138

PT-36 Repair & Accessories Kit ...................................................................................0558005221

SECTION 2 DESCRIPTION

2.4.1 PT-36 Torch Consumable Kits

2.4 Optional Accessories:

Test Flow Meter - This valuable troubleshooting tool allows measurement of the ac-

tual plasma gas ow through the torch ...............................................................................21317

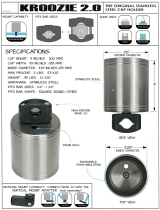

Bubble Muer - When used in conjunction with a water pump recirculating water

from the table and by using compressed air, this device creates a bubble of air which

enables a PT-36 Plasmarc Cutting Torch to be used underwater with slight sacrice

of cut quality. This system also permits operation above water as the ow of water

through the muer reduces fume, noise, and arc U.V. Radiation).

(for installation/operation instructions see manual 0558006722) ............................. 37439

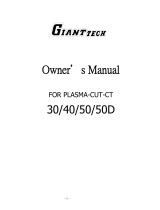

Air Curtain - This device when supplied with compressed air is used to improve the

performance of the PT-36 Plasmarc Cutting Torch when cutting underwater. The de-

vice mounts onto the torch and produces a curtain of air. This allows the plasma arc to

operate in a relatively dry zone, even though the torch has been submerged to reduce

noise, fume, and arc radiation. To be used in underwater applications only.

(for installation/operation instructions see manual 0558006404) .............................37440

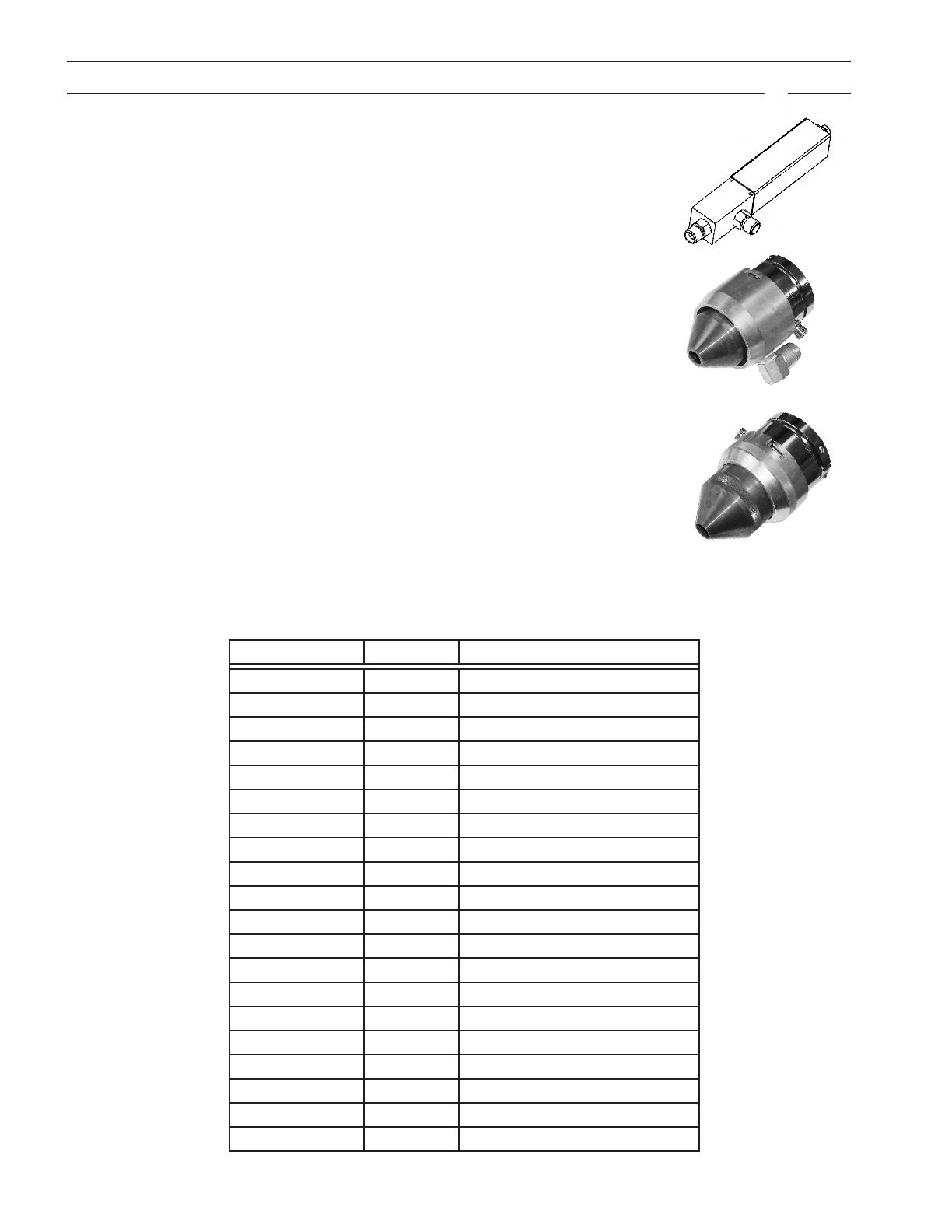

Part Number Quantity Description

0558003804 1 Torch Body PT-36 w/O-rings

996528 10 O-ring 1.614 ID x .070

0558002533 2 Bae, 4 Hole x .032

0558001625 2 Bae, 8 Hole x .047

0558002534 1 Bae, 4 x .032 Reverse

0558002530 1 Bae, 8 x .047 Reverse

0558005457 1 Bae, 4 Hole x .022

0558003924 3 Electrode Holder PT-36 w/O-ring

86W99 10 O-ring .364 ID x .070

37082 2 Nozzle Retaining Cup, Standard

21796 1 Shield Gas Diuser, Low Current

21944 5 Shield Gas Diuser, Standard

22496 1 Shield Gas Diuser, Reverse

37081 2 Shield Retainer, Standard

0558003858 2 Contact Ring w/screw

37073 6 Screw, Contact Ring

93750010 2 Hex Key Wrench .109"

996568 1 Nut Driver 7/16" (Electrode tool)

0558003918 1 Electrode Holder Tool PT-36

77500101 1 Silicon Grease DC-111 5.3oz