For warranty informaon please visit: hp://www.kichler.com/warranty

Para informacion de la garana por favor visite: hp://www.kichler.com/warranty

IS-16232-US

We’re here to help 866-558-5706

Hrs: M-F 9am to 5pm EST

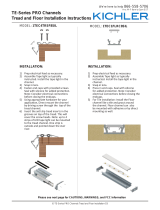

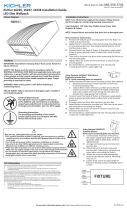

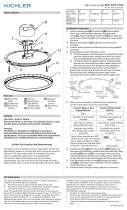

Kichler 16232 & 16233 Installaon Guide

LED Wall Pack

IMPORTANT: Read before removing xture from carton. Retain

for future reference.

SAFETY: This xture must be wired in accordance with the

NATIONAL ELECTRICAL CODE (NEC) and applicable local codes

and ordinances. A person familiar with the construcon and

operaon of the product and the hazards involved must install

this product. A qualied licensed electrician should complete all

work. Proper grounding is required for safety.

WARNING: Make certain power is OFF before installing or

maintaining xture.

RISK OF INJURY: Fixture may become damaged and/or unstable

if not installed properly.

Cauons:

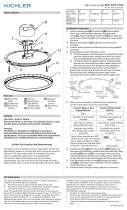

Installaon Instrucons:

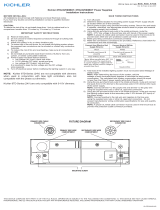

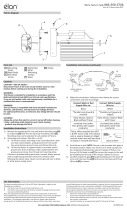

Fixture Diagram

NOTE: Turn o electrical supply at the breaker. Follow all

local electrical codes for wiring and grounding requirements.

NOTE: This xture is intended to be surface mounted on to a

wall in the lens down posion.

Tools Required: Phillips Screw Driver, Security Torx T-20 Bit

& Driver, Electric Drill, Drill Bit Set, Wire Strippers & Cuers

1) Unpack xture and ensure that there are no damaged

parts.

2) Open xture by removing the T-20 Security Torx screws on

the side of the xture.

3) Disconnect orange connector and remove LED and frame

assembly to allow for easier installaon.

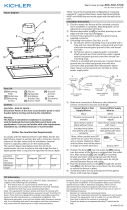

4) Inspect the 3 mounng hole locaons (Item A on g. 2)

and ensure that there are no components over them.

5) In order to mount the xture the backplate has to be

pierced at the mounng locaons. Use an appropriate

sized drill bit for the mounng screws up to 5/16”.

6) Align the backplate and mount securely with mounng

hardware appropriate for surface.

7) If electrical connecons are going to be made from a

conduit pipe, remove one of the conduit plugs from the

base and thread NPS conduit pipe into locaon.

8) If electrical connecons are going to be made through a

juncon box, drill the appropriate holes (Item C in Fig.2)

for the sized juncon box.

9) Connect leads from back of xture to the power supply

leads: Green to green (ground), black to black (hot), white

to white(neutral).

10) Reaach frame and glass assembly to base by slipping it

over the barrel pins.

11) Reconnect orange connector and reaach the frame

assembly using the Torx Screw.

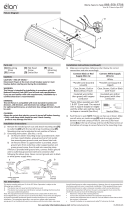

MOUNTING:

The back plate has a cast-in drill and knock-out template

to match any standard recessed juncon box, three 5/16”

knock-outs for mounng holes A and three 1/2” NPS

tapped holes D for surface conduit or photocontrol unit.

A – 5/16” Diameter Knockouts

B – 9/16” Diameter Knockouts

C – Knockouts for #10 screw

D – 1/2” NPS Tapped Holes

Use weatherproof silicone sealant to seal all holes and

gaps between xture and mounng surface.

This device complies with part 15 of the FCC Rules. Operaon is

subject to the following two condions:

1) This device may not cause harmful interference, and

2) This device must accept any interference received, including

interference that may cause undesired operaon.

Note: This equipment has been tested and found to comply with

the limits for a Class A digital device, pursuant to part 15 of the FCC

Rules. These limits are designed to provide reasonable protecon

against harmful interference in a residenal installaon. This

equipment generates, uses and can radiate radio frequency energy

and, if not installed and used in accordance with the instrucons,

may cause harmful interference to radio communicaons.

However, there is no guarantee that interference will not occur

in a parcular installaon. If this equipment does cause harmful

interference to radio or television recepon, which can be

determined by turning the equipment o and on, the user is

encouraged to try to correct the interference by one or more of the

following measures:

• Reorient or relocate the receiving antenna.

• Increase the separaon between the equipment and receiver.

• Connect the equipment into an outlet on a circuit dierent from

that to which the receiver is connected.

• Consult the dealer or an experienced radio/TV technician for

help.

FCC Informaon:

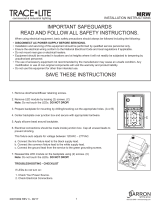

RISK OF FIRE, EXPLOSION AND ELECTRIC SHOCK

• This product should be installed, inspected, and maintained by a qualied

electrician only, in accordance with the NEC (Naonal Electric Code) and all

local codes.

• Turn o electrical power before inspecon, installaon or removal.

• Use only UL (or other NRTL) approved wire for input/output connecons.

Minimum size 18 AWG or 14 AWG for connuous runs.

• Make sure LEDs and drivers are cool to touch when performing maintenance.

Make sure the supply voltage is the same as the rated voltage of the luminaire.

• Do not install in a hazardous atmosphere, except where the ambient

temperature does not exceed the rated operang temperature of the xture.

• Keep ghtly closed when in operaon

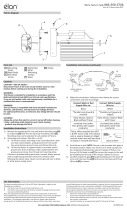

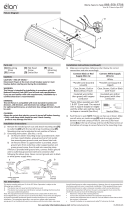

Electrical Requirements

The LED driver must be supplied with 120 to

277V, 50/60 Hz and connected to an individual,

properly grounded branch circuit protected by a

20 Ampere circuit breaker. Use min. 90°C supply.

Grounding Instrucons

The grounding and bonding of the overall

system shall be done in accordance with

NEC Arcle 600 and local codes

INSTALLATION AND SERVICE INSTRUCTIONS

SML-106/706/707/708 LED Wallpack

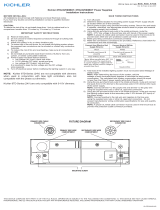

TEMPLATE

GR

GR

GND

A

A

A

C

B

31/4" OCT.BOX

4" OCT. BOX

D

D

D

TROUBLE ING CHECKLIST: If the light does not work.

Figure 2

Figure 1

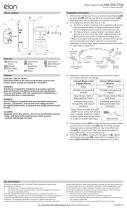

Black

Line

White

Neutral

Green

Ground

FIXTURE

Page is loading ...

IS-16232-CB

We’re here to help 866-558-5706

Hrs: M-F 9am to 5pm EST

Kichler 16232 & 16233 Installaon Guide

LED Wall Pack

IMPORTANT: Read before removing xture from carton. Retain

for future reference.

SAFETY: This xture must be wired in accordance with the

NATIONAL ELECTRICAL CODE (NEC) and applicable local codes

and ordinances. A person familiar with the construcon and

operaon of the product and the hazards involved must install

this product. A qualied licensed electrician should complete all

work. Proper grounding is required for safety.

WARNING: Make certain power is OFF before installing or

maintaining xture.

RISK OF INJURY: Fixture may become damaged and/or unstable

if not installed properly.

Cauons:

Installaon Instrucons:

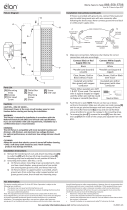

Fixture Diagram

NOTE: Turn o electrical supply at the breaker. Follow all

local electrical codes for wiring and grounding requirements.

NOTE: This xture is intended to be surface mounted on to a

wall in the lens down posion.

Tools Required: Phillips Screw Driver, Security Torx T-20 Bit

& Driver, Electric Drill, Drill Bit Set, Wire Strippers & Cuers

1) Unpack xture and ensure that there are no damaged

parts.

2) Open xture by removing the T-20 Security Torx screws on

the side of the xture.

3) Disconnect orange connector and remove LED and frame

assembly to allow for easier installaon.

4) Inspect the 3 mounng hole locaons (Item A on g. 2)

and ensure that there are no components over them.

5) In order to mount the xture the backplate has to be

pierced at the mounng locaons. Use an appropriate

sized drill bit for the mounng screws up to 5/16”.

6) Align the backplate and mount securely with mounng

hardware appropriate for surface.

7) If electrical connecons are going to be made from a

conduit pipe, remove one of the conduit plugs from the

base and thread NPS conduit pipe into locaon.

8) If electrical connecons are going to be made through a

juncon box, drill the appropriate holes (Item C in Fig.2)

for the sized juncon box.

9) Connect leads from back of xture to the power supply

leads: Green to green (ground), black to black (hot), white

to white(neutral).

10) Reaach frame and glass assembly to base by slipping it

over the barrel pins.

11) Reconnect orange connector and reaach the frame

assembly using the Torx Screw.

MOUNTING:

The back plate has a cast-in drill and knock-out template

to match any standard recessed juncon box, three 5/16”

knock-outs for mounng holes A and three 1/2” NPS

tapped holes D for surface conduit or photocontrol unit.

A – 5/16” Diameter Knockouts

B – 9/16” Diameter Knockouts

C – Knockouts for #10 screw

D – 1/2” NPS Tapped Holes

Use weatherproof silicone sealant to seal all holes and

gaps between xture and mounng surface.

This device complies with part 15 of the FCC Rules. Operaon is

subject to the following two condions:

1) This device may not cause harmful interference, and

2) This device must accept any interference received, including

interference that may cause undesired operaon.

Note: This equipment has been tested and found to comply with

the limits for a Class A digital device, pursuant to part 15 of the FCC

Rules. These limits are designed to provide reasonable protecon

against harmful interference in a residenal installaon. This

equipment generates, uses and can radiate radio frequency energy

and, if not installed and used in accordance with the instrucons,

may cause harmful interference to radio communicaons.

However, there is no guarantee that interference will not occur

in a parcular installaon. If this equipment does cause harmful

interference to radio or television recepon, which can be

determined by turning the equipment o and on, the user is

encouraged to try to correct the interference by one or more of the

following measures:

• Reorient or relocate the receiving antenna.

• Increase the separaon between the equipment and receiver.

• Connect the equipment into an outlet on a circuit dierent from

that to which the receiver is connected.

• Consult the dealer or an experienced radio/TV technician for

help.

FCC Informaon:

RISK OF FIRE, EXPLOSION AND ELECTRIC SHOCK

• This product should be installed, inspected, and maintained by a qualied

electrician only, in accordance with the NEC (Naonal Electric Code) and all

local codes.

• Turn o electrical power before inspecon, installaon or removal.

• Use only UL (or other NRTL) approved wire for input/output connecons.

Minimum size 18 AWG or 14 AWG for connuous runs.

• Make sure LEDs and drivers are cool to touch when performing maintenance.

Make sure the supply voltage is the same as the rated voltage of the luminaire.

• Do not install in a hazardous atmosphere, except where the ambient

temperature does not exceed the rated operang temperature of the xture.

• Keep ghtly closed when in operaon

Electrical Requirements

The LED driver must be supplied with 120 to

277V, 50/60 Hz and connected to an individual,

properly grounded branch circuit protected by a

20 Ampere circuit breaker. Use min. 90°C supply.

Grounding Instrucons

The grounding and bonding of the overall

system shall be done in accordance with

NEC Arcle 600 and local codes

INSTALLATION AND SERVICE INSTRUCTIONS

SML-106/706/707/708 LED Wallpack

TEMPLATE

GR

GR

GND

A

A

A

C

B

31/4" OCT.BOX

4" OCT. BOX

D

D

D

TROUBLE ING CHECKLIST: If the light does not work.

Figure 2

Figure 1

Black

Line

White

Neutral

Green

Ground

FIXTURE

Page is loading ...

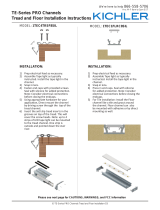

-

1

1

-

2

2

-

3

3

-

4

4

Kichler Lighting 16232AZT40 User manual

- Type

- User manual

- This manual is also suitable for

Ask a question and I''ll find the answer in the document

Finding information in a document is now easier with AI

in other languages

Related papers

-

Kichler Lighting 16236AZT30 User manual

Kichler Lighting 16236AZT30 User manual

-

Kichler Lighting 6UCSK30WHT User manual

-

Kichler Lighting 8TD24V090BKT User manual

Kichler Lighting 8TD24V090BKT User manual

-

Kichler Lighting 44248WHLED30 User manual

Kichler Lighting 44248WHLED30 User manual

-

Kichler Lighting 44249NILED30 User manual

Kichler Lighting 44249NILED30 User manual

-

Kichler Lighting 1TEC1FLRC8SIL User manual

Kichler Lighting 1TEC1FLRC8SIL User manual

-

Kichler Lighting 85049CH User manual

Kichler Lighting 85049CH User manual

-

Kichler Lighting 85054CH User manual

Kichler Lighting 85054CH User manual

-

Kichler Lighting 85081CH User manual

Kichler Lighting 85081CH User manual

-

Kichler Lighting 85068PN User manual

Kichler Lighting 85068PN User manual

Other documents

-

Eurofase 23250-017 Installation guide

-

Wayfair Canada LED Flush Mount Light User manual

-

HOWARD LIGHTING MWP2 Installation guide

-

Eurofase 26078-014 Installation guide

-

BARRON MRW Series Mini Polycarbonate Installation guide

BARRON MRW Series Mini Polycarbonate Installation guide

-

Sunco Lighting LED Vapor Tight Jelly Jars User manual

-

Eurofase 23251-014 Installation guide

-

GE FM Series Installation guide

-

Stonco Tall wall pack LED Install Instructions