Page is loading ...

Technical Manual

F or machines beginning with S erial No. G 3600

TMIN: 12345678 PSN: 12345678

Model

USN-10

High Temperature

with Booster

Undercounter

Dishwasher

Distribution of this manual is intended for

trained C hampion s ervice technicians

and other qualified service personnel.

R eproduction or other use of this manual,

without the expres s written cons ent of

C hampion Industries , Inc. is prohibited.

Des troy this manual only after receipt of

a revised edition.

NSN MODEL APL/CID HEAT

7320-01-506-6252 USN-10 Pending Electric

7320-01-506-6252 USN-10 Pending Electric

7320-01-506-6255 USN-10 Pending Steam

7320-01-506-6255 USN-10 Pending Steam

P. O. Box 4149

Winston-Salem, North Carolina 27115-4149

336/661-1556 Fax: 336/661-1660

Champion Industries, Inc.

Champion Manual P/N 113191 Rev C

®

®

February, 2007

COPYRIGHT © 2003 by Champion Industries, Inc.

Machine Data Plate with

Model & Serial Number

located on left front

corner of the lower panel

Complete the information below for quick reference.

Model Number Serial Number

Voltage and Phase

Factory Authorized Service Centers and Marine Products Installers

Headquarters San Diego Office Mayport Office

The Source The Source The Source

502 Rotary Street 616 Marsat Court 41 West 6

Th

Street

Hampton, VA 23661 Chula Vista, CA 91911 Atlantic Beach, FL 32233

Tel: (757) 825-1400 (619) TBD (904) 241-4982

(800) 497-2144 (800) 497-2144 (888) 889-0291

Fax: (757) 825-1202 (757) 825-1202 (904) 241-4039

Website: www.thesource2000.com Email: sales@thesource2000.com

Equipment information - Darlene Ehrenfried dehrenfried@thesource2000.com

Parts information HQ– Samantha Johnson [email protected]m

Service information HQ – Jim Luther [email protected]

U. S. Navy POC – Judy Lowman [email protected]

U. S. Navy POC – Ken Height, San Diego [email protected]

U. S. Navy POC – Tony Cox, Jacksonville FL [email protected]m

Please call for your Authorized- NSU Warranty Start up today!

i

TECHNICAL PUBLICATION SHEET

TECHNICAL PUBLICATION SHEET

ii

TECHNICAL MANUAL VALIDATION CERTIFICATE

TECHNICAL MANUAL VALIDATION CERTIFICATE

iii

APPROVAL AND PROCUREMENT RECORD

APPROVAL AND PROCUREMENT RECORD

iv

TECHNICAL MANUAL DEFICIENCY/EVALUATION REPORT (TMDER)

TECHNICAL MANUAL

DEFICIENCY/EVALUATION REPORT (TMDER)

(Form - NAVSEA 9086/10, REV. 6/85)

v

REVISION RECORD

Revision Revised Serial Number Comments

Date Pages Effectivity

3/15/00 All Proto 1 Issue Manual and replacement parts

lists.

12/14/01 58,59,62,63 G3600 Added remote control cabinet

and revised electric booster.

12/06/02 U2769 Started with new serial number range.

12/06/02 17, 24, 25 Revised information on operation of

dishwasher that does not apply to the

earlier models.

12/06/02 46, 47 Revised part numbers-0710027 to

0710227, 0309301 to 0309301-1 and

removed parts that are part of weld-

ments and not sold as seperate items.

12/06/02 48, 49 Revised part numbers-0510090 to

0710290, 0505042 to 109837, 112164

to 113514, 0501232 to 0710565and

removed parts that are part of weld-

ments and not sold as seperate items.

12/06/02 50 U2769 Inserted new overflow & screen.

12/06/02 56, 57 U2769 Inserted new electric tank heat.

12/06/02 58, 59 U2769 Inserted steam tank heat.

12/06/02 61 Revised part numbers-

0509698 to 0509699, 0709698 to

0509698, 0509700 to 0309701

12/06/02 67, 66 U2769 Inserted new remote control cabinet.

12/06/02 69 Revised part number 107500 to 107550

12/06/02 74, 75 U2769 Inserted new electric booster.

3/19/03 49-80 Replaced photograghs with drawings.

REVISION RECORD

6/30/03 47, 53, 55, 57, 59 Revised 108391 with 113622.

12/7/06 60 Added circuit board settings to page 60.

vi

SAFETY SUMMARY

SAFETY SUMMARY

General Safety Rules

• The following general safety rules must be observed in addition to the specific cautions and warnings

presented in this manual.

• Your Champion dishwasher may be an electric or steam heated machine using hot water

to clean and sanitize a variety of wares. Machine surfaces and wares become hot during and immedi-

ately following normal operations. Consult your supervisor and wear protective gear as directed to

avoid possible injury.

• Your dishwasher contains rotating spray arms.

Use caution when working around the dishwasher especially when loading or unloading wares.

• Operators must NOT bypass a safety interlock or control to operate the dishwasher.

• The service and maintenance instructions contained in this manual are intended for qualified service

personnel. These instructions assume that you are trained in basic electricity and mechanical theory.

If you are not a trained technician, then do not attempt to adjust or repair the dishwasher as serious

personal injury or damage to the dishwasher may result.

!

CAUTION:

Caution statements indicate any condition or practice which, if not strictly

observed or remedied, could result in damage to or destruction of the

dishwasher.

WARNING:

Warning statements indicate any condition or practice that could result in

result in personal injury or possible loss of life.

NOTE:

Note statements indicate any condition or practice which,

if observed, will help in the safe completion of a task.

Safety Symbols

• The following symbols appear throughout this manual alerting you to potential hazards. Statements

associated with each symbol are printed in italics.

vii

SAFETY SUMMARY

Warning and Caution Statement Listing

• The following listing gives the page number and text of all the warning and caution statements that appear

in this manual.

Warning Statements

Pg. 6- The installation of this unit must conform to local codes or, in the absence of local codes, to the National

Electrical Code and all National Codes governing plumbing, sanitation, safety and good trade practices.

Pg. 8- The installation of water supplies must conform to local codes or, in the absence of local code, all National

Codes governing plumbing, sanitation, safety and good trade practices.

Pg. 8- The installation of steam supplies must conform to local codes or, in the absence of local code, all National

Codes governing plumbing, sanitation, safety and good trade practices.

Pg. 10- The installation of drains must conform to local codes or, in the absence of local code, all National Codes

governing plumbing, sanitation, safety and good trade practices.

Pg. 10- The installation of ventilation must conform to local codes or, in the absence of local code, all National Codes

governing plumbing, sanitation, safety and good trade practices.

Pg. 11- The installation of electrical supplies and controls must conform to local codes or, in the absence of local

codes, the National Electrical Code and good trade practices.

Pg. 11- Dangerous voltages are present at the local electrical distribution system.

Dangerous voltages are present at the dishwasher when it is connected to the local electrical distribution

system.

Pg. 11- When working on the dishwasher, disconnect the electric service and place a red tag at the disconnect switch

to indicate work is being done on that circuit.

Pg. 12- The installation of electrical supplies and controls must conform to local codes or, in the absence of local

codes, the National Electrical Code and good trade practices.

Pg. 12- Dangerous voltages are present at the local electrical distribution system.

Dangerous voltages are present at the dishwasher when it is connected to the local electrical distribution

system.

Pg. 12- When working on the dishwasher, disconnect the electric service and place a red tag at the disconnect switch

to indicate work is being done on that circuit.

Pg. 19- Dangerous voltages are present at the local electrical distribution system.

Dangerous voltages are present at the dishwasher when it is connected to the local electrical distribution

system.

Pg. 19- When working on the dishwasher, disconnect the electric service and place a red tag at the disconnect switch

to indicate work is being done on that circuit.

Pg. 20- Perform the following checks before placing the machine into service for normal operation.

Pg. 20- Never bypass a safety device in order to operate the dishwasher for normal operation.

Pg. 22- Perform the following checks before placing the machine into service for normal operation.

viii

SAFETY SUMMARY (Cont.)

SAFETY SUMMARY

Warning Statements (Cont.)

Pg. 22- Never bypass a safety device in order to operate the dishwasher for normal operation.

Pg. 23- Dishwasher surfaces, dishracks and wares become hot during and immediately after washing operations.

Wear protective gear per your supervisor's directions.

Pg. 24- Dishwasher surfaces, dishracks and wares become hot during and immediately after washing operations.

Wear protective gear per your supervisor's directions.

Pg. 27- Deliming solutions or other acids must not come in contact with household bleach (sodium hypochlorite) or

any chemicals containing chlorine, iodine, bromine, or fluorine.

Mixing will cause hazardous gases to form.

Skin contact with deliming solutions can cause severe irritation and possible chemical burns.

Pg. 27- Consult your chemical supplier for an appropriate deliming solution, protective gear and safety procedures.

Pg. 28- When working on the dishwasher, disconnect the electric service and place a red tag at the disconnect switch

to indicate work is being done on that circuit.

Pg. 29- When working on the dishwasher, disconnect the electric service and place a red tag at the disconnect switch

to indicate work is being done on that circuit..

Pg. 35- When working on the dishwasher, disconnect the electric service and place a red tag at the disconnect switch

to indicate work is being done on that circuit

Pg. 35- Use Extreme Caution when performing tests on energized circuits.

ix

SAFETY SUMMARY

Caution Statements

Pg. 5- Check piping mounted underneath dishwasher before lifting to avoid damaging the machine.

Pg. 6- Check piping mounted underneath dishwasher before lifting to avoid damaging the machine.

Pg. 18- Perform the following checks before placing the machine into service.

Pg. 26- Do not hose down the exterior of the machine with water.

Pg. 28- Only qualified service personnel should perform preventive maintenance on the dishwasher.

Pg. 29- Only qualified service personnel should perform preventive maintenance on the dishwasher.

Pg. 35- Only qualified service personnel should perform preventive maintenance on the dishwasher.

-

SAFETY SUMMARY (Cont.)

x

LIMITED WARRANTY

Champion Industries Inc. (herein referred to as Champion), P.O. Box 4149, Winston-Salem, North Carolina 27115,

warrants machines, and parts, as set out below.

Warranty of Machines: Champion warrants all new machines of its manufacture bearing the name

"Champion" and installed within the United States to be free from defects in material and workman

ship for a period of one (1) year after the date of installation or fifteen (15) months after the date of shipment by

Champion, whichever occurs first. [See below for special provisions relating to glasswashers.] The warranty

registration card must be returned to Champion within ten (10) days after installation. If warranty card is not

returned to Champion within such period, the warranty will expire after one year from the date of shipment.

Champion will not assume any responsibility for extra costs for installation in any area where there are

jurisdictional problems with local trades or unions.

If a defect in workmanship or material is found to exist within the warranty period, Champion, at its election,

will either repair or replace the defective machine or accept return of the machine for full credit; provided, how

ever, as to glasswashers, Champion's obligation with respect to labor associated with any repairs shall end

(a) 120 days after shipment, or (b) 90 days after installation, whichever occurs first. In the event that Champion

elects to repair, the labor and work to be performed in connection with the warranty shall be done during regular

working hours by a Champion authorized service technician at a ship's homeport located within the continental

United States. Defective parts become the property of Champion. Use of replacement parts not authorized by

Champion will relieve Champion of all further liability in connection with its warranty. In no event will

Champion's warranty obligation exceed Champion's charge for the machine. The following are not covered by

Champion's warranty:

a. Lighting of gas pilots or burners.

b. Cleaning of gas lines.

c. Replacement of fuses or resetting of overload breakers.

d. Adjustment of thermostats.

e. Adjustment of clutches.

f. Opening or closing of utility supply valves or switching of electrical supply current.

g. Cleaning of valves, strainers, screens, nozzles, or spray pipes.

h. Performance of regular maintenance and cleaning as outlined in operator’s guide.

i. Damages resulting from water conditions, accidents, alterations, improper use, abuse,

tampering, improper installation, or failure to follow maintenance and operation procedures.

j. Wear on Pulper cutter blocks, pulse vanes, and auger brush.

Examples of the defects not covered by warranty include, but are not limited to: (1) Damage to the exterior or

interior finish as a result of the above, (2) Use with utility service other than that designated on the rating plate,

(3) Improper connection to utility service, (4) Inadequate or excessive water pressure, (5) Corrosion from

chemicals dispensed in excess of recommended concentrations, (6) Failure of electrical components due to

connection of chemical dispensing equipment installed by others, (7) Leaks or damage resulting from such

leaks caused by the installer, including those at machine table connections or by connection of chemical

dispensing equipment installed by others, (8) Failure to comply with local building codes, (9) Damage caused by

labor dispute.

Warranty of Parts: Champion warrants all new machine parts produced or authorized by Champion to be free

from defects in material and workmanship for a period of 90 days from date of invoice. If any defect in

material and workmanship is found to exist within the warranty period Champion will replace the defective

part without charge.

DISCLAIMER OF WARRANTIES AND LIMITATIONS OF LIABILITY. CHAMPION'S WARRANTY

IS ONLY TO THE EXTENT REFLECTED ABOVE. CHAMPION MAKES NO OTHER WARRANTIES,

EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED, TO ANY WARRANTY OF

MERCHANTABILITY, OR FITNESS OF PURPOSE. CHAMPION SHALL NOT BE LIABLE FOR

INCIDENTAL OR CONSEQUENTIAL DAMAGES. THE REMEDIES SET OUT ABOVE ARE

THE EXCLUSIVE REMEDIES FOR ANY DEFECTS FOUND TO EXIST IN CHAMPION DISHWASHING

MACHINES AND CHAMPION PARTS, AND ALL OTHER REMEDIES ARE EXCLUDED,

INCLUDING ANY LIABILITY FOR INCIDENTALS OR CONSEQUENTIAL DAMAGES.

Champion does not authorize any other person, including persons who deal in Champion dishwashing

machines to change this warranty or create any other obligation in connection with Champion Dishwashing Machines.

UNITED STATES NAVY LIMITED WARRANTY

xi

Revision Record........................................................................................................... v

Safety Summary .......................................................................................................... vi

Limited Warranty......................................................................................................... x

PP

PP

P

ARAR

ARAR

AR

T 1:T 1:

T 1:T 1:

T 1:

GENERAL SPECIFICAGENERAL SPECIFICA

GENERAL SPECIFICAGENERAL SPECIFICA

GENERAL SPECIFICA

TIONSTIONS

TIONSTIONS

TIONS

..............................................................................

..............................................................................

.......................................

11

11

1

1.1 About this Manual ............................................................................................... 1

1.2 Model Numbers ................................................................................................... 1

1.3 Standard Equipment............................................................................................. 2

1.4 Dimensions, Capacities, Ventilation, and Utilities............................................... 3

1.5 Electrical Power Requirements............................................................................ 4

PART 2: INSTALLATION .............................................................. 5

2.1 Unpack the Dishwasher ....................................................................................... 5

2.2 Permanent Placement........................................................................................... 6

2.3 Connections Between Dishwasher and Booster (Steam)..................................... 6

2.4 Water Connections .............................................................................................. 8

2.5 Steam and Condensate Connections (Steam) ...................................................... 8

2.6 Drain Connections ............................................................................................... 10

2.7 Ventilation Connections ....................................................................................... 10

2.8 Electrical Connections ......................................................................................... 11

2.9 Chemical Connections ......................................................................................... 12

PART 3: OPERATION ...................................................................14

3.1 Theory of Operation............................................................................................. 14

3.2 Description of Operator Controls and Indicators................................................. 15

3.2.2 Dishwasher................................................................................................. 16

3.3 Start up Procedure................................................................................................ 18

3.4 Safety and Operation Checks............................................................................... 20

3.5 Shutdown Procedure ............................................................................................ 24

3.6 Operation Summary ............................................................................................. 25

TABLE OF CONTENTS

TABLE OF CONTENTS

xii

PART 4: MAINTENANCE AND CLEANING ...................................26

4.1 Introduction .......................................................................................................... 26

4.2 Daily Cleaning Schedules .................................................................................... 26

4.3 Deliming Schedule............................................................................................... 27

4.4 Preventive Maintenance Schedules...................................................................... 28

4.5 Lubrication Schedules.......................................................................................... 30

PART 5: BASIC SERVICE .............................................................32

5.1 Introduction .......................................................................................................... 32

5.2 General Troubleshooting...................................................................................... 33

5.3 Component Repair and Replacement .................................................................. 35

5.3.1 Pressure Reducing Valve, (PRV), Adjustment ....................................... 35

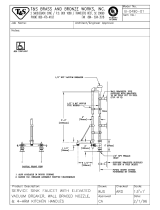

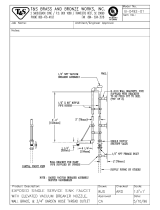

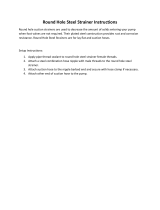

5.3.2 Water Line Strainers ............................................................................... 36

5.3.3 Vacuum Breaker Repair .......................................................................... 36

5.3.4 Water Solenoid Valve Repair .................................................................. 36

5.3.5 Float Switch Replacement ...................................................................... 37

5.3.6 Drain Valve and Overflow Assembly ..................................................... 37

5.3.7 Thermometer Replacement..................................................................... 37

5.3.8 Tank Heat Thermostat Adjustment and Replacement............................. 38

5.3.9 Tank Heat High Limit Adjustment and Replacement ............................. 38

5.3.10 Final Rinse Thermostat Adjustment and Replacement........................... 38

5.3.11 Steam Solenoid Valve Service ................................................................ 39

5.3.12 Steam Trap Replacement ........................................................................ 40

5.3.13 Steam Booster Service ............................................................................ 41

5.3.14 Pump Seal Replacement ......................................................................... 42

5.3.15 Door Safety Switch Assembly................................................................ 42

5.3.16 Fuse and Fuse Block Replacement ......................................................... 43

5.3.17 Motor Overload Adjustment and Replacement ...................................... 43

TABLE OF CONTENTS

xiii

TABLE OF CONTENTS

LIST OF FIGURES

Figure 6.1 – Doors, Gauges, Switches ........................................................................... 46

Figure 6.2 – Wash and Rinse Spray System................................................................... 48

Figure 6.3 – Scrap Screen, Pump strainer, and Overflow .............................................. 50

Figure 6.4 – Tank Heat Assembly (Prior to S/N G3599) ............................................... 52

Figure 6.5 – Tank Heat Assembly (After S/N G3600) ................................................... 54

Figure 6.6 – Tank Heat Assembly (After S/N U2769) ................................................... 56

Figure 6.7 – Steam Tank Heat Assembly (After S/N U2769) ........................................ 58

Figure 6.8 – Pump and Motor Assembly ....................................................................... 60

Figure 6.9 – Control Cabinet (Prior to S/N G3600)....................................................... 62

Figure 6.10 – Control Cabinet (After S/N G3600)........................................................... 64

Figure 6.11 – Control Cabinet (After S/N U2769)........................................................... 66

Figure 6.12 – Water Solenoid Valve and PRV.................................................................. 68

Figure 6.13 – Electric Booster (Prior to S/N G3599)....................................................... 70

Figure 6.14 – Electric Booster (After S/N G3600)........................................................... 72

Figure 6.15 – Electric Booster (After S/N U2769............................................................ 74

Figure 6.16 – No. 180 Steam Booster and Steam piping assembly ................................. 76

Figure 6.17 – Tank Piping with Steam Booster ............................................................... 80

Figure 6.18 – Dishracks.................................................................................................... 82

PART 6: REPLACEMENT PARTS .................................................45

6.1 Introduction .......................................................................................................... 45

6.2 Parts Procurement ................................................................................................ 45

PART 7: ELECTRICAL SCHEMATICS ...........................................85

PART 8: SPECIAL INSERTS .........................................................89

xiv

TABLE OF CONTENTS

This

Page

Intentionally

Left

Blank

1

PART 1: GENERAL SPECIFICATIONS

Welcome to Champion...

and thank you for allowing us to take care of your dishwashing needs.

1.1 About this Manual

All information, illustrations and specifications contained in this manual are based upon the

latest product information available at the time of publication. Champion constantly im-

proves its products and reserves the right to make changes at any time or to change specifica-

tions or design without notice and without incurring any obligation.

Manual Organization

This manual is divided into eight parts:

→ Part 1, General Specifications, introduces this manual and the dishwasher in general.

→ Part 2, Installation, discusses the installation of the dishwasher and describes the

connection of utilities and services.

→ Part 3, Operation, discusses theory of operation, operator controls, initial start up and

shutdown procedures.

→ Part 4, Maintenance and Cleaning, discusses lubrication, preventive maintenance,

cleaning and deliming.

→ Part 5, discusses basic troubleshooting and service procedures.

→ Part 6, discusses replacement parts procurement and provides parts diagrams and

parts lists.

→ Part 7, contains the dishwasher electrical schematic.

→ Part 8, contains special inserts and late breaking information.

1.2 Model Numbers

USN-10

The USN-10 series is a undercounter high temperature (180°F/82°C rinse) sanitizing dish-

washer. This model features electric or steam heat with booster.

The USN-10 is as front loading door model.

The USN-10 comes in the following model::

USN-10: 440V/60/3 Electric heat or Steam heat @ 15 PSI flow pressure

PART 1: GENERAL SPECIFICATIONS

2

PART 1: GENERAL SPECIFICATIONS

1.3 Standard Equipment

→ Heavy duty 304 stainless steel construction

→ Easy open front door loading

→ Closed construction with panels for easy service and cleaning

→ Flanged feet for deck mounting

→ Rotating upper and lower wash spray arms

→ Rotating lower and fixed upper rinse spray arms

→ 11 inch door clearance

→ 18" x 18" foot print, 34-1/4" high

→ Water resistant controls

→ Easy installation

→ Automatic tank fill

→ Built-in controls

→ Door safety switch

→ Low-water tank heat protection

→ Easy front access for service

→ 1/2 HP drip proof pump/motor assembly

→ Steam piping without threaded joints in tanks

→ 440V/60/3 power supply

→ 120VAC control circuit

→ Steam coil or electric tank heat

→ Easily removable scrap screens

→ Remote mounted control cabinet

Options and Accessories

→ External steam booster heater 70° rise (specified at time of order)

→ External electric booster heater 70° rise (specified at time of order)

(stainless steel, completely interplumbed and interwired)

→ Dishracks - dish or open (as specified by model)

3

PART 1: GENERAL SPECIFICATIONS

1.4 Dimensions, Capacities, Ventilation, and Utilities

Rack Capacity

Based on standard 16" X 16"

dishracks manually loaded

Rack Capacity

(racks/hr)

Capacities

Wash tank 5.0 gallons

Gal. per rack 0.8 gal/rack

Final rinse flow 36.0 gal/hr @ 20 psig

Dimensions

Height 34-3/8 inches

Width 18.0 inches

Length 18.0 inches

Volume crated 125 cu. ft.

Shipping weight crated 350 lbs.

Weight uncrated 200 lbs.

Utilities

Hot water: 3/4" NPT 180°F hot water connection, 36 GPM @ 20-22 psig flow pressure

Drain: 1" NPT drain connection @ 15 gal/min maximum flow rate.

Electric: 440/60/3 29.1 Amp Total

Tank heat: 3 KW heater 480/60/3

Booster heat: 20 KW heater 480/60/3

Steam heat: 480/60/3 2 amp for controls

Steam: 1-1/4" NPT steam connection (for machine and booster) @ 15-30 psig flow

Tank heat consumption 10 lbs./hr.

70°R Steam booster consumption 36 lbs./hr.

Condensate: 1/2" NPT machine return to boiler (no back pressure)

45

Cycle Time:

Wash 33

Dwell 5

Rinse 12

Total 50

4

PART 1: GENERAL SPECIFICATIONS

1.5 Electrical Power Requirements (Steam Heat)

Machine Full Load Amps

Operating Currents (480V/60/3 Supply)

Steam Heated

Dishwasher

Control Circuit 1.5 Amps

Model Voltage Booster Rise Machine Power Requirement

No. Hz/Ph (Steam) Full Load Amps (125% Service Factor)

USN-10 480/60/3 70° (E) 29.1 Amps 40 Amps

USN-10 480/60/3 70° (S) 1.5 Amps 15Amps

/