3M ST MM Plate, 8 Port, Operating instructions

- Type

- Operating instructions

This manual is also suitable for

3M ST MM Plate, 8 Port, is a high-quality fiber optic coupling plate designed for use in fiber distribution systems. It provides a reliable and organized way to connect and manage fiber optic cables, enabling efficient data transmission and communication. This 8-port plate is specifically suitable for ST (Straight Tip) connectors and supports multi-mode fiber optic connections, offering versatility in network configurations.

3M ST MM Plate, 8 Port, is a high-quality fiber optic coupling plate designed for use in fiber distribution systems. It provides a reliable and organized way to connect and manage fiber optic cables, enabling efficient data transmission and communication. This 8-port plate is specifically suitable for ST (Straight Tip) connectors and supports multi-mode fiber optic connections, offering versatility in network configurations.

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

-

13

13

-

14

14

-

15

15

-

16

16

3M ST MM Plate, 8 Port, Operating instructions

- Type

- Operating instructions

- This manual is also suitable for

3M ST MM Plate, 8 Port, is a high-quality fiber optic coupling plate designed for use in fiber distribution systems. It provides a reliable and organized way to connect and manage fiber optic cables, enabling efficient data transmission and communication. This 8-port plate is specifically suitable for ST (Straight Tip) connectors and supports multi-mode fiber optic connections, offering versatility in network configurations.

Ask a question and I''ll find the answer in the document

Finding information in a document is now easier with AI

Related papers

-

3M Mini D Ribbon (MDR) Connectors, 10350-1230-00 Series Operating instructions

-

3M E-9BM User manual

-

3M Better Buried Closure Kit Operating instructions

-

3M 533 User manual

-

3M 2178-XSB Datasheet

-

3M Distribution Box DDB, 100 Pair Operating instructions

-

3M Better Buried Closure Kit Operating instructions

-

3M Thin Printable Repulpable Single Coated Splicing Tape 9969B User guide

Other documents

-

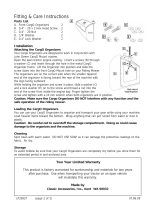

HOMZ 5832008EC.01 Installation guide

HOMZ 5832008EC.01 Installation guide

-

Jabra PanaCast 50 Video Bar System ZR Assembly Instructions

-

Jabra PanaCast User manual

-

Optical AA17084 User manual

-

Optical AA17089 User manual

-

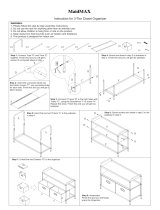

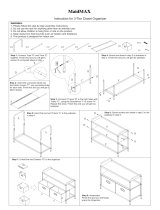

MaidMAX 903001-4 Installation guide

MaidMAX 903001-4 Installation guide

-

John Deere LP20937 Operating instructions

John Deere LP20937 Operating instructions

-

Enabling Devices 3955 User manual

Enabling Devices 3955 User manual

-

Vigoro HD750030-001 Operating instructions

Vigoro HD750030-001 Operating instructions

-

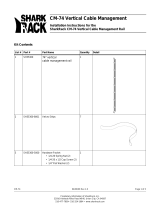

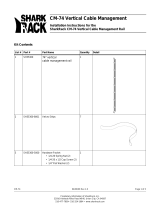

SharkRack CM-74 User manual

SharkRack CM-74 User manual