InstallingtheRockStakesonthe2024

DirectionalDrill

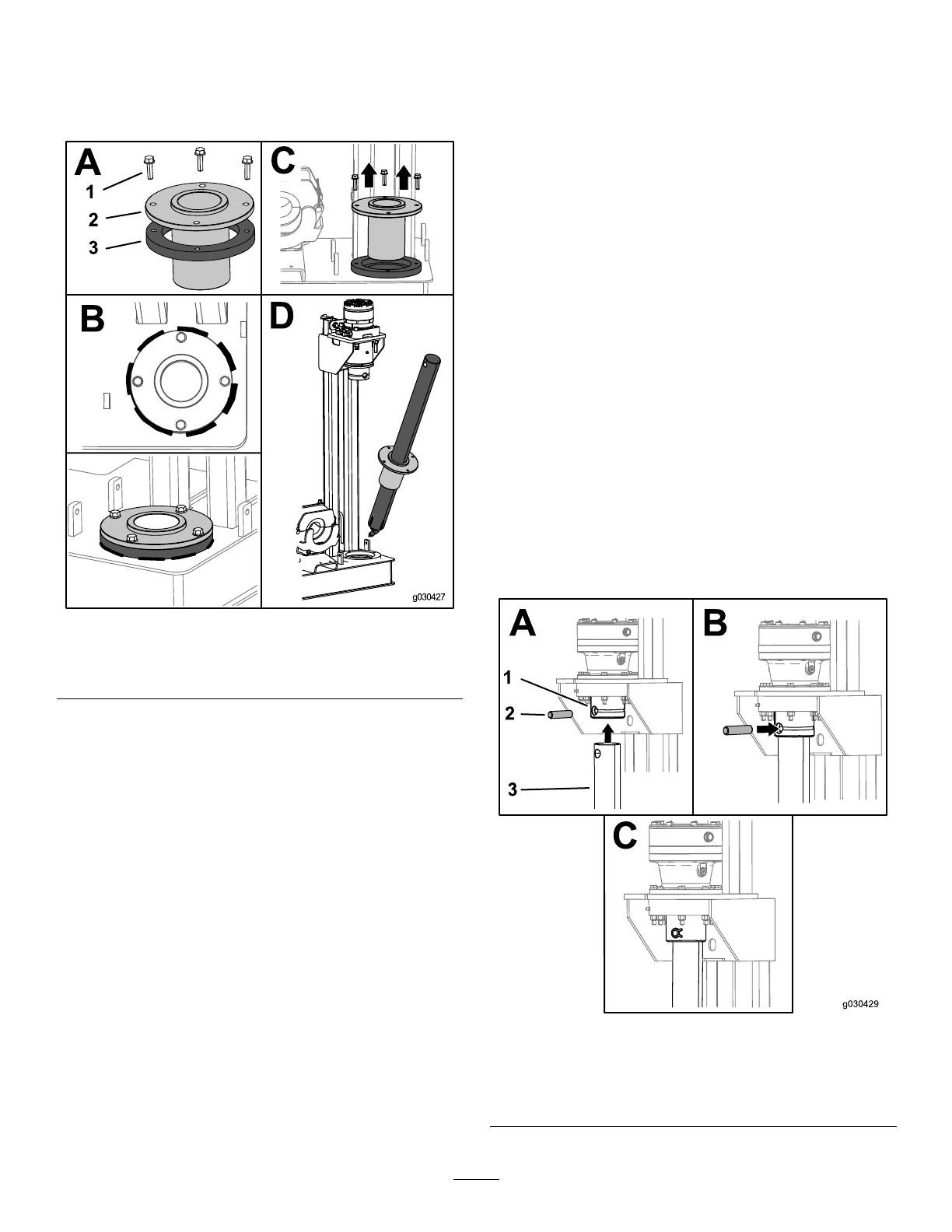

1.Securethestakeguideontotheguideringusingthe8

bolts(M8)(BoxAofFigure4).

Figure4

1.Bolts(M8)3.Guidering

2.Stakeguide

2.Placetheassemblyintotheholeofthethrustframe

foot.

3.Aligntheboltheadssothattheyaresquarewiththe

foot.

4.Weldtheguideringontothemachineusing7equally

spaced5cmby0.64cm(2inchby0.25inch)weldsas

showninBoxBofFigure4.

5.Removetheboltsandstakeguide(BoxCofFigure4).

6.Painttheweldedareawithblackpaint.

7.Placethestakeguideonthestakeandguidethestake

intotheguideringonthemachine(BoxDofFigure4).

8.Installthenewstakesbyaligningtheholeinthestake

withtheholeinthemotorcouplerandsecureitwith

theO-ringsandpinsincludedinthiskit(Figure3).

9.Securethestake-guideringontheweldedguidering

usingthe8bolts(M8-11/4x20mm)(Figure4).

10.Torquetheboltsto23to29N-m(17to21ft-lb).

InstallingtheStakesonthe

4045DirectionalDrill

PreparingtheMachineandRemoving

theCurrentStakes

Note:Having2peopleoraliftingmechanismmakesiteasier

toinstallthestakes.

1.Positionthethrustframe25.4cm(12inches)offthe

ground,withthestakesintheupposition.

2.Turnofftheengineandthebatterydisconnectswitch.

3.Supportthefootwithajackstandorequivalent.

4.Ifyourmachinehasacage,unlatchandopenthe

stake-downcagedoor.

5.Whileholdingthestakes,removethepinsande-clips

securingthestakestothemotors(Figure1).

6.Removetheexistingstakes.

InstallingtheDirtStakesonthe4045

DirectionalDrill

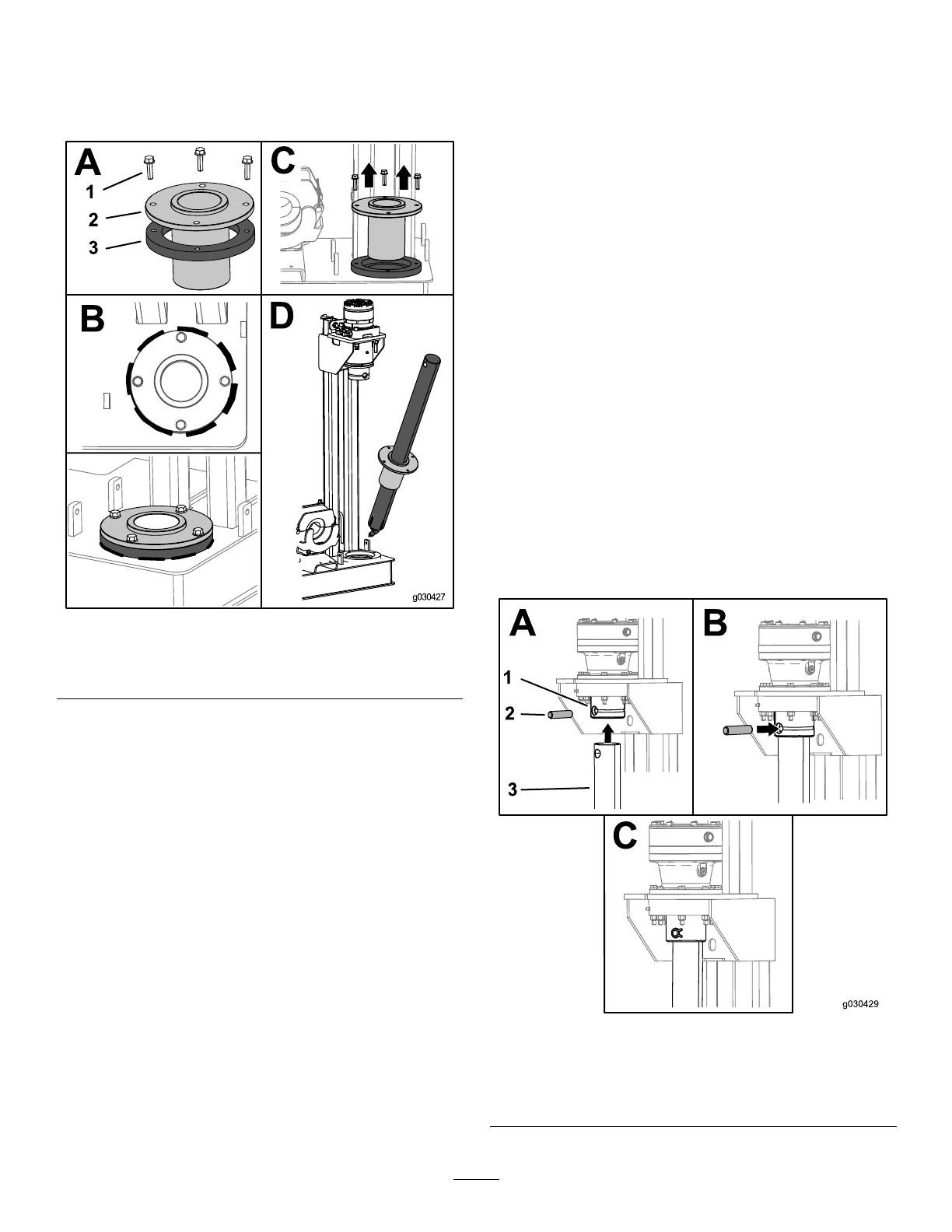

Installthenewstakesbyaligningtheholeinthestakewith

theholeinthemotorandsecureitwiththepinsande-clips

previouslyremoved(Figure5).

Figure5

Rockstakesshownforillustrativepurposesonly

1.Coupler3.Stake

2.Pin

3