5

Produced by ©Metaphor, 01-2011

Refrigerants

Applicable to all common non flammable

refrigerants including R717, R744 (CO

2

) and

non corrosive gases/liquids dependent on

sealing material compatibility.

For further information please refer to

installation instruction for ICF.

Use of the ICF control solution with flammable

hydrocarbons is not recommended.

For further information please contact the

local Danfoss sales company.

Temperature range

–60/+120°C (–76/+248°F).

Ambient temperature for ICF with ICAD:

–30°C/+50°C (–22°F/122°F)

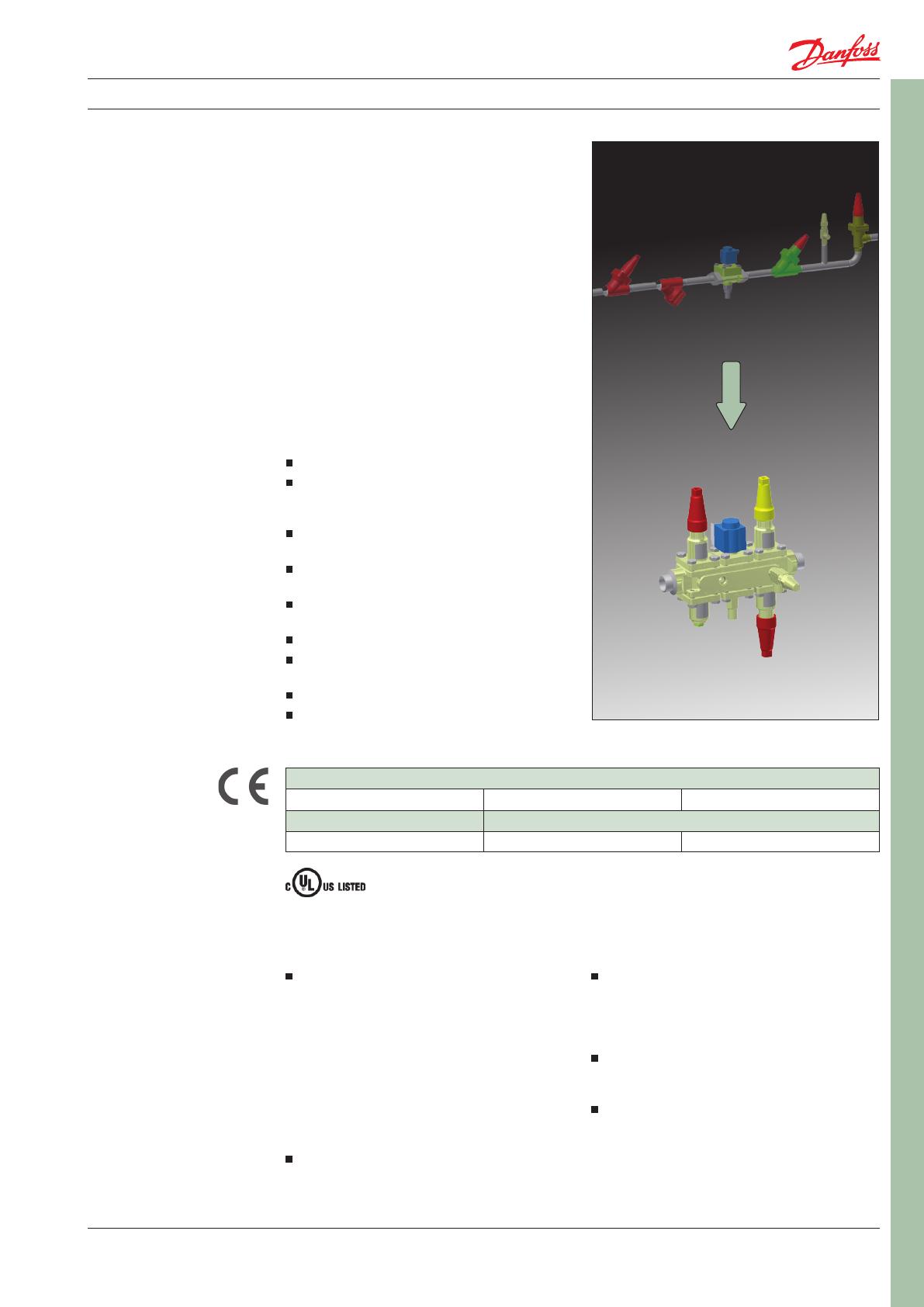

The valve train of the

Future since 2005

The ICF valve station is an innovative solution

that provides the full functionality of a

conventional valve station in a single compact

unit.

Eliminate project bottleneck:

Conventional valve stations of six or more

individual components and up to twelve welds.

ICF means two welds directly at the job site

Down time during service is reduced to a fraction

compared to conventional valve trains. The

unique design of the ICF ensures a quick pump

down and faster access to valve modules.

The ICF valve is a compact valve train ready for

the jobsite.

This solution provides you with a variety of

benefits:

Designed for Industrial Refrigeration

Supplied fully assembled. No need to

disassembly prior to installation under normal

welding procedures

Standard side ports to fit service valves,

pressure transmitters, sight glasses.

Applicable to all common non flammable

refrigerants including R744 and R717.

Direct Weld Connections (No leaks through

flanges)

Compact design, faster service

Available with different connection types

including ANSI and DIN, Socket weld

High capacities low pressure drop

Low weight design

Approvals

ICF valve station

Nominal bore

DN ≤ 25 (1 in.)

DN 32-40 (1¼ - 1½”)

Classified for Fluid group I

Category Article 3, paragraph 3 II

Technical data

Surface protection

The external surface is zinc-chromated to

provide corrosion protection.

Additional on-site corrosion protection is

recommended.

Pressure

The ICF is designed for:

Max. working pressure: 52 bar g (754 psig)

Opening differential pressure

Please refer to the individual function module

data.

CRN

Application Guide ICF Valve Station

DKRCI.PA.FT0.A1.02 / 520H4507