Page is loading ...

Vortex Flow Meters

RWG/RWBG Wafer Style Flow Meters

RNG Insertion Style Flow Meters

VRX-UM-00374-EN-06 (June 2018)

FLOW

Flow

Flow

User Manual

Vortex Flow Meters, RWG/RWBG Wafer Style Flow Meters & RNG Insertion Style Flow Meters

VRX-UM-00374-EN-06Page 2 June 2018

User Manual

VRX-UM-00374-EN-06 Page 3 June 2018

CONTENTS

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Specications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Flow Ranges. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Velocity Ranges. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Straight-Run Piping Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Installation Location. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Mechanical Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

RWG/RWBG Wafer Meter Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

RNG Insertion Meter Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Hot Tap Insertion Flow Meter Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Electrical Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

EMC Notication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Instructions Specic to Hazardous Area Installations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Power Terminals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Current Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

HART Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Wiring Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Preliminary Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Additional Installation Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Turbulence. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Swirl . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Sonic Noise . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Velocity Prole . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Flow Proling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Reducing the Pipe Diameter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Vortex Flow Meters, RWG/RWBG Wafer Style Flow Meters & RNG Insertion Style Flow Meters

VRX-UM-00374-EN-06Page iv June 2018

Introduction

Page 5 June 2018 VRX-UM-00374-EN-06

INTRODUCTION

The RNG/RWG/RWBG series vortex shedding flow meter family is designed to provide accurate and repeatable gas flow

measurement. These meters employ a patented ultrasonic technique to measure a form of turbulence created in the flow

stream. This turbulence, known as the Von Karman Vortex Street, is related to the flow through the pipe.

The RNG/RWG/RWBG series flow meter is a microprocessor based device, with HART compatible communications. The

primary output of the meter is a 2 wire, 4…20 milliampere (mA) current which is proportional to the flow.

With HART communications, users have the capability to remotely configure the meter. Typical operations, like re-scaling the

analog output, can be performed in comfort using a standard PC or HART 275/375/475 Communicator.

The wafer style meters are for pipe diameters four inches or less, and are installed between 150 lb flanges, or are

manufactured with pipe extensions and 150 lb flanges welded on the ends. These meters are calibrated in volumetric flow

units, that is Actual Cubic Feet per Minute (ACFM). Flow rates for the wafer style meters are listed in Table 2 .

The insertion style meters are retractable meters that are installed through the walls of a pipe or duct larger than four inches.

These meters can be installed through a 2 in. full port valve, which permits the unit to be retracted or inserted manually

without shutting down the system. Flow rates for the Insertion style meters are shown in Table 3.

DANGER

CAUTION SHOULD BE USED WHEN INSERTING OR RETRACTING AT PRESSURES EXCEEDING 60 PSIG (4.14 BARG).

SPECIFICATIONS

Wafer Insertion

Mounting Requirements Mounts between two 150 lb. flanges Options for 2 in. NPT, 2 in. 150# Flange, 2 in. 300# Flange, DN50 Flange

Operating Pressure –5…250 psig (–0.34 …17 barg)

Operating Temperature –20…300° F (–28…150° C)

Ambient Temperature –20…155° F (–28…68° C)

Accuracy ±1% of Reading over the upper 90% of the flow range

Repeatability 0.5% of reading

Input Power 28V DC Maximum

Output 4…20 mA (2 wire)

Table 1: Specifications

Flow Ranges

Gas / Air Application

Flow Ranges for RWG / RWBG Series

Model

Pipe Size

in. (mm)

Flow ACFM (m³/hr)

Minimum Maximum

RWG05 0.5 (13) 0.4 (0.7) 16 (27)

RWG10 1 (25) 1.2 (2.0) 45 (77)

RWG15 1.5 (38) 2.0 (3.4) 100 (170)

RWG20 2 (50) 5.0 (8.5) 200 (340)

RWG30 3 (76) 10.0 (17.0) 400 (680)

RWG40 4 (102) 20.0 (34.0) 600 (1019)

Table 2: Flow Ranges for RWG / RWBG Series

Velocity Ranges

Gas / Air Application

Velocity Range for RNG Series

Model

Pipe Size

in. (mm)

Velocity fps (mps)

Minimum Maximum

RNG

4 (102)

2 (0.6) 140 (43)

6 (152)

8 (203)

10 (254)

Table 3: Velocity Ranges for RNG Series

Flow measured in feet / second @ 14.69 psia, 60° F (meter / second

@ 1.013 bar, 16° C)

Installation

Page 6 June 2018VRX-UM-00374-EN-06

INSTALLATION

The flow meter is shipped completely assembled, tested and ready to install in its permanent location. See Figure 2 on page

7 through Figure 5 on page 9 for the applicable outline dimensions for specific meters.

Straight-Run Piping Considerations

The sensor should be installed with 20 diameters, or more, of straight, unobstructed, full area pipe upstream of the flow meter

installation and 10 diameters, or more, downstream. This condition provides the fully developed, symmetrical flow profile that

is necessary to obtain accurate and repeatable results. The first obstruction up and downstream should be a full area elbow. If

the minimum straight run is not possible, the general rule is to have 80% of the straight run upstream and 20% downstream

from the flow meter installation.

High intensity ultrasonic noises should not be located upstream or downstream from the sensor. Common ultrasonic noise

sources include the following:

• Slightly cracked valves operating with large pressure drops.

• Small pipe leaks in high pressure systems.

• Venturies operating at near-sonic flow rates.

• Sonic nozzles.

If these ultrasonic noise sources cannot be eliminated, the meter should be mounted with at least one elbow between the

flow meter and the noise source.

Installation Location

The RNG/RWG/RWBG series meters uses ultrasonics to measure flow. An ultrasonic noise can interfere with this technique,

therefore high intensity, ultrasonic noise sources should not be located upstream or downstream from the meter. Common

mechanical ultrasonic noise sources include the following:

• Slightly cracked valves operating with large pressure drops.

• Small pipe leaks in high pressure systems.

• Venturies operating at near-sonic flow rates.

• Sonic nozzles.

If these ultrasonic noise sources cannot be eliminated, the meter should be mounted with at least one elbow between the

flow meter and the noise source.

Temperature and Pressure Tap Locations

User supplied pressure and temperature sensors should be mounted downstream from the flow meter. The pressure sensor

should be approximately 3 to 5 pipe diameters and the temperature sensor approximately 4 to 8 pipe diameters downstream.

Mechanical Installation

The meter should be installed with at least 20 pipe diameters of straight pipe upstream and 10 pipe diameters downstream.

This condition provides the fully developed, symmetrical flow profile that is necessary to obtain accurate and repeatable

results. Shorter upstream/downstream piping may be used although a shift in calibration may occur. If severe turbulence or

distorted flow profiles are present, flow straighteners should be used. See “Additional Installation Requirements” on page 17

for additional information.

Installation

Page 7 June 2018 VRX-UM-00374-EN-06

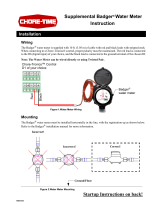

RWG/RWBG Wafer Meter Installation

The labeling of the flow direction on the meter should be aligned with the flow in the pipe. If liquids or condensate can be

present in the flow, the meter should be installed so that liquids will not accumulate on the ultrasonic transducers (the small

buttons on either side of the vortex strut).

The RWG/RWBG series wafer meters are designed to mount between two ANSI 150 lb flanges. The meter should be mounted

so its inside diameter is centered inside the pipe. See Figure 1.

OTE:N Gaskets (not provided) are necessary between the sensor and the ANSI flanges. Ensure that these gaskets are

properly installed and do not protrude into the flow stream.

The RWGxxF series flanged meters are designed to mount between two ANSI 150 lb flanges. See Figure 4 on page 8.

OTE:N Gaskets (not provided) are necessary between the ANSI flanges. Insure that these gaskets are properly installed and

do not protrude into the flow stream.

AVOID BENDING THE VORTEX STRUT OR DAMAGING THE TRANSDUCERS DURING INSTALLATION. DO NOT REMOVE

COVER PLATES WHILE UNIT IS OPERATING.

Flow Flow

CORRECT

(Meter Centered In Pipe)

INCORRECT

(Meter Not Centered In Pipe)

Figure 1: Wafer position in the piping

Flow

Flow

4.38"

+.12

C

-.00

5.75

Cable Entry

Accommodates

.19/.25 Dia Cable

3/4 -14 NPT Connector

2.25.06 .06

E Dia

Both Sides

A Dia

B Dia

.531 Dia 4 Holes

Spaced at 90° on

D Dia BC

4.50

3/4-14 NPT

Pipe Plug

Figure 2: 1/2 in., 1 in. and 1-1/2 in. meters

Model

Diameter A

in. (mm)

Diameter B

in. (mm)

Dimension C

in. (mm)

Dimension D

in. (mm)

Dimension E

in. (mm)

RWG/RWBG05 3.50 (89) 0.50 (13) 5.60 (142) 2.38 (61) 1.38 (35)

RWG/RWBG10 3.97 (101) 0.88 (22) 5.78 (147) 3.12 (79) 2.00 (51)

RWG/RWBG15 4.72 (120) 1.38 (35) 6.34 (161) 3.88 (99) 2.88 (73)

Installation

Page 8 June 2018VRX-UM-00374-EN-06

Flow

Flow

+.12

C

-.00

2.25.06 .06

4.38"

5.75

Cable Entry

Accommodates

.19/.25 Dia Cable

3/4 -14 NPT Connector

D Dia

Both Sides

A Dia

B Dia

4.50

3/4-14 NPT

Pipe Plug

Figure 3: 2 in., 3 in. and 4 in. meters

Model

Diameter A

in. (mm)

Diameter B

in. (mm)

Dimension C

in. (mm)

Dimension D

in. (mm)

RWG/RWBG20 3.97 (101) 1.75 (45) 5.92 (150) 3.15 (80)

RWG/RWBG30 5.22 (133) 2.75 (70) 6.62 (168) 4.55 (116)

RWG/RWBG40 6.87 (174) 3.75 (95) 7.52 (191) 6.19 (157)

5.75

A

SENSOR S.N.: 64

PRESSURE SENSOR:

OUTPUT: 4 - 20 mA

HEDLAND

by

4.69"

FLOW

FLOW

B

4.50

3/4-14 NPT

Pipe Plug

Figure 4: Outline dimensions for flanged series meters

Model Size

Dimension B

in. (mm)

Dimension A

in. (mm)

RWG05F15* 1/2 in. 9.88…10.00 (250…254) 5.60 (142)

RWG10F15* 1 in. 9.88…10.00 (250…254) 5.78 (147)

RWG15F15* 1-12 in. 9.88…10.00 (250…254) 6.34 (161)

RWG20F15* 2 in. 9.88…10.00 (250…254) 5.92 (150)

RWG30F15* 3 in. 11.88…12.00 (301…304) 6.62 (168)

RWG40F15* 4 in. 11.88…12.00 (301…304) 7.52 (191)

*150 lb RF ANSI Flange

Installation

Page 9 June 2018 VRX-UM-00374-EN-06

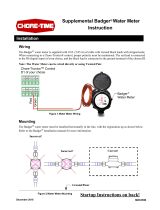

RNG Insertion Meter Installation

The RNG series insertion meters are designed to mount on a standard ANSI 150 lb, 2 in. pipe flange. If the main line can be

depressurized easily, then a simple installation consisting of a 2 in. nozzle and a 2 in. ANSI 150 Class flange may be used. This

permits the shortest shaft length which minimizes the clearance space. The measuring window should be installed in the

center of the line for line sizes 12 in. or less (see Figure 5 on page 9). For line sizes larger than 12 in., the measuring window

should be installed 25% to 50% of the way into the pipe. It is recommended that the internal dimensions of the line be

measured for accurate readings.

Insertion meters can be used in any size pipe four inches and larger in diameter. In order to calculate accurate volumetric,

mass, and standard flow measurements, it is recommended to enter the exact pipe size into the meter. Normally this

operation, along with overall meter configuration, is performed at the factory. However, the user can enter the pipe diameter

on site using the Badger Meter HART Interface or a HART 275/375/475 communicator.

OTE:N The torque requirement for the Conax fitting is 90…100 ft-lb. See Figure 5 on page 9. See “Additional Installation

Requirements” on page 17 for additional installation information and flow profiling.

5.75

4.38"

13.0" Maximum at

Maximum Insertion

C Maximum

Retracted

4.50"

Maximum

B Maximum

Insertion

4.50" Maximum

Retracted

FLOW

.75"

FLOW

4.50

3/4-14 NPT

Pipe Plug

A

Measuring

Window

Figure 5: Outline dimensions for RNG insertion meters

Model

Dimension A

in. (mm)

Dimension B

in. (mm)

Dimension C

in. (mm)

RNG12 12.00 (305) 12.88 (327) 21.50 (546)

RNG24 24.00 (609) 24.88 (632) 33.50 (851)

RNG36 36.00 (914) 36.88 (937) 45.50 (1156)

RNG48 48.00 (1218) 48.88 (1242) 57.50 (1461)

RNG60 60.00 (1524) 60.88 (1546) 69.50 (1765)

Installation

Page 10 June 2018VRX-UM-00374-EN-06

Hot Tap Insertion Flow Meter Installation

Where de-pressurizing the line for flow meter maintenance is impossible or undesirable, the “hot tap” method of installation

is used. This method involves inserting the flow meter through a 2 in. (51 mm) spool piece and a 2 in. (51 mm) full port valve

and will require a longer shaft length as well as greater clearance space for removal and installation.

DANGER

CAUTION SHOULD BE USED WHEN INSERTING OR RETRACTING AT PRESSURES EXCEEDING 60 PSIG (4.14 BARG).

Figure 6 shows a sample hot tap installation. With the exception of the spool piece, which must be a minimum of

4.5 in. (114.3 mm), all of the dimensions are suggestions only. Actual dimensions may vary depending on customer’s own hot

tap configuration.

To calculate the required insertion flow meters stem length:

• For pipe diameters less than or equal to 24 in. (609 mm): Calculate the distance from the center line of the pipe to the top

of the flow meter mounting flange.

• For pipe diameters greater than 24 in. (609 mm): Calculate the distance from the top of the flow meter flange to a point

1/4 of the pipe diameter into the pipe.

When flow profiling is required, calculate the distance from the bottom of the pipe to the top of the flow meter mounting

flange and subtract 2 in. (51 mm). Next round this distance up to the next largest 12 in. (305 mm) increment. This is the stem

length that should be ordered.

13.05" Maximum at

Maximum Insertion

FLOW

4.50" Maximum

Retracted

Standard ANSI

2 Inch 150 Lb. Flange

Determined

By Stem

Length

Determined

By Stem

Length

2" Full Port

Valve

Flow

4.50"

Maximum

Spool Piece

4.50" Minimum

5.75

Cable Entry

Accommodates

.19/.25 Dia Cable

3/4 -14 NPT Connector

4.38"

Figure 6: Hot tap configuration for RNG insertion gas meters

DANGER

USE CAUTION WHEN INSERTING OR RETRACTING AT PRESSURES EXCEEDING 60 PSIG (4.14 BARG).

Electrical Installation

Page 11 June 2018 VRX-UM-00374-EN-06

ELECTRICAL INSTALLATION

Electrical connections for the meter are made using screw terminals located inside the enclosure. To access these terminals,

remove the lid from the enclosure. The functions of these terminals are illustrated in Figure 7.

To install the cable, route it through the cable entry located on either side of the enclosure and attach the wires to the

appropriate terminals.

EMC NOTIFICATION

The ultrasonic sensing technology employes a 160 kHz carrier frequency and the flow meter is sensitive to radiated and

conducted noise at or near this frequency. Precautions must be taken not to subject the flow meter or associated cabling

to sources of RF noise that could interfere with the ultrasonic carrier. Any such interference can cause degradation in flow

meter performance.

Chassis

Ground

Cable Shield

Ground

+

4-20MA

-

EP RTN

EP PWR

EP OUT

EP IN

NC

Figure 7: Flow meter terminal functions

Terminal

Designator

Function

4-20 mA + Loop Power (+28 VDC maximum)

4-20 mA – Loop Power (–)

NC Not Used

EP RTN Pressure Sensor Power Supply Return

EP PWR Pressure Sensor Power

EP OUT Power Out to Pressure Sensor

EP IN Pressure Sensor Input

The vortex meter is available in two versions: CE or intrinsically safe for hazardous areas. A display is not available with the

intrinsically safe meter. The nameplate specifies the certifications that apply to the meter. Te electrical installation instructions

for both types of meters are the same, except the intrinsically safe meter has special consideration specified in this user

manual and in the control drawing accompanying the meter. The CE version is shown below.

Instructions Specic to Hazardous Area Installations

Page 12 June 2018VRX-UM-00374-EN-06

INSTRUCTIONS SPECIFIC TO HAZARDOUS AREA INSTALLATIONS

See the European ATEX Directive 94/9/EC, ANNEX II, 1.0.6 and the Vortex Intrinsically Safe Flow Meters Control Drawing for

RWG, RWBG and RNG Meters (shipped with the product; also available at badgermeter.com).

The following instructions apply to equipment covered by certificate number SIRA 03ATEX2543.

The certification marking is as follows:

1. The equipment may be used in zones 1 and 2 only with ammable gases and vapors with apparatus groups IIA and IIB and

with temperature classes T1, T2, T3 and T4. It is not suitable for zones where IIC gases or vapors may be present.

2. The equipment is only certied for use in ambient temperatures in the range –40° F (–40° C) to +176° F (+80° C) and should

not be used outside this range.

3. The equipment has not been assessed as a safety related device (as referred to by Directive 94/9/EC ANNEX II, Clause 1.5).

4. Installation, inspection and maintenance of this equipment shall be carried out by suitably trained personnel in

accordance with the manufacturer’s instructions and the applicable codes of practice (e.g., EN 60079-14 and EN 60079-17

in Europe).

5. Only spare parts supplied by Badger Meter may be used and installed in accordance with Badger Meter instructions.

WIRING

A two conductor foil shielded cable made of 14…22 AWG solid or stranded wire is required to make connections to the flow

meter (for example, Consolidated Wire P/N 5573-CL).

The shield is required to be attached to one of the shield ground points as illustrated in Figure 7 on page 11. The other end

of the shield should not be grounded.

When using the Zener Diode Barrier the maximum load resistance for the power depends on the supply voltage (see Figure 8

on page 14).

If a Barrier/Isolator is being installed, refer to the Barrier/Isolator manufacturers data sheet for maximum resistive loading on

the output. (Excitation voltage input to meter must be 15V DC minimum when output is at 20 mA)

The flow meter requires a minimum of 15V DC at the meter’s 4…20 mA (+) and (–) terminals to operate. With all loop loads

installed in the loop, the voltage at the meter must be at least 15V DC or the meter will operate erratically if at all. The

maximum load resistance for the meter depends on the supply voltage. The higher the supply voltage the greater the loop

load the meter will support.

The current sense resistor used in HART communications should be installed only for setup or troubleshooting as the current

sense resistor is an unnecessary loop load when the meter is operating under normal conditions.

OTE:N Current loops with large loads may work satisfactorily at low loop current outputs but cease to function as the output

current increases. The reason for this is that as the current increases the voltage drop across the sum of the loop loads

will increase in direct proportion to the current output. At some current output unique to that particular loop the

voltage drop across the sum of the loop loads will leave less than the minimum 15V DC required at the meters input

terminals.

If this occurs, the loop load must be reduced enough so that—at the maximum current output for the system—the

voltage at the meter’s power input terminals remains at least 15V DC

The external pressure sensor is limited to a 5 foot (1.5 meter) cable length.

Operation

Page 13 June 2018 VRX-UM-00374-EN-06

Various wiring configurations are shown in Figure 8 on page 14 and Figure 9 on page 15.

OPERATION

Power Terminals

The 4…20 mA terminals (+ and –) are used for the flow meter’s power supply.

Current Output

The current output is accessed through the 4…20 mA + and – terminal loop and provides an output current proportional to

the flow measured by the meter. This output is a standard 4…20 mA output, where 4 mA corresponds to no flow and

20 mA indicates 100 percent (full scale) flow. The current output will not be accurate if the load resistance on the current

output terminal is too high.

Load Table for Flow Indicator or Control System Using

Zener Diode Barrier

Power Supply Voltage 24 V 26 V

Maximum Voltage Drop 3 V 5 V

Maximum Resistances 136 Ω 225 Ω

For Loads Greater Than 225 Ω, see Optional Wiring Diagram

Figure D - Load TABLE

Table 4: Load table

Barriers and Barrier Isolator Examples

Stahl 9001/01-280-100-101 Zener Barrier

Turck MK33-221-Ex0-HL/24V DC (2 Channel)

Turck MK33-111-Ex-HLi/24V DC (1 Channel)

Table 5: Barriers and isolator examples

HART Communication

The vortex meter has the capability of HART Communication. However, it is not required that it be used. In most cases, the

meter is configured at the factory per the customer’s specifications. The user need only install the meter and connect power.

If HART Communication is desired a current sense resistor must be placed in series within the current loop.

The value of the resistor can range from 170…600 Ω and be rated at 0.25 watt or larger. The placement of the resistor is

illustrated in the wiring diagrams. The resistor will add to the total loop resistance and will raise the value of the required

power supply voltage if it remains in the loop.

There are two ways to communicate to the meter via the HART interface: the Badger Meter HART Interface or a

HART Communicator. The Badger Meter HART Interface is a PC-based software program that runs on Windows® 98,

Windows NT, Windows ME, Windows XP, Windows Vista® and Windows 7 operating systems.

The HART 275/375/475 Communicator is a handheld device that can communicate with any HART device that is registered

with the HART Communication Foundation. The HART 275/375/475 Communicator also provides access to all settings that

can be configured by the user. The 275 provides a menu driven interface. See Figure 10 on page 16 to view the menu map

for the HART 275 Communicator.

OTE:N HART 275 Communicator requires Badger Meter drivers for proper communications. (See communicator owner’s

manual for driver listing).

Wiring Diagrams

Page 14 June 2018VRX-UM-00374-EN-06

WIRING DIAGRAMS

The wiring diagrams illustrated below are for installations where no 4…20 mA pressure sensor is used.

Optional wiring diagram for loads > 225Ω

Figure 8: Without 4…20 mA output pressure transducer

Wiring Diagrams

Page 15 June 2018 VRX-UM-00374-EN-06

If an analog pressure gauge is used, it must be wired as shown below to avoid inadvertent current paths.

A single supply can be used to power the flow meter and the external pressure sensor. The 4…20 mA flow indication must be

taken from the source side of the loop.

Optional wiring diagram for loads > 225Ω

Figure 9: With 4…20 mA output pressure transducer

Wiring Diagrams

Page 16 June 2018VRX-UM-00374-EN-06

DEVICE SETUP

PV

AO

LRV

URV

Edit Mode

On / Off

Enable / Disable

Edit Mode

1

2

3

4

5

6

7

PROCESS

VARIABLES

1 VIEW FIELD

DEVICE

VARIABLES

1

TOTALIZER

CONTROL

2

TEST / STATUS

LOOP TEST

REVISION

NUMBERS

Flow

Profiling

(Method)

VOLTAGE

LEVELS

PRODUCT

INFORMATION

DEBUG

INFORMATION

1

2

3

4

5

6

7

DIAGNOSTICS

AND SERVICE

2

BASIC SETUP3 Tag

PV TYPE

& UNIT

1

2

RANGE VALUE3

STANDARD

CONDITIONS

PV Damping

Pipe ID

4

5

6

DETAILED

SETUP

4

REVIEW5

FLUID

PROPERTIES

Alarm Selection

Low Flow Cutoff

5

6

7

TEMPERATURE

SETUP

1

PRESSURE

SETUP

2

CONFIGURE

OUTPUTS

3

DEVICE INFO4

PASSWORD

PROTECTION

8

Process Variable

Analog Output

Percent of Range

Vortex Frequency

Process Temperature

Precess Pressure

1

2

3

4

5

6

PRESSURE SOURCE

Pressure Unit

User Specified Pressure Value

Pressure LRV

Pressure URV

Atmospheric Pressure

1

2

3

4

5

6

Manufacturer

Descriptor

Message

Date

Device ID

Write Protect

1

2

3

4

5

6

Total

Start / Stop

Reset

1

2

3

TEMPERATURE SOURCE

Temperature Unit

User Specified Temperatur Value

1

2

3

Protection On / Off

Enable / Disable Protection

Forgot Password?

1

2

3

PULSE OUTPUT

HART OUTPUT

LOCAL DISPLAY

1

2

3

View Status

Self Test

1

2

Fixed Current

D/A Trim

1

2

AGC Voltage

APP Voltage

ADC Voltage

UPP Voltage

1

2

3

4

PV Type

SELECT PV TYPE

PV Unit

SELECT PV UNIT

1

2

3

4

Base Temperature

Base Pressure

1

2

Process Density

Process Viscosity

Standard Density

PROPERTY SOURCE

User Specified Density Value

User Specified Viscosity Value

Property Table Name

Property Table Version Number

1

2

3

4

5

6

7

8

URV

LRV

Min Span

USL

LSL

1

2

3

4

5

Select from a

dynamic list

of units

Process Variable

Analog Output

Totalizer

Process Temperature

Process Pressure

Alternating PV & Totalizer

1

2

3

4

5

6

PULSE MODE

User Specified Frequency

Frequency URV

1

2

3

Property Table

User Specified Properties

Steam Table

1

2

3

Integrated RTD

External RTD

User Specified Temperature

Steam Table

1

2

3

4

Analog Input - Absolute

Analog Input - Gauge

User Specified Pressure

Steam Table

1

2

3

4

Polling Address

Number of Preambles

Burst Mode

Burst Command

1

2

3

4

MASS FLOW

VOLUME FLOW

STANDARD FLOW

PROCESS TEMPERATURE

PROCESS PRESSURE

Vortex Frequnecy

1

2

3

4

5

6

Universal Cmd Revision

Specific Cmd Revision

PV Unit

Select PV Unit

1

2

3

4

Model Number

Part Number

Meter Style

Sensor Option

Display Option

Model Deviation

Modification Date

Strut Size

Calibration Date

1

2

3

4

5

6

7

8

9

MPPS

Rynolds

Strouhal

WDRS

MTE

MPE

FCE

LXP

FCF

DCF

CSP

CFV

CSC

1

2

3

4

5

6

7

8

9

10

11

12

13

UDC Voltage

VCC Voltage

Loop Voltage

5

6

7

Scaled PV

Fixed Frequency

Vortex Frequency

Off

1

2

3

4

Figure 10: HART communicator menu tree v4.0

Troubleshooting

Page 17 June 2018 VRX-UM-00374-EN-06

TROUBLESHOOTING

Badger Meter Vortex flow meters are designed to ensure long term accuracy and reliability. The stainless steel body and self-

cleaning strut are specifically designed to withstand the rigors of industrial environments. As a result, periodic adjustment or

re-calibration is not normally required. Technical assistance is also available directly from Badger Meter, providing complete

re-calibration and repair service for the flow meter at a reasonable cost.

Preliminary Checks

DANGER

DO NOT OPEN ENCLOSURE IN HAZARDOUS AREAS WITH POWER APPLIED.

• Is the flow meter cable installed correctly?

• Is the proper power supplied to the proper terminals?

• Is the flow meter wired for 2 wire 4…20 mA operation.

• Is the shield tied to the shield ground terminal and only the shield ground terminal?

ADDITIONAL INSTALLATION REQUIREMENTS

Introduction

Installing a flow meter is something which requires careful consideration. It cannot just be placed in a line somewhere and

be expected to fulfill its purpose adequately. The geometry and condition of the pipe runs in the area of the installation must

be considered to ensure the best and most accurate operation of the flow-meter. This appendix provides suggestions for

optimum installations.

Most flow meter manufacturers define installation conditions in terms of upstream and downstream straight pipe lengths

from the point of installation. Unfortunately this is not the only requirement, and one needs to consider other peripheral

conditions, such as proximity and style of bends, and other equipment installed in the line. By doing this, you avoid problems

of turbulence, swirl, and sonic noise.

Turbulence

Turbulence is a disturbance of the flow caused by bends and obstructions in the flow stream (it is this phenomena which

makes the vortex flow meter work). Fortunately turbulence dies out fairly quickly, so by positioning the flow meter well away

from bends and obstructions this potential problem of measuring flow in turbulent conditions is overcome (see Figure 12).

Swirl

Unlike turbulence, swirl will not die away. Once created it will continue until dissipated on the next pipe bend in the system.

Swirl occurs after two bends, in close proximity, which are at an angle to each other. When designing an installation, keep the

flow meter out of any line which has two adjacent bends upstream (see Figure 13).

Sonic Noise

Sonic noise is created by valves (either flow control or pressure control valves) which are slightly open. Like swirl, sonic noise

will only dissipate on a bend so it is important to install flow meters out of the line of sight of valves. Sonic noise is caused by

liquid attaining sonic velocities through a slightly open valve that has a pressure difference across it. This noise travels both

up and down stream from the valve so you have to ensure that the flow meter is installed well away from the valve, preferably

around a bend (see Figure 14).

Velocity Prole

When using an RNG series insertion flow meter, it is necessary to consider the effects of the velocity profile across the pipe or

duct to optimize accuracy.

Additional Installation Requirements

Page 18 June 2018VRX-UM-00374-EN-06

In large pipes, the flow moves slowly at the pipe walls but is at maximum velocity in the center of the pipe creating a

continuously variable velocity across the pipe (see Figure 11). This velocity variation is called the velocity profile of the pipe,

and can be measured and plotted by using the insertion flow meter to measure velocities at various noted positions across

the pipe. As the maximum velocity is in the center of the pipe, it follows that if the flow meter is positioned in the center, it will

not measure average flow. The rule-of-thumb position is 25% of the way into the pipe, but the optimum position can only be

obtained by measuring the profile and working out the correct position from that.

Flow

1⁄8

¼

½

Figure 11: Typical velocity profile

Figure 12: Turbulence caused by bend or obstruction

Figure 13: Swirl caused by two bends in different planes and in close proximity to one another

Figure 14: Upstream/downstream sonic noise caused by slightly opened control valves

Additional Installation Requirements

Page 19 June 2018 VRX-UM-00374-EN-06

Flow Proling

If the flow meter is long enough to be inserted to the far side of the pipe, the flow through the pipe may be profiled at various

flow rates. The goal is to find a point in the pipe that remains a consistent percentage of the average flow rate over a wide

range of flow. A sample flow profile is shown in Table 6. In this example, the flow rate of a 48 in. pipe is measured every six

inches across the diameter of the pipe beginning and ending 3 in. from the near and far sides of the pipe. The distance in

inches from the nearside of the pipe is shown. Measurements are taken at a low, medium and high average flow. In Table 7,

the flow rate at each measurement point has been converted to a percentage of the average flow. It can be seen that point

number three (15 in. from the near side of the pipe) reads a consistent 102 percent of the average flow. The meter should be

placed in this position and the output should be divided by 1.02 to obtain the correct reading. Flow profiling will generally

improve measurement quality in insertion meter installations.

Flow

Flow Rate at Measurement Point (FPS)

1 2 3 4 5 6 7 8 Average (FPS)

Low Flow 1.90 2.00 2.04 2.06 2.06 2.04 2.00 1.90 2.0

Medium Flow 5.58 5.91 6.12 6.21 6.24 6.18 6.06 5.70 6.0

High Flow 10.92 11.70 12.24 12.48 12.60 12.48 12.18 11.40 12.0

Distance (in) 3 9 15 21 27 33 39 45

Table 6: Flow profile raw data

Flow

Flow Rate at Measurement Point (%)

1 2 3 4 5 6 7 8

Low Flow 95.0 100.0 102.0 103.0 103.0 102.0 100.0 95.0

Medium Flow 93.0 98.5 102.0 103.5 104.0 103.0 101.0 95.0

High Flow 91.0 97.5 102.0 104.0 105.0 104.0 101.5 95.0

Table 7: Flow profile normalized data

Reducing the Pipe Diameter

To decrease the variation of flow profile, the piping can be narrowed at the flow meter as shown in Figure 15. This will smooth

the flow and increase the effectiveness of flow profiling. Nearly any angle can be used on the down-stream side of the meter

to restore the original pipe diameter. However, if the angle of piping is seven degrees or less, nearly all the pressure drop

caused by the narrow pipe section will be recovered.

Figure 15: RNG insertion gas meter installed in a reduced pipe

Vortex Flow Meters, RWG/RWBG Wafer Style Flow Meters & RNG Insertion Style Flow Meters

www.badgermeter.com

Trademarks appearing in this document are the property of their respective entities. Due to continuous research, product improvements and enhancements, Badger Meter reserves

the right to change product or system specications without notice, except to the extent an outstanding contractual obligation exists. © 2018 Badger Meter, Inc. All rights reserved.

Control. Manage. Optimize.

The Americas | Badger Meter | 4545 West Brown Deer Rd | PO Box 245036 | Milwaukee, WI 53224-9536 | 800-876-3837 | 414-355-0400

México | Badger Meter de las Americas, S.A. de C.V. | Pedro Luis Ogazón N°32 | Esq. Angelina N°24 | Colonia Guadalupe Inn | CP 01050 | México, DF | México | +52-55-5662-0882

Europe, Eastern Europe Branch Oce (for Poland, Latvia, Lithuania, Estonia, Ukraine, Belarus) | Badger Meter Europe | ul. Korfantego 6 | 44-193 Knurów | Poland | +48-32-236-8787

Europe, Middle East and Africa | Badger Meter Europa GmbH | Nurtinger Str 76 | 72639 Neuen | Germany | +49-7025-9208-0

Europe, Middle East Branch Oce | Badger Meter Europe | PO Box 341442 | Dubai Silicon Oasis, Head Quarter Building, Wing C, Oce #C209 | Dubai / UAE | +971-4-371 2503

Slovakia | Badger Meter Slovakia s.r.o. | Racianska 109/B | 831 02 Bratislava, Slovakia | +421-2-44 63 83 01

Asia Pacic | Badger Meter | 80 Marine Parade Rd | 21-06 Parkway Parade | Singapore 449269 | +65-63464836

China | Badger Meter | 7-1202 | 99 Hangzhong Road | Minhang District | Shanghai | China 201101 | +86-21-5763 5412

Switzerland | Badger Meter Swiss AG | Mittelholzerstrasse 8 | 3006 Bern | Switzerland | +41-31-932 01 11 Legacy Document Number:RV-1001-R8, 09-VRX-UM-00357-EN

/