GB

Valid for serial no. 217, 6340457 342 101 GB 060822

PSFt 315 M

PSFt 315 R

Instruction manual

-- 2 --

TOCe

Rights reserved to alter specifications without notice.

1 DIRECTIVE 3........................................................

2SAFETY 3...........................................................

3 INTRODUCTION 4...................................................

4 TECHNICAL DATA 5.................................................

5 CONSUMABLES 5...................................................

5.1 Changing wire liner , replacing electrode conductors 5............................

5.2 Interchangeable connectors 6.................................................

5.3 Compressed air cleaning 6...................................................

5.4 Contact tip 7................................................................

5.5 Wire liners 7................................................................

5.6 Gas nozzles 7..............................................................

5.7 Gas protection 7............................................................

6 OPERATION 8.......................................................

7 MAINTENANCE 8....................................................

8 SPARE PARTS AND ACCESSORIES 8.................................

DIMENSION DRAWING 9................................................

ORDERING NUMBER 10.................................................

WEAR PARTS 12........................................................

ACCESSORIES 13.......................................................

-- 3 --

bg14e

1DIRECTIVE

DECLARATION OF CONFORMITY

ESAB Welding Equipment AB, S--695 81 Laxå, Sweden, gives its unreserved guarantee that welding

gun PSF 315 M / 315 R from serial number 217 complies with standard EN 60974--7, in accordance

with the requirements of directive (73/23/EEC) and addendum (93/68/EEC).

-- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- --------

Henry Selenius

Vice President

ESAB Welding Equipment AB

695 81 LAXÅ

SWEDEN Tel: + 46 584 81000 Fax: + 46 584 411924

Laxå 2002--04--25

2SAFETY

WARNING

READ AND UNDERSTAND THE INSTRUCTION MANUAL BEFORE INSTALLING OR OPERATING.

ARC WELDING AND CUTTING CAN BE INJURIOUS TO YOURSELF AND OTHERS. TAKE PRECAU-

TIONS WHEN WELDING. ASK FOR YOUR EMPLOYER’S SAFETY PRACTICES WHICH SHOULD BE

BASED ON MANUFACTURERS’ HAZARD DATA.

ELECTRIC SHOCK -- Can kill

S Install and earth the welding unit in accordance with applicable standards.

S Do not touch live electrical parts or electrodes with bare skin, wet gloves or wet clothing.

S Insulate yourself from earth and the workpiece.

S Ensure your working stance is safe.

FUMES AND GASES -- Can be dangerous to health

S Keep your head out of the fumes.

S Use ventilation, extraction at the arc, or both, to take fumes and gases away from your breathing zone

and the general area.

ARC RAYS -- Can injure eyes and burn skin.

S Protect y our eyes and body. Use the correct welding screen and filter lens and wear protective

clothing.

S Protect bystanders with suitable screens or curtains.

FIRE HAZARD

S Sparks (spatter) can cause fire. Make sure therefore that there are no inflammable materials nearby.

NOISE -- Excessive noise can damage hearing

S Protect y our ears. Use earmuffs or other hearing protection.

S Warn bystanders of the risk.

MALFUNCTION -- Call for expert assistance in the event of malfunction.

PROTECT YOURSELF AND OTHERS!

ESAB can provide you with all necessary welding protection an d accessories.

GB

-- 4 --

bg14e

Users of ESAB welding equipment have the ultimate responsibility for ensuring that anyone who

works on or near the equipment observes all the relevant safety precautions. Safety precautions

must meet the requirements that apply to this type of welding equipment. The following recommen-

dations should be observed in addition to the standard regulations that apply to the workplace.

All work must be carried out by trained personnel well--acquainted with the operation of the welding

equipment. Incorrect operation of the equipment may lead to hazardous situations which can result

in injury to the operator and damage to the equipment.

1. Anyone who uses the welding equipment must be familiar with:

S its operation

S location of emergency stops

S its function

S relevant safety precautions

S welding

2. The operator must ensure that:

S no unauthorized person is stationed within the working area of the equipment when it is

started up.

S no--one is unprotected when the arc is struck

3. The workplace must:

S be suitable for the purpose

S be free from drafts

4. Personal safety equipment

S Always wear recommended personal safety equipment, such as safety glasses, flame--proof

clothing, safety gloves.

S Do not wear loose--fitting items, such as scarves, bracelets, rings, etc., which could become

trapped or cause burns.

5. General precautions

S Make sure the return cable is connected securely.

S Work on high voltage equipment may only be carried out by a qualified electrician.

S Appropriate fire extinquishing equipment must be clearly marked and close at hand.

S Lubrication and maintenance must not be carried out on the equipment during operation.

3 INTRODUCTION

The PSFt 315M / 315 R is an self--cooled welding gun. The welding gun is

developed for use in robot applications or mechanised welding.

A range of accessories including welding tips, swan necks and contact nozzles are

also available.

Details of ESAB’s welding torches accessories can be found on page 13.

GB

-- 5 --

bg14e

4 TECHNICAL DATA

Welding gun PSF 315 M / 315 R

Permitted load at 60% intermittence

CO

2

MIX

315 A

285 A

Permitted load at 100% intermittence

CO

2

MIX

200 A

170 A

Electrode dimensions 0.8 -- 1.2 mm

Rec. gas flow l/min 10 -- 20 l/min

Weight, hose length

1.5 m

2.2 m

3m

2.0 kg

2.6 kg

3.2 kg

Duty cycle

The duty cycle refers to the time as a percentage of a ten--minute period that you can weld at a cer-

tain load without overloading.

5 CONSUMABLES

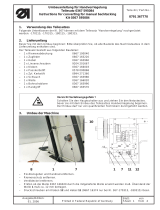

5.1 Changing wire liner, replacing electrode conductors

5.1.1 Install the correct nipple

ESAB Connection EURO Connection

Note! 2 nipples are supplied with each welding liner, 1 for an ESAB connection and 1 for a

EURO connection.

5.1.2 Remove the gas nozzle and tip adator.

5.1.3 Install the wire liner in the welding gun.

GB

-- 6 --

bg14e

5.1.4 Cut the wire liner to the correct length.

When cutting, the welding gun should be extended with the wire liner fully inserted in

the rear connection.

Cut the wire liner so that it protrudes by “X” in accordance with the table below.

Welding gun

Length

Adapter

Measu-

rement

X

Helix

Measu-

rement

X

PSF 315 M / 315 R

1.5 m 0368 145 001 27 mm 0368 683 001 22 mm

PSF 315 M / 315 R 2.2 m 0368 145 001 28 mm 0368 683 001 23 mm

PSF 315 M / 315 R 3.0 m 0368 145 001

31 mm 0368 683 001 26 mm

Sharp edges are not allowed on the inside of the wire liner guide after cutting.

5.1.5 Reinstall th e tip adaptor an d gas n o zzle.

5.1.6 Install the welding gun on the machine.

a) Turn the connecting piece clockwise when you encounter resistance

b) The welding rod goes in

5.2 Interchangeable connectors

Connectors are m anufactured with the same measurements between the mount and

the tip of the contact tip and are therefore directly interchangeable.

For dimensions and guaranteed tolerances, see diagram on page 9.

5.3 Compressed air cleaning

The connector has a connection and ducts for compressed air cleaning of the gas

nozzle.

GB

-- 7 --

bg14e

5.4 Contact tip

Contact tips are selected according to e lectrode diameter, type of shielding gas and

rating of the welding current being used. See table on page 13.

The contact tips are initially selected with the guidance of the CO

2

table. If seizing

occurs in the event of high welding data with Argon or mixed gas, select on the basis

of the MIX, AR table.

For HELIX, the table applies regardless of shielding gas type. HELIX contact tips

must be combined with a special tip adaptor, see spare parts list. Note that the item

number for HELIX includes 2 contact tips + 1 locking nut for installation.

5.5 Wire liners

In order to achieve good welding rod feed, the wire liner should be selected in

accordance with the table o n page 14. A PTFE--based wire liner produces less

friction and is kinder to the electrode, but normally has a shorter service life than a

steel spiral. It is suitable for all types of electrode, except for the majority of core wire

types thicker than 1.2 mm.

Steel spirals can be used for all except for stainless steel and aluminium electrodes.

For changing electrode guides – see the enclosed instructions.

Note! All welding guns are supplied with steel spirals for welding liner ∅1.0.

5.6 Gas nozzles

If you want a gas nozzle with a smaller opening diameter, this is available as an

accessory for each gun. See the spare parts list. Note that it is also possible to

exchange the connector type.

IMPORTANT! There is a spatter guard in the gas nozzle. T his must be in place to

prevent welding spatter penetrating the connector.

For good function, the gas nozzle must always be screwed in as far as it will go.

5.7 Gas protection

Several factors combine to provide good gas protection. T he most important of these

are:

1. Choice of shielding gas. -- Mixed gas and argon require a greater flow than

carbon dioxide

2. Set flow quantity. -- See technical data (should be measured at the gas nozzle).

3. Set welding current. -- High current requires a greater gas flow.

4. Position of the welding joint. -- A vertical position requires a greater gas flow.

5. Type of welding joint. -- An outer corner joint requires a greater gas flow than a

butt joint. A fillet weld joint requir e s a correspondingly sm aller gas flow.

6. The angle of the welding gun against the workpiece -- below 45° entails a risk of

poor gas protection.

GB

-- 8 --

bg14e

6 OPERATION

General safety regulations for the handling of the equipment can be found on

page 3. Read through before you start using the equipment!

The welding gun contains a lead for starting point searching. T his is connected to the

ring--shaped adapter plug in the welding gun’s feeder end. The connection lead from

starting point searching ( e.g. Smartac) is connected to the corresponding flat--pin

connection in the feeder’s terminal block.

7 MAINTENANCE

Note!

All guarantee undertakings from the supplier cease to apply if the customer himself

attempts any work in the product during the guarantee period in order to rectify any

faults.

Regular servicing reduces unnecessary and expensive operational stoppages.

1. Welding spray in the gas nozzle impairs the gas protection and increases the risk

of flash--over.

--Clean regularly and use a moderate amount of welding paste or welding spray.

2. The spray guard in the gas nozzle should be replaced when its front end has

become thin.

3. Every time the electrode bobbin is replaced, the welding hose should be

disconnected from the feeder and blown clean with compressed air.

4. The end of the electrode may not have any sharp edges when it is inserted into

the welding rod guide. This is particularly important in the case of PTFE--based

welding rod guides.

8 SPARE PARTS AND ACCESSORIES

PSF 315 M / 315 R is designed and tested in accordance with the international and Eu-

ropean standards IEC/EN 60974--7 and EN 60974--7. It is the obligation of the service

unit which has carried out the service or repair work to make sure that the product still

conforms to the said standard.

Spare parts may be ordered through your nearest ESAB dealer, see the last page of

this publication. When ordering, please state product type, serial number, designa-

tion and spare part number in accordance with the spare parts list.

This facilitates shipment and ensures correct delivery.

GB

Dimension drawing

-- 9 --

bg14dim

A

(mm)

B

(mm)

C

(mm)

D

(mm)

E

(mm)

F

(mm)

PSFt 315M, 25˚ 3.5

20 22 94 196.3 63.4

PSFt 315M, 25˚ extended 100 3.5 20 22 94 296.3 63.4

PSFt 315M, straight 3.5

20 22 94 209.3 0

PSFt 315M, straight,

extended 100 3.5 20 22 94 309.3 0

We

l

d

i

ng gun

P

S

F

t 31

5

M

,

P

S

F

t 31

5

R

Edition 060822

Ordering number

-- 1 0 --

bg14or

Ordering numbers for Welding gun PSFt 315 M, PSFt 315 R

0367 233 894 PSFt 315 M / 315 R 1.5 m, 25˚

EURO Connection

0367 233 896 PSFt 315 M / 315 R 1.5 m, straight

EURO Connection

0367 233 898 PSFt 315 M / 315 R 3.0 m, 25˚

EURO Connection

0367 233 900 PSFt 315 M / 315 R 2.2 m, 25˚

EURO Connection

0367 233 901 PSFt 315 M / 315 R 2.2 m, straight

EURO Connection

0367 233 905 PSFt 315 M / 315 R 3.0 m, straight

EURO Connection

We

l

d

i

ng gun

P

S

F

t 31

5

M

,

P

S

F

t 31

5

R

Edition 060822

-- 1 1 --

bg14or

Ordering numbers for other lengths

When ordering please quote:

-- N e c k t y p e

-- Wire diameter

-- Cable assembly length

These ordering numbers apply only to standard torch variations. Other variations will be issued with

part numbers on receipt of order. Refer to order confirmation.

Order form for torch with extended swan neck or custom specific length 0367 233 90x

PSF 315M / R Item no 0367 233 xxx 1.5 m 2.2 m

3.0 m

Free

length*

X (mm)

Swan neck 25˚ (0368 155 890) 894 900 898 196.3

Swan neck straight (0368 155 894) 896 901 905 209.3

Swan neck 25˚ ext. 100 (0368 155 892) 296.3

Swan neck straight, ext. 100 (0368 155 896) 309.3

Length Y (± 20 mm) 1300 mm 2040 mm 3000 mm

* Specify length Y = in the correct column (swan neck)

We

l

d

i

ng gun

P

S

F

t 31

5

M

,

P

S

F

t 31

5

R

Edition 060822

Wear p arts

-- 1 2 --

bg14wear

(W) = wear part (A) = accessory

Item

Qty Ordering no. Denomination Notes

102 1 0459 073 882 Gas nozzle, standard (W) D/d 20/16 mm

-- 1 0366 946 882 Gas nozzle, conical (A) (W) D/d 17/13 mm

-- 1 0468 194 882 Gas nozzle, straight (A) (W) D/d 18/13 mm

104 1 0366 396 003 Spatter protection (W) Included in item 102

105 1 0368 145 001 Adapter (W) M6

-- 0368 683 001 Adapter (A) HELIX, M7

106 1 Contact tip (W) See table on page 13

107 1 0366 397 002 Insulation bushing (W)

Edition 060822

We

l

d

i

ng gun

P

S

F

t 31

5

M

,

P

S

F

t 31

5

R

Accessories

-- 1 3 --

bg14a11a

NO TAG

Contact tip

The bore dimension of the contact tips is to be selected with regard to wire diameter,

type of shielding gas and actual intensity of the current -- we refer to the table below.

Standard M6 ESAB Standard M6 ABB

To start with, choose a contact tip as specified in the shortarc--table (CO

2

). Should

binding occur with high parameters when using Argon or gas mixture, choose contact

tip from the sprayarc table.

Welding wire Ordering No Marked Ordering No

Short arc

CO

2

Spray arc

MIX

Contact-

tip

hole Ø

M6x27ESAB

Wire

Ø

M6x30ABB

Contact

tip

hole Ø

(0.8) 0.6 0.9 0468 500 002 W0.8 ESAB 0.8 0153 500 202 1.0

0.8 (0.8) 1.0 0468 500 003 W0.8 ESAB 0.9 0153 500 203 1.1

0.9 0.8 1.1 0468 500 004 W0.9 ESAB 1.0 0153 500 204* 1.2

1.0 0.9 1.2 0468 500 005 W1.0 ESAB -- -- 1.2

1.1 (1.0) 1.3 0468 500 006 W1.2 ESAB -- -- 1.3

1.2 1.0--1.1 1.5 0468 500 007 W1.2 ESAB -- -- 1.5

Table 1

*)

Is delivered as standard

Helix M7

Helix M7 contact tip must be combined with special tip adapter. See spare parts list.

Ordering number Marked

M7

HELIX

0368 313 881 W0.8 --

0368 313 882 W0.9 --

0368 313 883 W1.0 --

0368 313 884 W1.2 --

Table 2

Edition 060822

We

l

d

i

ng gun

P

S

F

t 31

5

M

,

P

S

F

t 31

5

R

-- 1 4 --

bg14a11a

Wire liner

NO TAG

Welding wire *)

PTFE conduit incl.

wear insert (steel)

Wear insert separate

3m Steel PTFE (Al)

0.8 mm 0366 550 882 0366 545 880 0368 742 880

0.9--1.0 mm 0366 550 884 0366 545 881 0368 742 880

1.2 mm 0366 550 886 0366 545 882 0368 742 881

*) The wire guide aperture = 1.5 x wire diameter. The wire guide is marked with the max. wire diameter (stamped on the nipple).

Table 3

W

l

d

i

i

*

)

Steel spiral PTFE ceramic liner

Welding wire

*

)

3m 3 m **)

0.6--0.8 mm 0366 549 882 --

0.9--1.0 mm 0366 549 884 0457 969 882

1.2 mm 0366 549 886 0457 969 882

*) The wire guide aperture = 1.5 x wire diameter. The wire guide is marked with the max. wire diameter (stamped on the nipple).

**) To be cut to gun length. No wear insert needed.

Table 4

Gasflow meter

To measure the current gas flow a gasflow meter is available as option, ordering

number 0155 716 880.

-- 1 5 --

page

ESAB AB

SE--695 81 LAXÅ

SWEDEN

Phone +46 584 81 000

www.esab.co m

060517

ESAB subsidiaries and representative offices

Europe

AUSTRIA

ESAB Ges.m.b.H

Vienna--Liesing

Tel: +43 1 888 25 11

Fax: +43 1 888 25 11 85

BELGIUM

S.A. ESAB N.V.

Brussels

Tel: +32 2 745 11 00

Fax: +32 2 745 11 28

THE CZECH REPUBLIC

ESAB VAMBERK s.r.o.

Prague

Tel: +420 2 819 40 885

Fax: +420 2 819 40 120

DENMARK

Aktieselskabet ESAB

Herlev

Tel:+4536300111

Fax:+4536304003

FINLAND

ESAB Oy

Helsinki

Tel: +358 9 547 761

Fax: +358 9 547 77 71

FRANCE

ESAB France S.A.

Cergy Pontoise

Tel:+33130755500

Fax:+33130755524

GERMANY

ESAB GmbH

Solingen

Tel: +49 212 298 0

Fax: +49 212 298 218

GREAT BRITAIN

ESAB Group (UK) Ltd

Waltham Cross

Tel: +44 1992 76 85 15

Fax: +44 1992 71 58 03

ESAB Automation Ltd

Andover

Tel: +44 1264 33 22 33

Fax: +44 1264 33 20 74

HUNGARY

ESAB Kft

Budapest

Tel:+3612044182

Fax:+3612044186

ITALY

ESAB Saldatura S.p.A.

Mesero (Mi)

Tel:+3902979681

Fax:+390297289181

THE NETHERLANDS

ESAB Nederland B.V.

Utrecht

Tel: +31 30 2485 377

Fax: +31 30 2485 260

NORWAY

AS ESAB

Larvik

Tel:+4733121000

Fax:+4733115203

POLAND

ESAB Sp.zo.o.

Katowice

Tel: +48 32 351 11 00

Fax: +48 32 351 11 20

PORTUGAL

ESAB Lda

Lisbon

Tel: +351 8 310 960

Fax: +351 1 859 1277

SLOVAKIA

ESAB Slovakia s.r.o.

Bratislava

Tel:+421744882426

Fax:+421744888741

SPAIN

ESAB Ibérica S.A.

Alcalá de Henares (MADRID)

Tel: +34 91 878 3600

Fax: +34 91 802 3461

SWEDEN

ESAB Sverige AB

Gothenburg

Tel:+4631509500

Fax:+4631509222

ESAB international AB

Gothenburg

Tel:+4631509000

Fax:+4631509360

SWITZERLAND

ESAB AG

Dietikon

Tel: +41 1 741 25 25

Fax: +41 1 740 30 55

North and South America

ARGENTINA

CONARCO

Buenos Aires

Tel: +54 11 4 753 4039

Fax: +54 11 4 753 6313

BRAZIL

ESAB S.A.

Contagem--MG

Tel: +55 31 2191 4333

Fax: +55 31 2191 4440

CANADA

ESAB Group Canada Inc.

Missisauga, Ontario

Tel: +1 905 670 02 20

Fax: +1 905 670 48 79

MEXICO

ESAB Mexico S.A.

Monterrey

Tel: +52 8 350 5959

Fax: +52 8 350 7554

USA

ESAB Welding & Cutting Products

Florence, SC

Tel: +1 843 669 44 11

Fax: +1 843 664 57 48

Asia/Pacific

CHINA

Shanghai ESAB A/P

Shanghai

Tel: +86 21 5308 9922

Fax: +86 21 6566 6622

INDIA

ESAB India Ltd

Calcutta

Tel: +91 33 478 45 17

Fax: +91 33 468 18 80

INDONESIA

P.T. ESABindo Pratama

Jakarta

Tel: +62 21 460 0188

Fax: +62 21 461 2929

JAPAN

ESAB Japan

Tokyo

Tel: +81 3 5296 7371

Fax:+81352968080

MALAYSIA

ESAB (Malaysia) Snd Bhd

Selangor

Tel: +60 3 8027 9869

Fax:+60380274754

SINGAPORE

ESAB Asia/Pacific Pte Ltd

Singapore

Tel:+6568614322

Fax: +65 6861 31 95

SOUTH KOREA

ESAB SeAH Corporation

Kyungnam

Tel: +82 55 269 8170

Fax: +82 55 289 8864

UNITED ARAB EMIRATES

ESAB Middle East FZE

Dubai

Tel: +971 4 887 21 11

Fax: +971 4 887 22 63

Representative offices

BULGARIA

ESAB Representative Office

Sofia

Tel/Fax: +359 2 974 42 88

EGYPT

ESAB Egypt

Dokki--Cairo

Tel: +20 2 390 96 69

Fax: +20 2 393 32 13

ROMANIA

ESAB Representative Office

Bucharest

Tel/Fax: +40 1 322 36 74

RUSSIA

LLC ESAB

Moscow

Tel: +7 095 543 9281

Fax: +7 095 543 9280

LLC ESAB

St Petersburg

Tel: +7 812 336 7080

Fax: +7 812 336 7060

Distributors

For addresses and phone

numbers to our distributors in

other countries, please visit our

home page

www.esab.co m

/