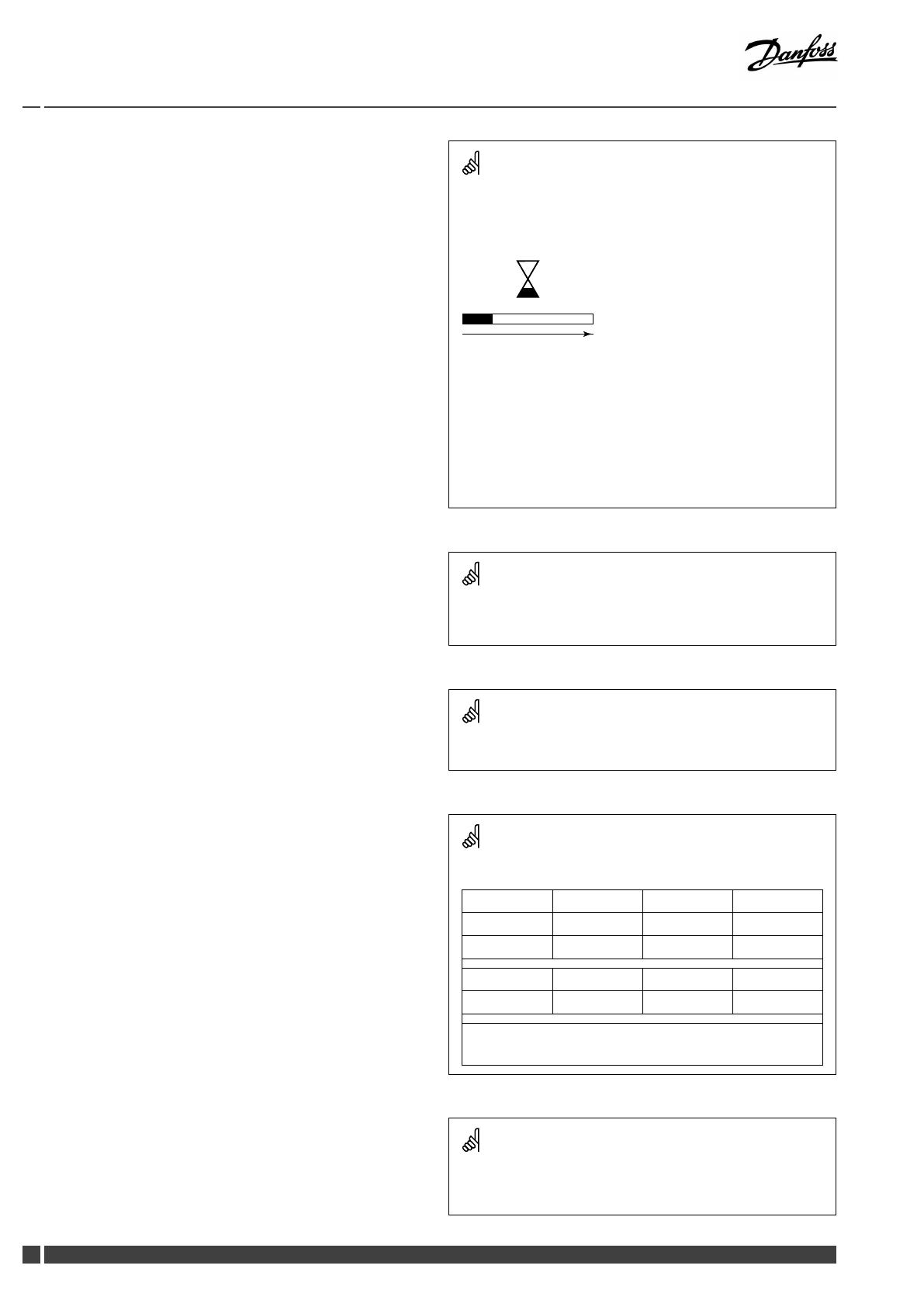

Automaticupdateofcontrollersoftware(rmware):

Thesoftwareofthecontrollerisupdatedautomaticallywhenthekey

isinserted(asofcontrollerversion1.11(ECL210/310)andversion

1.58(ECL296)).Thefollowinganimationwillbeshownwhenthe

softwareisbeingupdated:

Progressbar

Duringupdate:

•DonotremovetheKEY

Ifthekeyisremovedbeforethehour-glassisshown,youhave

tostartafresh.

•Donotdisconnectthepower

Ifthepowerisinterruptedwhenthehour-glassisshown,the

controllerwillnotwork.

AsthisOperatingGuidecoversseveralsystemtypes,specialsystem

settingswillbemarkedwithasystemtype.Allsystemtypesareshown

inthechapter:'Identifyingyoursystemtype'.

°C(degreesCelsius)isameasuredtemperaturevaluewhereasK

(Kelvin)oftenisusedfortemperaturedifferences.

TheIDno.isuniquefortheselectedparameter.

ExampleFirstdigitSeconddigitLastthreedigits

1117411174

-

Circuit1

Parameterno.

12174

1

2

174

-

Circuit2

Parameterno.

IfanIDdescriptionismentionedmorethanonce,itmeansthatthere

arespecialsettingsforoneormoresystemtypes.Itwillbemarked

withthesystemtypeinquestion(e.g.12174-A266.9).

ParametersindicatedwithanIDno.like"1x607"meanauniversal

parameter.

xstandsforcircuit/parametergroup.

4DEN-SMT/DK

VI.JM.Q3.02

DanfossDistrictEnergy

OperatingGuideECLComfort310,applicationP318

DisposalNote

Thisproductshouldbedismantledanditscomponents

sorted,ifpossible,invariousgroupsbeforerecycling

ordisposal.

Alwaysfollowthelocaldisposalregulations.

DanfossDistrictEnergy

VI.JM.Q3.02

DEN-SMT/DK

5

OperatingGuideECLComfort310,applicationP318

2.0Installation

2.1Beforeyoustart

TheECLapplicationkeyP318containstwosubtypes,P318.1and

P318.10.

ThebasicprinciplesforapplicationP318.1:

TemperaturecontrolofDHWbuffer

ThedesiredDHWtemperatureatS6determinesthebuffercharging

procedure.ThebuffertemperaturesensorsS6andS8,thesupply

temperaturesensorS2andthechargingtemperaturesensorS3are

themostimportantsensorsandmustbeconnected.Ifoneofthe

mentionedtemperaturesensorsisnotconnected,thecontrolvalve

M1willclose;alternatively,thecontrolpumpP1/V1willstop.

ThechargingtemperatureatS3isbasedonthedesiredDHW

temperatureatS6andasetchargingdifference.

TheapplicationallowsinternalorexternalDHWcirculation.When

connectedforexternalcirculation,thedesiredS3temperatureis

thesameasthedesiredDHWtemperature,whenchargingisnot

inprogress.

Optional:TemperaturecontrolofthecirculationpipeatS9ensures

thedesiredtemperaturebymeansofON/OFFcontrolofP3or

speedcontrolofV3.Duringthechargingprocessthecirculation

pumpcanbeswitchedOFForrunataminimumspeed.

Startbufferchargingprocess:

1.BuffertemperatureS6temperaturegetslowerthan('Desired

DHWtemperature'+'Startdifference').

Anexample:60°C+(-5)=55°C

2.X1isswitchedON

3.M1openstoapresetposition(alternatively,P1/V1isswitched

ON/presetspeed)inordertoincreasethesupplytemperature

S2.Returntemperaturelimitationisrespected.

4.P2/V2isswitchedONwhensupplytemperatureS2getshigher

than('DesiredDHWtemperature'+'Pumpstartdiff.').

Anexample:60°C+3K=63°C

V2startswithminimumspeed,forexample20%.

5.M1(orP1/V1)controlsthechargingtemperatureatS3.

6.V2increasesthespeedaslongasthechargingtemperatureS3

ishigherthan(desiredchargingtemperature-2K).

Stopbufferchargingprocess:

1.BuffertemperatureS6temperaturegetshigherthan(2K+

'DesiredDHWtemperature'+'Startdifference)

AND

LowerbuffertemperatureS8getshigherthan('DesiredDHW

temperature'+'Stopdifference).

Anexample:S6temperaturehigherthan(2+60°C+(-5)=

57°C)AND(60°C+(-8)=52°C)

2.P2isswitchedOFF,respecting'Char.Ppost-run'.V2changes

to0%.

NOTE:Post-runisnotrespectedifchargingtemperatureS3islower

thandesiredchargingtemperature.

3.X1isswitchedOFF.

4.M1closes(alternatively,P1/V1stops)ormaintainsthedesired

temperatureatS3.

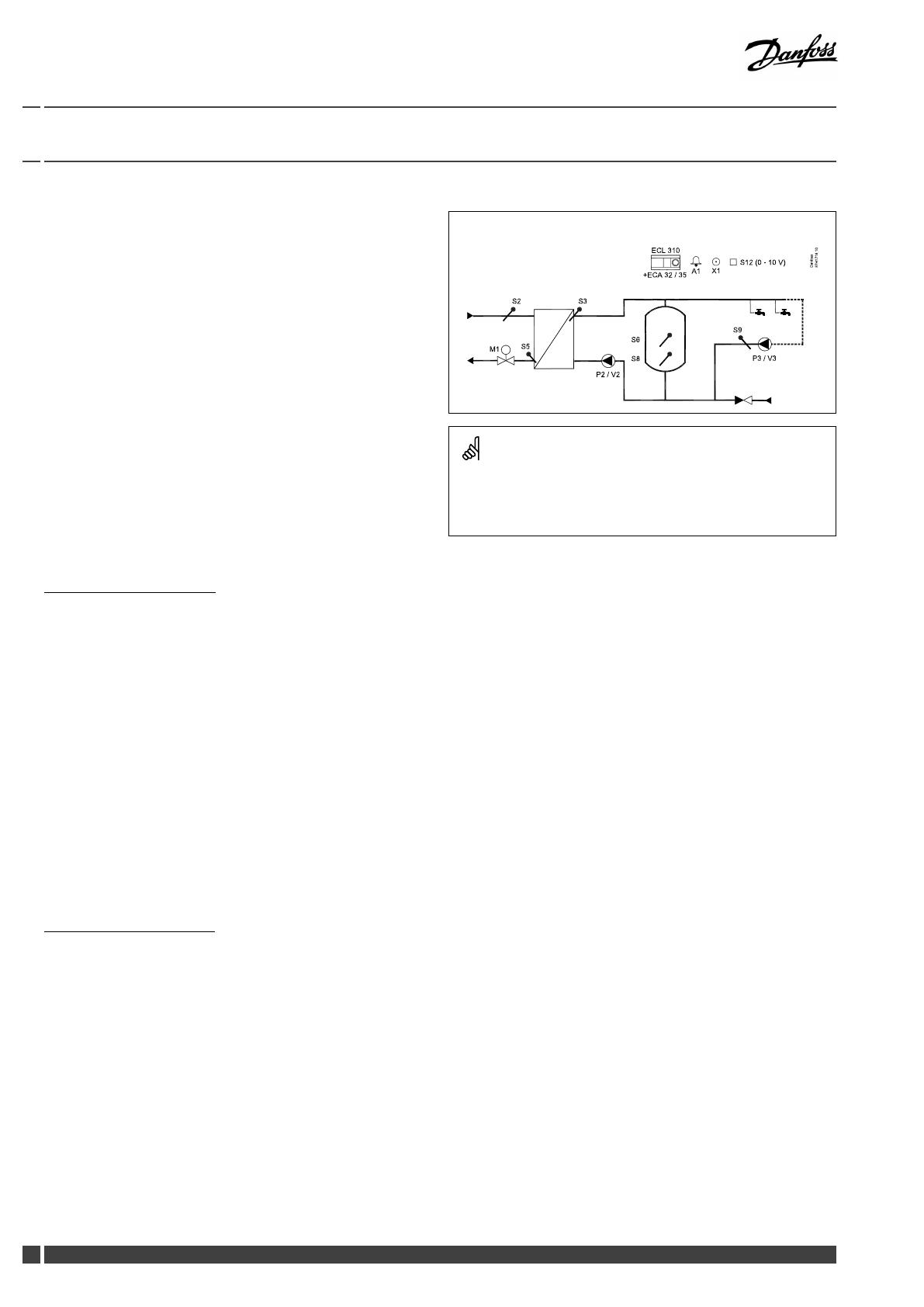

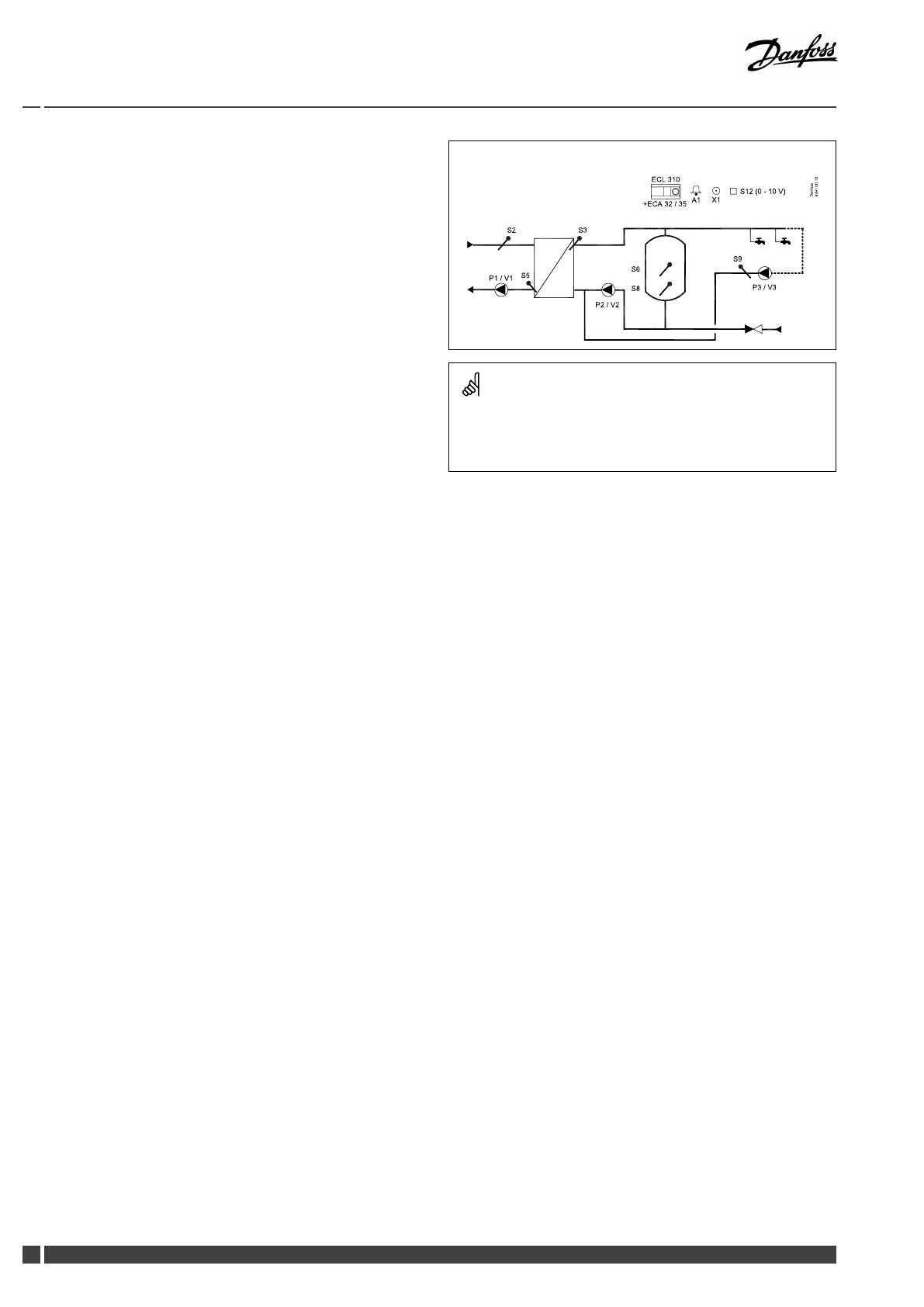

P318.1,ex.a,applicationwithcontrolvalveandinternalDHWcirculation:

Theshowndiagramisafundamentalandsimpliedexampleanddoes

notcontainallcomponentsthatarenecessaryinasystem.

AllnamedcomponentsareconnectedtotheECLComfortcontroller.

Listofcomponents:

ECL310

ECLComfort310controller

ECA32

Built-inextensionmodule,0-10Voutputs

ECA35

Built-inextensionmodule,0-10Voutputsand

PWMoutputs

S2

(mandatory)Supplytemperaturesensor

S3

(mandatory)Chargingtemperaturesensor

S5

Returntemperaturesensor

S6

(mandatory)Buffertemperaturesensor

S8

(mandatory)Lowerbuffertemperaturesensor

S9

DHWcirculationreturntemperaturesensor

S12

0-10VinputfordesiredtemperatureatS6

P2

Chargingpump(ON-OFFcontrolled)

V2

Speedcontrolofchargingpump(0-10VorPWM)

P3

Circulationpump(ON-OFFcontrolled)

V3

Speedcontrolofcirculationpump(0-10Vor

PWM)

M1

Motorizedcontrolvalve(3-pointcontrolled)

X1

Heatdemandsignal

A1

Alarm

6DEN-SMT/DK

VI.JM.Q3.02

DanfossDistrictEnergy

OperatingGuideECLComfort310,applicationP318

Bymeansofaweekschedule,theDHWcirculationcanbeON/

OFFcontrolled.

ThemotorizedcontrolvalveM1isopenedgraduallywhen

thechargingtemperatureislowerthanthedesiredcharging

temperatureandviceversa.

Alternatively,thecontrolpumpP1/V1isincreasedinspeedwhen

thechargingtemperatureislowerthanthedesiredcharging

temperatureandviceversa.

ThereturntemperatureS5canbelimited,forexamplenottobe

toohigh.Ifso,thedesiredchargingtemperatureatS3canbe

adjusted(typicallytoalowervalue);thisresultsinagradualclosing

ofthemotorizedcontrolvalveor,alternatively,alowerspeedof

thecontrolpump.

TheON-OFFoutputX1isONatDHWheatingdemand.

Asanoption,thedesiredDHWtemperaturecanbesetexternally.

Avoltagesignal(1-10Volt)canbeappliedtoinputS12(ECA32/

35).Thescaleforvoltageversustemperaturecanbeset.

Ananti-bacteriafunctionfortheDHWbufferisavailablefor

activationonselecteddaysoftheweek.

Theanti-bacteriafunctioncanbesettoincludetheDHW

circulation.

DanfossDistrictEnergy

VI.JM.Q3.02

DEN-SMT/DK7

OperatingGuideECLComfort310,applicationP318

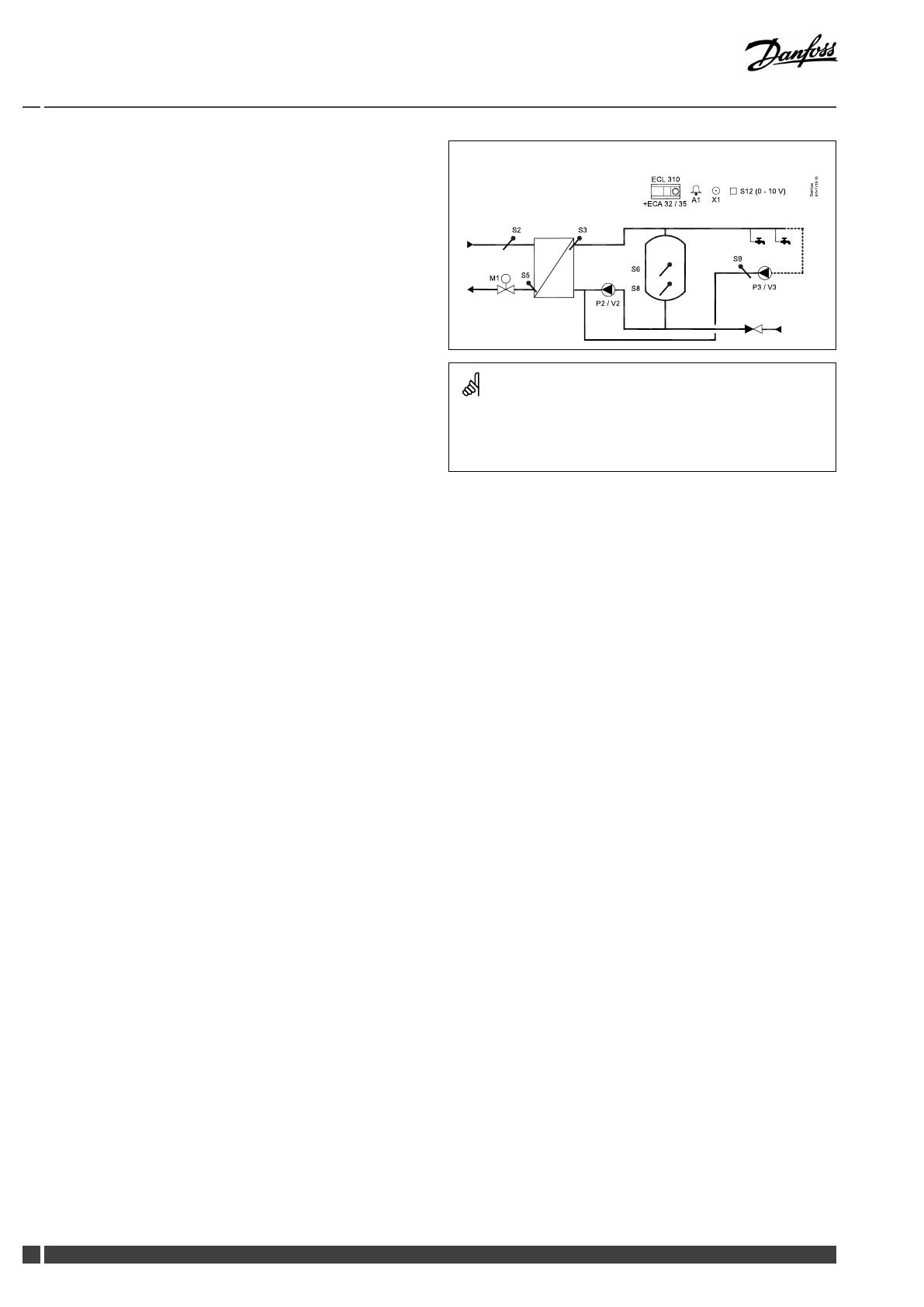

P318.1,ex.b,applicationwithcontrolvalveandexternalDHWcirculation:

Theshowndiagramisafundamentalandsimpliedexampleanddoes

notcontainallcomponentsthatarenecessaryinasystem.

AllnamedcomponentsareconnectedtotheECLComfortcontroller.

Listofcomponents:

ECL310

ECLComfort310controller

ECA32

Built-inextensionmodule,0-10Voutputs

ECA35

Built-inextensionmodule,0-10Voutputsand

PWMoutputs

S2

(mandatory)Supplytemperaturesensor

S3

(mandatory)Chargingtemperaturesensor

S5

Returntemperaturesensor

S6

(mandatory)Buffertemperaturesensor

S8

(mandatory)Lowerbuffertemperaturesensor

S9

DHWcirculationreturntemperaturesensor

S12

0-10VinputfordesiredtemperatureatS6

P2

Chargingpump(ON-OFFcontrolled)

V2

Speedcontrolofchargingpump(0-10VorPWM)

P3

Circulationpump(ON-OFFcontrolled)

V3

Speedcontrolofcirculationpump(0-10Vor

PWM)

M1

Motorizedcontrolvalve(3-pointcontrolled)

X1

Heatdemandsignal

A1

Alarm

8DEN-SMT/DK

VI.JM.Q3.02

DanfossDistrictEnergy

OperatingGuideECLComfort310,applicationP318

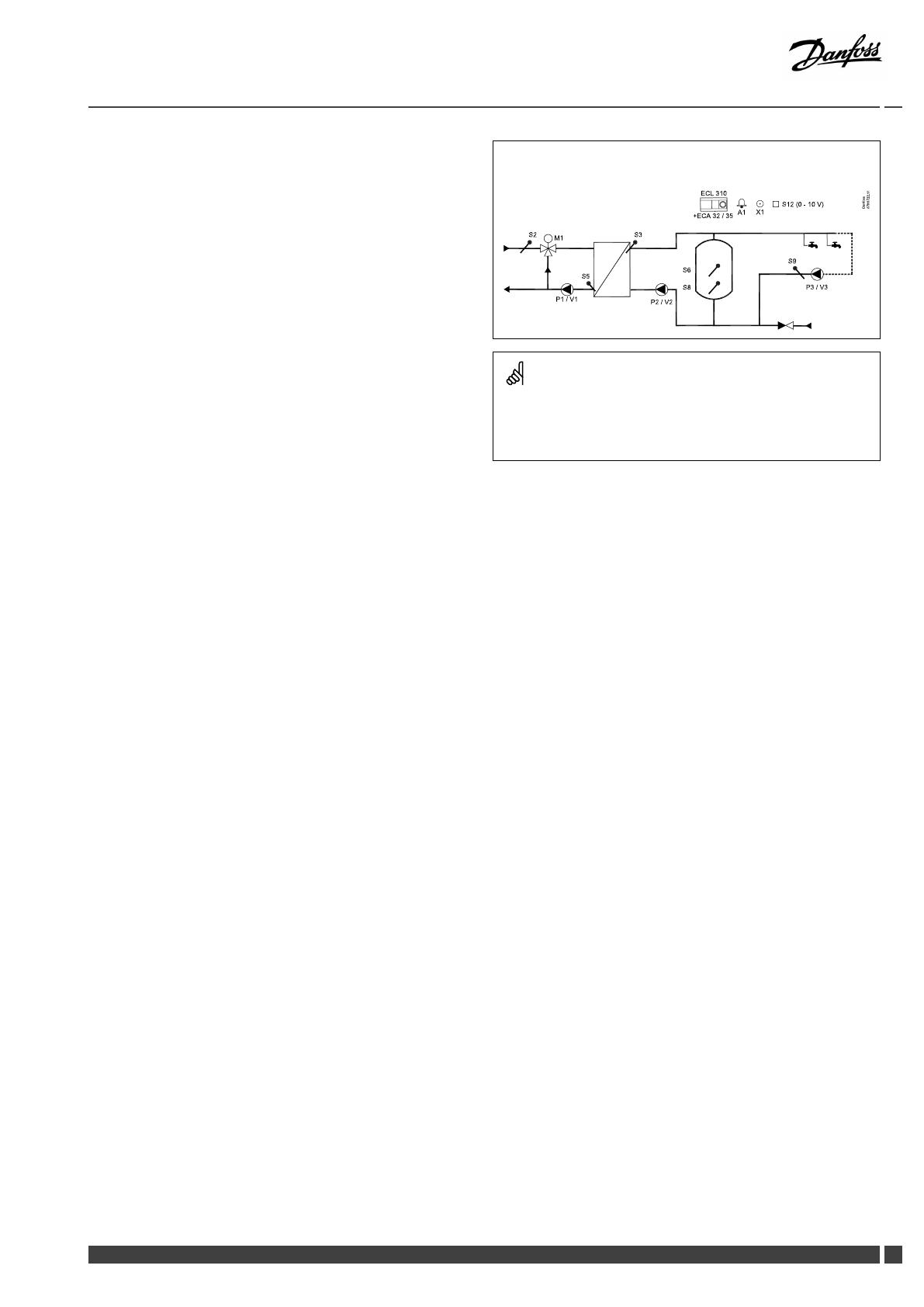

P318.1,ex.c,applicationwithcontrolpumpandinternalDHWcirculation:

Theshowndiagramisafundamentalandsimpliedexampleanddoes

notcontainallcomponentsthatarenecessaryinasystem.

AllnamedcomponentsareconnectedtotheECLComfortcontroller.

Listofcomponents:

ECL310

ECLComfort310controller

ECA32

Built-inextensionmodule,0-10Voutputs

ECA35

Built-inextensionmodule,0-10Voutputsand

PWMoutputs

S2

(mandatory)Supplytemperaturesensor

S3

(mandatory)Chargingtemperaturesensor

S5

Returntemperaturesensor

S6

(mandatory)Buffertemperaturesensor

S8

(mandatory)Lowerbuffertemperaturesensor

S9

DHWcirculationreturntemperaturesensor

S12

0-10VinputfordesiredtemperatureatS6

P1

Controlpump(ON-OFFcontrolled)

V1

Speedcontrolofcontrolpump(0–10VorPWM)

P2

Chargingpump(ON-OFFcontrolled)

V2

Speedcontrolofchargingpump(0-10VorPWM)

P3

Circulationpump(ON-OFFcontrolled)

V3

Speedcontrolofcirculationpump(0-10Vor

PWM)

X1

Heatdemandsignal

A1

Alarm

DanfossDistrictEnergy

VI.JM.Q3.02

DEN-SMT/DK9

OperatingGuideECLComfort310,applicationP318

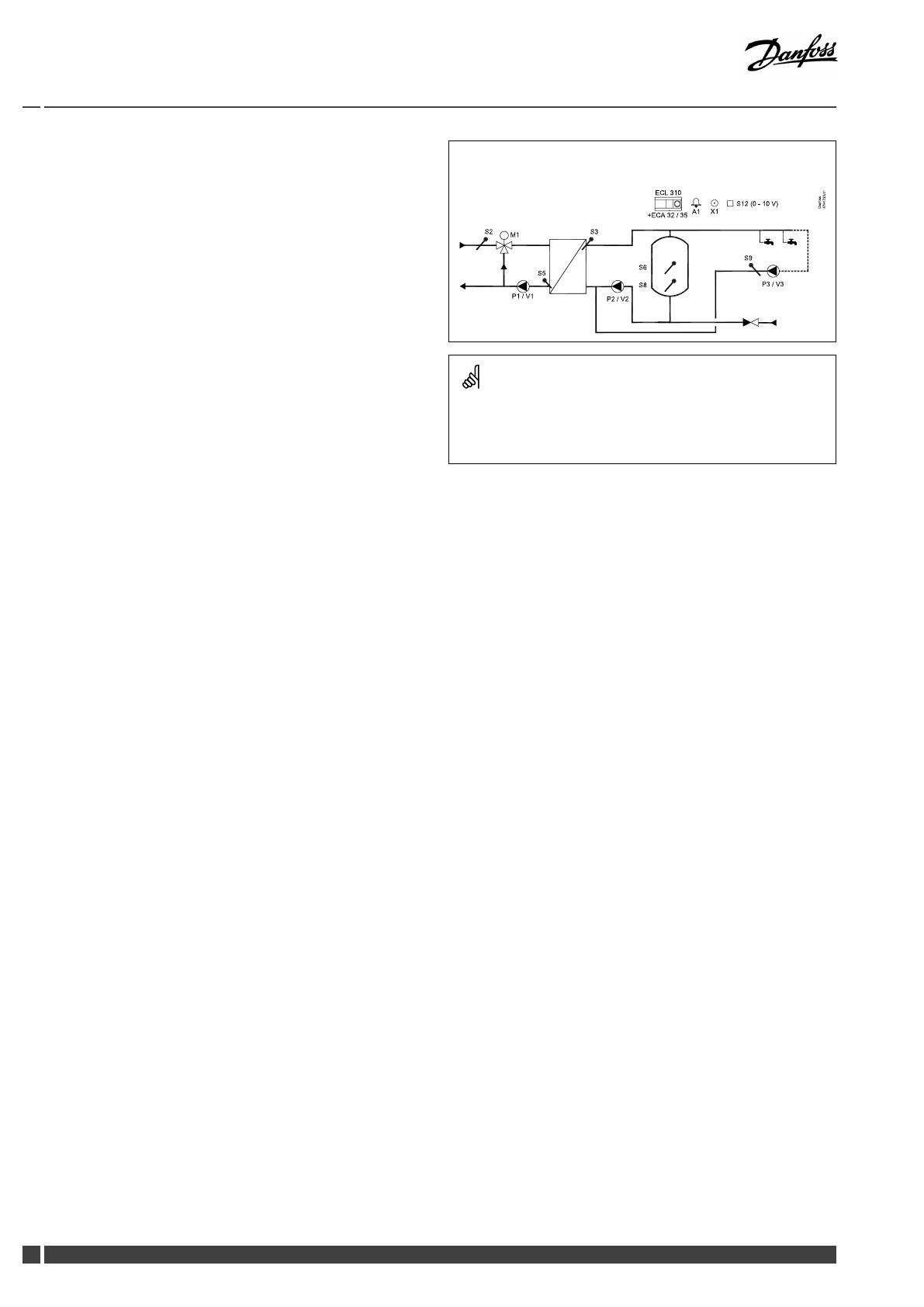

P318.1,ex.d,applicationwithcontrolpumpandexternalDHWcirculation:

Theshowndiagramisafundamentalandsimpliedexampleanddoes

notcontainallcomponentsthatarenecessaryinasystem.

AllnamedcomponentsareconnectedtotheECLComfortcontroller.

Listofcomponents:

ECL310

ECLComfort310controller

ECA32

Built-inextensionmodule,0-10Voutputs

ECA35

Built-inextensionmodule,0-10Voutputsand

PWMoutputs

S2

(mandatory)Supplytemperaturesensor

S3

(mandatory)Chargingtemperaturesensor

S5

Returntemperaturesensor

S6

(mandatory)Buffertemperaturesensor

S8

(mandatory)Lowerbuffertemperaturesensor

S9

DHWcirculationreturntemperaturesensor

S12

0-10VinputfordesiredtemperatureatS6

P1

Controlpump(ON-OFFcontrolled)

V1

Speedcontrolofcontrolpump(0–10VorPWM)

P2

Chargingpump(ON-OFFcontrolled)

V2

Speedcontrolofchargingpump(0-10VorPWM)

P3

Circulationpump(ON-OFFcontrolled)

V3

Speedcontrolofcirculationpump(0-10Vor

PWM)

X1

Heatdemandsignal

A1

Alarm

10DEN-SMT/DK

VI.JM.Q3.02

DanfossDistrictEnergy

OperatingGuideECLComfort310,applicationP318

P318.1,ex.e:Primarysideisacombinationofa3-portcontrolvalveanda

controlpump.InternalDHWcirculation:

Theshowndiagramisafundamentalandsimpliedexampleanddoes

notcontainallcomponentsthatarenecessaryinasystem.

AllnamedcomponentsareconnectedtotheECLComfortcontroller.

Listofcomponents:

ECL310

ECLComfort310controller

ECA32

Built-inextensionmodule,0-10Voutputs

ECA35

Built-inextensionmodule,0-10Voutputsand

PWMoutputs

S2

(mandatory)Supplytemperaturesensor

S3

(mandatory)Chargingtemperaturesensor

S5

Returntemperaturesensor

S6

(mandatory)Buffertemperaturesensor

S8

(mandatory)Lowerbuffertemperaturesensor

S9

DHWcirculationreturntemperaturesensor

S12

0-10VinputfordesiredtemperatureatS6

M1

Motorized3-portcontrolvalve(3-pointcontrolled)

P1

Controlpump(ON-OFFcontrolled)

V1

Speedcontrolofcontrolpump(0–10VorPWM)

P2

Chargingpump(ON-OFFcontrolled)

V2

Speedcontrolofchargingpump(0-10VorPWM)

P3

Circulationpump(ON-OFFcontrolled)

V3

Speedcontrolofcirculationpump(0-10Vor

PWM)

X1

Heatdemandsignal

A1

Alarm

DanfossDistrictEnergy

VI.JM.Q3.02

DEN-SMT/DK11

OperatingGuideECLComfort310,applicationP318

P318.1,ex.f:Primarysideisacombinationofa3-portcontrolvalveanda

controlpump.ExternalDHWcirculation:

Theshowndiagramisafundamentalandsimpliedexampleanddoes

notcontainallcomponentsthatarenecessaryinasystem.

AllnamedcomponentsareconnectedtotheECLComfortcontroller.

Listofcomponents:

ECL310

ECLComfort310controller

ECA32

Built-inextensionmodule,0-10Voutputs

ECA35

Built-inextensionmodule,0-10Voutputsand

PWMoutputs

S2

(mandatory)Supplytemperaturesensor

S3

(mandatory)Chargingtemperaturesensor

S5

Returntemperaturesensor

S6

(mandatory)Buffertemperaturesensor

S8

(mandatory)Lowerbuffertemperaturesensor

S9

DHWcirculationreturntemperaturesensor

S12

0-10VinputfordesiredtemperatureatS6

M1

Motorized3-portcontrolvalve(3-pointcontrolled)

P1

Controlpump(ON-OFFcontrolled)

V1

Speedcontrolofcontrolpump(0–10VorPWM)

P2

Chargingpump(ON-OFFcontrolled)

V2

Speedcontrolofchargingpump(0-10VorPWM)

P3

Circulationpump(ON-OFFcontrolled)

V3

Speedcontrolofcirculationpump(0-10Vor

PWM)

X1

Heatdemandsignal

A1

Alarm

12

DEN-SMT/DK

VI.JM.Q3.02

DanfossDistrictEnergy

OperatingGuideECLComfort310,applicationP318

ThebasicprinciplesforapplicationP318.10:

TemperaturecontrolofDHW

ThedesiredDHWtemperatureatS3determinesthetemperature

control.

TheDHWowtemperaturesensorS3andtheDHWcirculation

returntemperaturesensorS9arethemostimportantsensorsand

mustbeconnected.IfS3isnotconnected,thecontrolvalveM1will

close;alternatively,thecontrolpumpP1/V1willstop.IfS9isnot

connected,theDHWcirculationpumpwilloperateat100%.

TemperaturecontroloftheDHWcirculationpipeatS9ensuresthe

desiredtemperaturebymeansofspeedcontrolofV3.

ThemotorizedcontrolvalveM1isopenedgraduallywhenthe

DHWowtemperatureislowerthanthedesiredDHWtemperature

andviceversa.

Alternatively,thecontrolpumpP1/V1isincreasedinspeedwhen

theDHWowtemperatureislowerthanthedesiredDHWow

temperatureandviceversa.

ThereturntemperatureS5canbelimited,forexamplenottobe

toohigh.Ifso,thedesiredDHWtemperatureatS3canbeadjusted

(typicallytoalowervalue);thisresultsinagradualclosingofthe

motorizedcontrolvalveor,alternatively,alowerspeedofthe

controlpump.

ThesupplytemperatureS2isusedtocompensatetheproportional

bandXpinordertoimprovethetemperaturecontrolatdifferent

supplytemperatures.

ThewaterowsignalfromF1canbeusedtooverridethecontrol

valveinordertooptimizetheDHWtemperaturecontrol.This

pro-activefunctionalitycompensatesforthedelaybeforetheow

temperaturesensorS3measuresachangeintemperature.

Asanoption,thedesiredDHWtemperaturecanbesetexternally.

Avoltagesignal(1-10Volt)canbeappliedtoinputS12(ECA32/

35).Thescaleforvoltageversustemperaturecanbeset.

Ananti-bacteriafunctionfortheDHWcircuitisavailablefor

activationonselecteddaysoftheweek.Theanti-bacteriafunction

canbesettoincludetheDHWcirculation.

P318.10,ex.a,DHWapplicationwithcontrolvalve:

Theshowndiagramisafundamentalandsimpliedexampleanddoes

notcontainallcomponentsthatarenecessaryinasystem.

AllnamedcomponentsareconnectedtotheECLComfortcontroller.

Listofcomponents:

ECL310

ECLComfort310controller

ECA32

Built-inextensionmodule,0-10Voutputs

ECA35

Built-inextensionmodule,0-10Voutputsand

PWMoutputs

S2

Supplytemperaturesensor

S3

(mandatory)DHWowtemperaturesensor

S5

Returntemperaturesensor

S9

(mandatory)DHWcirculationreturntemperature

sensor

S12

0-10VinputfordesiredtemperatureatS3

F1

ColdWatermeter(pulsesignal)

P3

Speedcontrolofchargingpump(0-10VorPWM)

P3

DHWcirculationpump(ON-OFFcontrolled)

V3

Speedcontrolofcirculationpump(0-10Vor

PWM)

M1

Motorizedcontrolvalve(3-pointcontrolled)

A1

Alarm

DanfossDistrictEnergy

VI.JM.Q3.02

DEN-SMT/DK13

OperatingGuideECLComfort310,applicationP318

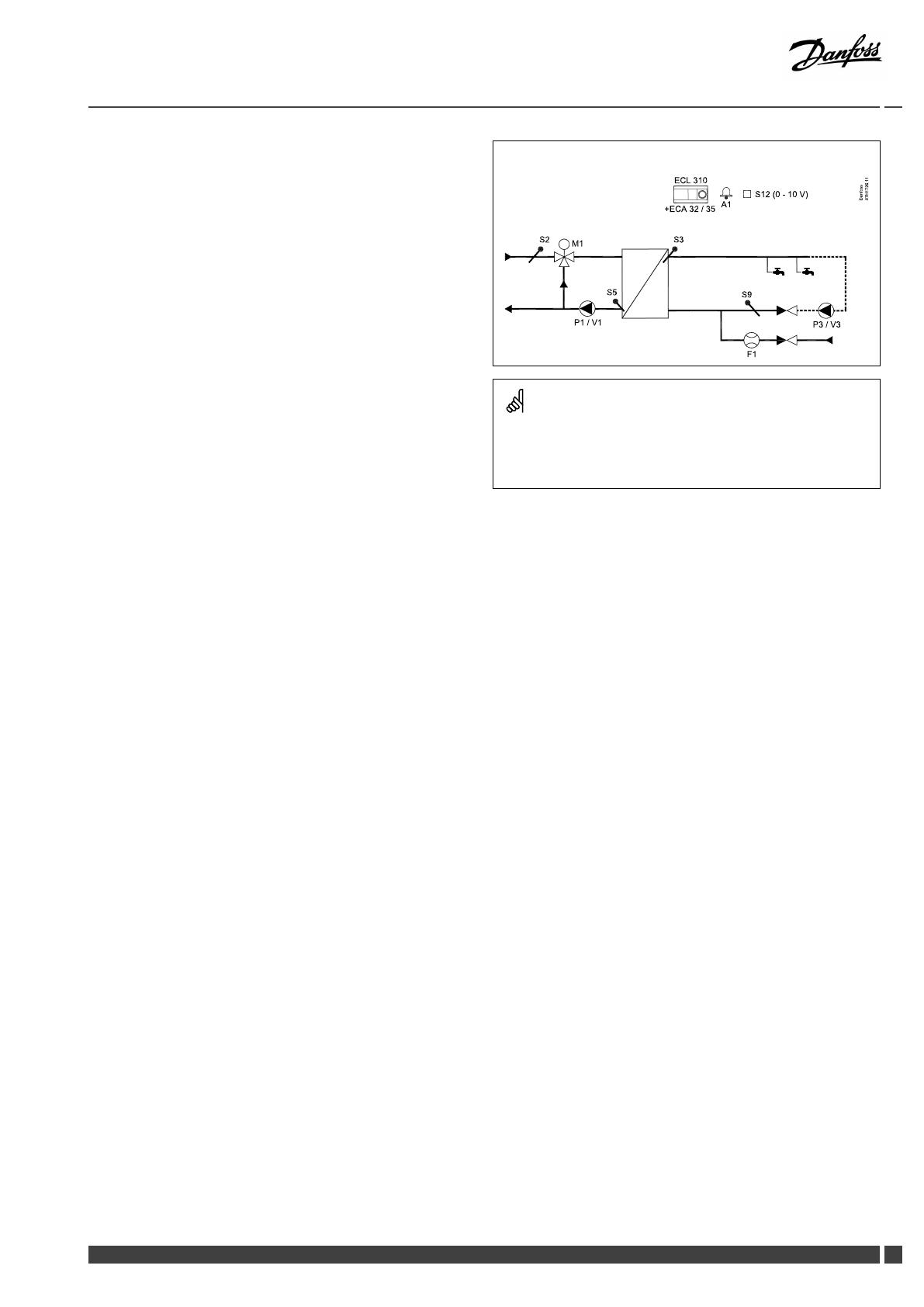

P318.10,ex.b,DHWapplicationwithcontrolpump:

Theshowndiagramisafundamentalandsimpliedexampleanddoes

notcontainallcomponentsthatarenecessaryinasystem.

AllnamedcomponentsareconnectedtotheECLComfortcontroller.

Listofcomponents:

ECL310

ECLComfort310controller

ECA32

Built-inextensionmodule,0-10Voutputs

ECA35

Built-inextensionmodule,0-10Voutputsand

PWMoutputs

S2

Supplytemperaturesensor

S3

(mandatory)DHWowtemperaturesensor

S5

Returntemperaturesensor

S9

(mandatory)DHWcirculationreturntemperature

sensor

S12

0-10VinputfordesiredtemperatureatS3

F1

ColdWatermeter(pulsesignal)

P1

Controlpump(ON-OFFcontrolled)

V1

Speedcontrolofcontrolpump(0-10VorPWM)

P3

DHWcirculationpump(ON-OFFcontrolled)

V3

Speedcontrolofcirculationpump(0-10Vor

PWM)

A1

Alarm

14DEN-SMT/DK

VI.JM.Q3.02

DanfossDistrictEnergy

OperatingGuideECLComfort310,applicationP318

P318.10,ex.c,DHWapplicationwithcontrolvalveandcontrolpump:

Theshowndiagramisafundamentalandsimpliedexampleanddoes

notcontainallcomponentsthatarenecessaryinasystem.

AllnamedcomponentsareconnectedtotheECLComfortcontroller.

Listofcomponents:

ECL310

ECLComfort310controller

ECA32

Built-inextensionmodule,0-10Voutputs

ECA35

Built-inextensionmodule,0-10Voutputsand

PWMoutputs

S2

Supplytemperaturesensor

S3

(mandatory)DHWowtemperaturesensor

S5

Returntemperaturesensor

S9

(mandatory)DHWcirculationreturntemperature

sensor

S12

0-10VinputfordesiredtemperatureatS3

F1

ColdWatermeter(pulsesignal)

P1

Controlpump(ON-OFFcontrolled)

V1

Speedcontrolofcontrolpump(0-10VorPWM)

P3

DHWcirculationpump(ON-OFFcontrolled)

V3

Speedcontrolofcirculationpump(0-10Vor

PWM)

M1

Motorizedcontrolvalve(3-pointcontrolled)

A1

Alarm

DanfossDistrictEnergy

VI.JM.Q3.02

DEN-SMT/DK

15

OperatingGuideECLComfort310,applicationP318

P318,ingeneral

UptotwoRemoteControlUnits,ECA30/31,canbeconnectedto

oneECLcontrollerinordertocontroltheECLcontrollerremotely.

AdditionalECLComfortcontrollerscanbeconnectedviatheECL

485businordertoutilizecommonoutdoortemperaturesignal,

timeanddatesignals.TheECLControllersintheECL485bus

systemcanworkasmasterandslaves.TheapplicationP318can

workaloneorasaslave.

Heat-meters:

Upto5heat-meterscanbeconnectedtotheM-busterminals.

DatacanbetransferredtotheSCADAsystemviaModbusandTCP/

IPtotheECLPortal.

TheP318applicationhaseventindicationsfor

•Chargingtemperature(P318.1)

•Tank(buffer)temperature(P318.1)

•DHWowtemperature(P310.10)

•Supplytemperature

•Anti-bacteria

Typically,aneventisregisteredifasettemperatureconditionis

notaccepted.Theeventscanbeprioritizedtobeindicatedas

informationoranalarm.

ThealarmA1(=relay6)canbeactivatedif:

•aneventoccurs

•atemperaturesensororitsconnectiondisconnects/short

circuits.(See:Commoncontrollersettings>System>Raw

inputoverview).

16DEN-SMT/DK

VI.JM.Q3.02

DanfossDistrictEnergy

OperatingGuideECLComfort310,applicationP318

PWM(PulseWidthModulation)

A200HzfrequencyisappliedtothePWMcontrolledpump.The

dutycycle(thepercentageoftheperiodtime)determinesthe

pumpspeed.

Pumpspeed,PWMor0–10Voltcontrolled

Sometypesofspeedcontrolledpumpsarelimitedtoaminimum

speed,forexample30%(PWMor3.0Volt).Eveniftheapplied

control%getslowerthan30%,thepumpspeedremainsonthe

minimumlevel*.

Furthermore,whentheappliedcontrol%getsbelow,forexample,

10%,thepumpswitchesOFF.Inordertogetthepumpswitched

ONagain,theappliedcontrol%mustexceed20%.

Thisbehaviorcan,atlowloadoratoobigpump,causeunstable

temperatureregulation.Toavoidthis,theP318hasafunction

wheretheappliedcontrolsignalisconvertedintoapulsedsignal.

Thepumpisshortlystoppedandthenstartedagain.Theresultisa

pumpspeedcontrolalsobelowtheminimumspeedlevel.

Theparameters"PWMperiod"(ID11565)and"Adapttime"(ID

11065)areusedforthisfunctionality.

*)Seethepumpmanufacturer'sdatasheet

Inputconguration

Inputs(asfromS7andup)whicharenotpartoftheapplicationcan

beconguredtobePt1000,0-10Volt,frequency(pulsecounter)

orDigitalinput.Thisfeaturemakesitpossibletocommunicate

extrasignals,suchastemperatures,pressures,ON/OFFconditions,

viaModbusandECLPortal.

ThecongurationisdonebymeansoftheECLTool(freesoftware

fordownload)ordirectlyinadedicatedmenuintheECLPortalor

theconnectionforModbus(BMS/SCADA).

Commissioning

WhentheP318hasbeenuploadedtheECLComfort310controller

startsinManualmode.Thiscanbeusedtoverifythecontrolled

componentsforcorrectfunctionality.

Dependingonsystemtype,itisrecommendedtochangesome

factorysettingsindividuallyinordertooptimizethefunctionality.

Thesesettingchanges,ifrequired,arelistedbelowthesystem

typesinthesection'Identifyingthesystemtype'.

Theapplicationkeymustbeinsertedinordertochangesettings.

Thecontrollerispre-programmedwithfactorysettingsthatareshown

inthe‘ParameterIDoverview’appendix.

DanfossDistrictEnergy

VI.JM.Q3.02

DEN-SMT/DK17

OperatingGuideECLComfort310,applicationP318

2.2Identifyingthesystemtype

Sketchyourapplication

TheECLComfortcontrollerseriesisdesignedforawiderange

ofheating,domestichot-water(DHW)andcoolingsystemswith

differentcongurationsandcapacities.Ifyoursystemdiffers

fromthediagramsshownhere,youmaywanttomakeasketch

ofthesystemabouttobeinstalled.Thismakesiteasiertouse

theOperatingGuide,whichwillguideyoustep-by-stepfrom

installationtonaladjustmentsbeforetheend-usertakesover.

TheECLComfortcontrollerisauniversalcontrollerthatcanbe

usedforvarioussystems.Basedontheshownstandardsystems,

itispossibletocongureadditionalsystems.Inthischapteryou

ndthemostfrequentlyusedsystems.Ifyoursystemisnotquite

asshownbelow,ndthediagramwhichhasthebestresemblance

withyoursystemandmakeyourowncombinations.

SeetheInstallationGuide(deliveredwiththeapplicationkey)for

applicationtypes/sub-types.

Adviceforsettings:

Factorysettingsinthesubtypearerelatedtoexamplea.

Someoftheapplicationexamplesneedchangeofdedicated

settings.

Seethedocumentationfortheapplication,deliveredwiththe

applicationkey.

P318.1,ex.a,cande

InternalDHWcirculation(DHWcirculationreturnpipeisconnected

totheDHWtank)

Issue:

Navigation:

IDno.:

Recommended

setting:

DHWcircuit(1):

InternalDHWcirculation

MENU\Settings\Application:'Cont.Tcontrol'

11054

OFF

P318.1,ex.b,dandf

ExternalDHWcirculation(DHWcirculationreturnpipeisconnected

totheheat-exchanger)

Issue:

Navigation:

IDno.:

Recommended

setting:

DHWcircuit(1):

ExternalDHWcirculation

MENU\Settings\Application:'Cont.Tcontrol'

11054

ON

Controlvalve(M1)orcontrolpump(P1/V1):

Nospecicsettingrelatedtocontrolitem.

18DEN-SMT/DK

VI.JM.Q3.02

DanfossDistrictEnergy

OperatingGuideECLComfort310,applicationP318

2.3Mounting

2.3.1MountingtheECLComfortcontroller

SeetheInstallationGuidewhichisdeliveredtogetherwiththe

ECLComfortcontroller.

Foreasyaccess,youshouldmounttheECLComfortcontrollernear

thesystem.

ECLComfort210/296/310canbemounted

•onawall

•onaDINrail(35mm)

ECLComfort296canbemounted

•inapanelcut-out

ECLComfort210canbemountedinanECLComfort310basepart

(forfutureupgrade).

Screws,PGcableglandsandrawlplugsarenotsupplied.

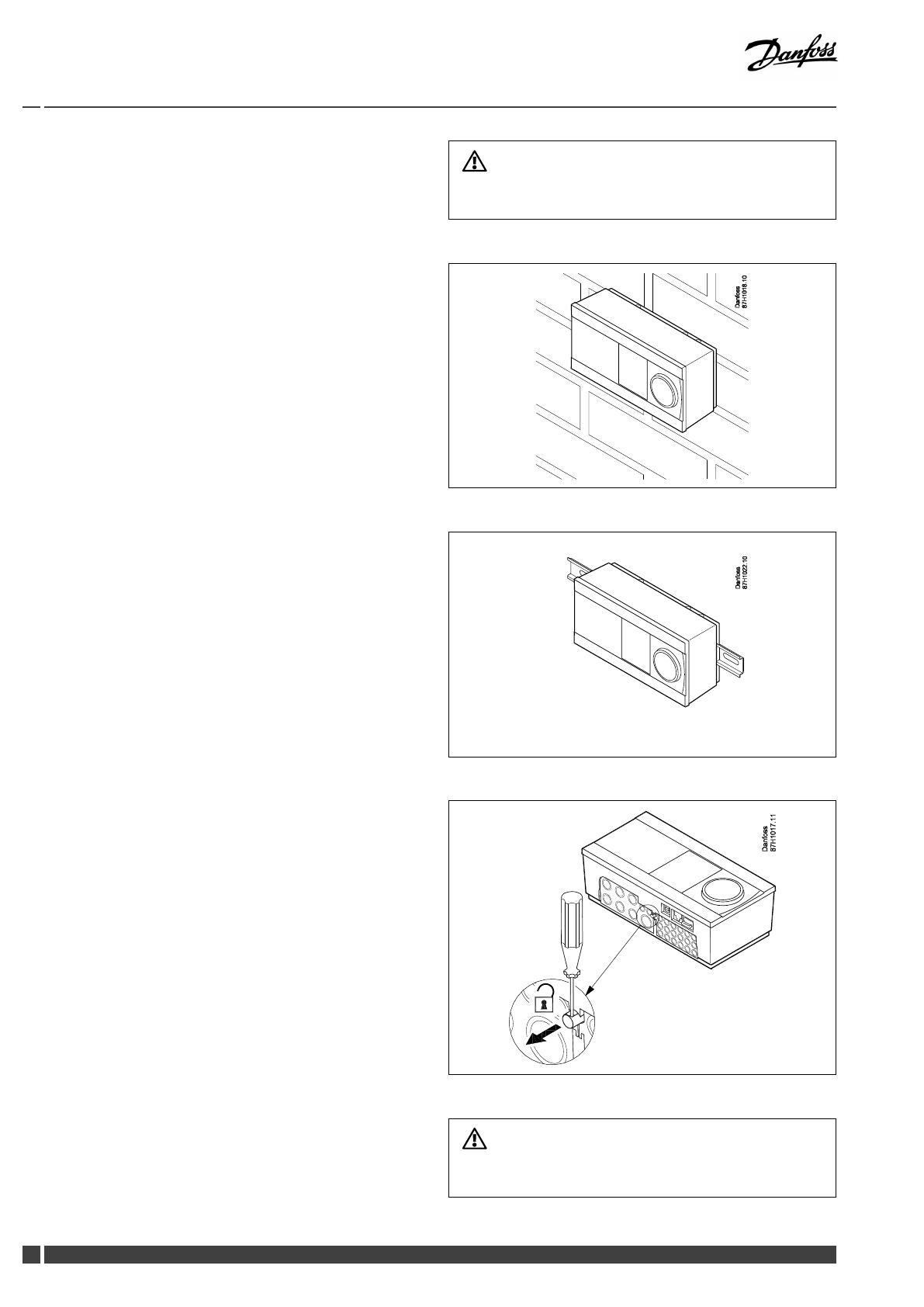

LockingtheECLComfort210/310controller

InordertofastentheECLComfortcontrollertoitsbasepart,secure

thecontrollerwiththelockingpin.

Topreventinjuriestopersonsorthecontroller,thecontrollerhasto

besecurelylockedintothebase.Forthispurpose,pressthelocking

pinintothebaseuntilaclickisheardandthecontrollernolonger

canberemovedfromthebase.

Ifthecontrollerisnotsecurelylockedintothebasepart,thereisarisk

thatthecontrollerduringoperationcanunlockfromthebaseandthe

basewithterminals(andalsothe230Va.c.connections)areexposed.

Topreventinjuriestopersons,alwaysmakesurethatthecontroller

issecurelylockedintoitsbase.Ifthisisnotthecase,thecontroller

shouldnotbeoperated!

DanfossDistrictEnergy

VI.JM.Q3.02

DEN-SMT/DK19

OperatingGuideECLComfort310,applicationP318

Theeasywaytolockthecontrollertoitsbaseorunlockitistousea

screwdriveraslever.

Mountingonawall

Mountthebasepartonawallwithasmoothsurface.Establishthe

electricalconnectionsandpositionthecontrollerinthebasepart.

Securethecontrollerwiththelockingpin.

MountingonaDINrail(35mm)

MountthebasepartonaDINrail.Establishtheelectrical

connectionsandpositionthecontrollerinthebasepart.Secure

thecontrollerwiththelockingpin.

DismountingtheECLComfortcontroller

Inordertoremovethecontrollerfromthebasepart,pulloutthe

lockingpinbymeansofascrewdriver.Thecontrollercannowbe

removedfromthebasepart.

Theeasywaytolockthecontrollertoitsbaseorunlockitistousea

screwdriveraslever.

20DEN-SMT/DK

VI.JM.Q3.02

DanfossDistrictEnergy

/