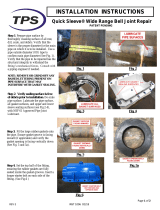

Romac Industries 217-1275 is a Bell Joint Leak Clamp designed to repair leaks in 10" & 12" Class 200 pipes. It features a special gasket that interlocks to create a tight seal, ensuring leak-free performance. The clamp is easy to install, requiring only simple hand tools and no special skills.

Key Features

- Repairs leaks in 10" & 12" Class 200 pipes

- Puzzle-joint gasket ensures a tight, leak-free seal

- Easy to install with hand tools

Use Cases

- Repairing leaks in water pipes

- Maintaining water distribution systems

- Preventing costly water damage

Romac Industries 217-1275 is a Bell Joint Leak Clamp designed to repair leaks in 10" & 12" Class 200 pipes. It features a special gasket that interlocks to create a tight seal, ensuring leak-free performance. The clamp is easy to install, requiring only simple hand tools and no special skills.

Key Features

- Repairs leaks in 10" & 12" Class 200 pipes

- Puzzle-joint gasket ensures a tight, leak-free seal

- Easy to install with hand tools

Use Cases

- Repairing leaks in water pipes

- Maintaining water distribution systems

- Preventing costly water damage

-

1

1

-

2

2

Romac Industries 217-1275 Installation guide

- Type

- Installation guide

Romac Industries 217-1275 is a Bell Joint Leak Clamp designed to repair leaks in 10" & 12" Class 200 pipes. It features a special gasket that interlocks to create a tight seal, ensuring leak-free performance. The clamp is easy to install, requiring only simple hand tools and no special skills.

Key Features

- Repairs leaks in 10" & 12" Class 200 pipes

- Puzzle-joint gasket ensures a tight, leak-free seal

- Easy to install with hand tools

Use Cases

- Repairing leaks in water pipes

- Maintaining water distribution systems

- Preventing costly water damage

Ask a question and I''ll find the answer in the document

Finding information in a document is now easier with AI

Related papers

-

Romac Industries 230-048000 Installation guide

-

Romac Industries 242-0663 Installation guide

-

Romac Industries 228-069011 Installation guide

-

Romac Industries 211-023802385 Installation guide

-

Romac Industries 202-0875067610 Installation guide

-

Romac Industries 201-09400940511 Installation guide

-

Romac Industries 207-09750930700 Installation guide

-

Romac Industries 320-11470411 Installation guide

-

Romac Industries 232-06135010D Installation guide

-

Romac Industries 243-1110 Installation guide

Other documents

-

Powerseal Pipeline Products 3232080000HA Installation guide

Powerseal Pipeline Products 3232080000HA Installation guide

-

Ford Meter Box FS1-1350-125-CC4 Installation guide

-

Charlotte Pipe PVC024020800HD User manual

-

Charlotte Pipe PVC 00304 1200 User manual

-

TRENCH TOUGH PLUS 043222 Installation guide

-

Total Piping Solutions QCRS120742001EX Installation guide

Total Piping Solutions QCRS120742001EX Installation guide

-

Smith Blair Inc 27400000380000 Installation guide

-

American Cast Iron Pipe 4006538 Installation guide

American Cast Iron Pipe 4006538 Installation guide

-

Multi-Fittings Corporation 040206 Installation guide

-

Aurora Vertical Turbine Owner's manual