Page is loading ...

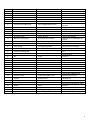

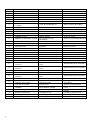

Part Name

Item

No.

Part Name

Item

No.

Parts are subject to possible modifica-

tion without notice due to improve-

ments.

The exploded assembly drawing should be used only for authorized service center.

1 HITACHI Label

2 Housing

3 Carbon Brush

4 Brush Holder

5 Noise Suppressor

6 Pillar Terminal

7 Connector (50091)

8 Cord

9 Cord Clip

10

Tapping Screw(W/Flange) D4 × !6

11

Tapping Screw(W/Washer) D4

×

20

12 Name Plate

13 Cord Armor

14 Terminal (A)

15 Switch Knob

16A Switch

17 Switch Holder

18 Ball Bearing (608VVMC2EPS2L)

19 Rubber Ring

20 Internal Wire

21 Internal Wire (A)

22 Stator

23 Armature

24 Retaining Ring For D15 Shaft

25 Ball Bearing (6002VVCMPS2S)

26 Spindle

27 Collet

28 Internal Wire (A)

29 Internal Wire (A)

30 Scale

31 Knob

32 Holder

33 Knob Screw M5

34 Nut M6

35 Spring

36 Nut M8

37 Base

38A Screw M8

×

100

39 Look Nut M8

40 Knob Bolt

41 Steel Ball D7.94

42 Wing Bolt M6

×

15

43 Lock Spring

44 Earth Terminal

501 Parallel Guide

502A

Wrench 10/13mm

503 Wrench 13/17mm

504 Chuck Sleeve

505 Template Guide D18

506 Machine Screw M5

×

6

Page is loading ...

Page is loading ...

3

English

English Deutsch Français

1

2

3

4

5

6

7

8

9

0

A

B

C

D

E

F

G

H

I

J

K

L

M

N

O

P

Q

R

S

T

U

V

W

X

Y

Z

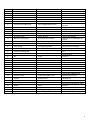

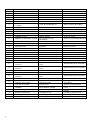

Knob Bolts

Handle knob

Loosen

Tighten

Scale

Loosen the knob

Loosen the handle knob

Push down

Push down

Nut

Screw

Read the scale

Set the cutting depth

Guide bars

Wing bolts

Lock spring

Guide surface

Auxiliary wood guide

Template guide

Bit

Template

Separate

Separate

Router feed

Router feed

Material

Rotation of bit

Router feed

Rotation of bit

Direction in which the router is

forced

Feed screw

Rod ass’y (Nuts, Rod)

Roller

Wing bolt (A)

Guide bar

Dust Collector set

Knopfschrauben

Handgriffknopf

Lockern

Anziehen

Skala

Den Knopf losdrehen

Den Handgriffknopf lösen

Nach unten drücken

Nach unten drücken

Mutter

Schraube

Skala ablesen

Einstellen der Frästiefe

Führungsstangen

Flügelschrauben

Verriegelungsfeder

Führungsfläche

Behelfsmäßige Holzführung

Schablonenführung

Fräse

Schablone

Abstand

Abstand

Vorschub der Oberfräse

Vorschub der Oberfräse

Werkstück

Drehrichtung der Fräse

Vorschub der Oberfräse

Drehrichtung der Fräse

Richtung, in die die Oberfräse

gedreht wird

Vorschubspindel

Stab (Mutter, Stange)

Rolle

Flügelschraube (A)

Führungsstange

Staubfängersatz

Boulons à tête ronde

Bouton de la poignée

Desserrer

Serrer

Echelle

Desserrer le bouton

Desserrer le bouton de la

poignée

Appuyer vers le bas

Appuyer vers le bas

Ecrou

Vis

Lecture de l’echelle

Réglage de la profondeur de

coupe

Barres de guidage

Boulons à oreilles

Ressort de verrouillage

Surface de guidage

Pièce de guidage auxiliaire en

bois

Guide-gabarit

Couteau

Gabarit

Séparation

Séparation

Avance de la défonceuse

Avance de la défonceuse

Pièce travaillée

Rotation du couteau

Avance de la défonceuse

Rotation du couteau

Forceagissant sur la

défonceuse

Vis-mètre

Emsemble Tige (Écrous, Tige)

Rouleau

Boulon à oreilles (A)

Barre de guidage

Ensemble de récupérateur à poussière

Page is loading ...

5

English

GENERAL OPERATIONAL PRECAUTIONS

WARNING! When using electric tools, basic safety

precautions should always be followed to reduce the risk

of fire, electric shock and personal injury, including the

following.

Read all these instructions before operating this product

and save these instructions.

For safe operations:

1. Keep work area clean. Cluttered areas and benches

invite injuries.

2. Consider work area environment. Do not expose

power tools to rain. Do not use power tools in

damp or wet locations. Keep work area well lit.

Do not use power tools where there is risk to

cause fire or explosion.

3. Guard against electric shock. Avoid body contact

with earthed or grounded surfaces. (e.g. pipes,

radiators, ranges, refrigerators).

4. Keep children away. Do not let visitors touch the

tool or extension cord. All visitors should be kept

away from work area.

5. Store idle tools. When not in use, tools should

be stored in a dry, high or locked up place, out

of reach of children.

6. Do not force the tool. It will do the job better and

safer at the rate for which it was intended.

7. Use the right tool. Do not force small tools or

attachments to do the job of a heavy duty tool.

Do not use tools for purposes not intended; for

example, do not use circular saw to cut tree

limbs or logs.

8. Dress properly. Do not wear loose clothing or

jewelry, they can be caught in moving parts.

Rubber gloves and non-skid footwear are

recommended when working outdoors. Wear

protecting hair covering to contain long hair.

9. Use eye protection. Also use face or dust mask

if the cutting operation is dusty.

10. Connect dust extraction equipment.

If devices are provided for the connection of dust

extraction and collection facilities ensure these are

connected and properly used.

11. Do not abuse the cord. Never carry the tool by

the cord or yank it to disconnect it from the

receptacle. Keep the cord away from heat, oil and

sharp edges.

12. Secure work. Use clamps or a vise to hold the

work. It is safer than using your hand and it frees

both hands to operate tool.

13. Do not overreach. Keep proper footing and balance

at all times.

14. Maintain tools with care. Keep cutting tools sharp

and clean for better and safer performance. Follow

instructions for lubrication and changing

accessories. Inspect tool cords periodically and if

damaged, have it repaired by authorized service

center. Inspect extension cords periodically and

replace, if damaged. Keep handles dry, clean, and

free from oil and grease.

15. Disconnect tools. When not in use, before servicing,

and when changing accessories such as blades,

bits and cutters.

16. Remove adjusting keys and wrenches. Form the

habit of checking to see that keys and adjusting

wrenches are removed from the tool before turning

it on.

17. Avoid unintentional starting. Do not carry a

plugged-in tool with a finger on the switch. Ensure

switch is off when plugging in.

18. Use outdoor extension leads. When tool is used

outdoors, use only extension cords intended for

outdoor use.

19. Stay alert. Watch what you are doing. Use common

sense. Do not operate tool when you are tired.

20. Check damaged parts. Before further use of the

tool, a guard or other part that is damaged should

be carefully checked to determine that it will

operate properly and perform its intended function.

Check for alignment of moving parts, free running

of moving parts, breakage of parts, mounting and

any other conditions that may affect its operation.

A guard or other part that is damaged should be

properly repaired or replaced by an authorized

service center unless otherwise indicated in this

handling instructions. Have defective switches

replaced by an authorized service center. Do not

use the tool if the switch does not turn it on and

off.

21. Warning

The use of any accessory or attachment, other

than those recommended in this handling

instructions, may present a risk of personal injury.

22. Have your tool repaired by a qualified person.

This electric tool is in accordance with the relevant

safety requirements. Repairs should only be carried

out by qualified persons using original spare parts.

Otherwise this may result in considerable danger

to the user.

PRECAUTIONS ON USING ROUTER

1. Single-hand operation is unstable and dangerous.

Ensure that both handles are gripped firmly during

operation.

2. The bit is very hot immediately after operation.

Avoid bare hand contact with the bit for any rea-

son.

6

English

Voltage (by areas)* (110V, 115V, 120V, 127V, 220V, 230V, 240V)

Power input 550W*

No-load speed 27000/min

Collet chuck capacity 8mm or 6.35mm(1/4") or 6mm

Main body stroke 52mm

Weight 2.3kg (without cord and standard accessories)

*Be sure to check the nameplate on product as it is subject to change by areas.

STANDARD ACCESSORIES

(1) Parallel Guide Ass’y ................................................... 1

(2) Template Guide .......................................................... 1

(3) Wrench ........................................................................ 2

(4) Screws (for mounting the nameplate guide) ........... 2

One scale, one knob screw, two wing bolts, and two lock

springs are packaged together with the standard

accessories (2), (3), and (4) mentioned above.

Standard accessories are subject to change without

notice.

OPTIONAL ACCESSORIES-sold separately

1. Feed Screw Assembly

2. Power switch

Ensure that the power switch is in the OFF position.

If the plug is connected to a receptacle while the

power switch is in the ON position, the power tool

will start operating immediately, which could cause

a serious accident.

3. Extension cord

When the work area is removed from the power

source, use an extension cord of sufficient thickness

and rated capacity. The extension cord should be

kept as short as practicable.

4. Attach the power tool to the holder

Ensure that the power tool is securely fixed to the

holder.

CAUTION

If it is not, it will be very dangerous.

The power tool can be securely fixed by tightening

the holder’s knob bolt. (Fig. 1)

5. Installing the handle knob

To install the handle knob, screw it into the holder

fixing hole securely. (Fig. 1)

MOUNTING AND DISMOUNTING BITS

1. Mounting Bits

(1) After fully inserting the bit into the collet chuck

hole, firmly tighten the collet chuck with the

accessory wrenches, as shown in Fig. 2.

CAUTION

Ensure that the collet chuck is firmly tightened after

inserting the bit. Failure to do so will result in

damage to the collet chuck.

(2) Use a proper bit which has the same diameter as

the collet.

2. Dismounting Bits

To dismount the bit, follow the mounting procedures

in reverse, starting with loosening the collet chuck

with the accessory wrenches.

HOW TO USE THE ELECTRIC ROUTER

1. Adjusting the cutting depth

(1) Adjusting the cutting depth with the scale:

1 Loosen the knob to have the scale move freely.

(Fig. 3)

2 As shown in Fig. 4 loosen the knob ass’y, push

downward on the handles until the bit lightly

contacts the sruface of the material, and reclamp

the knob ass’y. This preliminary setting is called

“cut 0 (zero)”.

3 Next, read the scale on the holder.

Pull the scale up to the desired cutting depth,

then tighten the knob (Fig. 5).

SPECIFICATIONS

4. Collet

8mm, 6.35mm, 6mm

5. Dust Collector set (Fig. 21Z)

Optional accessories are subject to change without notice.

APPRICATIONS

䡬 Woodworking jobs centered on grooving and

chamfering.

PRIOR TO OPERATION

1. Power source

Ensure that the power source to be utilized conforms

to the power requirements specified on the product

nameplate.

8 × 6.35 Chuck Sleeve

8 × 6 Chuck Sleeve

3. Chuck Sleeve

2. Trimmer Guide Assembly

7

English

For example, if a cutting depth of 10mm is desired

and the “cut 0” reading is as shown in Fig. 5

(a), raise the stopper pole arrow to the position

shown in Fig. 5 (b).

(2) With the scale set as described above, loosen the

knob ass’y and push downward on the handles until

the scale contacts the base.

The router is now adjusted to the desired cutting

depth.

(3) It is possible to decrease the clearance between the

bit tip and the material by loosening and moving

downward the nut on the screw.

This step provides convenience when moving the

router to align the bit with the cutting place.

(4) When adjusting the cutting depth without using the

scale, force the scale upward to prevent it from

getting in the way.

2. Guiding the Router

There are several ways of guiding the router. Select

the method most convenient for your work

requirements.

(1) Parallel Guide Ass’y

Use the parallel guide ass’y for chamfering along

the material side or for grooving.

To properly mount the parallel guide ass’y on the

router, first of all, as shown in Fig. 6, attach the

two wing bolts and the two lock springs to the

screw holes on the top side of the base. Insert the

guide bars in the holes on the base and adjust the

distance from the bit to the guide surface.

Tighten the two wing bolts to secure the parallel

guide ass’y.

Feed the router in a manner that the guide surface

of the parallel guide ass’y moves along the material

side.

An auxiliary wood guide can be mounted on the

parallel guide assembly, as shown in Fig. 7, and

fixed in position by utilizing the holes on the guide

surface.

(2) Template Guide

Use the template guide when employing a template

for producing a large quantity of identically shaped

products.

As shown in Fig. 8, secure the template guide to

the base of the router with two accessory screws.

At this time, ensure that the projection side of the

template guide is facing the bottom surface of the

base of the router.

A template is a profiling mold made of plywood

or thin lumber. When making a template, pay

particular attention to the matters described below

and illustrated in Fig. 9.

When using the router along the interior plane of

the template, the dimensions of the finished product

will be less than the dimensions of the template

by an amount equal to dimension “A”, the distance

between the edge of the template and the edge of

the bit. The reverse is true when using the router

along the exterior of the template.

Secure the template to the material. Feed the router

in a manner that the template guide moves along

the template as shown in Fig. 10.

(3) Router Base

Use of the router base as a guide is highly convenient

when working on material with dimensions too

large for use of the parallel guide assembly.

As shown in Fig. 11, secure a straight piece of board

(to be used as a guide) in the appropriate position

on the material, and feed the router in a manner

that the flat side of the router base moves along

the board guide.

Similarly, it is possible to process the material by

guiding the curved side of the router base along

a large dimension template as shown in Fig. 12.

(4) Bits with Pilot

A bit with a pilot is a bit with a rounded shaft with

no cutting edges on its lower portion. Feed the

router by sliding the pilot along the side of the

material as shown in Fig. 13.

3. Cutting

(1) Turn the switch to the ON position while the bit

is separated from the material as shown in Figs.

14 and 15. Do not start cutting operation until the

bit has reached full rotating speed.

(2) The bit rotates clockwise (arrow direction indicated

on the end bracket). To obtain maximum cutting

effectiveness, feed the router in conformance with

the feed directions shown in Fig. 16.

(3) As illustrated in Fig. 17, when the router is feed

in the direction indicated by the black arrow, a

certain force acts on the routher that causes it to

move in the direction indicated by the white arrow.

During operation, be sure to guide the router so

that it does deviate from the desired cutting line.

HOW TO USE THE OPTIONAL ACCESSORIES

1. Feed screw assembly

By using the feed screw assembly, the distance

between the bit and the parallel guide assembly or

trimmer guide assembly can be finely adjusted. As

shown in Fig. 18, attach the feed screw to the

parallel guide assembly or trimmer assembly, and

attach the rod to the base with the provided nuts.

Fine adjustment can be achieved by turning the

feed screw. Pushing the button on the feed screw

will release the grip of the screw and permit fast

movement of the guide assembly.

2. Trimmer guide assembly

Suitable for trimming, beveling or working the inner

surface of furniture or house fittings with plywood

or veneer surfaces. Insert the assembly guide bars

into the holes of the base, adjust the distance

between the bit and roller as desired, and tighten

the wing bolts on the base to fix the trimmer in

position. Then, loosen the wing bolt (A), shown in

Fig. 19, and set the roller to the appropriate position.

Ensure that the wing bolt (A), is firmly retightened

before using the machine, as shown in Fig. 20.

3. Chuck Sleeve

When using the 6mm or 6.35 mm ø bit for a collet

with an inner diameter of 8mm, you need the 8

× 6 or 8 × 6.35 chuck sleeve, respectively.

CAUTION

8 × 6 chuck sleeve is equipped with a groove, while

the 8 × 6.35 is not. Never use a 6mm ø shaft bit

with an 8 × 6.35 chuck sleeve, or a 6.35mm ø shaft

bit with an 8 × 6 chuck sleeve.

8

English

4. Collet

Use the proper collet according to the diameter of

the bit used.

5. Dust collector Set (Fig. 21Z)

Connect the dust collector set (Fig. 21Z) cleaner

to collect dust.

MAINTENANCE AND INSPECTION

1. Oiling

To ensure smooth vertical movement of the router,

occasionally apply a few drops of machine oil to

the sliding portions of the columns and end bracket.

2. Inspecting the mounting screws:

Regurarly inspect all mounting screws and ensure

that they are properly tightened. Should any of the

screws be loose, retighten them immediately. Failure

to do so could result in serious hazard.

3. Maintenance of the motor

The motor unit winding is the very “heart” of the

power tool. Exercise due care to ensure the winding

does not become damaged and/or wet with oil or

water.

4. Servicing

Consult an authorized service agent in the event of

power tool failure.

NOTE

Due to HITACHI’s continuing program of research and

development, the specifications herein are subject to

change without prior notice.

IMPORTANT

Correct connection of the plug

The wires of the main lead are coloured in accordance

with the following code:

Blue: -Neutral

Brown: -Live

As the colours of the wires in the main lead of this tool

may not correspond with the coloured markings

identifying the terminals in your plug proceed as follows:

The wire coloured blue must be connected to the terminal

marked with the letter N or coloured black. The wire

coloured brown must be connected to the terminal marked

with the letter L or coloured red.

Neither core must be connected to the earth terminal.

NOTE

This requirement is provided according to BRITISH

STANDARD 2769: 1984.

Therefore, the letter code and colour code may not be

applicable to other markets except The United Kingdom.

Information concerning airborne noise and vibration

The measured values were determined according to

EN50144.

The typical A-weighted sound pressure level: 84 dB (A)

Wear ear protection.

The typical weighted root mean square acceleration value:

4.0 m/s

2

.

Deutsch

ALLGEMEINE VORSICHTSMASSNAHMEN

WARNUNG! Bei der Verwendung von Elektrowerkzeugen

müssen immer die grundlegenden Vorsichtsmaßnahmen

befolgt werden, um das Risiko von Feuer, elektrischem

Schlag und persönlicher Verletzung und den

nachfolgenden Punkten zu vermeiden.

Lesen Sie diese Anweisungen völlig, bevor Sie dieses

Erzeugnis verwenden, und bewahren Sie diese

Anweisungen auf.

Für sicheren Betrieb:

1. Der Arbeitsplatz sollte sauber gehalten werden.

Unaufgeräumte Arbeitsplätze und Werkbänke

erhöhen die Unfallgefahr.

2. Die Betriebsbedingungen beachten.

Elektrowerkzeuge sollten nicht dem Regen

ausgesetzt werden.

Ebenfalls sollten Sie nicht an feuchten oder nassen

Plätzen gebraucht werden.

Der Arbeitsplatz sollte gut beleuchtet sein.

Verwenden Sie Elektrowerkzeuge nicht an Orten,

an denen die Gefahr von Feuer oder Explosion

besteht.

3. Schutzmaß nahmen gegen elektrische Schläge

treffen. Darauf achten, daß das Gehäuse nicht in

Kontakt mit geerdeten Flachen kommt, z. (z.B.

Rohre, Radiatoren, Elektroherde, Kühlschränke).

4. Kinder sollten vom Gerät ferngehalten werden.

Vermeiden, daß andere Personen mit dem

Werkzeung oder Verlängerungskabel in Kontakt

kommen.

5. Nicht benutzte Werkzeuge sollten sicher aufbewahrt

werden. Sie sollten an einem trockenen und

verschließbaren Ort aufbewahrt werden, damit

Kinder sie nicht in die Hände bekommen.

6. Werkzeuge sollten nicht mit übermäßiger Gewalt

verwendet werden. Ihre Leistung ist besser und

sicherer, wenn sie mit der vorgeschriebenen

Geschwindigkeit verwendet werden.

7. Nur die korrekten Werkzeuge verwenden. Niemals

ein kleineres Werkzeug oder Zusatzgerat für

Arbeiten verwenden, die Hochleistungsgerate

erfordern. Nur Werkzeuge verwenden, die dem

Verwendungszweck entsprechen, d.h. niemals eine

Kreissäge zum Sägen von Ästen oder

Baumstämmen verwenden.

8. Die richtige Kleidung tragen. Keine lose Kleidung

oder Schmuck tragen, da sich lose Kleidungsstücke

in den bewegenden Teilen verfangen kònnen. Bei

Arbeiten im Freien sollten Gummihandschuhe und

rutschfeste Schuhe getragen werden.

9. Es sollte eine Sicherheitsbrille getragen werden.

Bei Arbeiten mit Staubentwicklung sollte eine

Gesichtsoder Staubmaske getragen werden.

10. Schließen Sie eine Staubabsaugvorrichtung an.

Wenn Vorrichtungen für den Anschluß von

Staubabsaug- und -sammelvorrichtungen

vorhanden sind, so stellen Sie sicher, daß diese

angeschlossen sind und richtig verwendet werden.

11. Niemals das Kabel mißbrauchen. Ein Werkzeug

niemals am Kabel tragen oder bei Abtrennung

von der Steckdose das Kabel harausreißen. Das

Kabel sollte gegen Hitze, Öl und scharfe Kanten

geschützt werden.

12. Den Arbeitsplatz gut absichern. Zwingen oder einen

Schraubstock zur Befestigung des Werkstücks

verwenden. Das ist sicherer als die Benutzung der

Hände und macht beide Hände zur Bedienung des

Werkzeugs frei.

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

008

Code No. C99007074 YT

Printed in Japan

Y. Hirano

Hitachi Power Tools Europe GmbH

Siemensring 34, 47877 Willich, F. R. Germany

Hitachi Koki Co., Ltd.

Sinagawa Intercity Tower A, 15-1, Konan 2-chome

Minato-ku, Tokyo, Japan

95

Italiano

DICHIARAZIONE DI CONFORMITÀ CE

Si dichiara sotto nostra responsabilità che questo

prodotto è conforme agli standard o ai documenti

standardizzati EN50144, HD400, EN55014, EN60555

e/o EN50082-1 conforme alle direttive 73/23/CEE,

89/392/CEE e/o 89/336/CEE del concilio.

* Questa dichiarazione è applicabile ai prodotti cui sono

applicati i marchi CE.

Nederlands

EC VERKLARING VAN CONFORMITEIT

Wij verklaren onder eigen verantwoordelijkheid dat dit

produkt conform de richtlijnen of gestandardiseerde

documenten EN50144, HD400, EN55014, EN60555 en/of

EN50082-1 voldoet aan de eisen van EEG Bepalingen 73/

23/EEG, 89/392/EEG en/of 89/336/EEG.

* Deze verklaring is van toepassing op produkten voorzien

van de CE-markeringen.

Español

DECLARACIÓN DE CONFORMIDAD DE LA CE

Declaramos bajo nuestra única responsabilidad que este

producto está de acuerdo con las normas o con los

documentos de normalización EN50144, HD400,

EN55014, EN60555 y/o EN50082-1, según indican las

Directrices del Consejo 73/23/CEE, 89/392/CEE y/o 89/

336/CEE.

* Esta declaración se aplica a los productos con marcas

de la CE.

English

EC DECLARATION OF CONFORMITY

We declare under our sole responsibility that this product

is in conformity with standards or standardized

documents EN50144, HD400, EN55014, EN60555 and/or

EN50082-1 in accordance with Council Directives 73/23/

EEC, 89/392/EEC and/or 89/336/EEC.

* This declaration is applicable to the product affixed CE

marking.

Deutsch

ERKLÄRUNG ZUR KONFORMITÄT MIT CE-REGELN

Wir erklären mit alleiniger Verantwortung, daß dieses

Produkt den Standards oder standardisierten

Dokumenten EN50144, HD400, EN55014, EN60555 und/

oder EN50082-1 in Übereinstimmung mit den Direktiven

des Europarats 73/23/EWG, 89/392/EWG und/order 89/

336/EWG entspricht.

* Diese Erklärung gilt für Produkte, die die CE-Markierung

tragen.

Français

DECLARATION DE CONFORMITE CE

Nous déclarons sous notre seule et entière respon-

sabilité que ce produit est conforme aux normes ou

documents normalisés EN50144, HD400, EN55014,

EN60555 et/ou EN50082-1 en accord avec les Directives

73/23/CEE, 89/392/CEE et/ou 89/336/CEE du Conseil.

* Cette déclaration s’applique aux produits désignés CE.

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

-

13

13

-

14

14

-

15

15

-

16

16

-

17

17

-

18

18

-

19

19

-

20

20

-

21

21

-

22

22

-

23

23

-

24

24

-

25

25

-

26

26

-

27

27

-

28

28

-

29

29

-

30

30

-

31

31

-

32

32

-

33

33

-

34

34

Ask a question and I''ll find the answer in the document

Finding information in a document is now easier with AI

in other languages

- italiano: Hitachi FM 8 Manuale utente

- français: Hitachi FM 8 Manuel utilisateur

- español: Hitachi FM 8 Manual de usuario

- Deutsch: Hitachi FM 8 Benutzerhandbuch

- Nederlands: Hitachi FM 8 Handleiding

Related papers

-

Hitachi M 12VE Instruction And Safety Manual

-

Hitachi M 12V2 User manual

-

Hitachi M 12V2 User manual

-

Hitachi M 12SC Handling Instructions Manual

-

Hitachi M 8V2 Operating instructions

-

Hitachi M 12SE Handling Instructions Manual

-

Hitachi M 8SA2 Handling Instructions Manual

-

Hitachi M 12V2 Owner's manual

-

Hitachi KM 12SC User manual

-

Hitachi M 12SE User manual