5

CompletingtheInstallation

Partsneededforthisprocedure:

1

Fuse(10A)—525tractionunitonly

Procedure

1.FortheTX525,performthefollowingsteps:

A.Installthefuse(10A)tothefuse-block

locationshowninFigure26.

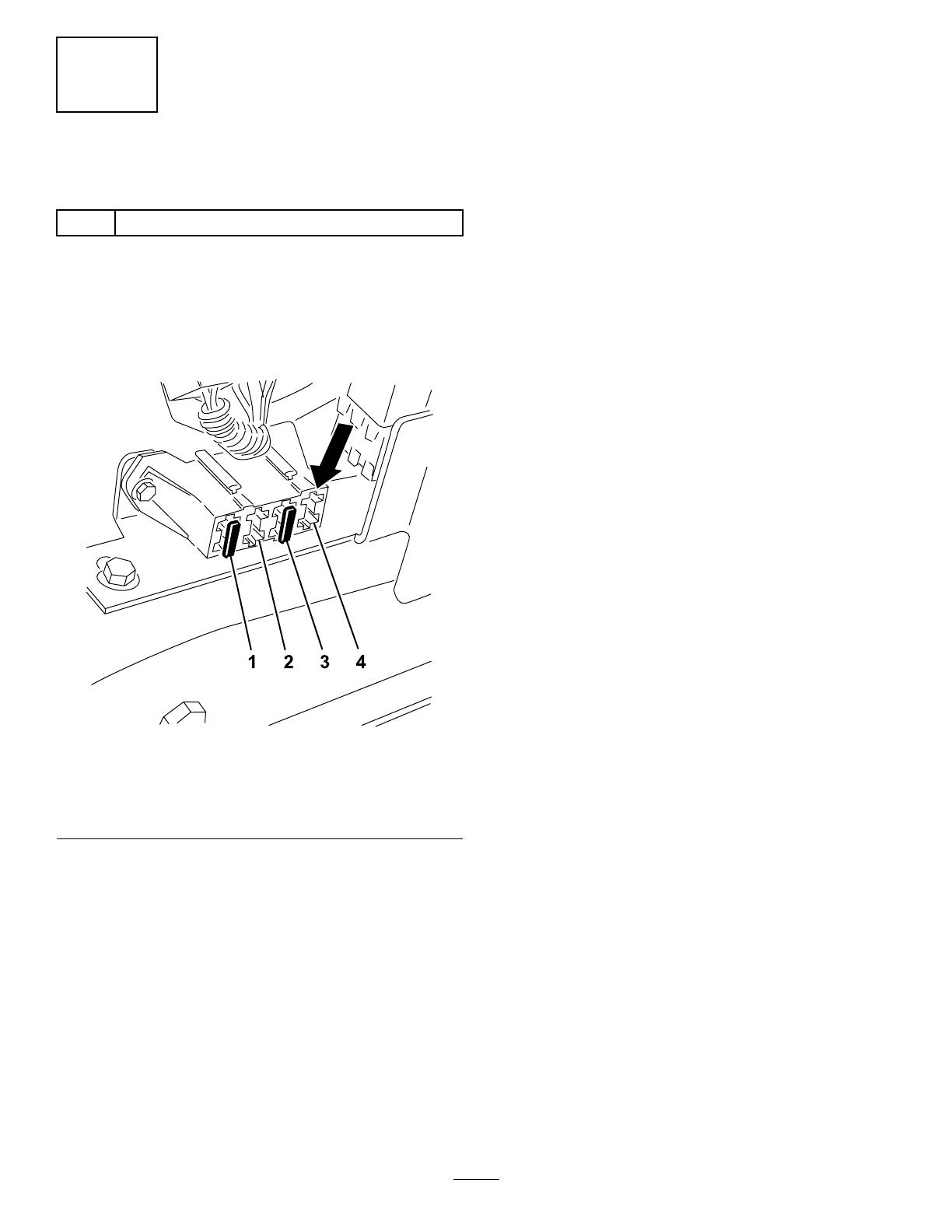

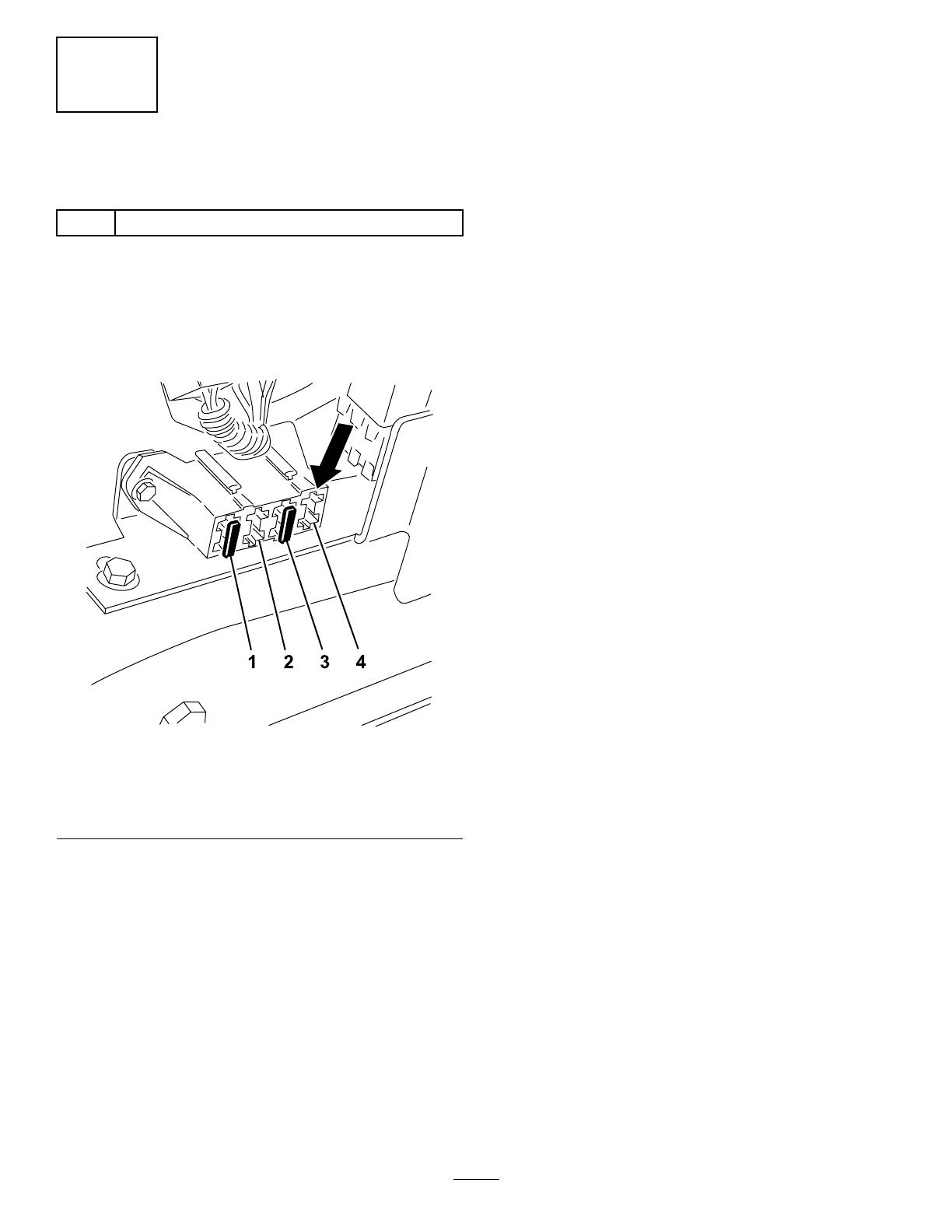

g357029

Figure26

1.Existingfuse(30A)3.Existingfuse(10A)

2.Empty

4.Addlightkitfuse(10A)

here.

B.Installthefuseandrearpanels.

Note:Reversetheproceduresforeach

panelasshownin2RemovingtheAccess

Panels(page2).

2.Installthenegative(-)batterycabletothe

battery.

3.Closeorinstallthehood,asapplicableforyour

machine.

4.Startthemachineandverifythatthelights

functionusingtheswitch.

9