Page is loading ...

Protect yourself and others by observing all safety information, warnings, and cautions. Failure to

comply with instructions could result in personal injury and/or damage to product or property.

Please retain instructions for future reference!

RANCN65

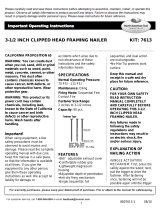

65MM COIL

NAILER

ADJUSTABLE

EXHAUST

AIR INLET

TRIGGER

MODE CONTROL

SINGLE / BUMP

DEPTH CONTROL

MAGAZINE RELEASE

NOTE: USE PLASTIC

COLLATED NAILS ONLY

Nail capacity (Qty): up to 300pcs

Nail size: 25 mm (1”) to 65mm (2-1/2”), 15deg, Plastic collated coil nails only.

Recommended operating pressure: 70-110 PSI (5-7.5 bar)

Maximum pressure: 8.3 bar (120 PSI)

Air inlet: Nitto style connector

Dimensions: 320 x 310 x 128 mm

Weight: 3.0 kg

• KEEP CHILDREN AWAY. All children should be kept away from the work area. Don’t let them

handle the tool.

• USE SAFETY GOGGLES AND EAR PROTECTION: Air tool operators and others in work area

should always wear safety glass to prevent the injury from fasteners and flying debris

when loading and unloading this tool. Maybe the noise would harm your hearing, wear the

ear protection to safeguard.

• NEVER USE OXYGEN, COMBUSTIBLE OR ANY OTHER BOTTLE GAS

as a power source or would cause explosion and serious personal injury.

• DO NOT CONNECT TOOL TO COMPRESSED AIR which pressure exceeds (8.3bar) 120psi.

• DO NOT PLACE OVER-LONG AIR HOSE in working area in case of the

• operator’s unexpected tripping .Make sure all connections are tight, the hose should be

near to air supply .

• CARRY THE TOOL ONLY BY THE HANDLE. Do not keep the trigger pull on safety yoke mecha-

nism to avoid unintentional firing of fastener.

• KEEP THE TOOL POINTED AWAY FROM YOURSELF and others at all time and keep hands, any

body parts away rear area to Safety guard against possible injury.

• DISCONNECT TOOL FROM AIR SUPPLY BEFORE LOADING fasteners to prevent a fastener from

being fired during connection.

• DO NOT KEEP THE TRIGGER OR SAFETY DEPRESSED during loading fasteners or the uninten-

tional firing of a fastener would cause personal injury.

• DISCONNECT TOOL FROM AIR SUPPLY HOSE and empty the compressor before performing

maintenance or when not in use.

• DO NOT DRIVE FASTENER ON SCAFFOLDINGS,LADDERS and on such similarly construction,

not working on airtight case, and vehicles. Don’t over reach, keep proper footing at all

times to ensure correct balance.

• DO NOT DRIVE FASTENERS CLOSE TO THE EDGE OF THE WORK PIECE.

• The work-piece would split allowing fastener to fly free or ricochet causing personal injury.

• DO NOT DRIVE FASTENER ON TOP OF NAILED FASTENER, or the fastener can ricochet causing

personal injury.

• NEVER USE A TOOL that is leaking air, had missing or damaged parts or requires repair and

make sure all the screws and securely tightened.

• MAKE DAILY INSPECTION FOR FREE MOVEMENT of trigger, safety mechanism and spring to

insure the tool can operate well.

• ONLY USE PARTS AND ACCESSORIES recommend by manufacturer.

GENERAL SAFETY

SPECIFICATIONS

IMPORTANT!: Read and understand all safety rules, operating

instructions before use.

• CLEAN work area Accidents occur where benches and work areas are cluttered or dirty,

floors must be kept clear.

• Make sure only use correct staplers as specified for your tool.(See Fastener specification)

15 Deg. coil nailer nailer for construction framing, pallet and crate assembly, deck construc-

tion, roof decks, fencing, sidewall sheathing and etc.

OPERATING INSTRUCTION

Description

WARNING!: Never free-fire the tool at high pressure

• Use clean, Dry and Regulated compressed air at 5-7.5bar (70-110psi)

• Never exceed maximum and minimum pressure. Too low or too high pressure would cause

noise, fast-worn or misfiring.

• When connecting air supply always keep hands and body from discharge area of tool.

• A filter-regulator-lubrication is required and should be located as close to tool as possible.

(see below)

• Keep air filter clean. A dirty filter will reduce the air pressure to the tool causing a reduction

in power and efficiency.

• Be sure all connections in air supply system are sealed to prevent air loss.

WARNING!: Always disconnect the tool from the compressed air before loading.

When loading the tool always point the tool away from yourself and others. Make

sure that you are not holding the tool with trigger depressed while loading the

tool.

Loading fastener and operation

• Disconnect the tool from the air supply Grasp the nailer firmly with one hand .Press the

latch with your thumb and pull the magazine back. Insert a strip of fasteners into maga-

zine Keeping it point down.

• Release the latch and pusher, slid the pusher against the nails until it contacts the nails and

lock into place. The tool is now ready for use.

• Connect the tool to the air supply. Make sure the air pressure is in the correct range de-

noted in the Technical Data.

GENERAL SAFETY Cont .....

• Then test the driving depth in a sample piece of wood before using. If the fasteners are

being driven too far or not far enough, adjust the regulator to provide less air pressure or

more air pressure.

Loading fastener and operation Cont .....

WARNING!: Never operate tool unless safety nose is contact with work-piece. Do

not operate tool without fasteners or damage to tool may result.

WARNING!: Never fire fasteners into air because fasteners may injury operator or

others and damage to tool may result.

MAINTENANCE

WARNING: Disconnect the tool from the air compressor before adjusting, clearing

jams, servicing, maintenance, relocating and when not in use.

• Regular lubrication, if your tool without using the in-liner automatic oilier, place 2 or 6

drops of pneumatic tool oil into the air inlet before each work day or after 2 hours of con-

tinuous use depending on the characteristic of work-piece or type of fasteners.

• Air-operated tools must be inspected periodically, and worn or broken parts must be re-

placed to keep the tool operating safely and efficiently. Check and change all worn or dam-

aged O-rings, seals, etc. Tight all the screws and caps in case personal injury.

• Make regular inspection for free movement of trigger, Spring and safety mechanism to

assure safe system is complete and functional: no loose and missing parts, no building or

sticking parts.

• Keep magazine and nose of tool clean and free of any dirt lint or abrasive particles.

• •Whentemperaturesarebelowfreezing,toolsshouldbekeptwarmbyanyconvenient,

safe method.

TROUBLESHOOTING

WARNING: If any of the following symptoms appears during your operating, stop

using the tool immediately, or serious personal injury could result. Only a qualified

persons or an authorized service centre can perform repairs or replacement of

tool.

SYMPTOM PROBLEM SOLUTIONS

Air leak near top of tool or

in trigger area

1. O-ring in trigger valve are

damage.

1. Check and replace O-ring.

2. Trigger valve head are dam-

age.

2. Check and replace.

3. Trigger valve stem ,seal or

O-ring are damaged.

3. Check and replace trigger valve

stem, seal or O-ring

Air leak near bottom of

tool.

1. Loose screws. 1. Tighten screws.

2. Worn or damaged O-rings

or bumper.

2. Check and replace O-rings or

bumper.

Air leak between body and

cylinder cap.

1. Loose screws. 1. Tighten screw.

2. Worn or damaged O-rings

or seals.

2. Check and replace O-rings or

bumper.

Blade driving fastener too

deep.

1. Worn bumper. 1. Replace bumper.

2. Air pressure is too high. 2. Adjust the air pressure.

Tool does not operate well:

can not drive fastener or

operate sluggishly.

1. Inadequate air supply. 1. Verify adequate air supply.

2. Inadequate lubrication. 2. Place 2 or 6 drops of oil into air

inlet.

3. Worn or damaged O-rings

or seals.

3. Check and replace O-rings or

seal.

4. Exhaust port in cylinder

head is blocked.

4. Replace damaged internal parts.

EXPLORED VIEW

For information on all ROSS products

please visit: www.rosstools.com.au

The ROSS logo and Bull device are trademarks of J.W. Ross Pty Ltd.

WARRANTY:

This product has been manufactured to a high quality standard. It is guaranteed

against faulty materials and workmanship for 36 months from the date of purchase.

Please retain your receipt as proof of purchase.

If the product is found to be defective within the relevant time period, we will either

replace all defective parts or, at our discretion, replace the unit free of charge.

This warranty will not apply:

(i) where this product has been subjected to misuse, abuse, accident or want of care;

(ii) where this product has been used for a purpose for which it was not designed or is

not suited;

(iii) where the service of this product has been undertaken by a non-authorised person

or company or if non-approved parts have been used;

(iv) where this product has been used for industrial purposes.

Should service become necessary during the warranty period, the purchaser should

contact an Authorised Service Centre or J W Ross. In order to obtain warranty service,

the purchaser must present the store receipt showing the name of the retailer and the

date of purchase.

The period of the warranty begins from the original date of purchase, notwithstanding

any subsequent repair or parts replacement.

Purchaser shall be responsible for all transport charges to and from the Authorised

Service Centre.

Damage in transit is not covered by this warranty. The purchaser should remove from

the product any liquids (if applicable) before sending the tool for service or repair.

Any accessories should be packed securely to prevent damage.

Warranty exclusions

Wear parts or service related parts required when performing normal and regular

maintenance of this product are not covered by warranty unless it is found to be defective

by an Authorised Service Centre. These include, but are not limited to:

accessories, bumpers, driver blades, “o” rings, seals, gaskets, air fittings, lubricants, tune-ups,

filters.

Distributed in Australia by J W Ross and Sons ( Australia ) Pty Ltd.

PO Box 352 North Ryde BC, NSW, 1670

Inquiries phone 1800 251 338

The J.W. Ross policy is one of continuous improvement and

the company reserves the right to alter designs, colours and

specifications without notice.

/