Page is loading ...

SERVICE MANUAL

Spreader/Sprayer

Residential Products

Issued: May 2016

Table of Contents

ABOUT THIS MANUAL

2016 The Toro Company

All Rights Reserved

This service manual was written expressly for Toro service technicians. The Toro Company has made every effort

to make the information in this manual complete and correct.

Basic shop safety knowledge and mechanical/electrical skills are assumed. The Table of Contents lists the

systems and the related topics covered in this manual.

The Spreader/Sprayer is covered in this manual. The manual may also be specied for use on later model

products.

Due to the compact design, parts were removed for photographic purposes when necessary.

We are hopeful that you will nd this manual a valuable addition to your service shop. If you have any questions

or comments regarding this manual, please contact us at the following address:

The Toro Company

Residential Contractor Service Training Department

8111 Lyndale Avenue South

Bloomington, MN 55420

The Toro Company reserves the right to change product specications on this manual without notice.

2 Table of Contents

TABLE OF CONTENTS

1. Safety

General Safety Information........................................................................................................................

2. Specications and Maintenance

Torque Specications.................................................................................................................................

Standard Torque (Inch Series)...................................................................................................................

Standard Torque (Metric Fasteners)..........................................................................................................

Other Torque Specications......................................................................................................................

Equivalents and Conversions....................................................................................................................

U.S. to Metric Conversions.........................................................................................................................

Recommended Maintenance Schedule.....................................................................................................

Premaintenance Procedures.....................................................................................................................

Lubrication...................................................................................................................................................

Engine Maintenance....................................................................................................................................

Electrical System Maintenance..................................................................................................................

Drive System Maintenance.........................................................................................................................

Controls System Maintenance...................................................................................................................

Maintaining the Sprayer System................................................................................................................

Cleaning.......................................................................................................................................................

Storage.........................................................................................................................................................

3. Spreader System

Spreader Subsystem Diagram...................................................................................................................

Spreader Bottom Section View Diagram..................................................................................................

Spreader Controls and Console View Diagram........................................................................................

Spreader Left Rear View Diagram..............................................................................................................

Spreader Right Side View Diagram...........................................................................................................

Hopper Spreader Asm. Diagram................................................................................................................

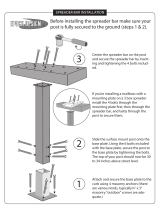

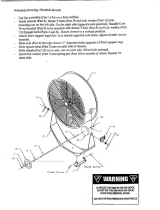

Hopper Replacement..................................................................................................................................

Removal...................................................................................................................................................

Installation...............................................................................................................................................

4. Chassis

Steering Subsystem Diagram....................................................................................................................

Frame Subsystem Diagram........................................................................................................................

Front Axle Assembly Replacement...........................................................................................................

Removal...................................................................................................................................................

Installation...............................................................................................................................................

Control Tower Replacement......................................................................................................................

Removal...................................................................................................................................................

Installation...............................................................................................................................................

5. Engine

Engine Subsystem......................................................................................................................................

Engine Replacement...................................................................................................................................

Removal...................................................................................................................................................

Installation...............................................................................................................................................

1-1

2-1

2-2

2-3

2-4

2-5

2-6

2-7

2-8

2-8

2-9

2-15

2-19

2-21

2-22

2-22

2-23

3-1

3-2

3-3

3-4

3-5

3-6

3-7

3-7

3-8

4-1

4-2

4-3

4-3

4-4

4-6

4-6

4-7

5-1

5-2

5-2

5-4

3Table of Contents

6. Sprayer System

Spray Subsystem 1 Diagram......................................................................................................................

Manifold-Valve Control Diagram................................................................................................................

Spray System Fitting Orientation Diagram...............................................................................................

Spray System Left Front View Diagram....................................................................................................

Spray System Rear View (Under Console) Diagram................................................................................

Spray System Right Rear View Diagram...................................................................................................

Valve Block Replacement...........................................................................................................................

Removal...................................................................................................................................................

Installation...............................................................................................................................................

Electrical Schematic...................................................................................................................................

7. Electrical

Electrical Subsystem Diagram...................................................................................................................

Electrical View Left Inside..........................................................................................................................

Electrical View Right Inside.......................................................................................................................

Electrical View Under Console..................................................................................................................

Electrical Schematic...................................................................................................................................

8. Drive System

Ground Drive Subsystem...........................................................................................................................

Transmission Replacement........................................................................................................................

Removal...................................................................................................................................................

Installation...............................................................................................................................................

6-1

6-2

6-3

6-4

6-5

6-6

6-7

6-7

6-8

6-10

7-1

7-2

7-3

7-4

7-5

8-1

8-2

8-2

8-4

Toro®- Spreader/Sprayer Service Manual 1-1Table of Contents

SAFETY

1

General Information

This symbol means WARNING or PERSONAL SAFETY

INSTRUCTION - read the instruction be-

cause if has to do with your safety. Failure

to comply with the instruction may result in

personal injury or even death.

This manual is intended as a service and

repair manual only. The safety instructions provided

herein are for troubleshooting, service, and repair of the

Toro Spreader/Sprayer. The Spreader/Sprayer and oper-

ator’s manual contains safety information and operating

tips for safe operating practices. Operator’s manuals are

available through your Toro parts source or:

The Toro Company

Publications Department

8111 Lyndale Avenue South

Bloomington, MN 55420

Think Safety First

Avoid injury due to inferior parts...

Use only original equipment parts to ensure that import-

ant safety criteria are met.

Avoid injury to bystanders...

Always clear the area of bystanders before starting or

testing powered equipment.

Avoid injury due to projectiles...

Always clear the area of sticks, rocks, or any other de-

bris that could be picked up and thrown by the powered

equipment.

Avoid modications...

Never alter or modify any part unless it is a factory ap-

proved procedure.

Avoid unsafe operation...

Always test the safety interlock system after making

adjustments or repairs on the machine. Refer to the

Electrical section in this manual for more information.

Avoid unexpected starting of engine...

Always turn off the engine and disconnect the spark plug

wire(s) before cleaning, adjusting, or repair.

Avoid lacerations and amputations...

Stay clear of all moving parts whenever the engine is

running. Treat all normally moving parts as if they were

moving whenever the engine is running or has the po-

tential to start.

Avoid burns...

Do not touch the engine, mufer, or other components

which may increase in temperature during operation,

while the unit is running or shortly after it has been run-

ning.

Avoid res and explosions...

Avoid spilling fuel and never smoke while working with

any type of fuel or lubricant. Wipe up any spilled fuel

or oil immediately. Never remove the fuel cap or add

fuel when the engine is running. Always use approved,

labeled containers for storing or transporting fuel and

lubricants.

Avoid asphyxiation...

Never operate an engine in a conned area without

proper ventilation.

Avoid injury from batteries...

Battery acid is poisonous and can cause burns. Avoid

contact with skin, eyes, and clothing. Battery gases can

explode. Keep cigarettes, sparks, and ames away from

the battery.

!

Toro®- Spreader/Sprayer Service Manual Table of Contents

SPECIFICATIONS AND MAINTENANCE

2-1

2

SPECIFICATIONS

2 - 4 TimeCutter

®

Z Service Manual

Torque Specifications

Recommended fastener torque values are listed in the

following tables. For critical applications, as

determined by Toro, either the recommended torque or

a torque that is unique to the application is clearly

identified and specified in the service manual.

These torque specifications for the installation and

tightening of fasteners shall apply to all fasteners which

do not have a specific requirement identified in the

service manual. The following factors shall be

considered when applying torque: cleanliness of the

fastener, use of a thread sealant (Loctite), degree of

lubrication on the fastener, presence of a prevailing

torque feature, hardness of the surface underneath of

the fastener’s head, or similar condition which affects

the installation.

As noted in the following tables, torque values should

be reduced by 25% for lubricated fasteners to

achieve the similar stress as a dry fastener. Torque

values may also have to be reduced when the fastener

is threaded into aluminum or brass. The specific

torque value should be determined based on the

aluminum or brass material strength, fastener size,

length of thread engagement, etc.

The standard method of verifying torque shall be

performed by marking a line on the fastener (head or

nut) and mating part, then back off fastener 1/4 of a

turn. Measure the torque required to tighten the

fastener until the lines match up.

Fastener Identification

Figure 1

Figure 2

Inch Series Bolts and Screws

(A) Grade 1

(B) Grade 5

(C) Grade 8

Metric Bolts and Screws

(A) Class 8.8 (B) Class 10.9

2

Torque Specications

Toro®- Spreader/Sprayer Service Manual

2

Table of Contents

SPECIFICATIONS AND MAINTENANCE

2-2

SPECIFICATIONS

TimeCutter

®

Z Service Manual 2 - 5

Standard Torque for Dry, Zinc Plated, and Steel Fasteners (Inch Series)

Note: Reduce torque values listed in the table above

by 25% for lubricated fasteners. Lubricated fasteners

are defined as threads coated with a lubricant such as

oil, graphite, or thread sealant such as Loctite.

Note: Torque values may have to be reduced when

installing fasteners into threaded aluminum or brass.

The specific torque value should be determined based

on the fastener size, the aluminum or base material

strength, length of thread engagement, etc.

Note: The nominal torque values listed above for

Grade 5 and 8 fasteners are based on 75% of the

minimum proof load specified in SAE J429. The

tolerance is approximately ± 10% of the nominal

torque value. Thin height nuts include jam nuts.

Thread Size

Grade 1, 5, &

8 with Thin

Height Nuts

SAE Grade 1 Bolts, Screws,

Studs, & Sems with Regular

Height Nuts (SAE J995

Grade 2 or Stronger Nuts)

SAE Grade 5 Bolts, Screws,

Studs, & Sems with Regular

Height Nuts (SAE J995

Grade 2 or Stronger Nuts)

SAE Grade 8 Bolts, Screws,

Studs, & Sems with Regular

Height Nuts (SAE J995

Grade 2 or Stronger Nuts)

In-lb In-lb N-cm In-lb N-cm In-lb N-cm

# 6 - 32 UNC

10 ± 2 13 ± 2 147 ± 23

15 ± 2 170 ± 20 23 ± 2 260 ± 20

# 6 - 40 UNF 17 ± 2 190 ± 20 25 ± 2 280 ± 20

# 8 - 32 UNC

13 ± 2 25 ± 5 282 ± 30

29 ± 3 330 ± 30 41 ± 4 460 ± 45

# 8 - 36 UNF 31 ± 3 350 ± 30 43 ± 4 31 ± 3

# 10 - 24 UNC

18 ± 2 30 ± 5 339 ± 56

42 ± 4 475 ± 45 60 ± 6 674 ± 70

#10 - 32 UNF 48 ± 4 540 ± 45 68 ± 6 765 ± 70

1/4 - 20 UNC 48 ± 7 53 ± 7 599 ± 79 100 ± 10 1125 ± 100 140 ± 15 1580 ± 170

1/4 - 28 UNF 53 ± 7 65 ± 10 734 ± 113 115 ± 10 1300 ± 100 160 ± 15 1800 ± 170

5/16 - 18 UNC 115 ± 15 105 ± 17 1186 ± 169 200 ± 25 2250 ± 280 300 ± 30 3390 ± 340

5/16 - 24 UNF 138 ± 17 128 ± 17 1446 ± 192 225 ± 25 2540 ± 280 325 ± 30 3670 ± 340

ft-lb ft-lb N-m ft-lb N-m ft-lb N-m

3/8 - 16 UNC 16 ± 2 16 ± 2 22 ± 3 30 ± 3 41 ± 4 43 ± 4 58 ± 5

3/8 - 24 UNF 17 ± 2 18 ± 2 24 ± 3 35 ± 3 47 ± 4 50 ± 4 68 ± 5

7/16 - 14 UNC 27 ± 3 27 ± 3 37 ± 4 50 ± 5 68 ± 7 70 ± 7 68 ± 9

7/16 - 20 UNF 29 ± 3 29 ± 3 39 ± 4 55 ± 5 75 ± 7 77 ± 7 104 ± 9

1/2 - 13 UNC 30 ± 3 48 ± 7 65 ± 9 75 ± 8 102 ± 11 105 ± 10 142 ± 14

1/2 - 20 UNF 32 ± 3 53 ± 7 72 ± 9 85 ± 8 115 ± 11 120 ± 10 163 ± 14

5/8 - 11 UNC 65 ± 10 88 ± 12 119 ± 16 150 ± 15 203 ± 20 210 ± 20 285 ± 27

5/8 - 18 UNF 75 ± 10 95 ± 15 129 ± 20 170 ± 15 230 ± 20 240 ± 20 325 ± 27

3/4 - 10 UNC 93 ± 12 140 ± 20 190 ± 27 265 ± 25 359 ± 34 374 ± 35 508 ± 47

3/4 - 16 UNF 115 ± 15 165 ± 25 224 ± 34 300 ± 25 407 ± 34 420 ± 35 569 ± 47

7/8 - 9 UNC 140 ± 20 225 ± 25 305 ± 34 430 ± 45 583 ± 61 600 ± 60 813 ± 81

7/8 - 14 UNF 155 ± 25 260 ± 30 353 ± 41 475 ± 45 644 ± 61 660 ± 60 895 ± 81

Toro®- Spreader/Sprayer Service Manual Table of Contents

SPECIFICATIONS AND MAINTENANCE

2-3

2

SPECIFICATIONS

2 - 6 TimeCutter

®

Z Service Manual

Standard Torque for Dry, Zinc, and Steel Fasteners (Metric Fasteners)

Note: Reduce torque values listed in the table above

by 25% for lubricated fasteners. Lubricated fasteners

are defined as threads coated with a lubricant such as

oil, graphite, or thread sealant such as Loctite.

Note: Torque values may have to be reduced when

installing fasteners into threaded aluminum or brass.

The specific torque value should be determined based

on the fastener size, the aluminum or base material

strength, length of thread engagement, etc.

Note: The nominal torque values listed above are

based on 75% of the minimum proof load specified in

SAE J1199. The tolerance is approximately ± 10% of

the nominal torque value. Thin height nuts include jam

nuts.

Thread Size

Class 8.8 Bolts, Screws, and Studs with

Regular Height Nuts

(Class 8 or Strong Nuts)

Class 10.9 Bolts, Screws, and Studs with

Regular Height Nuts (

Class 10 or Strong Nuts)

M5 X 0.8 57 ± 5 in-lb 640 ± 60 N-cm 78 ± 7 in-lb 885 ± 80 N-cm

M6 X 1.0 96 ± 9 in-lb 1018 ± 100 N-cm 133 ± 13 in-lb 1500 ± 150 N-cm

M8 X 1.25 19 ± 2 ft-lb 26 ± 3 N-m 27 ± 2 ft-lb 36 ± 3 N-m

M10 X 1.5 38 ± 4 ft-lb 52 ± 5 N-m 53 ± 5 ft-lb 72 ± 7 N-m

M12 X 1.75 66 ± 7 ft-lb 90 ± 10 N-m 92 ± 9 ft-lb 125 ± 12 N-m

M16 X 2.0 166 ± 15 ft-lb 225 ± 20 N-m 229 ± 22 ft-lb 310 ± 30 N-m

M20 X 2.5 325 ± 33 ft-lb 440 ± 45 N-m 450 ± 37 ft-lb 610 ± 50 N-m

Toro®- Spreader/Sprayer Service Manual

2

Table of Contents

SPECIFICATIONS AND MAINTENANCE

2-4

SPECIFICATIONS

TimeCutter

®

Z Service Manual 2 - 7

Other Torque Specifications

SAE Grade 8 Steel Set Screws

Thread Cutting Screws

(Zinc Plated Steel)

Conversion Factors

in-lb X 11.2985 - N-cm

ft-lb X 1.3558 = N-m

Wheel Bolts and Lug Nuts

** For steel wheels and non-lubricated fasteners.

Thread Cutting Screws

(Zinc Plated Steel)

* Hole size, material strength, material thickness and

finish must be considered when determining specific

torque values. All torque values are based on non-

lubricated fasteners.

N-cm X - 0.08851 = in-lb

N-cm X 0.73776 - ft-lb

Thread Size

Recommended Torque

Square Head Hex Socket

1/4 - 20 UNC 140 ± 20 in-lb 73 ± 12 in-lb

5/16 - 18 UNC 215 ± 35 in-lb 145 ± 20 in-lb

3/8 - 16 UNC 35 ± 10 ft-lb 18 ± 3 ft-lb

1/2 - 13 UNC 75 ± 15 ft-lb 50 ± 10 ft-lb

Type 1, Type 23, or Type F

Thread Size Baseline Torque*

No. 6 - 32 UNC 20 ± 5 in-lb

No. 8 - 32 UNC 30 ± 5 in-lb

No.10 - 24 UNC 38 ± 7 in-lb

1/4 - 20 UNC 85 ± 15 in-lb

5/16 - 18 UNC 110 ± 20 in-lb

3/8 - 16 UNC 200 ± 100 in-lb

Thread Size Recommended Torque**

7/16 - 20 UNF

Grade 5

65 ± 10 ft-lb 88 ± 14 N-m

1/2 - 20 UNF

Grade 5

80 ± 10 ft-lb 108 ± 14 N-m

M12 X 1.25

Class 8.8

80 ± 10 ft-lb 108 ± 14 N-m

M12 X 1.5

Class 8.8

80 ± 10 ft-lb 108 ± 14 N-m

Thread

Size

Threads per Inch

Baseline Torque*

Type A Type B

No. 6 18 20 20 ± 5 in-lb

No. 8 15 18 30 ± 5 in-lb

No. 10 12 16 38 ± 7 in-lb

No. 12 11 14 85 ± 15 in-lb

Toro®- Spreader/Sprayer Service Manual Table of Contents

SPECIFICATIONS AND MAINTENANCE

2-5

2

SPECIFICATIONS

2 - 8 TimeCutter

®

Z Service Manual

Equivalents and Conversions

Decimal and Millimeter Equivalents

Fractions Decimals mm Fractions Decimals mm

1/64 0.015625 0.397 33/64 0.515625 13.097

1/32 0.03125 0.794 16/32 0.53125 13.484

3/64 0.046875 1.191 35/64 0.546875 13.891

1/16 0.0625 1.588 9/16 0.5625 14.288

5/64 0.078125 1.984 37/64 0.578125 14.684

3/32 0.9375 2.381 19/32 0.59375 15.081

1/8 0.1250 3.175 5/8 0.6250 15.875

9/64 0.140625 3.572 41/64 0.640625 16.272

5/32 0.15625 3.969 21/32 0.65625 16.669

11/64 0.171875 4.366 43/64 0.671875 17.066

3/16 0.1875 4.762 11/16 0.6875 17.462

13/64 0.203125 5.159 45/64 0.703125 17.859

7/32 0.21875 5.556 23/32 0.71875 18.256

15/64 0.234375 5.953 47/64 0.734375 18.653

1/4 0.2500 6.350 3/4 0.7500 19.050

17/64 0.265625 6.747 49/64 0.765625 19.447

9/32 0.28125 7.144 25/32 0.78125 19.844

19/64 0.296875 7.541 51/64 0.796875 20.241

5/16 0.3125 7.541 13/16 0.8125 20.638

21/64 0.328125 8.334 53/64 0.828125 21.034

11/32 0.34375 8.731 27/32 0.84375 21.431

23/64 0.359375 9.128 55/64 0.859375 21.828

3/8 0.3750 9.525 7/8 0.8750 22.225

25/64 0.390625 9.922 57/64 0.890625 22.622

13/32 0.40625 10.319 29/32 0.90625 23.019

27/64 0.421875 10.716 59/64 0.921875 23.416

7/16 0.4375 11.112 15/16 0.9375 23.812

29/64 0.453125 11.509 61/64 0.953125 24.209

15/32 0.46875 11.906 31/32 0.96875 24.606

31/64 0.484375 12.303 63/64 0.984375 25.003

1/2 0.5000 12.700 1 1.000 25.400

1 mm = 0.03937 in. 0.001 in. = 0.0254 mm

Toro®- Spreader/Sprayer Service Manual

2

Table of Contents

SPECIFICATIONS AND MAINTENANCE

2-6

SPECIFICATIONS

TimeCutter

®

Z Service Manual 2 - 9

U.S. to Metric Conversions

To Convert Into Multiply By

Linear

Measurement

Miles

Yards

Feet

Feet

Inches

Inches

Inches

Kilometers

Meters

Meters

Centimeters

Meters

Centimeters

Millimeters

1.609

0.9144

0.3048

30.48

0.0254

2.54

25.4

Area

Square Miles

Square Feet

Square Inches

Acre

Square Kilometers

Square Meters

Square Centimeters

Hectare

2.59

0.0929

6.452

0.4047

Volume

Cubic Yards

Cubic Feet

Cubic Inches

Cubic Meters

Cubic Meters

Cubic Centimeters

0.7646

0.02832

16.39

Weight

Tons (Short)

Pounds

Ounces

Metric Tons

Kilograms

Grams

0.9078

0.4536

28.3495

Pressure

Pounds/Sq. In. Kilopascal

6.895

Work

Foot-pounds

Foot-pounds

Inch-pounds

Newton-Meters

Kilogram-Meters

Kilogram-Centimeters

1.356

0.1383

1.152144

Liquid Volume

Quarts

Gallons

Liters

Liters

0.9463

3.785

Liquid Flows

Gallons/Minute Liters/Minute

3.785

Temperature

Fahrenheit Celsius

1. Subtract 32°

2. Multiply by 5/9

Toro®- Spreader/Sprayer Service Manual Table of Contents

SPECIFICATIONS AND MAINTENANCE

2-7

2

Maintenance

WARNING

While you are maintaining or adjusting the machine,

someone could start the engine. Accidentally starting

the engine could seriously injure you or other

bystanders.

Remove the key from the ignition switch, engage

parking brake, and pull the wire(s) off the spark plug(s)

before you do any maintenance. Also push the wire(s)

aside so it does not accidentally contact the spark

plug(s).

WARNING

The engine can become very hot. Touching a hot

engine can cause severe burns.

Allow the engine to cool completely before service or

making repairs around the engine area.

Recommended Maintenance Schedule(s)

Maintenance Service

Interval

Maintenance Procedure

Before each use or daily

• Check the engine-oil level.

• Check the safety interlock system.

• Test the starter interlock.

• Check the machine for loose hardware.

• Check air cleaner; replace if dirty (may need more often under severe conditions).

• Clean the engine and the exhaust system area.

• Clean the grass and debris buildup from the machine.

After each use

• Clean and lubricate the spreader.

• Clean the sprayer tank.

• Clean the strainer.

• Clean the sprayer nozzles.

Every 50 hours

• Clean the foam air-cleaner element (more often under severe conditions).

• Check the pressure in the tires.

• Service the transaxle.

• Check sprayer system.

Every 80 hours

• Remove the engine shrouds and clean the cooling ns.

Every 100 hours

• Lubricate the grease ttings.

• Replace the dual element air lter.

• Change the engine oil.

• Change the engine oil (more often under severe condition).

• Check, clean and gap the spark plug.

Every 200 hours

• Service the spark arrester.

Monthly

• Clean the fuel sediment cup.

• Service the fuel strainer.

• Check the battery.

Yearly

• Torque the axle bolts.

Yearly or before storage

• Prepare the machine for storage.

50

Toro®- Spreader/Sprayer Service Manual

2

Table of Contents

SPECIFICATIONS AND MAINTENANCE

2-8

Premaintenance

Procedures

CAUTION

Raising the machine for service or maintenance

relying solely on mechanical or hydraulic jacks could

be dangerous. The mechanical or hydraulic jacks may

not be enough support or may malfunction allowing

the machine to fall, which could cause injury.

Do not rely solely on mechanical or hydraulic jacks for

support. Use adequate jack stands or equivalent

support.

Preparing Machine for

Maintenance

Perform the following before servicing, cleaning, or making

any adjustments to the machine.

1. Move the machine to a level surface.

2. Shut off the engine, set the parking brake, wait for

all moving parts to stop.

3. Remove the key from the key switch.

Lubrication

Lubricating the Grease Fittings

Service Interval: Every 100 hours

Grease type: National Lubricating Grease Institute (NGLI)

grade #2 multi-purpose gun grease.

Note: Refer to the lubrication chart for the grease

points and service intervals.

Lubrication Chart

Fitting Locations Initial Pumps

Number of

Places

1. Wheel bearings 1to2 2

2. Kingpin pivots 1to2 2

3. Front axle pivots 1to2 1

4. Steering control

pivot

1to2 1

Figure 1

1. Stop engine, set the parking brake, wait for all

moving parts to stop, and remove key.

2. Wipe clean the grease fittings with a rag (Figure 1).

3. Connect a grease gun to the fitting (Figure 1).

4. Pump grease into the fittings until grease begins to

ooze out of the bearings.

5. Wipe up any excess grease.

51

Toro®- Spreader/Sprayer Service Manual Table of Contents

SPECIFICATIONS AND MAINTENANCE

2-9

2

Engine Maintenance

Servicing the Air Cleaner

Service Interval: Before each use or daily

Every 100 hours

Important: Do not apply oil to the foam or

paper element.

Removing the Foam and Paper

Elements

1. Stop the engine, set the parking brake, remove the

key, and wait for all moving parts to stop before

leaving the operating position.

2. Clean around the air cleaner to prevent dirt from

getting into the engine and causing damage (Figure

2).

Figure 2

1. Air-cleaner cover 4. Hold-down rod

(carburetor)

2. Paper lter element

5. Wing nuts

3. Foam element

3. Rotate the wing nut that secures the air-cleaner

cover counterclockwise and remove the air-cleaner

cover (Figure 2).

4. Rotate the wing nut that secures the paper and

foam filter elements counterclockwise and remove

the filter elements from the hold-down rod of the

carburetor (Figure 2).

5. Carefully pull the foam element off the paper

element (Figure 2).

Note: Inspect the paper and foam filter elements for

damage or an excessive accumulation of dirt.

Replace all damaged filters. Clean the foam filter

element if it is dirty. Replace the paper filter element

if it is dirty.

Servicing the Foam Filter Element

Service Interval: Every 50 hours (more often

under severe

conditions).

1. Inspect the element for tears, an oily film, or

damaged (Figure 2).

Important: Replace the foam element if it is

worn or damaged.

2. Wash the foam element in liquid soap and warm

water. When the element is clean, rinse it

thoroughly.

3. Dry the element by squeezing it in a clean cloth.

Note: Allow the foam filter element to air dry.

Installing the Foam and Paper Filter

Elements

Important: To prevent engine damage, always operate

the engine with the complete foam and paper air-

cleaner assembly installed.

1. Carefully slide the foam filter element onto the paper

filter element (Figure 2).

2. Align the hole in the top plate of the paper filter

element with the hold-down rod of the carburetor

(Figure 2).

3. Secure the filter elements to the carburetor with the

wing nut (Figure 2) that you removed in step 4 of

Removing the Foam and Paper Elements.

4. Align the hole in the air-cleaner cover with the hold-

down rod (Figure 2) and secure the cover to the rod

with the wing nut that you removed in step 3 of

Removing the Foam and Paper Elements.

52

Toro®- Spreader/Sprayer Service Manual

2

Table of Contents

SPECIFICATIONS AND MAINTENANCE

2-10

Servicing the Engine Oil

Oil Type: Detergent oil (API service SJ or

higher) Engine Oil Capacity: 1.1 L (1.2 US qt)

Oil viscosity: Refer to the table below.

Figure 3

Changing the Engine Oil

Service Interval: Every 100 hours

Every 100 hours (more often under severe condition).

Important:

Do not operate the engine with the oil

level below the Low (or Add) mark on the dipstick, or

over the Full mark.

1. Move the machine to a level surface.

2. Stop the engine, remove the key, and wait for all

moving parts to stop before leaving the operating

position.

3. Allow the engine to cool.

4. Align a drain pan with a capacity of 1.5 L (1.6 US qt)

or greater below the drain valve at the bottom of the

skid plate and inboard from the battery tray (Figure

4).

Figure 4

4. Skid plate

5. Front of the machine

1. Drain valve

2. Hex-head stem

3. Battery tray

5.

Open the drain valve by rotating the hex-head stem

of the valve counterclockwise with a wrench (Figure

4).

Note:

Allow the engine oil to drain completely.

6.

Close the drain valve clockwise until the valve is

fully seated (Figure 4).

Note:

Wipe clean any residual oil from the drain

valve.

7.

Remove the dipstick from the filler neck of the

engine and wipe clean the dipstick with a rag (Figure

5).

Figure 5

1. Dipstick 2. Filler neck

8.

Slowly pour 1.1 L (1.2 US qt) of the specified oil into

the crank case of the engine through the filler

neck (Figure 5).

53

Toro®- Spreader/Sprayer Service Manual Table of Contents

SPECIFICATIONS AND MAINTENANCE

2-11

2

9. Insert the dipstick from the engine.

Note: Do not thread the dipstick into the filler neck

when checking the engine oil level.

Figure 6

1. Dipstick 3. Minimum oil level

2. Maximum oil level

10. Remove the dipstick from the filler neck and look at

the oil level in the dipstick (Figure 5).

Note: The engine oil level must cover between

the hatch marked areas on the dipstick (Figure 5).

11. If the oil level is low, add the specified oil into the

engine until the oil level is between the hatch

marked areas on the dipstick.

Note: Do not overfill the engine with oil.

12. Insert the dipstick into the filler neck and tighten

the dipstick hand tight (Figure 5).

Servicing the Spark Plug

Service Interval: Every 100 hours

Spark Plug Type: NGK BR6HS, Champion RTL86C, or

equivalent

Air Gap: 0.6 to 0.7 mm (0.02 to 0.03 inch)

Make sure the air gap between the center and side

electrodes is correct before installing the spark plug.

Use a spark plug wrench for removing and installing the

spark plug(s) and a gapping tool/feeler gauge to check and

adjust the air gap. Install a new spark plug(s) if necessary.

Removing the Spark Plug

1. Stop the engine, set the parking brake, remove the

key, and wait for all moving parts to stop before

leaving the operating position.

2. Remove the spark plug as shown in Figure 7.

Figure 7

54

Toro®- Spreader/Sprayer Service Manual

2

Table of Contents

SPECIFICATIONS AND MAINTENANCE

2-12

Checking the Spark Plug

Important:

Do not clean the spark plug(s). Always

replace the spark plug(s) when it has a black coating,

worn electrodes, an oily film, or cracks.

If you see light brown or gray on the insulator, the engine

is operating properly. A black coating on the insulator

usually means the air cleaner is dirty.

Set the gap to 0.6 to 0.7 mm (0.02 to 0.03 inch).

G008794

1

2

Figure 8

Installing the Spark Plug

Tighten the spark plug as follows:

•

New spark plug—12 to 15 N-m (8.7 to 10.8 ft-lb)

•

In-service spark plug—23 to 27 N-m (16.6 to 19.5 ft-lb)

Figure 9

Servicing the Engine Fuel

System

Cleaning the Fuel Sediment Cup

Service Interval: Monthly

1. Move the fuel shutoff valve to the Off position; refer

to Fuel Shut-Off Valve.

2. Align a drain pan under the body of the fuel shutoff

valve for the carburetor (Figure 10).

Figure 10

1. Fuel shutoff valve body

(carburetor)

3. Sediment cup

2. Seal

3.

Rotate the sediment cup counterclockwise and

remove the cup from the carburetor (Figure 10).

Note:

Check the seal for the sediment cup for

damage or wear; replace the seal if it is damaged or

worn.

4.

Clean the sediment cup in fresh gasoline or

kerosene.

5.

Thread the sediment cup into the body of the fuel

shutoff valve hand tight (Figure 10).

6.

Open the fuel shutoff valve and check for fuel leaks.

Servicing the Fuel Strainer

Service Interval: Monthly

Removing the Fuel Tank

1.

Move the fuel shutoff valve to the Off position; refer

to Fuel Shut-Off Valve.

2.

Align a drain pan with a 6.1 L (1.6 US gallons)

capacity with a under the carburetor.

3.

Rotate the sediment cup counterclockwise and

remove the cup from the carburetor.

Note:

Check the seal for the sediment cup for

damage or wear; replace the seal if it is damaged or

worn.

4.

Move the fuel shutoff valve to the On position.

Note:

Allow the fuel system to drain completely.

5.

Remove the 2 bolts 6 x 25 mm and 2 nuts 8 mm that

secure the fuel tank to the tank supports (Figure 11).

55

Toro®- Spreader/Sprayer Service Manual Table of Contents

SPECIFICATIONS AND MAINTENANCE

2-13

2

Figure 11

1. Fuel tank 5. Tank supports

2. Strainer

6. Bolt 6 x 25 mm

3. Fuel hose

7. Clamps

4. Nuts 8 mm

6.

Loosen the hose clamp and disconnect fuel hose from

the fitting on the carburetor (Figure 12).

Figure 12

1. Fitting (carburetor)

3. Fuel hose

2. Clamp

7.

Remove the fuel tank from the crankcase of the engine

(Figure 11 and Figure 13).

Figure 13

1. Fuel hose

3. Strainer

2. Boss 4. Fuel tank

Cleaning the Fuel Strainer

1.

Loosen the hose clamp and disconnect fuel hose

from the fitting at the fuel strainer (Figure 11).

2.

Rotate the fuel strainer counterclockwise and remove

it from the fuel tank (Figure 11).

Note:

Check the seal and fuel strainer for damage

or wear. Replace the seal or fuel strainer if the seal

or strainer are damaged.

3.

Clean the fuel strainer in fresh gasoline or kerosene.

4.

Thread the fuel strainer into the fuel tank (Figure 11).

5.

Torque the fuel strainer to 3.0 to 4.0 N-m (2.2 to 2.9

ft-lb).

6.

Align the fuel hose that you removed in step 1 over

the fitting on the fuel strainer (Figure 11 and Figure

13).

7.

Secure the hose to the strainer fitting with the clamp

(Figure 11 and Figure 13).

Installing the Fuel Tank

1. Apply medium-grade thread-locking compound to the

8 mm studs in the fuel tank and the 2 bolts 6 x 25

mm.

2. Align the fuel tank to the tank supports on the engine

(Figure 11).

3. Align the fuel hose that you removed in step 6 of

Removing the Fuel Tank to the fitting on the

carburetor (Figure 12 and Figure 13).

4. Secure the hose to the carburetor fitting with the

clamp (Figure 12).

5. Assemble the tank to the tank supports on the engine

with the 2 bolts 6 x 25 mm and 2 nuts 8 mm (Figure

11).

6. Torque the 6 mm bolts to 945 to 1171 N-m (86 to 106

in-lb).

7. Thread the sediment cup into the carburetor hand

tight.

56

Toro®- Spreader/Sprayer Service Manual

2

Table of Contents

SPECIFICATIONS AND MAINTENANCE

2-14

8.

Add fuel to the fuel tank, open the fuel shutoff valve,

and check for fuel leaks.

Note:

Do not add too much fuel to the tank before

you have confirmed that there are no fuel leaks.

Servicing the Spark Arrester

Service Interval: Every 200 hours

Removing the Spark Arrester

WARNING

Hot exhaust system components may ignite gasoline

vapors even after the engine is stopped. Hot particles

exhausted during engine operation may ignite

flammable materials. Fire may result in personal

injury or property damage.

Do not refuel or run engine unless spark arrester is

installed.

1. Stop the engine, set the parking brake, remove the

key, and wait for all moving parts to stop before

leaving the operating position.

2. Allow the muffler to cool.

3. Remove the 2 self-tapping screws that secure the tail

screen to the muffler cover and remove the screen

(Figure 14).

Figure 14

1. Fanged-head bolt

5. Self-tapping screw

2. Bolts

6. Mufer

3. Mufer cover 7. Spark arrester

4. Tail screen

8. Self-tapping screw

4. Remove the 2 bolts and 1 flanged-head bolt that

secures the muffler cover to the muffler (Figure 14).

5. Remove the self-tapping screw that secure the

spark arrester to the muffler and remove the spark

arrester (Figure 14).

57

Toro®- Spreader/Sprayer Service Manual Table of Contents

SPECIFICATIONS AND MAINTENANCE

2-15

2

Electrical System

Maintenance

Servicing the Battery

Service Interval: Monthly

Always keep the battery clean and fully charged. Use a

paper towel to clean the battery case. If the battery

terminals are corroded, clean them with a solution of four

parts water and one part baking soda. Apply a light

coating of grease to the battery terminals to prevent

corrosion.

Voltage: 12 volts

WARNING

CALIFORNIA

Proposition 65 Warning

Battery posts, terminals, and related

accessories contain lead and lead compounds,

chemicals known to the State of California to

cause cancer and reproductive harm. Wash

hands after handling.

DANGER

Charging or jump starting the battery may produce

explosive gases. Battery gases can explode causing

serious injury.

• Keep sparks, flames, or cigarettes away from

battery.

• Ventilate when charging or using battery in an

enclosed space.

• Make sure that the venting path of battery is

always open once the battery is filled with acid.

• Do not lean over the batteries.

• Always shield eyes and face from battery.

DANGER

Battery electrolyte contains sulfuric acid, which is

poisonous and can cause severe burns. Swallowing

electrolyte can be fatal or if it touches skin can cause

severe burns.

• Wear safety glasses to shield your eyes and rubber

gloves to protect your skin and clothing when

handling electrolyte.

• Do not swallow electrolyte.

• In the event of an accident, flush with water and call

a doctor immediately.

Checking the Battery Charge

CAUTION

If the ignition is in the On position there is potential for

sparks and engagement of components. Sparks could

cause an explosion or moving parts could accidentally

engage causing personal injury.

Be sure ignition switch is in the Off position before

charging the battery.

1. Move the ignition switch to the Off position and

remove the key.

2. Remove the free end of the battery strap from the

buckle and remove the battery cover from the

battery box (Figure 15).

Figure 15

1. Battery box 5. Battery cover

2. Battery support 6. Negative terminal

3. Buckle 7. Positive terminal

4. Battery strap

3. Measure the voltage of the battery with a voltmeter.

4. Use the table below to locate the charge state or the

battery, and if needed, the battery-charger setting

and charging interval recommended to charge the

battery to 12.6 volts or greater; refer to the battery

charge table below.

58

/