Page is loading ...

RKI Instruments, Inc.

Data Cal 2000

Operator’s Manual

Part Number: 71-0097RK

Revision: D

Released: 11/3/11

Warranty

Warranty

RKI Instruments, Inc. warrants gas alarm equipment sold by us to be free

from defects in materials and workmanship, and performance for a

period of one year from date of shipment from RKI Instruments, Inc. Any

parts found defective within that period will be repaired or replaced, at our

option, free of charge. This warranty does not apply to those items which

by their nature are subject to deterioration or consumption in normal

service, and which must be cleaned, repaired, or replaced on a routine

basis. Examples of such items are:

Warranty is voided by abuse including mechanical damage, alteration,

rough handling, or repairs procedures not in accordance with the

instruction manual. This warranty indicates the full extent of our liability,

and we are not responsible for removal or replacement costs, local repair

costs, transportation costs, or contingent expenses incurred without our

prior approval.

T

HIS WARRANTY IS EXPRESSLY IN LIEU OF ANY AND ALL OTHER

WARRANTIES AND REPRESENTATIONS, EXPRESSED OR IMPLIED, AND

ALL OTHER OBLIGATIONS OR LIABILITIES ON THE PART OF RKI

I

NSTRUMENTS, INC. INCLUDING BUT NOT LIMITED TO THE WARRANTY

OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. IN

NO EVENT SHALL RKI INSTRUMENTS, INC. BE LIABLE FOR INDIRECT,

INCIDENTAL, OR CONSEQUENTIAL LOSS OR DAMAGE OF ANY KIND

CONNECTED WITH THE USE OF ITS PRODUCTS OR FAILURE OF ITS

PRODUCTS TO FUNCTION OR OPERATE PROPERLY.

This warranty covers instruments and parts sold to users only by

authorized distributors, dealers, and representatives as appointed by RKI

Instruments, Inc.

We do not assume indemnification for any accident or damage caused

by the operation of this gas monitor and our warranty is limited to

replacement of parts or our complete goods.

Absorbent cartridges Batteries

Pump diaphragms and

valves

Filter elements

Fuses

Table of Contents

Table of Contents

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

System Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Docking Station . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

DM-2001, DM-2003, and DM-2009 Docking Modules . . . . . . . . . . . 7

Communication Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Power Cord . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4-Gas Mix Calibration Cylinder . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

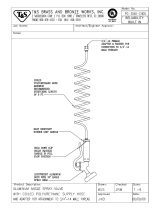

Demand Flow Regulator & 3 ft. Tube . . . . . . . . . . . . . . . . . . . . . . . 13

10 ft. Exhaust Tube . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Data Cal 2000 Hardware Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Setting the Docking Module Configuration Switches . . . . . . . . . . . 14

Mechanical Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Cable Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Tubing Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Installing the Data Cal 2000 Docking Station Software . . . . . . . . . . . 21

Launching the Data Cal 2000 Software . . . . . . . . . . . . . . . . . . . . . . . . 23

Overview of the Data Cal 2000 Software . . . . . . . . . . . . . . . . . . . . . . . 24

Data Cal 2000 Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Main Program Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Table of Contents

Setting Up the Data Cal 2000 Software . . . . . . . . . . . . . . . . . . . . . . . . 27

Setting Up the Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Viewing the Pre-Defined Cylinders . . . . . . . . . . . . . . . . . . . . . . . . . 32

Adding and Updating Cylinders . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Setting Up the Solenoids . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Connecting Instruments to the Data Cal 2000 . . . . . . . . . . . . . . . . . . . 38

Bump Testing Instruments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Calibrating Instruments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Deleting Instruments From the Main Window . . . . . . . . . . . . . . . . . . . 48

Charging Instruments With The Data Cal 2000 . . . . . . . . . . . . . . . . . . 48

Logs Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Viewing Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Deleting Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Alarm Trend Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Calibration Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Event Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Interval Trend Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Memo Feature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Bump Test Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Instrument/Module Function Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Open Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Edit Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Edit Function, Memo Entry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Download Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Clear Logs Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Reset Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Table of Contents

Power Off Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Configuration Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Parameter Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Database Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Sensor Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Password Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Optimizing the Database . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Spare Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

CAUTION: Read and understand this manual before using the

Data Cal 2000. Also read and understand the

Model GX-2001, Model GX-2003, and Model GX-

2009 Operator’s Manuals included with each

instrument.

1 • Introduction

Introduction

The Data Cal 2000 Docking Station is a comprehensive and reliable

system that provides charging, data downloading, configuration updating,

calibration, and bump testing for the GX-2001, GX-2003, and GX-2009

gas detectors. It is designed for use with a Windows-based PC and the

Data Cal 2000 Docking Station Software.

The purpose of this manual is to explain how to set up and use the Data

Cal 2000 Docking Station and the Data Cal 2000 Docking Station

Software. You will learn how to:

• install and launch the software

• install the hardware

• set up the Data Cal 2000 software and hardware

• download data from the GX-2001, GX-2003, and GX-2009

• perform a bump test

• perform a calibration

• view, print, and save data

• change instrument parameters

• change data logging parameters

• use the Data Cal 2000 to charge an instrument

CAUTION: The GX-2001, GX-2003, and GX-2009 detect

oxygen deficiency and elevated levels of oxygen,

combustible gases, carbon monoxide, and

hydrogen sulfide, all of which can be dangerous or

life threatening. When using the GX-2001,

GX-2003, and GX-2009 you must follow the

instructions and warnings in the Operator’s Manual

for each instrument to assure proper and safe

operation of the unit and to minimize the risk of

personal injury.

System Requirements • 2

CAUTION: The operator of this instrument is advised that if the

equipment is used in a manner not specified in this

manual, the protection provided by the equipment

may be impaired.

System Requirements

To use the Data Cal 2000 and the Data Cal 2000 Docking Station

Software, your personal computer must meet the following requirements:

• Operating Systems: Windows

®

98, Windows

®

ME, Windows

®

2000, Windows NT

®

4.0, or Windows

®

XP.

• Processor: IBM

®

compatible PC running Pentium

®

2 processor or

equivalent minimum

• Memory: 32 MB RAM minimum

• Hard Disk Space: 32 MB minimum

• CD-ROM Drive

3 • Specifications

Specifications

Table 1: Data Cal 2000 Specifications

Input Power 115 VAC, 50/60 Hz

Environmental

Conditions

• For Indoor Use Only

• -10° C to 40° C, below 80% Relative Humidity, Non-

Condensing

Number of

Docking Mod-

ules

Up to 10 docking modules

Applicable

Instruments

• GX-2001

• GX-2003

• GX-2009

Number of Cal-

ibration Gas

Cylinders

Up to 5 calibration gas cylinders and one zero air cylin-

der

Description • 4

Description

The Data Cal 2000 consists of the following components:

• Data Cal 2000 Docking Station

• DM-2001 Docking Module for GX-2001

• DM-2003 Docking Module for GX-2003

• DM-2009 Docking Module for GX-2009

• RS-232C serial communication cable for connection of the docking

station to a computer

• RS-485 serial communication cables for connection of the docking

station to a docking module and for daisy chain connection of

additional docking modules to each other

• Power cord

• A 4-gas mix calibration cylinder (optional)

• Demand flow regulator with 3 foot tube (optional)

• 10 ft. exhaust tube

• A Windows based PC compatible computer (user supplied) with the

Data Cal 2000 Docking Station Software loaded

The docking station is designed to be used on a table top with the DM-

2001, DM-2003, and/or DM-2009 docking modules extending to the right

of the docking station as shown in Figure 1 below. Any combination of

docking modules may be used up to a total of 10. If a laptop computer is

used, it may be placed on top of the docking station if desired.

Docking Station

Up to 10docking modules may be installed in any

combination of DM-2001's,DM-2003's, and DM-2009's.

DM-2009

DM-2001

DM-2003

POWER FAULT

Data Cal 2000

Figure 1: Data Cal 2000

5 • Description

Docking Station

The docking station manages the calibration, bump test, and information

exchange functions of the Data Cal 2000 once they have been initiated

through the software.The status LED’s are on the front panel. The power

switch and hose barb fittings for connection of calibration gas cylinders

and routing of calibration gas to the docking modules are located on the

back panel. Cable connectors for connecting the docking station to a

computer and to docking modules are also located on the back panel.

Three recesses are located on the right side of the docking station that

mate with tabs on the docking modules. These recesses allow table top

assembly of a docking module to the docking station.

Front Panel

The two status LED’s are located on the front panel in the upper left

corner. The left LED is green and is the POWER LED. It is on when the

docking station is turned on. The right LED is red and is the FAULT LED.

It is on when there is a communication error or some hardware problem

that affects communication between the docking station and the

computer or the docking station and the modules.

Docking Station

D

ata Cal 2000

POWER

FAULT

Figure 2: Data Cal 2000 Front Panel

Description • 6

Back Panel

The power switch is a rocker switch and is located in the upper right

corner of the back panel. The docking station is on when the upper half of

the switch, the “1” position, is pressed in, and off when the lower half of

the switch, the “0” position, is pressed in.

All the gas fittings are located on the back panel. They are hose barb

type fittings that accept 3/16” inner diameter (ID) tubing. At the bottom

left of the back panel is the GAS OUT fitting. This fitting is used to route

calibration gas from the docking station to the docking modules. To the

right of the GAS OUT fitting is the AIR fitting. This fitting is used to draw

fresh air while the Data Cal 2000 is performing a zeroing operation during

bump testing or calibration.

To the right of the AIR fitting are five additional fittings of the same type

labeled GAS1, GAS2, GAS3, GAS4, and GAS5. These fittings are used

to connect up to 5 calibration gas cylinders that are defined using the

software. Usually, only one or two calibration cylinders will be needed.

Typical gas cylinders needed are a 4-gas mix of %LEL CH

4

/O

2

/CO/H

2

S

or 3-gas mix of %LEL CH

4

/O

2

/CO and a %volume cylinder of CH4 (if the

%volume CH

4

TC sensor is installed on a GX-2003).

There are three connectors on the back panel. A DB-15 (15 pin)

receptacle in the upper left corner is used to connect the docking station

to the docking modules. It is labeled MODULE. A DB-9 (9 pin) plug to the

right of the MODULE connector is used to connect the docking station to

the serial port of a computer. It is labeled PC(RS-232C). A 3-pin

MODULE

PC(RS-232C)

GAS OUT

AIR GAS1 GAS2 GAS3 GAS4 GAS5

FUSE(5A)

AC IN

AC100V-AC240V

POWER

Fan Grill

Figure 3: Data Cal 2000 Back Panel

7 • Description

recessed plug in the lower right corner of the panel is used to connect an

AC line cord. It is labeled AC IN.

A fuse holder is located to the left of the AC IN connector. It is labeled

FUSE(5A). The fuse holder consists of a panel mounting socket and a

quarter turn fuse holder. The fuse is a 5 amp, 5 mm x 20 mm fuse.

A cooling fan is located inside the docking station on the right side above

the fuse holder. It draws warm air out of the docking station to prevent the

internal electronic components from overheating.

DM-2001, DM-2003, and DM-2009 Docking Modules

The docking modules are used to facilitate communication between a

GX-2001, GX-2003, or GX-2009 and the docking station and computer

and to apply fresh air and calibration gas to an instrument during a bump

test or calibration. They are also used to charge an instrument’s

rechargeable battery pack if one is installed. Two multi color LED’s, one

on the left front and one on the right front of a module, indicate the

operation status of the docking module.

Each module has three connection tabs on the left side near the bottom

of the module and three connection recesses on the right side near the

bottom of the module. The tabs from one module can be pushed into the

recesses on the docking station or on another module to mechanically

connect the module to the docking station or to another module. If

multiple modules are used, one of them will be connected to the docking

station and then each additional module will be connected to the end

module as shown below in Figure 4.

Connect any DM-2001s and DM-2003s first and then connect any

DM-2009s. This will allow the exhaust lines for the DM-2001 and

DM-2003 to easily be daisy-chained together and routed to an exhaust

area with a single exhaust tube. Each DM-2009 must have a dedicated

exhaust tube which can be easily routed away without interfering in the

daisy-chain configuration of the DM-2001s and DM-2003s.

Docking Station

D

ata Cal 2000

POWER

FAULT

Figure 4: Assembling Docking Modules to Data Cal 2000

Description • 8

Two DB-15 connectors on the back of each module allow connection to

other docking modules or directly to the docking station.

Two hose barb fittings that accept 3/16” ID tubing are located in the upper

left corner of the back of each module and are each labeled CAL. GAS.

They allow sample gas connection to the module and from the module to

another module. The right fitting (as viewed from the back) is for

connection to the GAS OUT fitting on the docking station or to the left

fitting of the previous module in the system. The left fitting is for

connection to the next docking module in the system or, if the docking

Calibration Gas

Fittings

Exhaust Fittings

Connector for

Cable from Data

Cal 2000 or Othe

r

Docking Module

ID Switch

Terminator Switch

Connector for

Cable From Other

Docking Module

Figure 5: Back of DM-2001 and DM-2003 Docking Module

Exhaust

Fitting

ID Switch

Calibration Gas

Fittings

T

erminator Switch

Connector for

Cable From

Other Docking

Module

Connector for

Cable From

Data Cal 2000

or Other

Docking Modul

e

Figure 6: Back of DM-2009 Docking Module

9 • Description

module is the last one in the flow system, it is plugged with a push-on

plug that is supplied with the docking station.

A two port exhaust routing fitting is located in the upper right corner of the

back of the DM-2001 and DM-2003 modules. It allows routing of the

exhausted calibration gas from all DM-2001 or DM-2003 modules to the

last module so the exhaust gas can be safely routed to a convenient

exhaust location. The DM-2009 module has only one exhaust fitting.

Exhaust from the DM-2009 may only be routed to an exhaust location

and cannot be routed to another module.

NOTE: Even though the exhaust gas can be routed to an area

to be safely dispersed, the docking station should still be

installed in a well ventilated area.

All three types of modules also include a 10-position rotary switch, the ID

switch, above the right DB-15 connector, and a 2-position slide switch,

the terminator switch, above the left DB-15 connector. The ID switch sets

the ID number of a module from 0 - 9, for a maximum of 10 module IDs.

The terminator switch is set to the down position if the module is the last

module in the system and to the up position for any other module.

Description • 10

DM-2001 Docking Module

The GX-2001 fits into the DM-2001 module as shown in Figure 7 below.

The module includes a snap-on sample adapter for the GX-2001. The

exhaust port of the adapter is connected to a port on the front left of the

module by a short tube and the adapter’s inlet port is connected to a port

on the top rear of the module by a coiled tube. The sample adapter snaps

onto the sensor side of the GX-2001 before the GX-2001 is installed into

the module.

DM-2001 DM-2001

O

2

CO

HC

H

2

S

Figure 7: DM-2001 Docking Module

11 • Description

DM-2003 Docking Module

The GX-2003 fits into the module as shown in Figure 8 below. A coiled

black tube with a plastic push-on fitting resides in a recess in the left rear

corner of the top of the module. The coiled tube routes gas to the

GX-2003 and extends to connect to the GX-2003’s inlet fitting. A straight

green tube comes out of the top of the module to the right of the coiled

tube and also has a plastic push-on fitting on its end. The fitting on this

tube is pushed onto the GX-2003 exhaust fitting and routes gas away

from the GX-2003.

Front ViewTop View

AIR

DISPLAY

(ADJ)

RESET

SILENCE

(SHIFT)

To GX-2003 Exhaust Fitting

To GX-2003 Inlet Fitting

DM-2003

Figure 8: DM-2003 Docking Module

Description • 12

DM-2009 Docking Module

The GX-2009 fits into the module as shown in Figure 9 below.

Communication Cables

The number of communication cables needed depends on how many

docking modules are used. Every system has at least two cables, an RS-

232C cable with a DB-9 receptacle on each end (docking station cable

supplied with docking station) to connect the docking station to a

computer and an RS-485 cable with a DB-15 plug on each end (docking

module cable supplied with docking module) to connect the docking

station to the first docking module. For every additional docking module,

an additional RS-485 cable is needed to connect the additional module to

the previous module.

POWER

CHARGE

IR Port

CAL.

DM-2009 DM-2009

CAL.

POWER

CHAR GE

Instrument Retaining

Tab

Instrument Cradle

Charging Contacts

Figure 9: DM-2009 Docking Module

13 • Data Cal 2000 Hardware Setup

Power Cord

A three-pronged AC power cord is provided with the Data Cal 2000. One

end connects to a standard AC wall outlet and the other end plugs into

the AC power socket on the back of the docking station.

4-Gas Mix Calibration Cylinder

The Data Cal 2000 may be ordered with or without calibration gas and a

demand flow regulator. The standard configuration of the Data Cal 2000

includes a demand flow regulator and one 58 liter 4-gas mix calibration

cylinder which typically contains 50% LEL CH

4

/12.0% oxygen/50 ppm

CO/25 ppm H

2

S. If another cylinder is required for your system, for

example if you need a % volume CH

4

cylinder for a 5-sensor GX-2003, it

will have to be ordered separately along with an additional demand flow

regulator.

Demand Flow Regulator & 3 ft. Tube

The standard configuration of the Data Cal 2000 includes one demand

flow regulator with 3 feet of flexible polyurethane tubing. The demand

flow regulator screws onto a calibration cylinder and the tube is used to

connect the regulator to the appropriate calibration gas fitting on the back

of the docking station. When the regulator senses a vacuum at its fitting,

it allows the gas from the cylinder to flow.

10 Foot Exhaust Tube

The Data Cal 2000 comes with a 10 foot 5/16” I.D. exhaust tube. This

exhaust tube is intended to be used as the collective exhaust for any

connected DM-2001s and DM-2003s. Any connected DM-2009s require

their own dedicated exhaust. Another 10 foot 5/16” I.D. tube is

recommended for each connected DM-2009. This extra tubing is not

included in the Data Cal 2000 kit or in the DM-2009 but can be

purchased from RKI Instruments, Inc.

Data Cal 2000 Hardware Setup

There are two parts to preparing the Data Cal 2000 Docking Station for

use: hardware setup and software setup.This section describes

hardware setup. The hardware setup consists of setting the docking

module configuration switches, simple mechanical assembly, cable

installation, and tubing installation.

Data Cal 2000 Hardware Setup • 14

Setting the Docking Module Configuration Switches

The docking module configuration switches determine module ID and the

order in which the modules are physically installed. Before using the Data

Cal 2000, you will need to set the configuration switches as described

below. If you are adding a module or modules to a system that is already

setup, make sure the system is setup as described below after the new

module or modules are added.

ID Switch

The ID switch is located above the right DB-15 connector on the back of

the docking module. It is a 10 position rotary switch with settings from 0

to 9. A Data Cal 2000 may have up to 10 docking modules. Each module

in the system must have a unique ID for the system to work properly.

When you receive a Data Cal 2000, set the ID setting for each module in

the system so that no two modules have the same ID. The IDs should be

set sequentially to make it easy to keep track of the IDs. For example, if

you have 5 modules in a system, the IDs should be set to 0, 1, 2, 3, & 4.

Although the system will still operate properly if ID numbers are skipped,

for example using IDs 0, 3, 4, 6, & 8, setting them sequentially makes it

easier to keep track of the module IDs and spot duplicate ID settings. If it

is necessary to change the ID on a module, use a small flat blade

screwdriver to adjust the switch to the desired setting. A small arrow in

the middle of the switch points to the current ID setting.

0

19

28

37

46

5

Figure 10: ID Switch Setting

15 • Data Cal 2000 Hardware Setup

Termination Switch

The termination switch is located above the left DB-15 connector on the

back of the docking module. It is a two position slide switch. The switch

position indicates whether the module is physically the last module in the

installation or not. When the Data Cal 2000 is viewed from the front, the

last module in the installation is the module on the far right and it must

have the termination switch set to the down position for the Data Cal

2000 to operate properly. All other modules in the system must have the

switch set to the up position. If only one module is used in a system, that

module must have the termination switch set to the down position.

Mechanical Assembly

The Data Cal 2000 is designed for table top use. Perform the following

steps to assemble the docking station and docking modules.

1. Find a location that is well ventilated and near a window so that the

exhaust can be routed out of the window.

2. Find a table or other flat surface that is large enough to

accommodate the docking station and the number of modules in

your system.

Set switch to UP position if module IS NOT the last one.

Set switch to DOWN position if module IS the last one.

Figure 11: Termination Switch Setting

/