Page is loading ...

Jetline Engineering, 15 Goodyear Street, Irvine, CA 92618

Telephone: (949) 951-1515 • Fax: (949) 951-9237

April 2005

Firmware Version 2.1

IMPORTANT

Read this manual carefully before installing,

commissioning or operating this product.

OPERATION MANUAL

for 9640

Microprocessor

Controller

OM-9640-04-2005

9640 Microprocessor Controller

- 2 -

9640 Microprocessor Controller

- 3 -

LIMITED WARRANTY

Jetline Engineering, of Irvine, California, U.S.A., warrants all new equipment to be free from defects

in material and workmanship for the period of one (1) year, provided that the equipment is installed

and operated according to instructions.

Jetline Engineering’s obligation under this warranty is expressly limited to replacing or repairing

any defective part or correcting any manufacturing defect without charge during the warranty period,

if Jetline’s inspection conrms the existence of such defects. Jetline’s option of repair or replacement

will be F.O.B. factory at Irvine, California, and therefore no compensation for transportation costs of

any kind will be allowed.

The warranty period begins on the date of sale to the original-purchase user of the equipment.

Jetline Engineering will not be liable for any loss or consequential damage or expense accruing

directly or indirectly from the use of equipment covered by this warranty.

This warranty supersedes all previous Jetline warranties and is exclusive with no other guaran-

tees or warranties expressed or implied.

9640 Microprocessor Controller

- 4 -

NOTICE

The installation, operation and maintenance guidelines set out in this manual will enable you to

maintain the equipment in peak condition and achieve maximum efciency with your welding opera-

tion. Please read these instructions carefully to become aware of every advantage.

CAUTION

Only experienced personnel familiar with

the operation and safe practice of welding

equipment should install and/or use

this equipment.

9640 Microprocessor Controller

- 5 -

Table of Contents

Section I Safety Precautions .............................................................................................................7

A. Arc Welding ..........................................................................................................7

B. Electric Shock .......................................................................................................7

C. Arc Rays ................................................................................................................8

D. Fumes and gases ...................................................................................................8

E. Cylinders ...............................................................................................................8

F. Welding .................................................................................................................9

G. Moving Parts .........................................................................................................9

H. EMF Information ..................................................................................................9

I. Principal Safety Standards ..................................................................................10

Section II Introduction .....................................................................................................................11

Section III Specications ..................................................................................................................12

Section IV Description ......................................................................................................................13

Section V Controls ...........................................................................................................................14

Section VI Modes of Operation ........................................................................................................15

A. Operator Mode ....................................................................................................15

B. Set-up Mode ........................................................................................................21

C. Calibration Mode ................................................................................................24

Section VII Operational Sequence .....................................................................................................29

Section VIII Mechanical Installation ...................................................................................................30

Section IX Electrical Installation ......................................................................................................31

A. Input Power .........................................................................................................31

B. Output Connections ............................................................................................31

C. Interconnections ..................................................................................................34

Section X Maintenance ....................................................................................................................38

A. Calibration ...........................................................................................................38

B. Regular Maintenance ..........................................................................................40

Section XI Parts List .........................................................................................................................41

Section XII PCB Descriptions ............................................................................................................46

Section XIII Electrical Diagrams and Screen Listings ........................................................................50

Index ...............................................................................................................................60

9640 Microprocessor Controller

- 6 -

9640 Microprocessor Controller

- 7 -

Section I.

Safety Precautions

CALIFORNIA PROPOSITION 65 WARNING

This product contains chemicals, including lead,

known to the state of California to cause cancer,

and birth defects or other reproductive harm.

Wash hands after use. §248224

A. Arc Welding

Arc Welding can be hazardous. Protect your-

self and others from possible serious injury or

death. Keep children away. Pacemaker wear-

ers keep away until consulting your doctor.

In welding, as in most jobs, exposure to certain

hazards occurs. Welding is safe when precau-

tions are taken. The safety information given

below is only a summary of the more complete

safety information that will be found in the

Safety Standards listed at the end of this section.

Read and follow all Safety Standards.

Have all installation, operation, maintenance

and repair work performed only by qualied

people.

B. Electric Shock

Touching live electrical parts can cause fatal

shocks or severe burns. The electrode and work

circuit is electrically live whenever the output is

on. The input power circuit and machine internal

circuits are also live when power is on. When

using mechanized wire feed, the wire, wire reel,

drive roll housing and all metal parts touching

the welding wire are electrically live. Incorrectly

installed or improperly grounded equipment is

a hazard.

1. Do not touch live electrical parts.

2.

Wear dry, hole-free insulating gloves and

appropriate body protection.

3. Disconnect input power before installing

or servicing this equipment. Lockout/ta-

gout input power according to OSHA 29

CFR 1910.147 (see Safety Standards).

4. Properly install and ground this equipment

according to the operation manual and

national, state and local codes.

5. Always verify the supply ground-check

and be sure that input power cord ground

wire is properly connected to ground

terminal in disconnect box or that cord

plug is connected to a properly grounded

receptacle outlet.

6. When making input connections, attach

proper grounding conductor rst - double-

check connections.

7.

Frequently inspect input power cord for

damage or bare wiring. Replace cord im-

mediately if damaged - bare wiring can

kill.

8. Turn off all equipment when not in use.

9.

If earth grounding of the workpiece is required,

ground it directly with a separate cable - do not

use work clamp or work cable.

10. Do not touch electrode if you are in con-

tact with the work, ground, or another

electrode from a different machine.

11. Use only well-maintained equipment.

Repair or replace damaged parts at once.

Maintain unit according to manual.

12. Wear a safety harness if working above

oor level.

13. Keep all panels and covers securely in

place.

14. Clamp work cable with good metal-to-

metal contact to workpiece or worktable

as near the weld as practical.

WARNING

9640 Microprocessor Controller

- 8 -

C. Arc Rays

Arc rays can burn eyes and skin; noise can

damage hearing; ying slag or sparks can injure

eyes.

Arc rays from the welding process produce

intense visible and invisible (ultraviolet and

infrared) rays that can burn eyes and skin. Noise

from some processes can damage hearing. Chip-

ping, grinding and weld cooling throw off pieces

of metal or slag.

1. Use approved ear plugs or ear muffs if noise

level is high.

2. Use a welding helmet tted with a proper

shade of lter to protect your face and eyes when

welding or watching.

3. Wear approved safety glasses with side

shields.

4. Use protective screens or barriers protect

others from ash and glare; warn others not to

watch the arc.

5. Wear protective clothing made from durable,

ame-resistant material (wool and leather) and

foot protection where necessary.

D. Fumes and Gases

Fumes and gases can be hazardous to your

health.

Welding produces fumes and gases. Breathing

these fumes and gases can be hazardous to your

health.

1. Keep your head out of the fumes. Do not

breathe the fumes.

2. If inside, ventilate the area and/or use exhaust

at the arc to remove welding fumes and gases.

3. If ventilation is poor, use an approved air-

supplied respirator.

4. Read the Material Safety Data Sheets

(MSDS) and the manufacturer’s instruction for

metals, consumables, coatings, cleaners, and

degreasers.

5. Work in a conned space only if it is well

ventilated, or while wearing an air-supplied

respirator. Always have a trained watch person

nearby.

6. Do not weld in locations near degreasing,

cleaning, or spraying operations. The heat and

rays of the arc can react with vapors to form

highly toxic and irritating gases.

7. Do not weld on coated metals, such as gal-

vanized, lead or cadmium plated steel, unless

the coating is removed from the weld area, the

area is well ventilated, and if necessary, while

wearing an air-supplied respirator. The coatings

and any metals containing these elements can

give off toxic fumes if welded.

E. Cylinders

Cylinders can explode if damaged.

Shielding gas cylinders contain gas under high

pressure. If damaged, a cylinder can explode.

Since gas cylinders are normally part of the

welding process, be sure to treat them care-

fully.

1. Protect compressed gas cylinders from exces-

sive heat, mechanical shocks, slag, open ames,

sparks, and arcs.

2. Install cylinders in an upright position by

securing to a stationary support or cylinder rack

to prevent falling or tipping.

9640 Microprocessor Controller

- 9 -

3. Keep cylinders away from any welding or

other electrical circuits.

4. Never weld on a pressurized cylinder - ex-

plosion will result.

5. Use only correct shielding gas cylinders,

regulators, hoses and ttings designed for the

specic application; maintain them and associ-

ated parts in good condition.

6. Turn face away from valve outlet when open-

ing cylinder valve.

7. Keep protective cap in place over valve

except when cylinder is in use or connected for

use.

8. Read and follow instructions on compressed

gas cylinders, associated equipment, and CGA

publication P-1 listed in Safety Standards.

F. Welding

Welding can cause re or explosion.

Welding on closed containers, such as tanks,

drums, or pipes, can cause them to blow up.

Sparks can y off from the welding arc. The

ying sparks, hot workpiece, and hot equipment

can cause res and burns. Accidental contact of

electrode to metal objects can cause sparks, ex-

plosion, overheating, or re. Check and be sure

the area is safe before doing any welding.

1. Protect yourself and others from ying sparks

and hot metal.

2. Do not weld where ying sparks can strike am-

mable material.

3. Remove all ammables within 35 ft. (10.7 m) of

the welding arc. If this is not possible, tightly cover

them with approved covers.

4. Be alert that welding sparks and hot materials

from welding can easily go through small cracks

and openings to adjacent areas.

5. Watch for re, and keep a re extinguisher

nearby.

6. Do not weld on closed containers such as

tanks, drums, or pipes, unless they are properly

prepared according to AWSF4.1 (see safety

Standards).

7. Connect work cable to the work as close to

the welding area as practical to prevent welding

current traveling long, possibly unknown paths

and causing electric shock and re hazards.

8. Wear oil-free protective garments such as

leather gloves, heavy shirt, cufess trousers,

high shoes, and a cap.

G. Moving Parts

Moving parts, such as fans, rotors, and belts can

cut ngers and hands and catch loose clothing.

1. Keep all doors, panels, covers, and guards

closed and securely in place.

2. Have only qualied people remove guards

or covers for maintenance and troubleshooting

as necessary.

H. EMF Information

Considerations About Welding and the Ef-

fects of Low Frequency Electric and Magnetic

Fields

The following is a quotation from the General

Conclusions Section of the U.S. Congress, Of-

fice of Technology Assessment, Biological

Effects of Power Frequency Electric & Mag-

netic Fields - Background Paper, OTA-BP-E-53

(Washington, DC: U.S. Government Printing

Ofce, May 1989):

9640 Microprocessor Controller

- 10 -

“.... there is now a very large volume of scientic

ndings based on experiments at the cellular

level and from studies with animals and people

which clearly establish that low frequency

magnetic elds can interact with, and produce

changes in, biological systems. While most of

this work is of very high quality, the results are

complex. Current scientic understanding does

not yet allow us to interpret the evidence in a

single coherent framework. Even more frustrat-

ing, it does not yet allow us to draw denite

conclusions abut questions of possible risk or to

offer clear science-based advice on strategies to

minimize or avoid potential risks.”

To reduce magnetic elds in the work place, use

the following procedures:

1. Keep cables close together by twisting or

taping them.

2. Arrange cables to one side and away from

the operator.

3. Do not coil or drape cables around the

body.

4. Keep welding power source and cables as

far away as practical.

5. Connect work clamp to workpiece as close

to the weld as possible.

About Pacemakers:

The above procedures are among those also

normally recommended for pacemaker wearers.

Consult your doctor for complete information.

I. Principal Safety Standards

Reference as applicable

Safety in Welding and Cutting, ANSI Standard

Z49.1, from American Welding Society, 550

N.W. LeJeune Rd, Miami, FL 33126

Safety and Health Standards, OSHA 29 CFR

1910, from Superintendent of Documents, U.S.

Government Printing Ofce, Washington, D.C.

20402

National Electric Code, NFPA Standard 70 from

National Fire Protection Association, Battery-

march Park, Quincy, MA 02269

Recommended Safe Practices for the Prepara-

tion for Welding and Cutting of Containers That

Have Held Hazardous Substances, American

Welding Society Standard AWS F4.1, from

American Welding Society, 550 N.W. LeJeune

Rd, Miami, FL 33126

Safe Handling of Compressed Gases in Cylin-

ders, CGA Pamphlet P-1, from Compressed Gas

Association, 1235 Jefferson Davis Highway,

Suite 501, Arlington, VA 22202

Code for Safety in Welding and Cutting, CSA

Standard W117.2, from Canadian Standards

Association, Standards Sales, 178 Rexdale Bou-

levard, Rexdale, Ontario, Canada M9W 1R3

Sales Practices for Occupation and Educational

Eye and Face Protection, ANSI Standard Z87.1,

from American National Standards Institute,

1430 Broadway, New York, NY 10018

Cutting and Welding Processes, NFPA Standard

51B, from National Fire Protection Association,

Batterymarch Park, Quincy, MA 02269

9640 Microprocessor Controller

- 11 -

Section II.

Introduction

This detailed technical manual is meant to be

used in conjunction with the 9640 Quick Start

manual and the manual for the circumferential

welding system which you have purchased. The

Quick Start manual is written for the operator

and deals only with the routine operation of

the control. This technical manual provides

details of the set up and calibration procedures

for the control as well as providing information

about the interfacing of the system with other

9600 series controls and ancillary controls. It

also provides troubleshooting and maintenance

information.

The 9640 microprocessor controller has been

developed to provide high quality, precision

control of all Jetline circumferential welding

ssytems. The quality design and workmanship

of this control will provide many years of de-

pendable service. Its modern technology will

help to provide you with top quality repeatable

weld results. The 9640 is one of a series of

microprocessor controls, all of which have the

same hardware design. Each 9600 series control

is rendered unique by its own custom designed

rmware to facilitate the set up and operation

of the control.

The 9640 control is a microprocessor based

control designed and built to provide low cost,

accurate, repeatable control of the drive motor.

It is available in two versions:

9640

This control includes a motor controller and

can therefore be connected directly to the

rotation drive motor. It is used for motors

up to ½ HP of the type used on Jetline stan-

dard circumferential systems. It provides

rotary travel speed accuracy levels suitable

for most conventional applications

.

9640-0 This control does not include a motor

controller. Instead, it provides a 0 to

+10VDC enable contact which can

be used to control a precision motor

control module and a precision motor

or a module for a higher horsepower

motor . With the precision module and

motor, the unit can be used for the most

demanding applications where the

ultimate in accuracy and consistency

are demanded.

The system has three modes of operation. Please

turn to the indicated page to obtain more details

of these modes.

Operator Mode:

This is the mode used by the welding operator

to run the unit. It permits travel speed, start and

stop delays and weld time to be adjusted.

Turn to page 15

Setup Mode:

This mode is used during the setting up of the

unit. It permits the setting of the jog speeds, arc

wait and home sequence modes.

Turn to page 21

Calibration Mode:

In this mode, the closed loop can be turned on

and off, the unit can be set for inch or metric

units and the calibration can be checked and

set.

Turn to page 24

9640 Microprocessor Controller

- 12 -

Section III.

Specications

Applications

For use with circumferential welding systems:

9640 Used for standard systems

- Benchmaster

(Replaces standard control)

- CWP (Standard accuracy)

- CWB2 and CWB5

- CWL

- CW5 (Up to ½ HP motors)

- Third party systems

9640-0 Used for precision and large

motor applications

- Benchmaster

(Precision accuracy

models)

- CWP (Precision accuracy models)

- CW5 (Ove ½ HP motors)

- Third party systems

9640-R1 This option can be added to

allow remote control of the

travel speed.

Processor: Intel

®

80C196KC, 20 MHz.

Display: 2 x 20 Backlit LCD

Panel: Polycarbonate overlay

Input: 120/240VAC, 1 ph, 50/60 Hz

3/2 amps

Power cord: 6 ft. (1.8 m) long

Dimensions:

Weight: 16 lbs. (7 kg)

Height: 8” (200 mm)

Width: 10” (250 mm)

Depth: 6” (150 mm)

8”

(200mm)

8 ¾”

(222mm)

16” Dia

(8mm)

5

Connections:

Welding Power Supply

Outputs: Contactor, Emergency Stop

Inputs: Arc On, Pulse Lock-out, Down

slope

Second 9600 Control

Output: Emergency stop, Pulse Lockout

Input: Remote Run, Emergency Stop,

Pulse Lockout

Motor (90VDC Permanent Magnet)

Output: Motor voltage, Pneumatic Torch

Lift

Input: Tach-generator voltage, Limit

Switches

9640 Microprocessor Controller

- 13 -

Section IV.

Description

The 9640 control is a microprocessor-based

control designed for the control of circumfer-

ential welding systems. The 9640 is one of a

series of controls designed for ease-of-use and

for accurate control of various drive motors for

different weld applications.

The 9640 is packaged in a conveniently-sized

enclosure with Amphenol connectors. The en-

closure has four mounting holes to permit it to

be fastened to the welding xture or to a control

podium. The front panel is a membrane overlay

with a backlit LCD display and switches to con-

trol the setup and operation of the unit.

The 9640 control has been designed to be easy

to use. Its operation is made easier by the use of

the display which guides you through the setup

process and, during the welding sequence, tells

you what is happening.

DOWN

UP

TRAV SPEED 1.8rpm

ADJUST

The display has two lines of text, the upper line

is the primary one. This is the line that is used

to set the value of the parameter you are setting.

This is done by calling up the line for the param-

eter required and then turning the adjust knob to

increase or decrease the value. The second line

is used to display status messages (information)

about the progress of the weld sequence to let

you know what stage the process is in. Most of

these messages are normally only displayed after

the start push-button has been pressed.

TRAV SPEED 0.7rpm

SERIES 9600 CONTROL

POWER STOPSTART

REV FOR

UP

DOWN

EMERGENCY

STOP

ADJUST

9640 Microprocessor Controller

- 14 -

The push-button power switch is used

to provide primary power to the 9640

control. The rst press of the switch

turns on the control. The screen will

become active and display the start-

up message. A second press of this push-button

switches the control off.

These two touch pads are used to

scroll the display up and down. The

down touch pad scrolls down the dis-

play - this takes you through the vari-

ous control options in a logical order.

The up touch pad is used to go back through

the lines of the display options. In the standard

operating mode of the 9640 control, these touch

pads have no other purpose.

The adjustment knob is used to change

the value which is currently displayed.

You will note that the knob “incre-

ments”, each incremental movement

of the knob increases the value by

its smallest increment. If the knob is rotated

quickly, you will see that the numbers increase or

decrease faster. The knob can be used to preset

the speed before the motor starts or to change

the speed when the motor is running.

These two touch pads are used to

jog the travel in a reverse or for-

ward direction. When the touch

pad is pressed, travel will begin in the direction

selected and will continue as long as the pad is

pressed. When the touch pad is released, travel

will stop. In addition to the jog facility provided

by the touch pads, they are capable of providing

two more functions.

POWER

UP

DOWN

REV

FOR

Rapid Jog: This is achieved by pressing the

forward or reverse touch pad for a short time,

releasing it and then quickly pressing it again.

Travel will start and, after a short time, will

speed up to the “rapid” speed. Rapid travel will

continue until the touch pad is released.

Maintained Jog: This is achieved by first

pressing the forward or reverse touch pad and,

while still pressing this touch pad, pressing

and releasing the start button. The forward or

reverse switch can then be released. The travel

will rotate at rapid speed until it is stopped by

pressing the stop button. This feature is useful

for rotating the headstock through a considerable

distance to a desired position.

Depressing and releasing the start

push-button will start the weld se-

quence which will continue until

the stop or emergency stop button is

pressed. Pressing the start push-but-

ton while the forward or reverse touch pad is

pressed will initiate maintained, rapid speed

rotary travel.

Depressing and releasing the stop

push-button will stop the weld se-

quence.

The emergency stop push-button is a

large, red mushroom-headed switch

designed to stop all operations quickly

in the event of an emergency. When

pressed, the travel will be immediately

stopped and power will be removed from the

motor. To reactivate the system, the switch must

be reset by being pulled out. After reactivation,

travel must be restarted in the normal way using

the start button.

START

STOP

EMERGENCY

STOP

Section V.

Controls

ADJUST

9640 Microprocessor Controller

- 15 -

Section VI.

Modes of Operation

A. Operator Mode

This is the mode which is used by the operator

to run the circumferential xture. The system is

automatically set to this mode when the control

is switched on.

To set the conditions for operation, the operator

can scroll through the various screens and make

the appropriate changes. These changes will be

displayed on the top line of the display.

As the system is operating, various informa-

tion messages appear on the lower line of the

display.

Display Screens - Upper Line

Screen 1 WELCOME SCREEN

This screen appears automatically when the unit

is switched on and remains on the screen for ap-

proximately 3 seconds. It identies the model

of the control.

The next screen will appear automatically.

Screen 2 TRAVEL SPEED

When the second screen appears, it displays

the current level of travel speed. If this speed

is correct, the start button can be pressed to im-

mediately initiate the weld sequence. If a start

delay has been programmed, travel will start

after the start delay time has elapsed.

Jetline Engineering

Model 9640

TRAV SPEED 0.7rpm

Speed will be displayed in RPM (revolutions per

minute). If a part diameter has been specied

(see Screen 4), the speed will be displayed in

IPM (inches per minute) or CPM (centimeters

per minute). Selection of IPM or CPM is made

in the calibration mode (see Screen 37).

If it is desired to change the speed, this is done

by turning the adjust knob to increase or de-

crease the speed as necessary. As the change

is made, the number on the display changes

accordingly.

The travel speed can be adjusted from the mini-

mum to maximum value which has been set in

the calibration mode (see Screens 28 and 31).

Press the scroll down arrow to proceed to the

next screen.

Screen 3 TORCH LIFT

This screen permits you to manually operate

the torch lift. When the screen reads Out, the

torch lift will be in a retracted position prior to

the start of the weld sequence. The pneumatic

torch lift can be lowered by turning the adjust

knob to In. No other screen can be selected

until the adjust knob is turned to place the torch

in the Out position.

Press the scroll down arrow to proceed to the

next screen.

Screen 4 DIAMETER

This screen allows the diameter of the part being

welded to be specied. If it desired to change

the diameter, this is done by turning the adjust

knob to increase or decrease the value as neces-

sary. As the change is made, the number on the

display changes accordingly.

DIAMETER 5.60in

TORCH LIFT Out

9640 Microprocessor Controller

- 16 -

If the diameter is entered as a zero, the speed

display will always be in revolutions per minute

(RPM). When a diameter is entered, the speed

value is automatically changed to inches per

minute (IPM) or centimeters per minute (CPM).

The control carries out the necessary calcula-

tions of revolutions per minute to maintain the

correct surface speed.

The diameter can be adjusted from 0 to 999.99

inches (or centimeters).

Screen 5 START DELAY

This screen allows a start delay to be set by

turning the adjust knob to increase or decrease

its value. As the change is made, the number

on the display changes accordingly.

The start delay initiates when the “Arc On” sig-

nal has been received from the welding power

supply. If arc wait mode is Off, the start delay

initiates when the contactor signal is given to

the welding power supply (at the end of PTL

start delay time).

The start delay is used to start rotational travel

at the correct time in the weld start up sequence.

If the 9640 controlled welding xture is part of a

system and a power supply with current upslope

is being used, it is recommended to initiate

travel when the current has sloped up to about

50% of its weld value. This will ensure that the

weld pool is correctly established before travel

starts. If, for example, the total time for initial

current and upslope is set to two seconds on the

welding power supply, a travel start delay of ap-

proximately one second would be appropriate.

Try different start delay times for yourself.

The travel start delay can be set from 0 to 99.9

seconds.

Press the scroll down arrow to proceed to the

next screen.

Screen 6 STOP DELAY

This screen allows a stop delay to be set by turn-

ing the adjust knob to increase or decrease its

value. As the change is made, the number on

the display changes accordingly.

When the stop push-button is pressed (or when a

remote stop signal is received), travel will con-

tinue until the stop delay has timed out. After

the stop delay has elapsed, rotation will stop.

The stop delay time can be set from 0 to 99.9

seconds.

The stop delay is used to stop the travel at the

correct time in the weld sequence. If the 9640

controlled xture is part of a system and a power

supply with current downslope is being used, it is

recommended to stop the travel when the current

has sloped down to the nal current level. If,

for example, the total time for downslope is set

to 10 seconds, a travel stop delay of 10 seconds

would be appropriate. This will produce an ac-

ceptable weld taper and avoid a crater crack in

the end of the weld.

Press the scroll down arrow to proceed to the

next screen.

Screen 7 WELD TIMER

This screen allows the weld timer to be activated

or deactivated by turning the adjust knob to

select On or Off.

If the weld timer is set to On, the weld length

will be controlled by time. The weld time will

commence at the same time as the start delay

time. At the end of the weld time, the stop delay

will be initiated and a signal will be sent to the

power supply (if one is interconnected) to initiate

the downslope and nal weld sequence.

STOP DELAY 3.9sec

WELD TIMER On

START DELAY 2.8sec

9640 Microprocessor Controller

- 17 -

If the weld timer is set to Off, the weld length

will be controlled manually by pressing the stop

push-button, this will initiate the downslope and

stop delay time (if one has been programmed).

An alternative method of controlling the length

of the weld is by an external signal. The xture

could be tted with limit switches. If this is

the case, the switches can be used to dene an

end of travel position and can be used to send

a signal to the 9640 control to initiate the stop

sequence. An encoder controller could also be

interconnected.

Press the scroll down arrow to proceed to the

next screen.

If the weld timer has been set to On, the fol-

lowing screen will appear. If the weld time is

set to Off, the next screen will be Screen 9,

Pass Counter.

Screen 8 WELD TIME

This screen allows the length of the weld time to

be set by turning the adjust knob to increase or

decrease its value. As the change is made, the

number on the display changes acordingly.

The weld time can be set from 0 to 999.9 sec-

onds.

Press the scroll down arrow to proceed to the

next screen.

Screen 9 PASS COUNTER

This screen permits the number of desired weld

passes to be entered. This facility will only be

active if the weld timer is turned to Off and

the circumferential xture is tted with limit

switches.

The number of weld passes required should be

specied by turning the adjust knob to increase

or decrease the value. As the change is made, the

number on the display changes accordingly.

The number of passes can be set from 1 to 99.

Press the scroll down arrow to proceed to the

next screen.

Screen 10 TRAVEL SPEED (Locked)

This is the nal control screen and it is similar to

screen 2. However, with this screen displayed,

it is impossible to change to the travel speed

setting. This screen has been created so that any

accidental movement of the adjust knob cannot

inadvertently affect the travel speed setting.

To change the travel speed, press the scroll up

or down arrow to proceed to screen 2.

Display Screens - Lower Line

The second line of the display is reserved for

messages that inform the status of the system.

These messages fall into one of three catego-

ries:

• Messages that appear prior to welding.

• Messages that can appear at any time.

• Messages that appear during a weld se-

quence.

PRE-WELD MESSAGES

Speed Adjustment Locked

This message is displayed when the operation of

the adjust knob is locked out. When this mes-

sage is displayed, the adjust knob has no effect

and the travel speed cannot be altered.

TRAV SPEED 0.7rpm

Adjustment Locked

WELD TIME 86.5sec

PASS COUNTER 2

TRAV SPEED 0.7rpm

Adjustment Locked

9640 Microprocessor Controller

- 18 -

High Limit

This message will be displayed whenever the ad-

just knob is turned clockwise and the upper limit

of the parameter being adjusted has been reached.

The message remains on the screen until the value

is reduced below the limit.

This message also appears during welding if the

upper limit of speed is reached, in this case, the

message appears only as long as the adjust knob

is being turned clockwise.

Low Limit

This message is displayed whenever the adjust

knob is turned counterclockwise and the lower

limit of the parameter being adjusted has been

reached. The message will remain displayed on the

screen until the value of the parameter is increased

above the limit.

This message also appears during welding if the

lower limit of speed is reached, in this case, the

message appears only as long as the adjust knob

is being turned counterclockwise.

Jog forward

Whenever the forward jog touch pad is pressed,

the screen will display the message shown above.

Travel will proceed in a forward direction at the

pre-programmed forward jog speed setting (this

speed is set in the setup mode of operation of the

9640 control - see Screen 11).

Rotation will continue as long as the touch pad is

pressed. The message will remain on the screen

for as long as the travel is being jogged forward.

Jog reverse

Whenever the reverse jog touch pad is pressed,

the screen will display the message shown above.

Travel will proceed in a reverse direction at the

pre-programmed reverse jog speed setting (this

speed is set in the setup mode of operation of the

9640 control - see Screen 12).

Rotation will continue as long as the touch pad is

pressed. The message will remain on the screen for

as long as the travel is being jogged in reverse.

Rapid jog forward

When the forward jog touch pad is pressed, then

released and then quickly pressed again, after a

short period of time, rotation will speed up to the

pre-programmed rapid forward jog speed (this

speed is set in the setup mode of operation of the

9640 control - see Screen 13).

Rotation will continue at rapid speed as long as

the touch pad is pressed. The message will remain

on the screen as long as the xture is rotating at

this speed.

Rapid jog reverse

When the reverse jog touch pad is pressed, then

released and then quickly pressed again, after a

short period of time, rotation will speed up to the

pre-programmed rapid reverse jog speed (this

speed is set in the setup mode of operation of the

9640 control - see Screen 13).

Rotation will continue at rapid speed as long as

the touch pad is pressed. The message will remain

on the screen as long as the xture is rotating at

this speed.

TRAV SPEED 7.5rpm

Jog Reverse Rapid

TRAV SPEED 7.5rpm

Jog Forward Rapid

TRAV SPEED 0.2rpm

Cannot go any lower

TRAV SPEED 2.0rpm

Jog Reverse

TRAV SPEED 4.0rpm

Jog Forward

TRAV SPEED 10.0rpm

Cannot go any higher

9640 Microprocessor Controller

- 19 -

Maintained forward

When the forward jog touch pad is pressed and

held until the start button is pressed and released,

the xture will rotate forward at maximum speed

and will continue to do so until the stop button is

pressed.

This message remains on the screen as long as the

xture is rotating at maximum speed.

Maintained reverse

When the reverse jog touch pad is pressed and

held until the start button is pressed and released,

the xture will rotate in the reverse direction at

maximum speed and will continue to do so until

the stop button is pressed.

The message will remain on the screen as long as

the xture is rotating at maximum speed.

Jogging disabled

This message is displayed when a jog touch pad is

pressed while the system is in any programming

screen.

When the control is being set up (start or stop

delays are being set), or whenever the system is in

setup or calibration mode, travel is disabled.

Jogging is only possible when the control is

displaying the travel speed screen (Screens 2 or

10).

ANYTIME MESSAGES

Emergency stop

If the emergency stop button is pressed, the above

message will be displayed. This can occur at any

time and the message will remain on the screen

until after the emergency stop button is reset by

pulling out the knob.

DURING WELD MESSAGES

PTL start delay

This message will be displayed after the start but-

ton has been pressed (or a remote start signal has

been received) and during the time that the PTL

start delay is timing out. Time counts down from

the pre-programmed value to zero.

This message will only be displayed if the auto-

matic torch lift facility is set to On in the set-up

mode (see Screen 18)

Waiting for arc on

At the end of the PTL start delay time, the 9640

sends a signal to the welding power supply to initi-

ate the arc. If the arc wait mode (Screen 14) has

been set to On, this screen will be displayed until

the control has received a signal from the power

supply indicating that the arc has been correctly

established. This avoids the weld sequence start-

ing before the arc is fully established.

Start delay

The travel start delay will be initiated and the

above message will be displayed as follows:

When the start signal (local or remote) is given

(if Auto torch lift is Off or PTL start delay time

is 0)

At the end of the PTL start delay time (if arc wait

mode is Off and Auto torch lift is On)

TRAV SPEED 0.7rpm

PTL Start Delay 3.6sec

TRAV SPEED 0.7rpm

Start Delay 2.6sec

TRAV SPEED 0.7rpm

Waiting for arc on

TRAV SPEED 10.0rpm

Maintained Forward

STOP DELAY 3.9sec

Jogging Disabled

TRAV SPEED 0.0rpm

Maintained Reverse

TRAV SPEED 0.0rpm

Emergency Stop On

9640 Microprocessor Controller

- 20 -

After the arc has been established (if arc wait

mode is set to On).

Time counts down from the pre-programmed

value (as set in Screen 5) to zero. At the end

of this time, the carriage starts traveling at the

pre-programmed travel speed.

Sensing delay

After any of the above delays have timed out,

and following the initiation of the travel, this

message will be displayed (providing that

Closed Loop Mode is On, Screen 24).

The message will continue to be displayed dur-

ing the time that the closed loop sensing delay

is timing out. Time counts down from the

pre-programmed value (as set in Screen 26) to

zero. During this time, the travel speed runs in

open loop.

Weld Time

If the Weld Timer is set to On (screen 7) and

after the arc has been established, the weld time

is started. The weld time is displayed and counts

down from the pre-programmed value (as set in

Screen 8) to zero.

If the Weld Timer is set to Off (screen 7), the

weld time will be displayed when the arc is

initiated and will count up to indicate the weld

elapsed time.

Stop delay

The above message will be displayed after the

stop push-button is pressed, the weld timer has

timed out or a remote stop signal has been given

to the 9640 control. Time counts down from

the pre-programmed value to zero. During this

time the travel continues at the pre-programmed

travel speed. At the end of the stop delay time,

rotation stops.

PTL stop delay

This message will be displayed after the travel

has stopped and during the time that the PTL stop

delay is timing out. Time counts down from the

pre-programmed value to zero.

This message appears when the welding system

is tted with a solenoid-operated pneumatic

torch lift and Screen 18 is switched to On.

Home delay

This message will be displayed after the PTL

stop delay time has elapsed, or if there is no PTL

stop delay, at the end of the stop delay time.

Time counts down from the pre-programmed

value to zero.

At the end of the Home Delay time, the xture

will rotate at maximum speed in reverse until

the home limit switch is encountered and will

then stop.

Returning Home

This message will be displayed whenever the

xture is rotating back to the home position at

the end of the weld.

At Forward Limit

This message will be displayed whenever the

forward jog touch pad is pressed and the xture

is at the forward limit. Under these circum-

TRAV SPEED 0.7rpm

Sensing Delay 0.8sec

TRAV SPEED 0.7rpm

Weld Time 142.3sec

TRAV SPEED 0.7rpm

Stop Delay 5.7sec

TRAV SPEED 0.7rpm

Home Delay 1.4sec

TRAV SPEED 10.0rpm

Returning Home

TRAV SPEED 0.7rpm

At Forward Limit

TRAV SPEED 0.7rpm

PTL Stop Delay 2.9sec

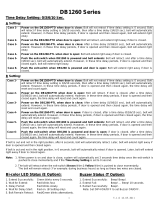

/