Page is loading ...

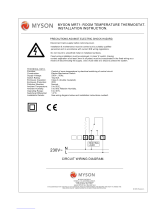

MYSON

MYSON Eastern Avenue, Team Valley, Gateshead, Tyne & Wear NE11 0PG, UK

01.11.2011

heatingthroughinnovation.

MYSON

heatingthroughinnovation.

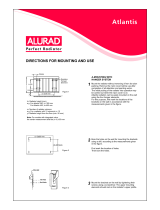

Column Radiator Series

Installation & Technical Guide

02

COLUMN.

MYSON COLUMN radiator's aesthetically sophisticated design was conceived for

technologically superior heating. Their design form makes them suitable for a wide range

of architectural applications from retro to modern.

Contents/Warranty

03

04

05

06

07

08

12

Kontec

Basics

Myson, Inc. Limited Warranty

Myson, Inc warrants the following products against defects in material and workmanship to the original owner for the

duration listed from date of installation or three months after date of shipment, whichever comes first.

The remedy in all cases shall be to repair or replace the product at Myson’s discretion upon verification of a factory defect. If

replacement is required, and an exact replacement product is no longer available, Myson reserves the right to furnish a

similar product of equal value.

NO REMOVAL, SHIPPING OR INSTALLATION EXPENSES ARE REIMBURSIBLE

The original purchaser is responsible for determining the suitability of the Myson product for their installation. Installation

and troubleshooting should be performed by a competent technician with knowledge of hydronic heating and/or basic

electricity.

Damages occurring during shipment, transit, storage or handling, abuse, neglect, accident, misapplication, incorrect power

line voltage, mproper water source or connection, fire, flood or other Acts of God are not covered. Freight damage claims

MUST be made within 10 days of receipt from Myson. No Exceptions.

STEEL PANEL RADIATORS -- SELECT, T6, DÉCOR, COLUMN AND BENCH

The duration of warranty for steel panel radiators is 5 Years.

•

Painted finishes will not peel or flake from the surface of the radiator

•

The body of the radiator and its welded joints will not leak when the product is properly installed and maintained

according to Myson's instructions.

What is not covered:

•

Rust occurring from improperly sealed threaded connections or oxygen corrosion

•

Electrolytic corrosion caused by failure to flush the system properly after initial installation

Contents

What is covered:

Important information

Product description

Model overview / connection dimensions

Piping & rough-in

Wall bracket position information

Optional Floor bracket information

Heating outputs / weights / water content

Piping arrangements

Valve selection

Heat output factors / System start - up

13

9 - 10

11

Important Information 03

BEFORE YOU BEGIN

SAFETY PRECAUTIONS

Rad

iators are hot when in use, and as such, present a

risk of burns

to

users

on

prolonged

contact.

The

temperature

of

a

radiator

is

dependent

on

the

temperature

of

the

system

water,

as

set

by

the

system installer or user. Installers and users

should ensure that those who may come into close proximity to hot radiators are aware of the risk of burns. Installers

and users should take all necessary steps to minimise the risks of burns. If the risk is significant, consideration should be

given to installing low surface temperature radiators, or to placing guards in front of the radiators.

For the correct installation of radiators it is essential that the fixing of the radiator is carried out in such a way

that it is suitable for intended use AND predictable misuse. A number of elements

need to be taken into

consideration including the fixing method used to secure the radiator to the wall, the type and condition of the wall

itself, and any additional potential forces or weights that may happen to be applied to the radiator, prior to

finalising installation. IN ALL CASES IT IS STRONGLY RECOMMENDED THAT A SUITABLY QUALIFIED

PROFESSIONAL INSTALLER OR SIMILAR TRADESPERSON CARRIES OUT THE INSTALLATION.

INTRODUCTION

The Myson Column Radiator will keep any room in comfort and style. We at Myson Inc. thank you for your purchase of the

Column Radiator. Each radiator combines Myson’s compact design and advanced steel construction with a durable baked

epoxy/polyester enamel powder coat finish. Myson’s sleek styling and thorough testing provides attractiveness and

dependability. Myson’s goal is to assure the highest performance, quality, reliability and outstanding customer service.

CAUTION

Step 1 Read this entire instruction manual thoroughly before beginning installation.

Step 2 To ensure full efficiency of your Myson Décor Steel Panel Radiator, please follow all

the instructions carefully .

Step 3 Failure to follow these instructions will invalidate the manufacturer’s warranty.

APPLICATION

Myson radiators are only for use in recirculating closed loop hydronic-heating systems. These radiators are not recom-

mended for gravity systems. DO NOT USE STEAM IN THESE RADIATORS.

INSPECT FOR DAMAGE

NOTE: Inspect materials for concealed shipping damage. You only have 10 days to file a freight claim. If items are

damaged or missing, please call Myson at 1-800-698-9690.

INSPECTION FOR COMPLETENESS

Unpack the radiator carefully to avoid damage or loss of parts. The Column Radiator will come with the following parts:

• Wall mounting bracket kit

• Plastic inserts for noise suppression

• Stainless steel solid plug

• Vent plug

IT IS STRONGLY RECOMMENDED THAT A SUITABLY QUALIFIED PROFESSIONAL

INSTALLER OR SIMILAR TRADESPERSON CARRIES OUT THE INSTALLATION.

Myson products are designed to be installed by professional tradespeople. Myson instructions are meant to be thorough;

however it is assumed that the installer has the appropriate technical knowledge related to building codes, standard trade

practices, and proper use of the tools of the trade. Should a homeowner without such knowledge or skill take it upon him/

herself to attempt the installation, Myson will not be responsible for any damages, injuries or unsatisfactory performance of the

Myson product used.

DESIGN AND LAYOUT CONDITIONS

Myson Column Radiators should only be used with a properly sized recirculation pump closed loop hydronic heating system.

Please consult national and local codes for specific restrictions that may be imposed on your installation. Position your radiator

away from your circulator pump to avoid either excess pressure that could force water out the air vent or excess suction that

could draw air into the system. The preferred positioning for the Column radiator is below a window where it can minimize

downdrafts from glazed areas.

Myson Inc./Rettig USA 45 Krupp Drive, P.O. Box 1460, Williston, VT 05495 www.mysoncomfort.com

Radiators

2 - COLUMN:

Standard Heights: 18, 24, & 79 inches (45, 60, & 200 cm)

Coatings:

1. Undercoat: electrophoretic, using water-soluble paints,

conforming to

DIN 55900 part 1, stoved at 329

° F;

2. Finish: electrostatic powder coating, conforming to DIN 55900 part 2,

i

n a state-of-t

he-art facility. (On request, and at a supplementary charge,

a range of RAL and sanitary ware colours can be offered.) This

particularly

r

obust coating is stoved at an object temperature of

356

°

F

.

Packaging: 1. Cardboard packaging

2. Edge protection

3. Shrink foil

COLUMN product description

Quality certificates

MYSON offers its customers strong

brands that meet highest quality

standards. All the production sites’

production processes are certified ac-

cording to ISO. The quality and perfor-

mance specifications of the convectors

and heating panels have been verifi ed

by recognised European institutions.

The standards that the quality certifi -

cates require us to maintain give you

security, the best heating performance

and premium product quality. For the

MYSON warranty conditions, please

refer to the table of contents page of

this manual.

Strong brands of the highest quality

Connections:

4 x internal thread G 1/2“ BSP,

welded-in for supply and return.

Vent and drain plugs (or dummy

plug) are included

Maximum positive

operating pressure:

145 psi

Maximum operating

temperature:

max.

72psi

max.

04

Myson Inc./Rettig USA 45 Krupp Drive, P.O. Box 1460, Williston, VT 05495 www.mysoncomfort.com

PRODUCT DESCRIPTION

12 - 3045

Overall Height [cm]

Number of Columns

Number of Sections

Additional sizes and models are available as special order

Tested to positive

pressure:

188.5 psi

248° F

Manufacture

MYSON COLUMN radiators are

manufactured using a unique

laser

welding proce

ss that virtually eliminates

the visible

welding

points

associated

with

the

traditional

methods

of

manufacturing

this

type

of

radiator.

The

clean

finish

significantly

enhances

the

aesthetic qualities of the radiator.

Tube Details

Precision, D-

profile steel

tube is used

for

all

outside

surfaces

which

ensures

high

outputs

and

soft,

rounded

edges

for

maximum

safety.

All

MYSON

COLUMN

radiators are

manufactured and tested to EN 442.

Paint Finish

Every MYSON COLUMN radiator

undergoes a multi-stage pre-treatment

process followed by an epoxy polyester

primer coating. A stoved epoxy

polyester

powder coat in white (RAL

9016) is applied to all front and rear

surfaces allowing

the MYSON

COLUMN to be fitted without further

painting.

MYSON COLUMN radiators carry a 5 year

guarantee against defects caused by

faulty materials or manufacture.

3 - COLUMN:

Standard Heights: 12, 18, & 24 inches (30, 45, & 60 cm)

4

-

COLUMN:

Standard Height

:

24

inches

(60 cm)

See pages 9 & 10 for standard number of sections and outputs

ABOVE EXAMPLE:

12 Sections, 3 Column, 18"High

10

10

10

COLUM

N model overview / connection dimensions

Dimension and Mounting Quick Reference

Myson Inc./Rettig USA 45 Krupp Drive, P.O. Box 1460, Williston, VT 05495 www.mysoncomfort.com

05

Length equals the number of

sections times 2"

Example:

56 sections times 2"

equals 112"

2"

1"

1 1/4"

1 1/4"

All tappings are 1/2" BSPT

C

L

LKD16AN

C

L

1 3/4"

1 3/4"

Shown with DAV12 and

LKD16AN valves. See page 12

for additional valve choices .

DAV12

4"

3/4"

1-3/16"

2-5/16"

3-1/4"

5/8"

2"

1/2"

Position 2

Position 1

Column Radiator Wall Brackets

4 Column

5

1

/2"

3 Column

4"

2 Column

2

1

/2"

Pipe centers from finished wall are

dependent on which mounting slot is

selected on the mounting bracket and

the number of columns.

2 Column 3 Column 4 Column

Position 1 Min: 2

1

/

2

"

3

1

/

4

"

4"

Position 2 Max:

2

7

/

8

"

3

5

/

8

"

4

3

/

8

"

To obtain pipe centers using Myson

valves multuply the number of

sections by 2" and add 3.5".

Example: A 12 section radiator would

be 12 x 2"+ 3.5" = 27.5"

MYSON COLUMN RADIATOR

ROUGH -IN SPECIFICATIONS

COLUMN piping & rough-in

Standard models

Suitable for mono-flo, home run or 2-pipe systems

Rough-in dimension shown at right is for a TRV and a

LKD valve or a pair of LKD valves.

When using FF valves add 3-5/8" to overall length.

Recommendation:

Radiator tappings and valve spuds are 1/2"BSP.

Professional expertise is required when sealing these

"straight" threads. Failure to properly seal the

connections will result in leaks resulting in property

damage.

NOTE ! Myson is not responsible for damage resulting from improper workmanship.

NOTE ! Rough-in information is given for Myson control valves. Valve specifications vary by manufacturer.

Myson will not be responsible for damage or repair of property resulting from the use of non-Myson valves.

06

Overall Length + 3-1/2"

LKD16AN

FF16WAC

TRV

•

All installations require 2 valves per radiator

•

All valves are ½” BSP thread for connection to the

radiator and ½”

NPT thread for connection to the

system (also includes compression nut and ferrule

for connection to ½” copper)

•

Valves are available in 3 basic patterns: angle,

straight, and inverted angle (TRV only)

•

Basic Installation: use 2 – LKD16AN (angle) or

LKD16SN (straight) manual

valves, nickel plated with

screwdriver stops and caps

•

Basic upgrade: use 1 - FF16WAC and 1 - FF16LAC

manual valves, angle only, chrome plated with white

handles (FF16WAC

is adjustable for balancing,

FF16LAC is fixed open but can be closed for service)

•

TRV (thermostatic radiator valves) are available for

automatic temperature control of individual radiators:

available in 3 body patterns, with or without

thermostatic

head (sensor), use in conjunction with

LKD or FF

Myson Inc./Rettig USA 45 Krupp Drive, P.O. Box 1460, Williston, VT 05495 www.mysoncomfort.com

NOTE: See page 5 or 7 for rough-in from finished

wall to pipe centers.

See page 12 for additional valve information

A

ll MYSON COLUMN radiators

are ordered without an internal

baffle. This will not effect the

output of the radiator except in

cases where the radiator is less

than 4 sections long or is a 2

column radiator less than 8

sections long. These smaller

radiators should be ordered with

a baffle in the supply position.

Contact MYSON Tech Support for

more information.

MYSON COLUMN radiators are suitable for the use of

BBOE

(Bottom Bottom Opposite End), TBSE (Top

Bottom Same End) and

TBOE (Top Bottom Opposite

End) connections. TTOE (Top Top Opposite End)

connections cannot be used.

A

ll systems must be designed wi

t

h

suitable pipe sizing

and

w

i

t

h

adequate

pump

head. Failure to do this

m

ay lead to trapped air and cold spots because of

insufficient pressure and water flow will not drive the

air from the radiator. The taller and more tubes a

radiator has, the more likely this is to happen.

The installation work must be carried out with

precautions taken to avoid

contamination

which

could

lead

to

corrosion.

If

a

corrosion

inhibitor

or

other

water treatment is to be used, the

Manufacturer’s Instructions must be strictly followed.

The MYSON COLUMN radiator's large diameter

steel tube contruction ensures a negligible

pressure drop through the radiator. The pressure

drop through the radiator can be ignored in the

design of most hydronic systems.

Two-part cover for base-plate

in white plastic 106 x 128mm

2" 1

3

/

16

"

5

/

8

"

3

/

4

"

13

/

32

"

3

/

16

"

1

/

4

"

15

/

64

"

9

/

16

"

19

/

32

"

9

/

64

"

9

/

16

"

11

/

16

"

3

/

16

"

11

/

16

"

1

/

2

"

13

/

16

"

3

/

8

"

2

5

/

16

"

3

1

/

4

"

11

/

32

"

1

/

4

"

25

/

32

"

Radiator

Bracket

Angle Wall

Bracket

insert

Ensure tight

fit here

1

9

/

32

"

2

7

/

16"

7

/

16

"

A

(see table below)

25

/

32

"

1

3

/

16

"

7

/

16

"

3

/

4

"

1"

1

/

2

"

15

/

32

"

Wall &

Bracket

Wall &

Radiator

A = Distance between Wall & Center

Wall Bracket &

Radiator Bracket

25

/

32

"

7

/

16

"

1

7

/

32

" 2

1

/

2

" 3

1

/

4

"

4"

1

3

/

16

"

7

/

16

"

1

5

/

8

" 2

7

/

8

" 3

5

/

8

"

4

3

/

8

"

2 column 3 column 4 column

180

-

300mm

For use with

2-6 column radiators

8

26

120

40

26

60

100

Dimensions of base-plate for

Clamped Floor Bracket FK

( = base-plate cover)

91

75

104

8

116

Dimensions of base-plate

for Floor Bracket SK

Two-part cover for base-plate

in white plastic 110 x 135mm

Complete system for free-standing

radiators, from 2-6 column up to

1000mm height. Painted to

RAL 9016.

Comprises;

- 3mm thick base-plate fixing for

either finished or unfinished floor

Clamped Floor

Bracket FK

Order Code

For 2-6 Column Rads.

Base-Plate Cover

FK1021

COVERFK

Complete system for free-standing

radiators, from 2-6 column up to

1000mm height. Painted to RAL 9016.

Comprises;

- 3mm thick base-plate for fixing to

either finished or unfinished floor

- upright support 35 x 10 x 1.5mm,

fixing set with adjustable bracket,

security fixing, anti-vibration insert

- adjustable bottom support with

spacer and security fixing,

anti-vibration insert, white plastic

end stop for top of upright.

Height of

Upright

Order Code

460

610

760

910

Base-Plate Cover

Height of

Radiator

300

450

600

750

SK20046

SK20061

SK20076

SK20091

COVERSK

Operating Pressures

Every MYSON COLUMN radiator is tested to a pressure of

13 bar (188.5 psi) and is suitable for a working pressure of up to

10 bar (145 psi).

20

10

30

Radiator Brackets

Floor Bracket SK

Mounting Brackets (supplied with every radiator) - Wall Brackets

Fixing Brackets - Clamped Floor Bracket FK

COLUMN Mounting Bracket Detail

COLUMN Technical Information

09

Myson Inc./Rettig USA 45 Krupp Drive, P.O. Box 1460, Williston, VT 05495 www.mysoncomfort.com

07

50 30

16 20

10.5

5

6.5

6

14

15

3.6

14

18

4.5

17 12

20.5

34.5

59 83

8.5

6

20

Radiator

Bracket

Angle Wall

Bracket

insert

Ensure tight

fit here

32.5

62

11

A

(see table below)

20

30

11

19

25

13

11.5

Wall &

Bracket

Wall &

Radiator

A = Distance between Wall & Centre

Wall Bracket &

Radiator Bracket

20mm 11mm 31mm 62.5 81.5 100.5

30mm 11mm 41mm 72.5 91.5 110.5

Connections

All MYSON COLUMN radiators are fitted with 4 x 1/2 inch

BSP connections.

Radiators include plug and vent.

Radiators are manufactured with an internal baffle. The tapping

with the baffle is identified with a red plastic cap, all others being

blue. It is important that the water inlet is connected to the

tapping identified in red.

N.B. The radiator is suitable for the use of BBOE (Bottom Bottom

Opposite End), TBSE (Top Bottom Same End) and TBOE (Top

Bottom Opposite End) connections. TTOE (Top Top Opposite

End) connections cannot be used.

2 column 3 column 4 column

3

9

/

16

"

2

15

/

16

"

4

3

/

32

"

5

/

16

"

Dimensions of base-plate

for Floor Bracket SK

Two-part cover for bas

e

-plate

i

n

white plastic 4

5

/

16

" x 5

5

/

16

"

Complete system for free-standing

radiators, from 2-6 column up to

1000mm height. Painted to RAL 9016.

Includes:

- 3mm thick base-plate for fixing to

either finished or unfinished floor

- upright support 35 x 10 x 1.5mm,

fixing set with adjustable bracket,

security fixing, anti-vibration insert

- adjustable bottom support with

spacer and security fixing,

anti-vibration insert, white plastic

end stop for top of upright.

Height of

Upright

Order Code

18"

24"

30"

Base-Plate Cover

Height of

Radiator

12"

18"

24"

Radiator Brackets

Floor Bracket SK (Optional)

Fixing Brackets (supplied with every radiator) - Wall Brackets

08

COLUMN Technical Information

COLUMN Floor Bracket Detail

4

9

/

16

"

Myson Inc./Rettig USA 45 Krupp Drive, P.O. Box 1460, Williston, VT 05495 www.mysoncomfort.com

The table on the right gives

recommendations for the

number of brackets to be used

with each radiator.

The strength of the wall should

be checked for its load-bearing

capabilities before installation.

Type

2 to 4 Column

Number of Sections

0 - 20

21 - 40

4 6

Up to 39” Height: Wall -

Mounted Angle Brackets - RW

Radiator Bracket - RH

4

6

Floor Mounting Floor

bracket - SK

2 3

4 6

Over 39” Height: Wall -

Mounted Angle

Brackets - RW

Radiator Bracket - RH

4

6

08

4,

4,

4,

KOM-ASK2

Height

24in

Height

18in

Height

79in

Architecture Range - Bench Radiator

Accessories

4 COLUMN

Height

1

2in

Height

1

8in

Height

2

4in

Height

24in

H

L

Special order only.

The Bench Radiator is

sold complete, but can be

sold seperately if required.

4 COLUMN3 COLUMN2 COLUMN

2

1

/

2

in

4in

5

1

/

2

in

Micro Fibr

e Cleaning Brush

Product Code: COLUMNBRUSH2

Towel Rail

Clip-on rail to fit all

radiators up to 1m

long (20 sections)

Product Code: 12SECRAIL

16SECRAIL

20SECRAIL

Decorative Foot

Product Code: COLDECFOOT

Fixing Brackets

Product Code: FK1021

Product Code: COVERFK

Floor Brackets

Product Code: SK20046

Product Code: SK20061

Product Code: SK20076

Product Code: SK20091

Product Code: COVERSK

COLUMN Sizes & Outputs

COLUMN Sizes & Outputs

11

Length inc. seat Height inc. seat Depth inc. seat Output Output

Order Code

(mm - inches) (mm - inches) (mm - inches) (watts) (Btu/h)

1850 - 73 472 - 19 365 - 14 1489 5080 23 SEC 056150

1850 - 73 522 - 21 365 - 14 1738 5930 23 SEC 066150

2150 - 85 472 - 19 365 - 14 1816 6196 23 SEC 056180

2150 - 85 522 - 21 365 - 14 2119 7230 23 SEC 066180

2350 - 93 472 - 19 365 - 14 2053 7005 23 SEC 056200

2350 - 93 522 - 21 365 - 14 2396 8175 23 SEC 066200

Myson Inc./Rettig USA 45 Krupp Drive, P.O. Box 1460, Williston, VT 05495 www.mysoncomfort.com

NOTES:

1. All dimensions are nominal.

2. Heat outputs are based on 180

0

F AWT

and 68

0

F EAT (mean water to air

temperature of 112

0

F)

3. For heat outputs at other temperatures see page 13.

2 COLUMN

No. of Sections

Weight (lbs)

Ou

tput (Btu/h)

Order Code

12

19.8

12 - 2045

16

26.5

16 - 2045

20

33.0

20 - 2045

24

39.6

24 - 2045

28

46.2

28 - 2045

36

59.4

36 - 2045

12

25.9

12 - 2060

16

34.6

16 - 2060

20

43.2

20 - 2060

24

52.0

24 - 2060

28

60

.5

28 - 2060

6

41.4

6 - 2200

8

55.2

8 - 2200

10

69

.0

10 - 2200

12

82.8

12 - 2200

15

103.5

15 - 2200

Water Content (gals)

1.68

2.24

2.80

3.36

3.92

5.00

2.10

2.80

3.50

4.20

4.90

3.00

4.02

5.02

6.02

7.53

Length (in)

3 COLUMN

No.

of Sections

Weight (lbs)

Output (Btu/h)

Order Code

32

16

27.5

2380

16 - 3030

40

20

34.4

2975

20 - 3030

56

28

48.2

4265

28 - 3030

72

36

62.0

5355

36 - 3030

24

12

29.6

2674

12 - 3045

32

16

39.5

3565

16 - 3045

40

20

49.4

4456

20 - 3045

48

24

59.3

5347

24 - 3045

56

28

69.3

6239

28 - 3045

24

12

41.4

3566

12 - 3060

32

16

55

.2

4

755

16 - 3060

40

20

69

.0

5944

20 - 3060

48

24

82

.

8

7132

24 - 3060

56

28

103.5

8321

28 - 3060

Water Content (gals)

2.42

3.02

4.23

5.44

2.41

3.22

4.02

4.83

5.63

3.

00

4.

02

5.

0

2

6.

0

2

7.5

3

Length

(in)

72

36

88.9

8021

36 - 3045

7.24

No.

of Sections

Weight (lbs)

Output (Btu/h)

Order Code

24

12

51.6

4

213

12 - 4060

32

16

68.8

5618

16 - 4060

40

20

86.0

7022

20 - 4060

48

24

103.2

8

426

24 - 4060

Water Content (gals)

4.00

5.33

6.67

8.00

Length (in)

09

24

1847

32

24

62

40

3078

48

3

693

56

4309

72

5540

24

2448

32

3265

40

4081

4

8

4897

56

5713

12

4041

16

5388

20

6735

24

8082

30

10103

Height

600 mm

Height

450 mm

Height

2000 mm

2 COLUMN

Architecture Range - Bench Radiator

3 COLUMN

4 COLUMN

Height

300 mm

Height

450 mm

Height

600 mm

Height

750 mm

Height

600 mm

Height

750 mm

4 COLUMN3 COLUMN2 COLUMN

63

mm

101

mm

139

mm

Floor Brackets

Product Code: SK20046

Product Code: SK20061

Product Code: SK20076

Product Code: SK20091

Product Code: COVERSK

10

COLUMN Sizes & Outputs

BEN

CH Sizes & Outputs

Length (mm - inches) No. of Sections Output (watts) Output (Btu/h) Order Code

600 - 24 12 435 1485 12 SEC 2045

800 - 32 16 580 1980 16 SEC 2045

1000 - 40 20 725 2474 20 SEC 2045

1200 - 47 24 870 2969 24 SEC 2045

1400 - 55 28 1015 3464 28 SEC 2045

1800 - 72 36 1305 4454 36 SEC 2045

600 - 24 12 564 1925 12 SEC 2060

800 - 32 16 752 2567 16 SEC 2060

1000 - 40 20 940 3209 20 SEC 2060

1200 - 47 24 1128 3850 24 SEC 2060

1400 - 55 28 1317 4492 28 SEC 2060

300 - 12 6 881 3006 6 SEC 2200

400 - 16 8 1175 4008 8 SEC 2200

500 - 20 10 1468 5010 10 SEC 2200

600 - 24 12 1762 6012 12 SEC 2200

750 - 30 15 2202 7515 15 SEC 2200

Length (mm - inches) No. of Sections Output (watts) Output (Btu/h) Order Code

800 - 32 16 566 1933 16 SEC 3030

1000 - 40 20 708 2416 20 SEC 3030

1400 - 55 28 991 3382 28 SEC 3030

1800 - 71 36 1274 4348 36 SEC 3030

600 - 24 12 606 2068 12 SEC 3045

800 - 32 16 808 2757 16 SEC 3045

1000 - 40 20 1010 3446 20 SEC 3045

1200 - 47 24 1212 4135 24 SEC 3045

1400 - 55 28 1414 4825 28 SEC 3045

1800 - 72 36 1818 6203 36 SEC 3045

600 - 24 12 781 2665 12 SEC 3060

800 - 32 16 1042 3554 16 SEC 3060

1000 - 40 20 1302 4442 20 SEC 3060

1200 - 47 24 1562 5331 24 SEC 3060

1400 - 55 28 1823 6219 28 SEC 3060

600 - 24 12 935 3251 12 SEC 3075

800 - 32 16 1270 4335 16 SEC 3075

1000 - 40 20 1588 5418 20 SEC 3075

1200 - 47 24 1906 6502 24 SEC 3075

1400 - 55 28 2223 7586 28 SEC 3075

Length (mm - inches) No. of Sections Output (watts) Output (Btu/h) Order Code

600 - 24 12 997 3402 12 SEC 4060

800 - 32 16 1330 4537 16 SEC 4060

1000 - 40 20 1662 5671 20 SEC 4060

1200 - 47 24 1994 6805 24 SEC 4060

1400 - 55 28 2327 7939 28 SEC 4060

600 - 24 12 1214 4144 12 SEC 4075

800 - 32 16 1619 5525 16 SEC 4075

1000 - 40 20 2024 6906 20 SEC 4075

1200 - 47 24 2429 8287 24 SEC 4075

1400 - 55 28 2834 9668 28 SEC 4075

Myson Inc./Rettig USA 45 Krupp Drive, P.O. Box 1460, Williston, VT 05495 www.mysoncomfort.com

No.

o

f Sections

Weight (lbs)

Output (Btu/h)

Order Code

53 x 19 x 14

5

75

3528

23-05-6100

53 x 21 x 14

6

8

7

4231

23-06-6100

61 x 19 x 14

5

85

4185

23-05-6120

61 x 21 x 14

6

99

5022

2

3-06-6120

73 x 19 x 14

5

1

46

6452

23-05-6150

73 x 21 x 14

6

1

61

7530

23-06-6150

85 x 19 x 14

5

1

72

7868

23-05-6180

85 x 21 x 14

6

1

90

9182

23-06-6180

9

3 x 19 x 14

5

1

86

8895

23-05-6200

Water Content

(gals)

3.75

4.49

4.41

5.28

4.52

6.50

5.34

7.64

5.90

Dimensions (in)

LxHxW

93 x 21 x 14

6

2

05

10383

23-06-6200

8.42

3"

1

3

/

8

"

Thermostat

H

14

9

/

16

"

11

13

/

16

"

5

5

/

16

"

A

15

/

16

"

5

5

/

16

"

1

3

/

16

"

2

3

/

4

"

2

15

/

16

"

3

15

/

16

"

Thermostat

1

/

2

" Valve Body

Detail "A"

Y

Radiator Length + 13

3

4

"

Technical Data

Radiator Length - 2

9

/

16

"

Radiator Lenth + 1

3

/

8

"

3

15

/

16

"

NOTE: All dimensions are nominal.

Radiator Length

39

3

/

8

39

3

/

8

47

1

/

2

47

1

/

2

59

1

/

16

59

1

/

16

70

7

/

8

7

0

7

/

8

78

3

/

4

78

3

/

4

Rough - in (cc)

36

13

/

16

36

13

/

16

44

11

/

16

56

1

/

2

68

5

/

16

76

3

/

16

(in)

(in)

44

11

/

16

56

1

/

2

68

5

/

16

76

3

/

16

X

10

Typical hydronic system types

Myson Inc./Rettig USA 45 Krupp Drive, P.O. Box 1460, Williston, VT 05495 www.mysoncomfort.com

11

The following drawings are general examples.

Consult a certified heating professional for your specific application.

RADIATOR optional piping arrangements

RADIA

TOR valve selection

Valve application

Myson Inc./Rettig USA 45 Krupp Drive, P.O. Box 1460, Williston, VT 05495 www.mysoncomfort.com

12

All installations require 2 valves per radiator

All valves are ½” BSP thread for

connection to the radiator and

½” NPT thread for connection to the system (also includes compression nut

and ferrule for connection to ½” copper

Valves are available in 3 basic patterns: angle, straight, and inv

erted angle (TRV only)

Basic Installation: use 2 – LKD16AN (angle)

or LKD16SN (straight)

manual valves, nickel plated with screwdriver stops and caps

Basic upgrade: use 1 ‐ FF16WAC and 1 – FF16LAC manual valves, angle

only, chrome plated with white handles (FF16WAC is adjustable for

balancing, FF16LAC is fixed open but can be closed for service)

TRV (thermostatic radiator valves) are available for

automatic temperature control of individual

radiators: available in 3 body patterns, with or without thermostatic head (sensor), use in conjunction

with LKD or FF

TRV remote sensors and adjusters

available for special applications

DCK12 – 4” chrome nipple with

compression connection available for use with all Myson valves,

includes escutcheon (connects valve to heating system)

D

A

V

1

2

– same as

DCK12

with addition of integral ball stop angle valve

D

e

co

rative pipe covers and

e

scutcheo

ns

available in chrome or white (use

to cover exposed copper pipe used in radiator installation)

LKD16AN LKD16SN FF16WAC FF16LAC TRVanglew/HEAD

RemoteSensorRemoteAdjuster TRVstraight TRVinvertedangle TRVHEADonly

DCK DAV

C

O

LUM

N C

onversion

F

a

ct

ors / Start-up & Maintenance

Heat output factors / Start - up and Maintenance

Myson Inc./Rettig USA 45 Krupp Drive, P.O. Box 1460, Williston, VT 05495 www.mysoncomfort.com

13

Failure to flush system of debris and flux may cause premature radiator failure, which

can result in leaks and property damage NOT covered under the Myson Warranty.

Step 1 Fill and vent the system.

Step 2 Run the system for two (2) hours at full temperature with all radiator valves in the open position.

Step 3 Shut off and drain the system while the water is still hot.

Step 4 Refill the system.

Step 5 Reheat, vent, and balance the system.

Step 6 Once the Décor Radiator is filled with water the system should be left filled.

Step 7 System should be checked for leaks on seasonal start-ups. Leaks must be repaired

as automatic system fill valves allow fresh water/oxygen into the system attacking radiators

internally.

SYSTEM START-UP

MAINTENANCE &

CLEANING

1

Once

operating,

avoid

the introduction of fresh water and oxygen to the system to prevent corrosion.

2 An occasional wiping with a damp cloth using a non-abrasive detergent can protect the finish of your

Myson Décor Panel Radiator.

3 The use of abrasive cleaners will damage the surface of your radiator and void the

manufacturer’s warranty.

Heat Output

The heat outputs for all MYSON COLUMN radiators can be found on pages 9 and

10. The tabulated figures are quoted in accordance with EN 442 for a mean water to

air temperature of 112

0

F. This is based on an average water temperature of 180

0

F

and an ambient air temperature of 68

0

F. When the difference is not 112

0

F, the

output should be multiplied by the appropriate factor from within the table below:

Aver. Water Temp.

0

F

Ambient Air Temp.

0

F

190 68

180 68

170 68

160 68

150

68

140 68

120 68

Water to Air

(D

elta T

0

F)

Conversion Factor

122

1.14

112 1.00

102

.91

92 .79

82

.68

72

.58

52

.38

N

O

TES

Notes

Myson Inc./Rettig USA 45 Krupp Drive, P.O. Box 1460, Williston, VT 05495 www.mysoncomfort.com

14

N

O

TES

Notes

Myson Inc./Rettig USA 45 Krupp Drive, P.O. Box 1460, Williston, VT 05495 www.mysoncomfort.com

15

heatingthroughinnovation.

MYSON

Myson Inc./Rettig USA 45 Krupp Drive, P.O. Box 1460, Williston, VT 05495 www.mysoncomfort.com

COLUMN 7/2016

/