2 OM CentrifMicro II-5

Table of Contents

Introduction ............................................... 3

Features of the Control Panel................... 4

General Description................................... 5

Component Description ............................ 6

Operator Interface Touch Screen ........................... 6

Unit/Compressor Controller Description...............6

Software................................................................. 7

Unit Controller....................................................... 7

Compressor Controller ..........................................8

Guardister Board ................................................ 9

Signal Converter Board .........................................9

Transducer Converter Board..................................9

PLAN Isolator .......................................................9

Field Wiring Diagram..........................................10

Dual/Multi-Chiller Operation ................ 12

Multiple Chiller Setup .........................................12

WCC Settings ......................................................15

Ice Mode Operation................................. 16

Operator Interface Touch Screen........... 16

Navigation ........................................................... 16

Screen Descriptions .............................................18

VIEW Screens .....................................................18

SET Screens......................................................... 23

SERVICE Screen ................................................. 37

HISTORY Screens............................................... 38

Download from the USB .....................................39

ACTIVE ALARM Screen.................................... 40

Unit Controller......................................... 43

Navigating ........................................................... 43

Screen Descriptions .............................................46

SET Screens......................................................... 49

Unit Controller Setpoints..................................... 51

Compressor Controller ........................... 61

Navigating ........................................................... 61

Compressor Controller Setpoints......................... 62

Optional Starter Screens......................... 67

Low Voltage Starters, 200 – 600 Volts.... 68

General ................................................................ 68

LED Display........................................................ 69

Faults and Alarms ................................................ 74

Troubleshooting................................................... 77

Preventive Maintenance ...................................... 82

Medium/High Voltage Starters, 2300V

– 7.2KV..................................................... 83

View Parameters.................................................. 84

Set Parameters..................................................... 84

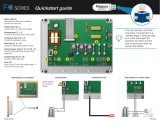

Quick Start........................................................... 86

Troubleshooting................................................... 88

Fault/Log Codes .................................................. 90

LED Diagnostics ................................................. 93

Preventive Maintenance ...................................... 93

Sequence of Operation............................ 94

Unit Operation..................................................... 94

Operating the Chiller Control System... 96

Interface Panel On/Off ........................................ 96

Start/Stop Unit..................................................... 96

Change Setpoints................................................. 97

Alarms ................................................................. 97

Component Failure .............................................. 97

Standby Power..................................................... 97

Maintenance Schedule ............................ 98

McQuay" and MicroTech II are registered trademarks of McQuay International

2005 McQuay International

"Illustrations and information cover McQuay International products at the time of publication and we reserve the right to make changes in design and

construction at anytime without notice."

Manufactured in an ISO certified facility.

ETL applies only to models