1. Introduction 2

2. Specifications 3

2.1 Engine 3

2.2 Fuelsystem 3

2.3 Ignitionsystem 4

2.4 Gearbox 4

2.5 Cuttingattachment 5

2.6 Specialaccessories 6

2.6.1 Fortheuser 6

2.6.2 Forservice 6

2.7 Tighteningtorques 7

3. Clutch 9

3.1 Disassembly 9

3.2 Assembly 10

4. Engine 11

4.1 Muffler/sparkarresting

screen 11

4.2 Leakagetesting 11

4.2.1 Preparations 12

4.2.2 Pressuretest 12

4.2.3 Vacuumtest 13

4.3 Oilseals 14

4.4 Exposingthecylinder/

spacerflange 15

4.5 Cylinderandpiston 16

4.5.1 Removal 16

4.5.2 Installation 16

4.6 Pistonrings 18

4.7 Crankcase 18

4.7.1 Removingthecrank-

shaft 18

4.7.2 Installingthecrankshaft20

5. Ignitionsystem 23

5.1 Sparkplugterminal 23

5.2 Ignitionmodule 24

5.2.1 Ignitiontiming 24

5.2.2 Removalandinstalla-

tion 25

5.3 Flywheel 26

6. Rewindstarter 27

6.1 General 27

6.2 Startercover 27

6.3 Rewindspring 28

6.3.1 Replacement 28

6.3.2 Tensioning 28

6.4 Starterrope

(ElastoStart) 29

6.5 Startergrip

(ElastoStart) 30

6.6 Startercarrier/pawl 30

7. Throttlecontrol 31

7.1 Throttletrigger/interlock

lever(throttlecablewith

oneshort-circuitwire) 31

7.2 Throttlecablewithone

short-circuitwire 32

7.3 Contactspring/detent

springincontrolhandle

(throttlecablewithone

short-circuitwire) 33

7.4 Throttletrigger/interlock

lever(throttlecablewith

twoshort-circuitwires)33

7.5 Throttlecablewithtwo

short-circuitwires 34

7.6 Adjustingthethrottle

cable 34

8. Fuelsystem 35

8.1 Airfilter 35

8.2 Carburetor 35

8.2.1 Leakagetesting 35

8.2.2 Removaland

installation 36

8.2.3 Adjustment

(twoadjustingscrews)37

8.2.4 Adjustment

(oneadjustingscrew) 38

8.3 Tankvent 39

8.4 Pickupbody 39

8.5 Fueltank/hoses 40

9. AVsystem 41

9.1 Repair 41

10. Shaft 43

10.1 Cowhornhandle 43

10.2 Loopedhandle 43

10.3 Driveshaft/insulating

tube 45

10.4 Protectivetube 46

11. Cuttingtooldrive 47

11.1 Bearinghousing

(FS75) 47

11.2 Gearbox(FS80,85) 47

11.3 Gearbox(FC75) 48

11.4 Clutchdrum 50

12. Cuttingdevice(HL75)51

12.1 Gearbox 51

12.2 Cuttingblade 51

12.3 Gearwheel 53

13. Specialservicetools

andaids 55

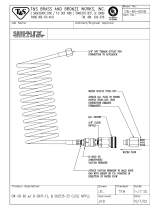

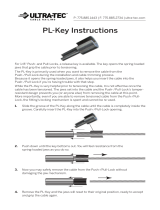

13.1 Specialtools 55

13.2 Servicingaids 57

©1996,AndreasStihlAG&Co.,Waiblingen

FS75

Contents

1

ThisRepairManualcontainsa

detaileddescriptionofallthetypi-

calrepairworkrequiredforthese

seriesofpowertools.

Repairstobeundertakenonstan-

dardpartsandassemblieswhich

areusedinseveralSTIHLpower

toolseriesaredescribedinsepa-

raterepairmanuals.

Attentionisdrawntotheseinstruc-

tionsattherelevantpointsinthis

manual.

SincethebrushcuttersFS75,

FS80,FS85,FC75andthe

hedgetrimmerHL75arealmost

identical,thedescriptionsandser-

vicingproceduresinthismanual

generallyapplytoallfivemodels.

Differencesaredescribedindetail.

Theillustratedsparepartslists

shouldalsobeconsultedwhencar-

ryingoutrepairs,fortheyshowthe

installedpositionandsequenceof

assemblyfortheindividualparts.

Thelatesteditionoftherespective

partslistsshouldalwaysbeused

whendeterminingthepartnum-

bersoftherequiredreplacement

parts.Microfilmsaremoreup-to-

datethanprintedsparepartslists!

Faultsinthemachinemaybedue

toseveralcauses.

Notethe"Summaryoffaults"for

allfunctiongroupsinthemanual

"Troubleshooting,standard

repairs".

Notethe"TechnicalInformation"

sheets,fortheydescribetechnical

changesimplementedafterpubli-

cationofthisRepairManual.The

TechnicalInformationsheetssupp-

lementthepartslistuntilanewedi-

tionispublished.

Thespecialtoolsmentionedinthe

textarelistedinthelastchapterof

thismanual.Thetoolscanalso

beidentifiedinthemanualof

"STIHLtools"onthebasisoftheir

partnumber.

Themanuallistsallthetoolssupp-

liedbySTIHL.

Thefollowinggraphicsymbolsare

usedinthetextandillustrationsin

ordertomakethismanualeasier

touseandunderstand:

Inthetext:

•

=Activitytobecarriedout;

correspondstotheactivityin

thepictureabovethetext.

-=Activitytobecarriedout,butis

notshowninthepictureabove

thetext.

Intheillustrations:

- =Shortarrowindicating:Note

- =Longarrowindicating:Goto

RepairManualsandTechnicalIn-

formationsheetsshouldalwaysbe

onhandwhereverrepairsarecar-

riedout.Theymustnotbepassed

ontothirdparties.

Repairscanbecarriedoutmore

easilybymountingthepowerunit

ontheassemblystand(2)

59108903100withtheclamping

plate(1)59108902100.

Thepowerunitcanthenbeswivel-

ledintothemostsuitableworking

position,leavingbothhandsfree

fortheworkitself.

SecuredwithM5x30screwsafter

disassemblingtheprotectivetube,

shroud,startercoverandremo-

vingthefueltank.

AlwaysuseoriginalSTIHLreplace-

mentparts.

OriginalSTIHLpartscanbeiden-

tifiedbytheSTIHLpartnumber,

the logoandtheSTIHL

partssymbol .

Thesymbolmayappearaloneon

smallparts.

1. Introduction

11

22

392RA001 VA

2

2.1 Engine STIHLsingle-cylindertwo-strokeenginewithspecialimpregnatedcylinder

bore

Displacement: 25.4ccm

Bore: 34mm

Pistonstroke: 28mm

PoweroutputtoISO8893: 0.9kW(1.2HP)at8000rpm

Max.permissibleenginespeed

withoutcuttingblades(cut-offspeed):10500rpm(

+000rpm)

Max.speedoftheoutputshaft

(nominalvalue,gearhead): 8500rpm(FS75,FC75)

7500rpm(FS80,85)

Idlespeed: 2800rpm

Bearings: Heavy-dutydeepgrooveball

bearingsforcrankshaft;needle

cagesonsmallandbigends

Bigenddiameter: 8mm

Conrodlength: 52.5mm

Rewindstarter: ElastoStart

Pawls: Singlepawlsystem

Reservepullonroperotor: Atleastturn

Starterrope: Dia.3.0mm,800mmlong

Clutch: Centrifugalclutchwithoutlinings

Diameter: 66.5mm

Clutchengagesat: 3700rpm

Crankcaseleakagetest

atgaugepressure: 0.5bar

undervacuum: 0.5bar

2.2 Fuelsystem Carburetor: Diaphragmcarburetorwithoneor

twoadjustingscrews

Standardsettingforcarburetors

withtwoadjustingscrews

HighspeedadjustingscrewH: Backoffapprox.1turn

LowspeedadjustingscrewL: Backoffapprox.1turn

(standardsetting)

Carburetorleakagetestatgauge

pressure: 0.8bar

Functionoftankvent

atgaugepressure: 0.5bar

undervacuum: 0.1bar

Fueltankcapacity: 0.44l(440ccm)

Octanenumber: Atleast90RON

Fuelmixture: Regularbrandnamepetrol

Brandnametwo-strokeengineoil

Mixratio: 1:50whenusingSTIHL1:50

two-strokeengineoil

1:25whenusingallotherbrand-

nametwo-strokeengineoils

Airfilter: Foamandfeltelements

2. Specifications

3

2.3 Ignition system Type: Transistorized (breakerless)

magneto ignition with integrated

ballast

Air gap: 0.2 ... 0.5 mm

Ignition timing: 1.55 ... 2.25 mm before TDC at

n = 8000 rpm

Spark plug (suppressed): Bosch WSR 6F, NGK BPMR 7 A or

Champion RCJ 6Y

Electrode gap: 0.5 mm

Spark plug thread: M14 x 1.25

Length of thread: 9.5 mm

2.4 Gearbox * Type: Helical-toothed bevel gears

Gear ratio: 1.4 **

1.24 ***

Bearing: Deep groove ball bearing

Lubrication: STIHL gear lubricant

* FS 75 only has a bearing housing

** FS 80, 85

*** FC 75

4

2.5 Cutting attachment *

FS 75 FS 80 FS 85 FC 75

STIHL "Supercut 10-1"

mowing head

STIHL "Supercut 20-2" STIHL "Supercut 20-2"

mowing head mowing head

STIHL "Autocut 11-2"

mowing head

STIHL "Autocut 21-2" STIHL "Autocut 30-2"

mowing head mowing head

STIHL "Autocut 30-2" STIHL "Polymatic 30-2"

mowing head mowing head

STIHL "Polymatic 30-2" STIHL "Polymatic 30-2"

mowing head mowing head

STIHL "Polycut 10-3"

mowing head

STIHL "Polycut 20-3" STIHL "Polycut 20-3"

mowing head mowing head

Grass cutting blade Grass cutting blade

230-4 ** 230-4 **

Grass cutting blade Grass cutting blade

230-8 ** 230-8 **

Brush knife 250-3 **

Circular saw blade 200 ***

(scratcher-tooth)

Circular saw blade 200 ***

(chisel-tooth)

Blade

* Some cutting attachments may not be available in some countries on account of the different conditions

prevailing in each country.

** Only approved for brushcutters with cowhorn handle or looped handle with U-bar, together with the

guard 4119 713 4500.

*** Only approved for brushcutters with cowhorn handle.

5

2.6 Specialaccessories

2.6.1 Fortheuser Safetyharness

Safetygoggles

Barscabbardformetalcuttingtools

STIHLmulti-purposegrease(80gtube) 07811201109

STIHLgearlubricant(80gtube) 07811201117

2.6.2 Forservice Carburetorpartskit

forWalbrocarburetorWT447 41330071060

Carburetorpartskit

forZamacarburetorC1Q-S28A 42270071060

Gasketpanel(DINA3) 04572814003

6

2.7 Tighteningtorques

DGandP-type(Plastoform)screwsareusedinthermoplasticandalloyedmaterials.Thesescrewscutathread

inthematerialwhentheyarescrewedinforthefirsttime.Thematerialispermanentlydeformed.Thescrews

canberemovedandrefittedasoftenasdesired.Thestrengthofthescrewconnectionisnotimpairedifthespe-

cifiedtighteningtorqueismaintained.

Itisthereforeessentialtouseatorquewrench.

Fastener Thread Forcomponent Tighteningtorque Remarks

size (Nm)

Splinescrew IS-M5x25 Crankcase 9.5

Splinescrew IS-M5x25 Spacerflange/cylinder 5.5 1)

Splinescrew IS-DG5x24 Cylinder/crankcase 9.5

Splinescrew IS-M5x16 Muffler/cylinder 9.5

Splinescrew IS-M5x16 Muffler/crankcase 9.5

Splinescrew IS-M5x16 Tensioner/spacerflange 3.5

Splinescrew IS-M5x16 Fanhousing/crankcase 5.5

Splinescrew IS-M5x16 Starter/crankcase 5.5

Splinescrew IS-M4x20 Ignitionmodule/cylinder 4.5

Splinescrew IS-M5x16 Shroud/fanhousing 3.5

Splinescrew IS-M5x16 Shroud/startercover 3.5

M8 Clutch 21.0

M8 Startercarrier 20.0

M14x1.25 Sparkplug 20.0

Plastoformscrew IS-P5.5x12 Roperotorinstartercover 3.5

Splinescrew IS-M5x16 AVsleeve(clampingscrew) 5.5

Splinescrew IS-DG5x12 AVsleeve/protectivetube 2.5

Nut M5 Filterhousing/carburetor 4.0

Splinescrew IS-M5x18 Clampingcollar/bearinghousing 6.5 2)

Self-tappingscrew IS-B3.5x9.5 Bearinghousing/protectivetube 3.0 2)

Splinescrew IS-M5x33 Clampingcollar/guard 4.5 2)

Studbolt Detentspring/slidecontrol 1.0

Splinescrew IS-M5x16 Controlhandle,clampingcollar/

protectivetube(loopedhandle) 3.5 2)

Splinescrew IS-M6x50 Loopedhandle/protectivetube 3.5 2)4)

Splinescrew IS-DG5x16 Loopedhandle/handlehose 2.5 2)4)

Splinescrew IS-M6x25 Bracket,loopedhandle/protectivetube 4.5 3)

Splinescrew IS-M4x19 Controlhandle/handlemouldings

(loopedhandle) 1.0

Splinescrew IS-M5x16 Controlhandle,clampingcollars/

protectivetube 3.5

Plastoformscrew IS-P6x14 Linelimiterblade/guard 2.5 2)

Splinescrew IS-DG5x24 Gearhousing/protectivetube 9.0 3)

Splinescrew IS-M6x20 Gearhousing/protectivetube 7.5 4)

Screwplug M11x10 Gearbox 10.0

7

Fastener Thread Forcomponent Tighteningtorque Remarks

size (Nm)

Splinescrew IS-M5x18 Deflectorshield 4.3 3)

Locknut M10x1L Cuttingtool 25.0 3)

Plastoformscrew IS-P4x16 Controlhandle/handlemouldings

(cowhorn) 1.03)

Splinescrew IS-M5x30 Controlhandle(cowhorn) 2.0 3)

Splinescrew IS-M6x35 Clamp,tensioner/

protectivetube 4.5 3)

Splinescrew IS-DG5x12 Clamp/guard 5.5 4)

Splinescrew IS-DG5x12 Apron/guard 5.5 1)4)

Splinescrew IS-DG6x25 Guard/gearhousing/

tensioner 7.5 4)

Locknut M8x1.25L Blade 25.0 4)

Bearingbolt IS-M10x63 Wheel/guard 19.0 1)4)

Nuts,bolts M4 Allothers 2.5

Nuts,bolts M5 Allothers 4.5

Splinescrew IS-M4x16 Gearboxcover/gearhousing 3.5 5)

Splinescrew IS-M5x20 Bladeguide/gearhousing 9.5 5)

Splinescrew IS-M5x20 Gearbox/gearhousing 9.5 5)

Nut M5 Blade 9.5 5)

Screwplug M11x10 Gearboxcover 5.5 5)

WheninsertingtheDGandP-typescrewsinanexistingthread:

–InserttheDGorP-typescrewintheholeandturnitanticlockwiseuntilitgentlydropsintotheholeinaxial

direction.

–Turnscrewinclockwiseandtightenwiththespecifiedtorque,

Thisensuresthatthescrewengagestheexistingthreadanddoesnotcutanewthread,thuspreservingthe

strengthofthescrewconnection,

1)Withwasher

2)FS75

3)FS80,85

4)FC75

5)HL75

Note:Screwdriverspeedwhenworkinginplastic:Plastoformscrewsmax.600rpm,

DGscrews max.500rpm.

8

Refertomanual"Troubleshooting,

standardrepairs"fortroubleshoo-

tingprocedures..

•

Removescrewonstartercover.

•

Removescrew(1)onfan

housing.

-Liftoffshroud(2).

•

Removescrews.

-Pullofffanhousingwithprotec-

tivetubeandsetitaside.

•

Examineclutchdrum:itmustnot

bescoredorshowsignsofex-

cessivewear.

Important!Theremainingwall

thicknessmustbemeasuredifthe

insidediameterisdistinctlyworn.

Anewclutchdrummustbefitted-

see11.4-ifthewallthicknesshas

declinedtolessthan80%ofthe

originalvalue.

•

Disconnectsparkplugterminal

(1).

•

Removesparkplug(2).

•

Insertthelockingstrip(1)

00008935903inthecylinder.

3. Clutch

3.1 Disassembly

1122

392RA003 VA

392RA006 VA

11

392RA008 VA

392RA004 VA

80%

100%

145RA006

!

VA

11

22

392RA007 VA

392RA002 VA

9

•

Unscrew clutch from crankshaft

stub, turning it in the direction of

the arrow.

- Disassemble and reassemble

clutch, see manual "Trouble-

shooting, standard repairs".

•

Screw clutch onto crankshaft

with the smaller hexagon facing

outwards and torque down to

21 Nm.

•

Ensure that inlays are present in

fan housing; insert them if

necessary.

•

Position motor on fan housing,

ensuring that stubs (1) engage in

inlays (2).

- Insert screws in fan housing and

torque down to 5.5 Nm.

- Remove locking strip from

cylinder.

- Screw in spark plug and torque

downto20Nm.

Important! Check that the separa-

te connecting nut is securely loca-

ted on the screw thread of spark

plugs with separate nut and

tighten the nut if necessary.

- Reconnect spark plug terminal to

spark plug.

- Fit shroud.

392RA010 VA

392RA009 VA

392RA011 VA

11

11

22

22

392RA012 VA

3.2 Installation

10

Seemanual"Troubleshooting,

standardrepairs"fortrouble-

shootingprocedures.

Sparkarresterscreen

•

Removescrew(1).

•

Pulloutsparkarresterscreen(2).

-Cleansparkarresterscreen,fit

newscreenifnecessary.

Muffler

-Removeshroud,see3.1.

•

Removeouterscrew.

•

Removeinnerscrews.

-Liftoffmuffler.

•

Raisetongue(1)onretainer.

•

Pulloutseal(2).

Thepartsareinstalledinreverse

order.

-Presstonguedownagainafter

insertingseal.

-Tightenmufflerscrewstoa

torqueof9.5Nm.

-Refitshroud.

Defectiveoilsealsandgasketsor

cracksincastingscauseleaks.

Suchfaultsallowsupplementary

airtoentertheengineandthus

impairthefuel-airmixture.

Thismakesadjustmentofthe

specifiedidlespeeddifficult,ifnot

impossible.

Italsopreventsasmoothtransi-

tionfromidlespeedtopartorfull

throttle.

Thecrankcasecanbethoroughly

checkedforleakswiththecarbure-

torandcrankcasetesterandthe

vacuumpump.

11

22

392RA013 VA

392RA015 VA

11

22

392RA016 VA

4. Engine

4.1 Muffler/sparkarresterscreen 4.2 Leakagetesting

392RA014 VA

11

-Removecarburetor,see8.2.2.

•

Fitgasketinfrontofspacer

flange.

-Setpistontotopdeadcentre

(TDC)(canbeseenthroughthe

inletport).

-Checkthatsparkplugisseated

securely.

•

Fittestflange(1)11288504200.

•

Fitandtightennuts(2).

-Removeouterscrewonmuffler.

-Backoffinnerscrewshalf-way.

•

Slidesealingplate(1)

00008558106betweengasket

andcylinderexhaustportand

lightlyretighteninnerscrews.

Note:Thesealingplatemustfill

thespacebetweenthemounting

screwscompletely.

-Carryoutpreparatorysteps,

see4.2.1.

•

Slidepressurehoseoftester

11068502905overnippleon

testflange.

•

Closeventscrew(1)onrubber

bulb.

-Pumpairintocrankcasewith

rubberbulbuntilpressuregauge

indicatesapressureof0.5bar.

Thecrankcaseisairtightifthis

pressureremainsconstantforat

least20seconds.

4.2.1 Preparations 4.2.2 Pressuretest

392RA017 VA

11

392RA019 VA

11

22

392RA018 VA

392RA020 VA

143RA046 VA

1

12

•

Ifthepressuredrops,theleak

mustbelocatedandthefaulty

partreplaced.

Note:Tolocatetheleak,coatthe

suspectareawithoilandpressuri-

zethecrankcaseagain.Bubbles

willappearattheoil-coatedareaif

aleakexists.

-Thencarryoutvacuumtest,

see4.2.3.

-Openventscrewanddisconnect

hosewhentestiscomplete.

-Removetestflange.

-Loosenthemufflerscrews.

-Drawoutthesealingplateand

tightenthemufflerscrewswith

9.5Nm.

-Fitouterscrewofmufflerand

tightenwith9.5Nm.

-Installcarburetor,see8.2.2.

Oilsealstendtofailwhensub-

jectedtoavacuum,i.e.thesealing

lipliftsawayfromthecrankshaft

duringthepiston’sinductionstroke

becausethereisnointernalcoun-

terpressure.

Faultsofthiskindcanbedetected

withtheaidofavacuumpump.

Thepreparationsarethesameas

forthepressuretest,see4.2.2.

•

Connectsuctionhoseofvacuum

pump00008503501tonippleof

testflange.

•

Closeventscrew(1)onpump

cylinder.

•

Actuatelever(2)untilpressure

gauge(3)indicatesavacuumof

0.5bar.

Note:Theoilsealsareingood

conditioniftheindicatedvacuum

ismaintainedorifthepressure

risestonomorethan0.3bar

within20seconds.

Theoilsealsmustbereplacedif

thepressureinthecrankcasecon-

tinuestorise.

-Openventscrewanddisconnect

hosewhentestiscomplete.

-Removetestflange.

-Loosenmufflerscrews.

-Removesealingplateand

tightenscrewstoatorqueof9.5

Nm.

-Fitouterscrewinmufflerand

tightentoatorqueof9.5Nm.

-Installcarburetor,see8.2.2.

392RA021 VA

392RA020 VA

33

11

22

392RA022 VA

4.2.3 Vacuumtest

13

Itisnotnecessarytodisassemble

thecompleteengineifonlytheoil

sealshavetobereplaced.

Clutchside:

-Removeflywheel,see5.3.

-Lightlytaptheoilsealwitha

suitabletubeorpunchtoknock

itoutofitsseat.

•

Fitpuller(1)59108904400

(jaws00008933706withprofile

No.3.1).

-Tensionlegs.

-Pulloutoilseal.

Important!Thecrankshaftstub

mustnotbedamaged.

-Cleanthesealingareawithcom-

merciallyavailablesolvent-based

degreasingagentnotcontaining

CFCsorhalocarbons,see13.2.

-Greasesealinglipsofoilseal,

see13.2.

-Slideoilsealovercrankshaft

stubwithopensidefacing

crankcase.

•

Pressitfullyhomewiththepress

sleeve(1)41128932401.

-Fitflywheel,see5.3.

Starterside:

-Removestartercarrier,see6.6.

-Lightlytaptheoilsealwitha

suitabletubeorpunchtoknockit

outofitsseat.

•

Fitpuller(1)59108904400

(jaws00008933706withprofile

No.3.1).

-Tensionlegs.

-Pulloutoilseal.

Important!Thecrankshaftstub

mustnotbedamaged.

-Cleanthesealingareawithcom-

merciallyavailablesolvent-based

degreasingagentnotcontaining

CFCsorhalocarbons,see13.2.

-Greasesealinglipsofoilseal,

see13.2.

•

Slideassemblysleeve(1)

41128932400overcrankshaft

stub.

-Slideoilsealoverassembly

sleevewithopensidefacing

crankcase.

•

Pressitfullyhomewiththepress

sleeve(1)11158934600.

-Removeassemblysleeve.

-Fitstartercarrier,see6.6.

11

392RA023 VA

11

392RA025 VA

11

392RA005 VA

11

392RA024 VA

11

392RA026 VA

4.3 Oilseals

14

Alwayscheckandrepairthefuel

system,carburetor,airfilterand

ignitionsystembeforelookingfor

faultsontheengine.

Refertomanual"Troubleshooting,

standardrepairs"fortroubleshoo-

tingprocedures.

-Removefanhousingwithpro-

tectivetube,see3.1.

-Removemuffler,see4.1.

-Removecarburetor,see8.2.2.

-Removeignitionmodule,see5.2.

•

Removethrottlecablefrom

tensioner.

•

Removescrews.

-Removespacerflangeand

gasket.

•

Pullscrews(1)outofspacer

flangeifnecessary.

•

Loosenscrew(2)andremove

withbushing.

•

Drawtensioner(3)offspacer

flange.

•

Removeadjustingscrewfrom

tensioner.

Thepartsareassembledinrever-

seorder.

•

Insertscrew(1)withbushing(2).

-Useanewself-lockingnutfor

thescrew.

•

Useanewgasket.

-Tightendownthescrewsofthe

spacerflangetoatorqueof

5.5Nm.

392RA027

VA

392RA028

VA

392RA030

VA

2

392RA031

1

VA

392RA029

1

3

2

1

VA

392RA032

VA

4.4 Exposingthecylinder/

spacerflange

15

-Preparations,see4.4.

•

Unscrewcylinderbasescrews.

Note:Thetwoscrewsattheback

arenotvisible.

-Drawcylinderoffpiston.

-Examinecylinderandreplaceif

necessary.

-Thematchingpistonmustal-

waysbefittedwheninstallinga

newcylinder.Newcylindersare

thereforeonlysuppliedwith

piston.

-Beforeremovingthepiston,de-

cidewhetherthecrankshaftmust

alsoberemoved.Thecrank-

shaftmustbeblockedbysliding

thewoodenassemblyblockbe-

tweenthepistonandcrankcase

inordertoremovetheclutchand

startercarrier.

-Removecylindergasket.

•

Prisethehooklesssnaprings

outoftheannulargrooves.

•

Pushpistonpin(1)outofthe

pistonwithassemblydrift(2)

11148934700.

Note:Ifthepistonpinisstuck,it

canbeloosenedbylightlytap-

pingtheassemblydriftwithaham-

mer.Thepistonmustbeheld

steadyduringthisprocesstoen-

surethatnojoltsaretransmittedto

theconrod.

-Removepistonfromconrodand

drawneedlecageoutofsmall

end.

•

Checkpistonringsandreplaceif

necessary,see4.6.

•

Thoroughlycleansealingarea

(1).

•

Wetneedlecage(2)withoiland

fititinthesmallend.

•

Lightlyheatpistontofacilitatein-

stallationandslipitoverthecon-

rod.

•

Noteinstalledpositionofpiston:

1=Marking

2=Flywheel

•

Pushassemblydriftthrough

pistonandsmallend(needle

cage)withthesmalldiameter

firstandlineupthepiston.

392RA033

VA

366RA066

VA

12

366RA068

1

2

VA

392RA034

1

2

VA

145RA080 VA

366RA067 VA

366RA070 VA

4.5 Cylinderandpiston

4.5.1 Removal 4.5.2 Installation

16

•

Fitpistonpin(1)onstubofas-

sembly drift (2) and slide it into

the piston (the pin slides home

easily if the piston is hot).

•

Modify sleeve of assembly tool

5910 890 2208 as shown above.

a=35.5mm

b=17.3mm

c = 21.0 mm

•

Insert hookless snap rings with

assembly tool (1) 5910 890 2208.

Note: Refer to manual "Trouble-

shooting, standard repairs" for in-

formation on using the assembly

tool.

•

Fit new cylinder gasket.

•

Lightly oil the piston and piston

rings and rest the piston (1) on

the wooden assembly block (2)

1108 893 4800.

•

Line up the piston rings so that

the radii at the ring gap meet at

thefixingpininthepistongroove.

•

Use clamping strap (1)

0000 893 2600 to enclose piston

and piston rings.

- Ensure that piston rings are

positioned correctly.

- Coat inside of cylinder with oil

and line it up in accordance with

its subsequent installed position.

The piston rings may break if this

is not done.

366RA071VA

2

1

366RA075

1

VA

366RA073 VA

392RA205

a

c

b

VA

145RA090 VA

366RA072

1

VA

366RA074

1

2

VA

17

•

Slidecylinderoverpiston;the

clampingstrapslipsdownward

andthepistonringsslipintothe

cylinder.

-Removeclampingstrapand

assemblyblock.

-Lineupcylinderandcylinder

gasket.

•

Tightencylinderbasescrewsto

atorqueof9.5Nmwithsocket

(1)08125422104.

See4.4forfurtherassemblysteps.

-Removepiston,see4.5.1.

Note:Cokingresiduesmustnot

beallowedtoenterthecrankcase

whenfittingthepistonringsand/or

cleaningthegrooves.

-Removepistonringsfrompiston.

•

Scrapethegroovescleanwitha

pieceofoldpistonring.

•

Fitthenewpistonringsinthe

groovessothattheradiiface

upwards.

-Installpiston,see4.5.2.

-Removecylinder,see4.5.1

•

Unscrewstartercarrierfrom

crankshaftstub.

•

Unscrewclutchfromcrankshaft

stub.

•

Pullflywheeloffcrankshaftstub,

see5.3.

392RA037 VA

145RA098 VA

392RA036 VA

366RA065 VA

145RA099 VA

366RA078 VA

4.6 Pistonrings4.7Crankcase

4.7.1 Removingthecrankshaft

392RA035

1

VA

18

•

Removepiston,see4.5.1.

•

Unhookguardfromhousing.

•

Removethescrewssecuringthe

twohalvesofthecrankcase.

-Partlyunscrewspindleofassem-

blytoolZS59100072220(left-

handthread).

•

HoldassemblytoolZSagainst

housinghalfonstartersideso

thatthenotchmarked"1"isat

thebottom.

•

Insertscrewsforthestarterco-

verintheholesmarked"15"and

tightenthemdownuntiltheyrest

againsttheperforatedplate.

Note:Assemblyfixtureswithout

holes"14"and"15"canbemodi-

fiedasillustratedabove.

Thediagramshowstheperforated

diskasseenfrombelow.

•

Turnspindle(1)anticlockwise

untilthecrankshafthasbeen

forcedoutofthedeepgroove

ballbearing.Thisalsocauses

thetwohalvesofthehousingto

comeapart.

•

Placesleeve(1)5910893170

(30mm)andsleeves(2)

59108931702(35mm)overthe

holesontheclutch-sidehalfof

thehousing.

-PositionassemblytoolZS

againstthesleevessothatthe

notchmarked"12"isatthe

bottom.

392RA038 VA

392RA040 VA

15

15

15

1

15

14/6

15

14

15

392RA204

31.3

10.9

4.7

52.3

30.5

23.4

33.6

35.7

5

30.5

23.4

5.5

14

VA

11

392RA041 VA

392RA052 VA

11

22 22

392RA042 VA

392RA039 VA

19

•

Insert three M5 x 72 bolts in the

holes marked "14".

- Slide washers onto the bolts and

screw on the nuts.

•

Turn spindle (1) anticlockwise

until the crankshaft has been

forced out of the deep groove

ball bearing.

•

Crankshaft (1), conrod (2) and

needle bearing form an insepa-

rable unit and must always be

replaced as a complete unit.

- New deep groove ball bearings

and oil seals must also be fitted

when replacing the crankshaft.

•

Carefully drive the oil seals out

of the crankcase.

•

Press the deep groove ball bea-

ring out of its seat with press

arbor (1) 4119 893 7200.

•

Press the deep groove ball bea-

ring out of its seat with press

arbor (1) 4119 893 7200.

- Examine both halves of the

crankcase for cracks and replace

them.

Both halves of the crankcase can

be replaced if the crankcase is da-

maged.

Each half of the crankcase is supp-

lied with fitted deep groove ball

bearing.

If the original crankcase is used

again, remove the gasket residues

and clean the mating surfaces.

The mating surfaces must be ab-

solutely clean to ensure a perfect

seal.

•

Bushings must be present. New

bushings must be driven into the

crankcase if necessary.

- Heat area of bearing seat on

starter side of crankcase to

approx. 120

°

C.

•

Press deep groove ball bearing

into crankcase by hand as far as

possible.

366RA086 VA

366RA091 VA

11

392RA041 VA

11

22

366RA085 VA

366RA090 VA

392RA043 VA

14

14

14

12

4.7.2 Installing the crankshaft

11

366RA087 VA

11

366RA089 VA

20

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

/