Automationdirect.com Productivity 1000 P1-04RTD User manual

- Type

- User manual

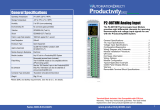

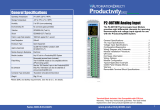

Automationdirect.com Productivity 1000 P1-04RTD helps you receive and process data from analog sensors and devices. You can use it to create a temperature control loop in your oven or other environment. The device has 4 differential input channels and a variety of features:

- Automatic sensor type detection.

- Range selection for each channel.

- Resolution up to 0.1°C or °F.

- Linearization for Pt100, Pt1000, and JPt100 RTD sensors.

- Excitation current of 210µA.

- Burnout detection within 2 seconds.

- Open circuit detection time of 200ms @ 16.7 Hz and 90ms @ 470Hz.

Automationdirect.com Productivity 1000 P1-04RTD helps you receive and process data from analog sensors and devices. You can use it to create a temperature control loop in your oven or other environment. The device has 4 differential input channels and a variety of features:

- Automatic sensor type detection.

- Range selection for each channel.

- Resolution up to 0.1°C or °F.

- Linearization for Pt100, Pt1000, and JPt100 RTD sensors.

- Excitation current of 210µA.

- Burnout detection within 2 seconds.

- Open circuit detection time of 200ms @ 16.7 Hz and 90ms @ 470Hz.

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

Automationdirect.com Productivity 1000 P1-04RTD User manual

- Type

- User manual

Automationdirect.com Productivity 1000 P1-04RTD helps you receive and process data from analog sensors and devices. You can use it to create a temperature control loop in your oven or other environment. The device has 4 differential input channels and a variety of features:

- Automatic sensor type detection.

- Range selection for each channel.

- Resolution up to 0.1°C or °F.

- Linearization for Pt100, Pt1000, and JPt100 RTD sensors.

- Excitation current of 210µA.

- Burnout detection within 2 seconds.

- Open circuit detection time of 200ms @ 16.7 Hz and 90ms @ 470Hz.

Ask a question and I''ll find the answer in the document

Finding information in a document is now easier with AI

Related papers

-

Automationdirect.com Productivity 1000 P1-04DAL-2 User manual

-

Automationdirect.com Productivity 1000 P1-04THM User manual

-

Automationdirect.com Productivity 1000 P1-4ADL2DAL-1 User manual

-

Automationdirect.com Productivity 2000 P2-08TD1P User manual

-

Automationdirect.com Productivity 1000 P1-08NE3 User manual

-

Automationdirect.com Productivity 1000 P1-15TD2 User manual

-

Automationdirect.com Productivity 1000 P1-16TR User manual

-

Automationdirect.com Productivity 1000 P1-540 User manual

-

Automationdirect.com Productivity 2000 P2-06RTD User manual

-

Automationdirect.com Productivity 2000 P2-08NAS User manual

Other documents

-

Multi-Link ZipLink User manual

-

Automation Direct Productivity2000 P2-08ND3-1 User manual

Automation Direct Productivity2000 P2-08ND3-1 User manual

-

AutomationDirect StrideLinx Remote Access Solution Operating instructions

AutomationDirect StrideLinx Remote Access Solution Operating instructions

-

Automation Direct PRODUCTIVITY 2000 User manual

Automation Direct PRODUCTIVITY 2000 User manual

-

Automation Direct SL4848-RR Quick start guide

Automation Direct SL4848-RR Quick start guide

-

Solo SL4896-RRE Quick start guide

-

AutomationDirect SL4824 Series Quick start guide

AutomationDirect SL4824 Series Quick start guide

-

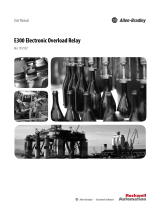

Rockwell Automation Allen-Bradley E300 User manual

Rockwell Automation Allen-Bradley E300 User manual

-

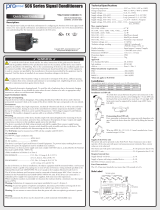

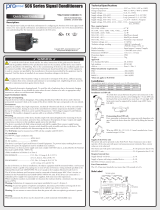

AutomationDirect ProSense SC6 Series Quick start guide

AutomationDirect ProSense SC6 Series Quick start guide

-

AutomationDirect SOLO Basic SLB4848 Series Quick start guide

AutomationDirect SOLO Basic SLB4848 Series Quick start guide