Page is loading ...

USER

MANUAL

MODEL NUMBER:

FI-10N-SM

FI-10NK-SM

FI-10NV-SM

AND RELATED UNITS

10 Gallon Smart Foam Unit

English (Original Instrucons)

Page 2 of 9 | 09152015

User Manual: 10 Gallon Smart Foam Unit | English

READ ALL INSTRUCTIONS BEFORE OPERATING EQUIPMENT

Model No.: FI-10N-SM, FI-10NK-SM, FI-10NV-SM AND RELATED UNITS

Read this manual completely and understand the

machine before operang or servicing it.

• Readallinstruconsbeforeinstallingoroperangunit.

• Alwayswearappropriatepersonalprotecveequipment

(PPE)whenoperangorservicingunit.

• Alwaysfollowallchemicalsafetyprecauonsand

handlinginstruconsprovidedbythechemical

manufacturerandSafetyDataSheet(SDS).

• Ifthisunitismodiedorservicedwithpartsnotlistedin

thismanual,theunitmaynotoperatecorrectly.

• Neverpointthedischargewandatyourself,another

person,oranyobjectyoudonotwantcoveredin

chemical.

• Alwayskeeptheairtriggerportcleanandfreeof

blockagesordebris.Iftheportbecomesdirtyor

blocked,disconnectthecompressedairsourcefrom

theunitimmediatelyandcleanouttheportbefore

proceeding.

• Alwayskeepthedischargehosefreeofkinksor

obstrucons.

• Alwaysrinseanddrainunitaeruse(asdescribedinthe

AerUseInstrucons).Alwaysstoreunitdisconnected

fromthecompressedairsource.

• Donotexceedanincomingairpressureof100psi(7

bar).

• Donotexceedauidtemperatureof100˚F(37˚C).

• Alwaysushtheunitwithfreshwaterfor5minutes

whenswitchingfromanalkalinetoanacidoranacidto

analkaline.

• Onlyusecleananddryair.Airmustbelteredandfree

ofmoistureorpumplifewillbediminished.Ifneeded,

installawaterseparator(WS-20CFM)beforetheunit.

• Donotuseanairlubricatorbeforetheunit.

WARNING

PROTECT THE ENVIRONMENT

Pleasedisposeofpackagingmaterials,oldmachine

components,andhazardousuidsinanenvironmentallysafe

wayaccordingtolocalwastedisposalregulaons.

Alwaysremembertorecycle.

*Specicaonsandpartsaresubjecttochangewithoutnoce.

OPTIONS

Pump Seal Material

FI-10N

Santoprene(standard)

-SM

Viton (V)

Kalrez(K)

Addboldoponcodestoitemnumberasshown.Forstandard

opons,nooponcodeisneeded.

Examples:

• FI-10N-SM(standardunitwithSantoprenepumpseals)

• FI-10NV-SM(unitwithVitonpumpseals)

Page3of9|09152015

User Manual: 10 Gallon Smart Foam Unit | English

READ ALL INSTRUCTIONS BEFORE OPERATING EQUIPMENT

Model No.: FI-10N-SM, FI-10NK-SM, FI-10NV-SM AND RELATED UNITS

REQUIREMENTS

Compressedairrequirements 40-80psi(3-5bar)with5-10cfm(141-283l/min)

Liquidtemperaturerange 40-100˚F(4.4-37˚C)

Chemicalcompability Chemicalproductsusedwiththisequipmentmustbeformulatedforthistypeof

applicaonandcompablewithunitmaterialsandpumpseals.Formoreinformaon

onchemicalcompability,consultthemanufacturerorSDSforyourproductor

contactourcustomerservicedepartment.

SPECIFICATIONS

Powertype Compressedair

Chemicalpickuptype Drawsfrompre-mixedsoluon

Numberofproductsunitcandrawfrom Oneproduct

Capacity 12.5gallons(47.3liters)

Dischargehosediameter/length 20.(9.1m)bondedhose,with5/8in.(15.9mm)and1/4in.(6.4mm)inside

diameter

Dischargewand/ptype Ultrahighmolecularweight(UHMW)polyethylenehandleandwandextension,with

65fanpandbuilt-inzerop

Outputdistance Withzerop:17-21.(5.2m–6.4m)

Withfanp(ST65150):16-20.(4.9m–6.1m)

Outputvolume Withzerop:20-32gal/min(75-121l/min)offoam

Withfanp(ST65150):20-32gal/min(75-121l/min)offoam

Flowrate* 2gal/min(7.6l/min)

Pumpseals Santoprene,Viton,orKalrez

Wheeltype Two10inchnon-markingwheels

*Diluonratesandowratesgivenarebasedonchemicalwithviscosityofwaterandfactoryairpressuresengs.

Page 4 of 9 | 09152015

User Manual: 10 Gallon Smart Foam Unit | English

READ ALL INSTRUCTIONS BEFORE OPERATING EQUIPMENT

Model No.: FI-10N-SM, FI-10NK-SM, FI-10NV-SM AND RELATED UNITS

Operaon Instrucons:

1. Verifythatthedrainplug(DP-A)issecurelyclosed.

2. Followallinstruconsfromthechemicalmanufacturer.

Fillthetankwithwaterandtheadvisedpercentageof

chemicalconcentrate.

3. Verifythatthevalve(PVCV34FM)atthebaseofthe

suconlineisopen,toallowuidintothesuconline.

4. Verifythattheairtriggerportiscleanandfreeof

blockagesordebris,andthedischargehoseisnotkinked

orobstructed.

5. Withthewandpointedinasafedirecon,connectanair

linetotheairinletng(AP25).

Note: When you connect the air line, listen for any sound

from the unit. If you hear the pump acvate and begin to

cycle, disconnect the air line immediately. This indicates

that there is a blockage or other problem somewhere

in the system, which could cause the unit to acvate

spontaneously. The problem must be addressed before

proceeding (see “Troubleshoong Instrucons”).

6. Placethumbovertheairtriggertoacvatetheunitand

beginfoaming.

7. Whiletheunitisrunninganddischargingproduct,adjust

theneedlevalve(NV14Y)asneededtoregulatethe

wetnessordrynessofthefoamfollowingthestepsbelow:

a. Closeneedlevalvecompletelyinclockwisedirecon.

b. Openneedlevalveincounter-clockwisedirecon2

completeturns.

c. Connuetoopenneedlevalvein¼turnincrements,

allowing30secondsbetweenadjustments,unl

desiredconsistencyoffoamisachieved.

8. Releasetheairtriggertostopfoaming.

Note:Whenyoureleasetheairtrigger,theunitwillshut

oanddepressurize.Foamthatisalreadyinthedischarge

hosemayseepout,butnomorefoamwillbecreated

unlyoucovertheairtriggeragain.

Aer Use Instrucons:

1. Openthedrainplug(DP-A)anddraintheunittank.

2. Rinsetheunittankthoroughlywithfreshwater.Then

replacethedrainplugandllthetankwithfreshwater.

3. Acvatetheunitandallowittorunfor2-4minutes,or

unlallchemicalhasbeenushedfromthesystem.

4. Openthedrainplug(DP-A)anddrainanywaterremaining

intheunittank.Thenreplaceandsecurethedrainplug.

5. Disconnecttheairlinefromtheairng(AP25).

6. Allowanyliquidremaininginthedischargehosetodrain

outthroughthedischargewandbeforestoringtheunit.

Maintenance Instrucons:

Tokeepyourunitoperangproperly,periodicallyperformthe

followingmaintenanceprocedures:

Note:Beforeperforminganymaintenance,ensurethatthe

unithasbeendisconnectedfromtheairsupplyaccordingtothe

“AerUseInstrucons.”Alsoensurethattheunittankisempty,

and/orclosethevalve(PVCV34FM)atthebaseofthesucon

linetoshutotheowofliquidfromthetank.Reopenthe

valveaermaintenanceiscomplete.

• Inspecttheairpump(P56/P56K/P56V)forwearandleaks.

• Inspectallhosesforleaksorexcessivewear.Make

sureallhoseclampsareingoodcondionandproperly

secured.

• Checktheairtriggerportonthehandlefordebrisand

cleanasneeded.Whencleaning,becarefulnottopush

debrisintotheport,asitmaybecomelodgedinsideand

createablockage.

• Cleanandreplacethelter(AFR25)locatedwithin

theairregulator(R25)asneeded.Accessthelterby

unthreadingtheairregulatorbowl(ABR25)fromtheair

regulator(R25).

• Checkthesuconlineandstrainer(STR38-IL)fordebrisor

blockages,andcleanasneeded.

• Drainyouraircompressortankonaregularbasistohelp

extendpumplife.Anairsourcewithahighmoisture

contentwillacceleratepumpwear.Note:Ifyourair

sourcehasahighmoisturecontent,youmaywishto

installawaterseparator(WS-20CFM)beforetheunit.

Page 5 of 9 | 09152015

User Manual: 10 Gallon Smart Foam Unit | English

READ ALL INSTRUCTIONS BEFORE OPERATING EQUIPMENT

Model No.: FI-10N-SM, FI-10NK-SM, FI-10NV-SM AND RELATED UNITS

Troubleshoong Instrucons:

• Checktoensurethatthedischargehoseisuncoiled

properly,andthattherearenokinksthatcouldobstruct

uidow.

• Checkthesuconlineandstrainerfordebrisordamage.

Cleanorreplaceasneeded.Topreventdamagetothe

unit,thestrainer(STR38-IL)mustalwaysbeused.

• Ifthepumpiscyclingbutwillnotpullproduct,andthe

suconlineisclear,makesurethevalve(PVCV34FM)at

thebaseofthesuconlineisopen.

• Checktheairregulatorbowl(ABR25)andairlter(AFR25)

fordebrissuchaswater,oil,orrustparcles.Cleanby

unthreadingtheairregulatorbowl(ABR25)fromtheair

regulator(R25).

• Iftheneedlevalve(NV14Y)isopentoofar,thepump

(P56/P56K/P56V)maycycleimproperlyduetolackofair

pressure.Ifthisoccurs,closeandreadjusttheneedle

valve(NV14Y)asdescribedintheOperaonInstrucons.

• Makesureproperfoamingchemicalandconcentraon

arebeingused.

• Ifairpassesthroughthepump(P56/P56K/P56V)without

cycling,thepumpneedstobereplaced.

• Ifsoluonbacksupintotheairregulatorbowl(ABR25),

thecheckvalve(CV38)needstobereplaced.

• Iffoamcomesoutwet,nomaerwheretheneedlevalve

(NV14Y)isposioned,thecheckvalve(CV38)mayneedto

bereplaced.

• Checkforproperairpressureontheairgauge(AG100).

Theairregulator(R25)isfactorysetat50psi(3.4bar).

Operangrangeis40to80psi(3to5bar)with5to10

CFM(141.6to283.3l/min).

• Iftheunitoperatesatareducedpressure:

1. Checktheaircompressorsupplyingtheunit.Ifthe

pressureislessthan40psi,turntheunitounlthe

compressorcancatchup.

2. Iftheairsupplyis50psi(3.4bar)orabove,check

theairgauge(AG100),whichshouldreadnear50psi

(3.4bar).Iftheairgaugereadsmoreorlessthan50

psi(3.4bar),adjustthepressurebyturningtheknob

onthetopoftheairregulator(R25).

3. Iftheproblempersists,thestainlesssteelmixing

mesh(SS-MESH)insidetheteeng(SST12HB38)

couldbeplugged.Removeandcleanthemesh

followingtheinstruconsbelow:

a. Ensurethattheunithasbeenushedand

disconnectedfromtheairsupplyaccordingto

the“AerUseInstrucons.”Alsoensurethat

theunittankisempty,and/orthatthevalve

(PVCV34FM)atthebaseofthesuconlineis

closed.

b. Removethestainlesshosebarb(HBSS1258)

fromtheteeng(SST12HB38).

c. Thestainlesssteelmixingmesh(SS-MESH)

islocatedinsidetheteeng(SST12HB38).

Removetheoldmeshandthescreenthat

holdsitinplace.Ifthemeshandscreenare

ingoodcondion,theycanbecleanedand

re-used.Ifnot,theyshouldbereplacedwith

newparts.

d. Insertthenewmesh(SS-MESH).

e. Insertthenewscreen(SSST).Makesureitis

seatedsecurely,butnotbentordeformed.

f. Reconnectthehosebarb(HBSS1258)tothe

teeng(SST12HB38).Aachthe5/8inch

hosetothehosebarb(HBSS1258)andsecure

itwiththescrewbandclamp(SSC58).

g. Ifyoufoundalotofparclesorblockages

insidethemesh,checkthesuconline

strainer(STR38-IL)tomakesureitisinplace

andoperangcorrectly.

• Iftheunitacvateswhentheairtriggerportisnot

covered:

1. Verifythattheairtriggerportiscleanandfreeof

blockagesordebris,andthedischargehoseisnot

kinkedorobstructed.

2. Iftheproblempersists,trybypassingtheairtrigger.

Todothis,disconnectthe1/4inchhosefrom

thewand.Pointthewandinasafedireconand

connectanairlinetotheunit.Then,useyourthumb

orngertosealtheopenportofthe1/4inchhose

atthewand.

a. Iftheunitacvateswhenyouconnecttheair

line,thevalveblock(SM-PV)mayneedtobe

replaced.

b. Iftheunitdoesnotacvatewhenyou

connecttheairline,thehoseorwand

assemblymayneedtobereplaced.

• Iftheunitdoesnotacvatewhentheairtriggerportis

covered:

1. Conrmtheincomingairsupplyisconsistently50psi

(3.4bar)ontheairguage(AG100).

2. Iftheproblempersists,thevalveblock(SM-PV)may

needtobereplaced.

Page6of9|09152015

User Manual: 10 Gallon Smart Foam Unit | English

READ ALL INSTRUCTIONS BEFORE OPERATING EQUIPMENT

Model No.: FI-10N-SM, FI-10NK-SM, FI-10NV-SM AND RELATED UNITS

SSP12

SSAXLE14

AS1-VS

W15

FWAX15

PVCV34FM

COT

TANK-10N

DFP7

DP-A

TANK ASSEMBLY

ITEM NUMBER: TANK-10N-A

SSC58

SSC14

HBSS1258

HBSS1814

SMH

Air Trigger Port

PW1238

ST65150

WAND ASSEMBLY

ITEM NUMBER: SMWA

DISCHARGE HOSE ASSEMBLY

ITEM NUMBER: H5814-20

Page7of9|09152015

User Manual: 10 Gallon Smart Foam Unit | English

READ ALL INSTRUCTIONS BEFORE OPERATING EQUIPMENT

Model No.: FI-10N-SM, FI-10NK-SM, FI-10NV-SM AND RELATED UNITS

H38B-H

SST12HB38

SSC38

P56, P56K, or P56V

P56-BRKT

P56-BRKT-SCREW

NV14Y

AG100

R25

BPS-58SO

BPS-SSR

SN1414

HBSSEL1438

P18

HBSSEL1438

H14B-H

CV38

(Available per .)

(Available per .)

HBBEL1414

HBSSEL1438

SM-PV

EC14-2

HBSS1438

BACK PLATE

ITEM NUMBER: PA-PF-SM

HBSS1414

HBSS1258

FWP12

FWLG14

SSA14

TW916

BPS-58S0

AP25

NV14Y

BACK PLATE

Outside View

Page8of9|09152015

User Manual: 10 Gallon Smart Foam Unit | English

READ ALL INSTRUCTIONS BEFORE OPERATING EQUIPMENT

Model No.: FI-10N-SM, FI-10NK-SM, FI-10NV-SM AND RELATED UNITS

HHPB3414

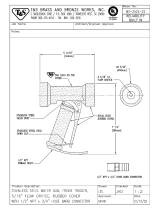

STR38-IL

HBSSEL1438

SSC38

BPS-58SO

PVCV34FM

BPS-58SO

SUCTION LINE

SC1212

HBSS1258

EC58

HBSS1258

EC58

H58-6

ITEM NUMBER

EC58 OETIKERCLAMP0.625ID

H58-6 6FT.OF5/8INCHBLUEHOSE

HBSS1258 STAINLESSSTEELHOSEBARB1/2MPTBY5/8INCHBARB

SC1212 S.S.COUPLER1/2inBY1/2in

InstallaonInstrucons

1.Removewand(PW1238)fromhandle(SMH)

2.ThreadHBSS1258fromhoseaachmentintohandle(SMH)

3.Threadwand(PW1238)ontocoupler(SC1212)attheendof

hoseaachment.

OPTIONAL HOSE ATTACHMENT (INCLUDED)

ITEM NUMBER: SM-EA

Page 9 of 9 | 09152015

User Manual: 10 Gallon Smart Foam Unit | English

READ ALL INSTRUCTIONS BEFORE OPERATING EQUIPMENT

Model No.: FI-10N-SM, FI-10NK-SM, FI-10NV-SM AND RELATED UNITS

ITEM NUMBER DESCRIPTION

AG100 1.5INCHDRYMODEL20DUALSCALEGAUGE

AP25 PLUG1/4NPTMAIRFITTING-BRASS

AS1-VS 1/4-20X1/2PHILTRUSSMACHSCREW19-8W/516

ORANGEVIBRASEALPATCH

B8X58 8-15x1/2FLATPHILTY-A18-8PLN

BPS-58SO BackPanelScrew-5/8inchwithStandO

BPS-SSR 1/4INCHPUSHNUTBOLTRETAINERSTAINLESSSTEEL

BX-10N 18-1/2x16x42GluedInsideJointECT48

COT 1/8X1COTTERPIN18-8S/S

CV38 PVCCHECKVALVE3/8BARBS-SSSPRING

DFP7 7INCHHINGEDCAPASSEMBLY-INCLUDESBLACKCAP,

LIDFLANGEANDHINGEPIN

DFP7-C 7INCHFILLCAPPOLYETHYLENEBLACK

DFP7-F 7INCHTANKLIDFLANGEPOLYETHYLENE

DFP7-PIN HINGEPINFORDFP7-C&DFP7-C

DFP7-C-BL 7INCHFILLCAPPOLYETHYLENEBLUEPANTONE

DFP7-C-GN 7INCHFILLCAPPOLYPROGREENPANTONE

DFP7-C-RD 7INCHFILLCAPPOLYPROREDPANTONE

DFP7-C-YL 7INCHFILLCAPPOLYPROYELLOWPANTONE

DP-A DRAINPLUGASSEMBLYFORNATURALPORTABLE

UNITS

DP FRONTDRAINPLUGFORPORTABLEUNIT

POLYETHYLENE

DP-G FKMLATHECUT60DUROMETERFKM

EC14-2 OETIKERCLAMP13.8

EC58 OETIKERCLAMP0.625ID

FWAX15 FLATAXLEWASHER

FWP12 7/8IDX1.5ODX0.05THKSSFW

FWP14 C-8161/2inSSWASHER

H14B-H 1/4INCHBLUEHOSE-Availableper.

H38B-H 3/8INCHBLUEHOSE-Availableper.

H5814 BONDEDHOSE5/8inID-1/4inID

H58-6 6FT.OF5/8INCHBLUEHOSE

HBBEL1414 1/4MPTX1/4HOSEBARBBRASS90DEG

HBSS1258 STAINLESSSTEELHOSEBARB1/2MPTBY5/8INCH

BARB

HBSS1414 HOSEBARBSTAINLESSSTEEL1/4MPTX1/4BARB

HBSS1438 STAINLESSHOSEBARB1/4MPTX3/8BARB

HBSS1814 1/8MPTX1/4STAINLESSHOSEBARB

HBSSEL1438 STAINLESSHOSEBARBELBOW1/4INCHNPTX3/8

HOSEBARB

HHPB3414 HEXHEADPOLYREDUCERBUSHING3/4X1/4

NV14Y FLOWCONTROLVALVE-INCLUDESBLACKKNOB

NV14Y-HNDL BLACKKNOBFORNEEDLEVALVE-2839-1/4

P18 PLUG1/8MPTHEXHEAD304SS

P56 PUMPWITHSANTOPRENESEALS-INCLUDESHOSE

BARBS,AIRFITTING,ANDEXHAUSTBARB

P56K PUMPWITHKALREZSEALS-INCLUDESHOSEBARBS,

AIRFITTING,ANDEXHAUSTBARB

P56V PUMPWITHVITONSEALS-INCLUDESHOSEBARBS,

AIRFITTING,ANDEXHAUSTBARB

20756103B PolyproG57AirPortxHBStraight,w/Vitono-ring

HB14P 1/4inBRASSHBAIRFITTING/G57/P56

HB5638 HOSEBARBFORP56PUMP

HB5638K HOSEBARBFORP56KPUMP

HB5638V HOSEBARBFORP56VPUMP

P56-BRKT PUMPBRACKET-STAINLESSSTEEL

P56-BRKT-SCREW HILOSCREWFORRETAININGP56-BRKT

PLPF PORTABLEFOAMERBACKPLATEW/HINGEANDHOLES

PLPF-PIN 302STAINLESSPORTABLEPLATEHINGEPIN

PVCV34FM PVCVALVE3/4inFPTX3/4inMPT

PW1238 POLYWAND-1/2MPTX3/8FPT-UHMW

R25 AIRREGULATOR-1/4fptTWOPORT1/8fptTWOPORT

-INCLUDESFILTERANDBOWL

ABR25 METALAIRBOWLforR25

AFR25 AIRFILTERforR25

S142058-VS 1/4-20X5/8PHILTRUSSMACHINESCREW18-8

W/#516VIBRASEALORANGEPATCH

SC1212 S.S.COUPLER1/2inBY1/2in

SM-PV PNEUMATICVALVEFORSMARTTECHNOLOGYUNITS

SMH HANDLEFORBONDEDHOSE-1/2inFPTAND1/8in

FPT-UHMW

SN1414 STAINLESS1/4MPTX1/4MPTNIPPLE

SSA14 SS304MALE/FEMALEADAPTOR1/4NPTX1/4NPT

SSAXLE14 14½”longwiththe5/8”diameterbar&2through

holeswithcountersinksbeveledends

SSC14 WORMGEARCLAMP,SS1/4IN

SSC38 WORMGEARCLAMP,S/S(.25-.63)

SSC58 WORMGEARCLAMP,SS5/8IN

SSP12 STAINLESSSTEELAXLEPLATE-2.5inchX1inch-2

HOLE

SST12HB38 STAINLESSTEECOMBO1/2inFPTX3/8inBARBWITH

SSSTANDS.S.MESH

SS-MESH

STAINLESSSTEELMESHWITHSSSTFORREPLACEMENT

SSST

SCREENDISC.687DIA.10X10MESH@.020DIA.300

SERIESS.S.

ST65150 VEEJETNOZZLE65150-3/8MPT

STR38-IL INLINESTRAINER3/8BARB20MESH304STAINLESS

EDPMGSKT

TANK-10N 10GALLONNATURALTANK

TW916 1/2INTTOOTHL/W410SS

W15 NONMARKINGWHEELFORPORTABLEUNITS

/