colorCONTROL ACS7000

Contents

1. Safety ........................................................................................................................................ 7

1.1 Symbols Used ................................................................................................................................................. 7

1.2 Warnings .......................................................................................................................................................... 7

1.3 CE Compliance ................................................................................................................................................ 7

1.4 Proper Use ....................................................................................................................................................... 8

1.5 Proper Environment ......................................................................................................................................... 8

2. Functional Principle, Technical Data ....................................................................................... 9

2.1 Measuring Principle ......................................................................................................................................... 9

2.2 Structure of the System ................................................................................................................................... 9

2.3 Operating Modes ............................................................................................................................................. 9

2.4 Technical Data ............................................................................................................................................... 10

3. Delivery ................................................................................................................................... 13

3.1 Unpacking ...................................................................................................................................................... 13

3.2 Storage .......................................................................................................................................................... 13

4. Installation .............................................................................................................................. 14

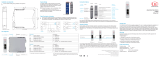

4.1 Controller ....................................................................................................................................................... 14

4.2 Controller Elements ....................................................................................................................................... 14

4.3 LEDs Controller .............................................................................................................................................. 15

4.4 Electrical Connections Controller .................................................................................................................. 15

4.4.1 General ......................................................................................................................................... 15

4.4.2 Supply Voltage (Power) ................................................................................................................ 15

4.4.3 Digital I/O ...................................................................................................................................... 16

4.4.4 Color Switching Outputs .............................................................................................................. 17

4.4.5 RS422 ........................................................................................................................................... 18

4.4.6 Ethernet, EtherCAT ....................................................................................................................... 18

4.4.7 Synchronization ............................................................................................................................ 19

4.4.8 Triggering ...................................................................................................................................... 19

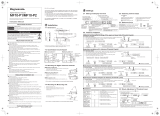

4.5 Sensor Cable, Optical Fiber .......................................................................................................................... 20

4.6 Attaching the Sensor ..................................................................................................................................... 21

5. Operation ................................................................................................................................ 24

5.1 Commissioning .............................................................................................................................................. 24

5.2 Operation Using Web Pages ......................................................................................................................... 25

5.2.1 Requirements ............................................................................................................................... 25

5.2.2 Access via Ethernet ...................................................................................................................... 26

5.2.3 Measured Value Presentation with Web Pages ........................................................................... 26

5.3 User Interface, Settings ................................................................................................................................. 27

5.3.1 Introduction .................................................................................................................................. 27

5.3.2 Login, Switching User Level ......................................................................................................... 27

5.3.3 Sensor Fine Positioning, Positioning Target ................................................................................ 28

5.3.4 Measuring Rate, Control Behavior ............................................................................................... 28

5.3.5 Light Source ................................................................................................................................. 30

5.3.6 Corrections, Referencing ............................................................................................................. 30

5.3.7 Standard Observer, Illuminant, Color Difference ......................................................................... 32

5.3.8 Color Management ....................................................................................................................... 33

5.3.8.1 Color Table .................................................................................................................. 33

5.3.8.2 Create, Edit Teach Color ............................................................................................. 33

5.3.9 Digital interfaces ........................................................................................................................... 35

5.3.9.1 Parameters Overview .................................................................................................. 35

5.3.9.2 Selecting a Digital Interface ........................................................................................ 37

5.3.9.3 Ethernet ....................................................................................................................... 37

5.3.9.4 RS422 Interface ........................................................................................................... 38

5.3.9.5 ColorOut ...................................................................................................................... 39

5.3.9.6 EtherCAT ..................................................................................................................... 39

5.3.10 Averaging, Error Handling, Statistics .......................................................................................... 40

5.3.10.1 Parameters Overview .................................................................................................. 40

5.3.10.2 Video Averaging .......................................................................................................... 40

5.3.10.3 Color Value Averaging ................................................................................................ 40

5.3.10.4 Error Handling (Hold Last Value) ................................................................................ 42

5.3.10.5 Statistics ...................................................................................................................... 42

5.3.11 Output Data Rate .......................................................................................................................... 42

5.3.12 Trigger Mode ................................................................................................................................ 43

5.3.13 Synchronization ............................................................................................................................ 44

5.3.14 Save / Load Setup ....................................................................................................................... 44

5.3.15 Export, Import all Setups .............................................................................................................. 44

5.3.16 Manage Setups on PC ................................................................................................................ 45

5.3.17 Extras ............................................................................................................................................ 46

5.4 Detection ........................................................................................................................................................ 47

5.4.1 Location Chart .............................................................................................................................. 47

5.4.2 Temporal Display .......................................................................................................................... 49

5.4.3 Color Tolerance Parameters ......................................................................................................... 50

5.5 Color Measurement ....................................................................................................................................... 52

5.6 System ........................................................................................................................................................... 54

5.7 Spectrum ....................................................................................................................................................... 54

5.7.1 Comparison .................................................................................................................................. 54

5.7.2 Video Signal ................................................................................................................................. 55

5.7.3 CIE Diagram ................................................................................................................................. 56