WaterWay PD11006 Operating instructions

- Type

- Operating instructions

This manual is also suitable for

WaterWay PD11006 is a 48-frame center and side discharge pump designed for use with permanently installed pools, hot tubs, and spas. It features a powerful motor that can handle a variety of flow rates and pressures, making it ideal for a wide range of applications. The pump is also self-priming, so it can be used to remove water from below the water level. Additionally, the PD11006 is equipped with a thermal protector to prevent overheating, and it is backed by a one-year warranty.

WaterWay PD11006 is a 48-frame center and side discharge pump designed for use with permanently installed pools, hot tubs, and spas. It features a powerful motor that can handle a variety of flow rates and pressures, making it ideal for a wide range of applications. The pump is also self-priming, so it can be used to remove water from below the water level. Additionally, the PD11006 is equipped with a thermal protector to prevent overheating, and it is backed by a one-year warranty.

-

1

1

-

2

2

WaterWay PD11006 Operating instructions

- Type

- Operating instructions

- This manual is also suitable for

WaterWay PD11006 is a 48-frame center and side discharge pump designed for use with permanently installed pools, hot tubs, and spas. It features a powerful motor that can handle a variety of flow rates and pressures, making it ideal for a wide range of applications. The pump is also self-priming, so it can be used to remove water from below the water level. Additionally, the PD11006 is equipped with a thermal protector to prevent overheating, and it is backed by a one-year warranty.

Ask a question and I''ll find the answer in the document

Finding information in a document is now easier with AI

Related papers

-

WaterWay 810-0231 User manual

WaterWay 810-0231 User manual

-

WaterWay 3J10070-1E User manual

-

WaterWay 810-0190 User manual

WaterWay 810-0190 User manual

-

WaterWay 810-0176 User manual

WaterWay 810-0176 User manual

-

WaterWay 810-0187 User manual

WaterWay 810-0187 User manual

-

WaterWay 810-0270 User manual

WaterWay 810-0270 User manual

-

WaterWay 810-0139 User manual

WaterWay 810-0139 User manual

-

WaterWay 810-0216 User manual

WaterWay 810-0216 User manual

-

WaterWay SMF120 Owner's manual

WaterWay SMF120 Owner's manual

-

WaterWay 48 Frame Power Defender Executive User manual

WaterWay 48 Frame Power Defender Executive User manual

Other documents

-

Swim'n Play 4ft User manual

Swim'n Play 4ft User manual

-

Swim'n Play 4ft User manual

Swim'n Play 4ft User manual

-

Addendum Ultimate Pools Installation guide

-

Maytronics Supreme M4 Assembly Instructions Manual

-

Trane CVHH Installation, Operation and Maintenance Manual

-

Maytronics Supreme M3 User manual

-

Jandy AquaLink RS Troubleshooting Manual

-

Holden VK Owner's manual

Holden VK Owner's manual

-

Sea Ray 1990 310 EXPRESS CRUISER Owner's manual

-

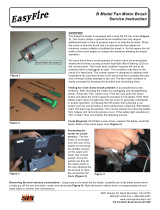

Sierra Products B Model User manual

Sierra Products B Model User manual