3-2

Z Master 7500-D Series Service Manual

March 2018 - Digital Edition

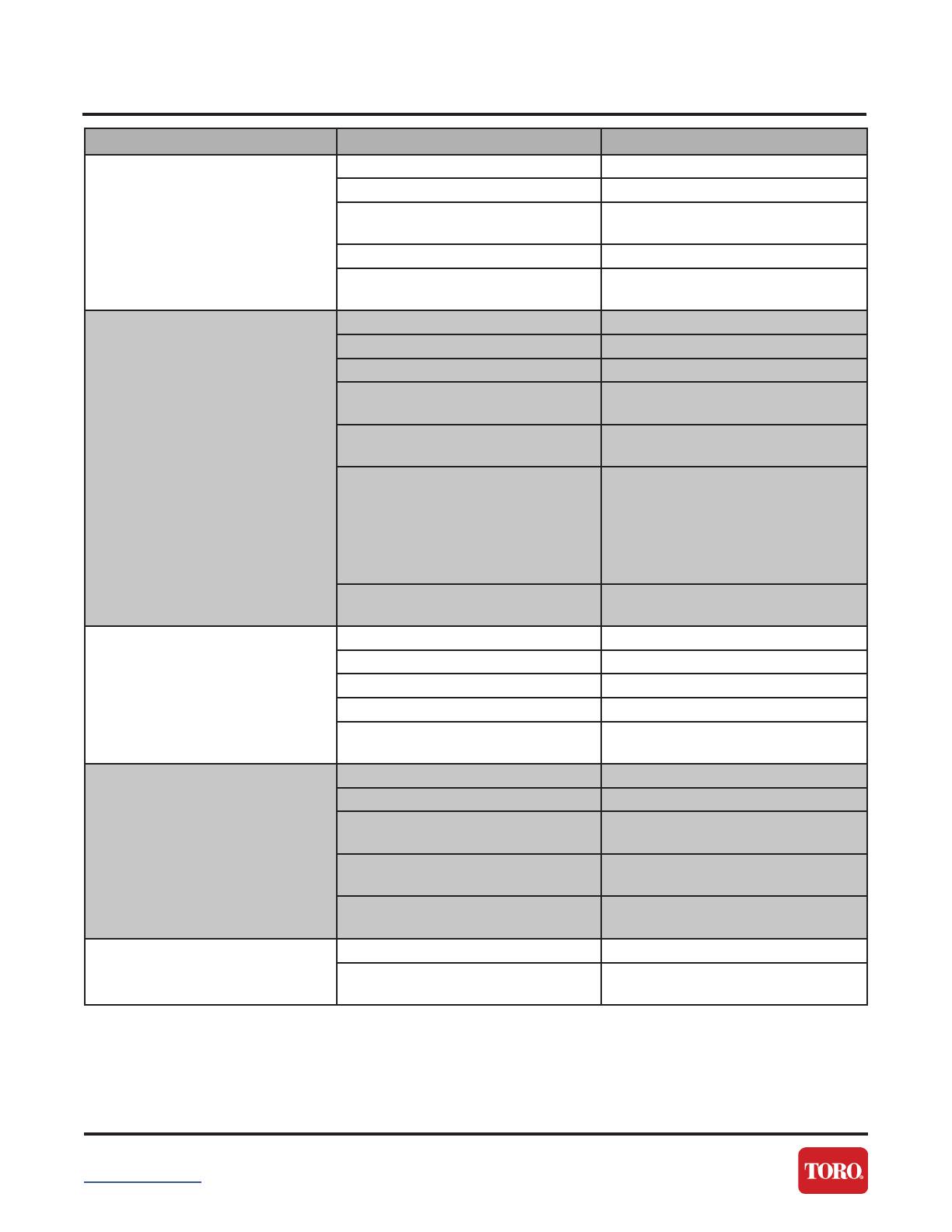

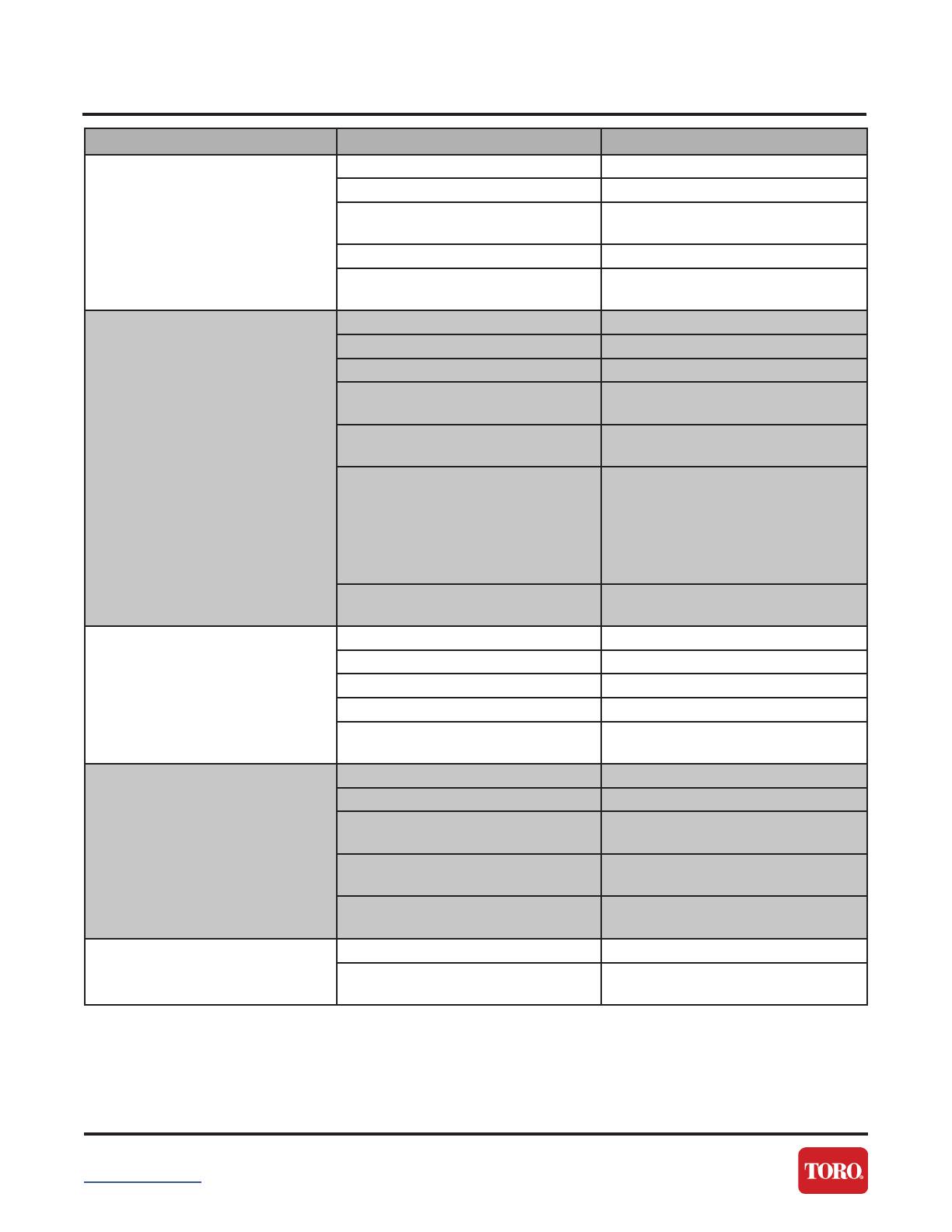

Table of Contents

TROUBLESHOOTING

Problem Possible Cause Next Step...

The starter does not crank The parking brake is not engaged Set the parking brake

The battery is dead Charge the battery

The electrical connections are

corroded or loose

Check the electrical connects for

good contact

The fuse is blown Replace the fuse

The relay or ignition switch is worn

or damaged

Test and replace faulty relay or

ignition switch

The engine does not start,

starts hard, or fails to keep

running

The fuel tank is empty Fill the fuel tank

The oil level in the crankcase is low Add oil to the crankcase

There is dirt in the fuel filter Replace the fuel filter

There is dirt, water, or stale fuel in

the fuel system

Clean and flush the fuel system

The air cleaner is dirty Clean or replace the air cleaner

element

The electrical connections are

corroded, loose, or damaged

Check the electrical connections for

good contact

Clean the connector terminals

thoroughly with electrical-contact

cleaner, apply dielectric grease, and

make the appropriate connections

The relay or switch is worn or

damaged

Test and replace faulty relay or

switch

Engine loses power The engine load is excessive Reduce the ground speed

The air cleaner is dirty Clean the air cleaner element

The oil level in the crankcase is low Add oil to the crankcase

There is dirt in the fuel filter Replace the fuel filter

There is dirt, water, or stale fuel in

the fuel system

Clean and flush the fuel system

The engine overheats The engine load is excessive Reduce the ground speed

The oil level in the crankcase is low Add oil to the crankcase

The cooling system is contaminated/

low

Inspect coolant for proper level and

condition. Correct as needed.

The cooling fan/belt is damaged. Ensure the condition of the both the

fan and belt

The radiator is plugged/damaged. Inspect radiator fins for plugging

bends, repair as needed

The unit pulls to the left or right

(with levers fully forward)

The tracking needs adjustment Adjust the tracking

The rear tire pressure is unmatched. Check and adjust the tire pressure

to 124 kPa (18 psi)