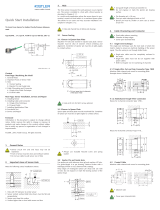

3. Hole

3.1 Unmachined Sensor

For use in flat cavity wall with sensor fitted at right angles

to cavity.

• Hole and thread must be free of debris and shavings

• Use checking tool Mat. No. 55155779 also to lapp

hole

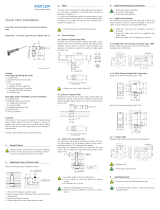

Quick Start Installation

2 mm Cavity Pressure Sensor with conductive spacer sleeve

Type 6185AAN… (–2,2 pC/bar, 2 000 bar, 200 °C)

Type 6185ACN… (–2,2 pC/bar, 2 000 bar, 200 °C)

6185A_002-788e-11.16

Content

Front Page: Machining the Mold

1. General Notes

2. Important Areas of Sensor Hole

3. Hole

3.1 Unmachined Sensor

3.2

Cavity-Matched Sensor

4. Cable Channeling and Connector

Rear Page: Sensor Installation, Service and Repair

5. Installing Sensor

6. Installing Cable and Connector

7. Installing Identification Plate

8. Functional Test

9. Service and Repair

Foreword

Information in this document is subject to change without

notice. Kistler reserves the right to change or improve its

products and make changes in the content without obliga-

tion to notify any person or organization of such changes or

improvements.

To the extent permitted by law Kistler does not accept any

liability if this Quick Start Installation guide is not followed or

products other than those listed under Accessories are used.

© 2016, Kistler Group. All rights reserved.

1. General Notes

• Sensor diameter ø2 mm may not be machined

• Front of sensor must be clean and without notches

• Only use recommended installation accessories

1. Sensor contact surface must be flat and perpendicular

2. Hole with H7 tolerance to center sensor

3. Chamfer protects O-ring during installation

4. No centering mounting bore

5. Sharp edges reduce witness mark on part

2. Important Areas of Sensor Hole

Note the following critical installation criteria:

• Use cleaning spray Type 1003

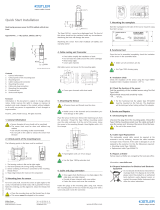

4. Cable Channeling and Connector

• Fixed cable reduces mounting

• Do not run cables next to hot runner cartridge

• Chamfer all sharp edges

• Cover open channels/slots

4.1 Contact Element in Holding Plate

Adherence to the centering and position alignment (0,3

mm) to the spacer sleeve Type 1720A1 in the mold insert is

required.

4.2 Single-Wire Cable Technology

The single-wire technology uses the tool steel to ensure elec-

trical shielding of the sensor signal. Thus the wiring is routed

through drilled holes or channels.

• Single-wire cable must be completely enclosed in mold

• Single-wire cable must not be routed with power

cables

4.2.1 Single-Wire Cut and Grip Connector Type 1839

Machine cable channel and recess for mounting plate.

Example of a mounting bore:

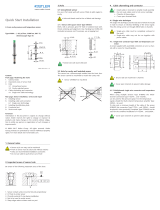

3.2 Cavity-Matched Sensor

For use in cavity with sloped, textured or free-form surface

install sensor with keyway pin Mat. No. 3.211.718.

3.2.1 Machining Sensor Front

Grind sensor front or install sensor in hole and then machine

complete cavity profile. Then remove sensor. Clean hole and

sensor.

3.1.1 Sensor with Conductive Spacer Sleeve Type

1720A1

Electrical discharge machine (EDM), mill or precision grind H7

hole in hardened tool steel. Check centering and alignment.

4.2.2 Multichannel Single-Wire Connectors

Recess for 4-channel connector Type 1722A4…

• Observe radii

• Cover open channels to prevent cable damage

Recess for 8-channel connector Type 1722A8…

Example of a channel 1722A8...

• Only uncoated variants Type 6185AA ... permitted

M3

x0,35

40

3,1

0,05

M8x0,75

0

4,2

5,2

+

4

Outline

Outline

Kistler Group

Eulachstrasse 22

8408 Winterthur, Switzerland

Tel. +41 52 224 11 11

Fax +41 52 224 14 14

info@kistler.com www.kistler.com

6185A_002-788e-11.16 ©2016, Kistler Group

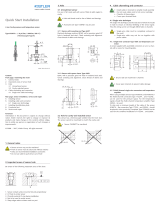

5. Installing Sensor

• Ensure all sensor hole and threads are clean

• Use checking tool Art. No. 55155779

•

• A chamfered cable channel or cable hole prevents

damaged cables

8. Functional Test

On completion of mold assembly, test sensor insulation and

sensitivity.

• Ensure that connector is dry

• Use cleaning spray Type 1003

8.1 Insulation Test

Use insulation tester Type 5495 to check sensor insulation.

Resistance >1013 Ω.

8.2 Sensor Functional Check

Test the sensitivity of the installed sensor using Test Set Type

5495.

Approximate measured sensitivity value: –2,1 … –2,6 pC.

9. Service and Repair

Piezoelectric pressure sensors are maintenance-free. Insulation

and sensitivity of the installed sensor should, however, be

checked after each molding run.

• Ensure that connector is dry

• Cover sensor hole during cleaning

• Use cleaning spray Type 1003

9.1 Insulation Test

See chapter 8.1.

9.2 Sensor Functional Check

See chapter 8.2.

9.3 Removing Sensor

Push sensor out of cavity by using a flat pen or control tool

Mat. No. 3.050.241.

• Do not use a hammer on the sensor front

• Do not use a sharp center punch

9.4 Single-Wire Repair

Slightly damaged cables can be repaired using the Repair Kit

Type 1207. If single-wire cables have been severed, solder

ends, slide over Teflon tube and cover with shrink tubing.

• Do not overheat sensor and cable when using hot

air blower

9.5 Repairs at Kistler

Factory repairs at Kistler are arranged by the local sales office

Information: www.kistler.com

9.6 Disposal Instructions for Electrical and Electronic

Equipment

Do not discard old electronic instruments

in municipal trash. For disposal at end

of life, please return this product to an

authorized local electronic waste disposal

service or contact the nearest Kistler

Instrument sales office for return instruc-

tions.

5.1 Installing Sensor with Conductive Spacer Sleeve

Type 1720A1

Screw connect sensor into conductive spacer sleeve.

5.1.1 Machining Conductive Spacer Sleeve

Cut conductive spacer sleeve with enough excess length

(with cutting wheel, as dry as possible). Then grind to

required dimension to guarantee a clearance of 0,01 ... 0,03

mm. Please ensure that the sensor is not damaged when

clamping it for cutting or grinding. Grind spacer sleeve at a

right angle and flush, afterwards debur it.

For multi-cavity applications each spacer sleeve should be

numbered and allocated to a sensor.

5.1.2 Mounting Sensor with Conductive Spacer Sleeve

Install sensor with spacer sleeve. Ensure a clearance of

0,01 … 0,03 mm.

Sensor may not be preloaded when assembling the mold.

• Do not preload sensor

• For multi-cavity applications each spacer sleeve

should be numbered

6. Installing Cable and Connector

• Check again that edges of cable duct and hole are

chamfered

• Use a metal plate to cover open ducts/slots

• Attach cap and place on connector

6.1 Single-Wire Technology

• Single-wire cable must be completely enclosed in

the mold

• Single-wire cable may not be routed with power

cables

• Ensure that all contact surfaces and threads are clean

and dry

6.1.1 Cut & Grip Connection

Cut the single-wire cable to length and do not strip the

insulation. Loosen the knurled connector by hand without

removing the rear section.

6.1.2 Installing Single-Wire Connector

Install connector and mounting plate in recess. Attach cap

using one of the screws. Place cap on open connector.

Installation of Connector Type 1839 and Mounting Plate

7. Installing Identification Plate

Rivet plate to side of mold or fit with four M2.5 screws.

Installation of Multichannel Connector

Example: Type 1722A...

5.2 Installing Contact Element in Holding Plate

Pull the cable through the mounting bore and encase it with

a silicone and fluoropolymer hose on the side of the contact

element. Push crimp contact into the contact element and

fasten on holding plate with installation nipple.

• Do not strip cable

/