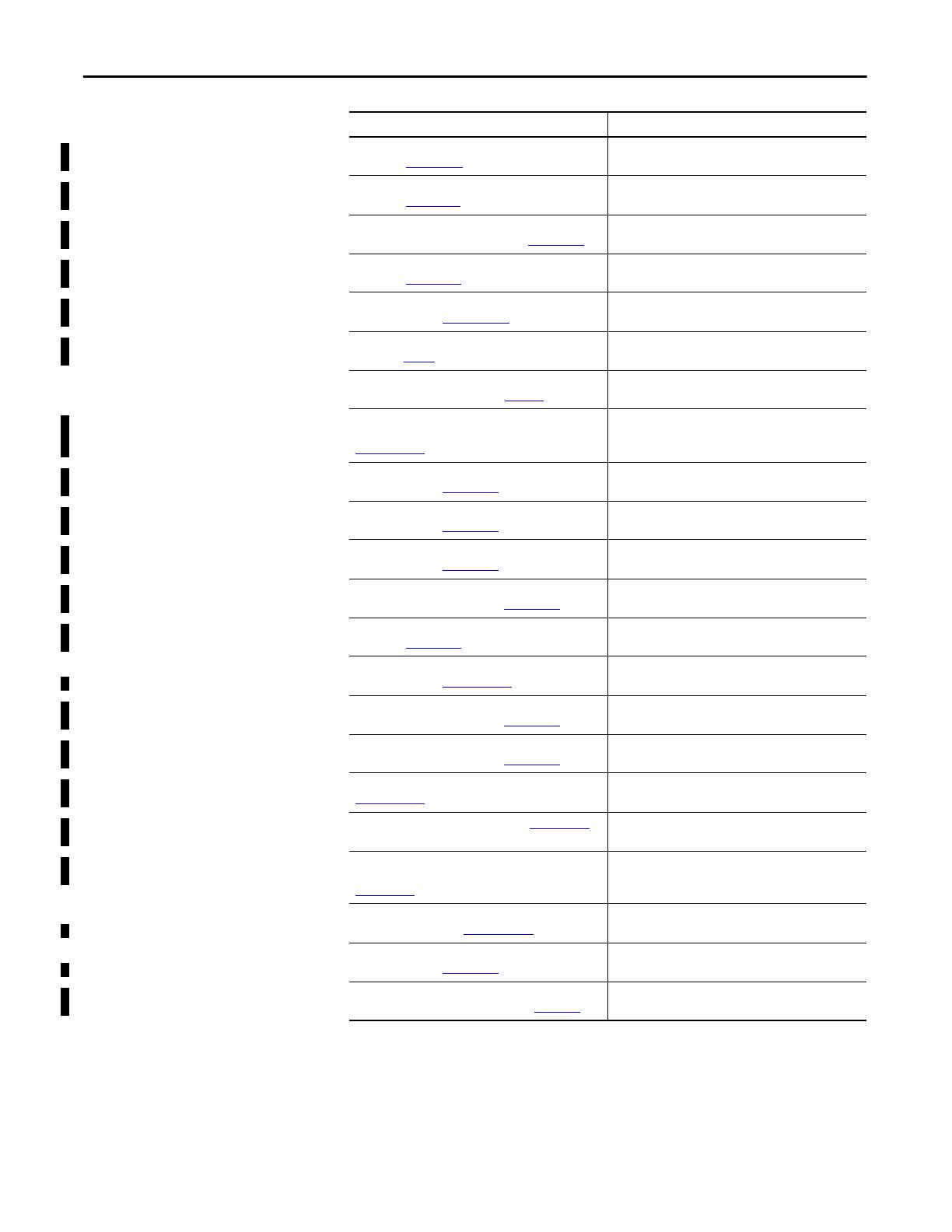

16 Rockwell Automation Publication 1756-UM001O-EN-P - October 2014

Preface

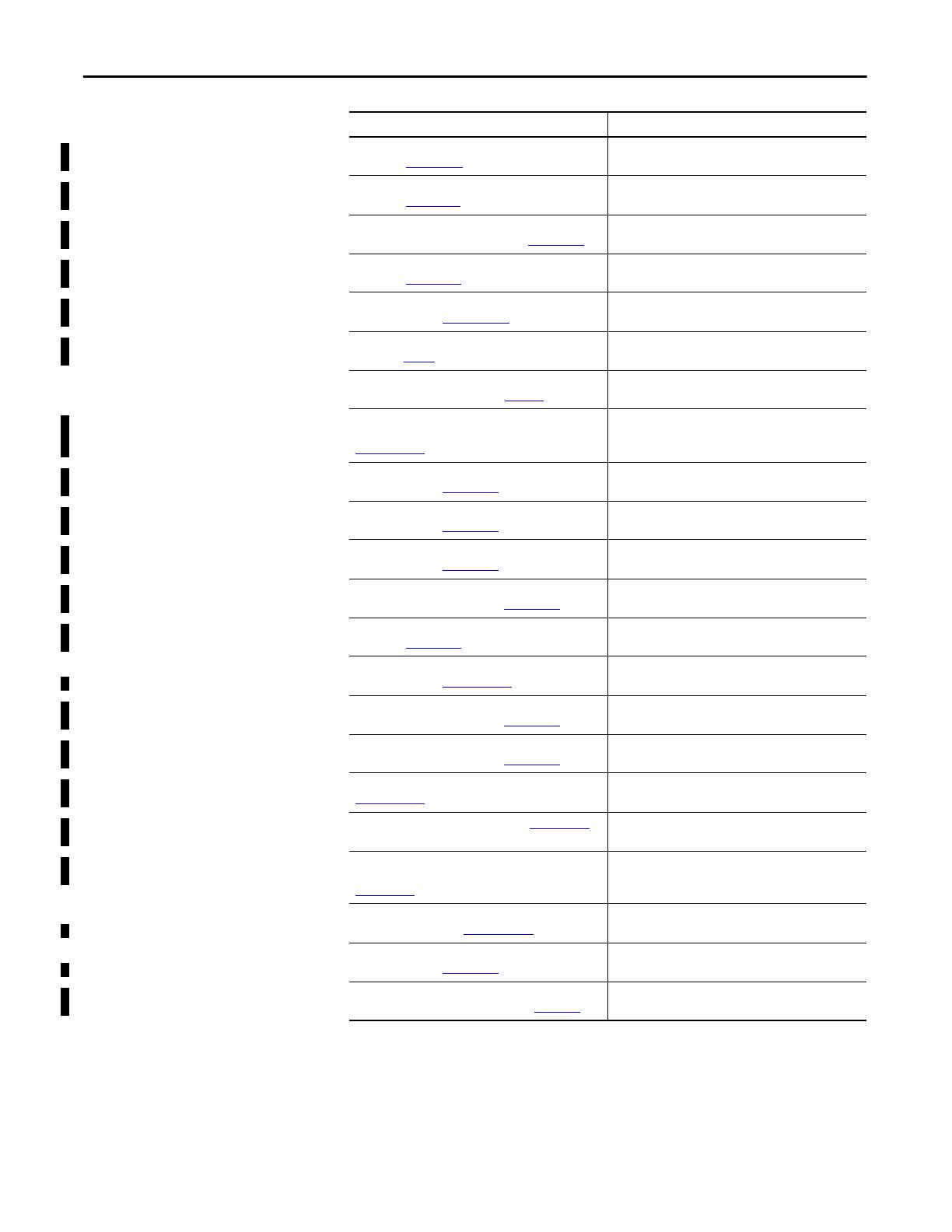

DeviceNet Network Configuration User Manual,

publication DNET-UM004

Provides information about DeviceNet modules and

devices.

Ethernet Design Considerations Reference Manual,

publication ENET-RM002

Provides additional information about network design for

your system.

EtherNet/IP and ControlNet to FOUNDATION Fieldbus

Linking Device User Manual, publication 1788-UM057

Provides more information about using the available

Foundation Fieldbus devices.

EtherNet/IP Network Configuration User Manual,

publication ENET-UM001

Provides information about EtherNet/IP communication

modules.

FOUNDATION Fieldbus Design Considerations Reference

Manual, publication PROCES-RM005

Provides more information about using the available

Foundation Fieldbus devices.

Guidelines for Handling Lithium Batteries Technical Data,

publication AG-5.4

Provides information regarding storage, handling,

transportation, and disposal of lithium batteries.

Integrated Architecture and CIP Sync Configuration

Application Technique, publication IA-AT003

Describes how to configure CIP Sync with Integrated

Architecture® products and applications.

Integrated Motion on the EtherNet/IP Network

Configuration and Startup User Manual, publication

MOTION-UM003

Details how to design your ControlLogix system for

Integrated Motion on the EtherNet/IP network

applications.

Logix5000 Controllers Add-On Instructions Programming

Manual, publication 1756-PM010

Provides more information about using add-on

instructions.

Logix5000 Controllers General Instructions Reference

Manual, publication 1756-RM003

Provides more information about GSV instructions, SSV

instructions, objects, and attributes.

Logix5000 Controllers I/O and Tag Data Programming

Manual, publication 1756-PM004

Provides information for creating and configuring

program tags for optimal task and program execution.

Logix5000 Controllers Major, Minor and I/O Faults

Programming Manual, publication 1756-PM014

Provides more information for I/O faults.

Logix5000 Controllers Messages Programming Manual,

publication 1756-PM012

Provides information for controller messages.

Logix5000 Controllers Motion Instructions Reference

Manual, publication MOTION-RM002

Provides programmers with details about the motion

instructions that are available for a Logix5000 controller.

Logix5000 Controllers Nonvolatile Memory Card

Programming Manual, publication 1756-PM017

Provides information about changing the project that is

available to load from nonvolatile memory,

Logix5000 Controllers Produced and Consumed Tags

Programming Manual, publication 1756-PM011

Provides more information for produced and consumed

tags.

Motion Coordinate System User Manual, publication

MOTION-UM002

Details how to create and configure a coordinated motion

application system.

PhaseManager User Manual, publication LOGIX-UM001

Provides more information about instructions for use with

equipment phases.

Runtime/On-line Addition of ControlLogix (1756) I/O over

ControlNet and EtherNet/IP White Paper, publication

LOGIX-WP006

Provides information for adding to the I/O Configuration

while online.

SERCOS and Analog Motion Configuration and Startup

User Manual, publication MOTION-UM001

Details how to configure a sercos motion application

system.

Using ControlLogix in SIL2 Applications Safety Reference

Manual, publication 1756-RM001

Provides specific configuration and programming

considerations.

Using Logix5000 Controllers as Masters or Slaves on

Modbus Application Solution, publication CIG-AP129

For more information about using Modbus sample

programs.

Resource Description