Page is loading ...

User’s

Manual

Contents

1. Introduction

1.1 For Safe Use of Product ..............................................2

1.2 Warranty ......................................................................4

1.3 ATEX Documentation ..................................................5

2. Handling Cautions

2.1 ModelandSpecicationsCheck .................................7

2.2 SelectingtheInstallationLocation ..............................7

2.3 PressureConnection ..................................................7

2.4 InstallationofanExplosion-ProtectedInstrument ......7

2.5 EMCConformityStandards ..................................... 27

2.6 Pressure Equipment Directive (PED) ...................... 28

2.7 Safety Requirement Standards ................................ 29

3. Installation

3.1 Mounting................................................................... 30

3.2

MountingtheDiaphragmSeals ......................................30

3.3 DiaphragmSealsInstallationConsideration ............ 31

3.4 MountingtheFlushingConnectionRing .................. 32

3.5 AfxingtheTeonFilm ............................................. 33

3.6 Rotating Transmitter Section .................................... 34

3.7 ChangingtheDirectionofIntegralIndicator............. 34

4. Installing Impulse Piping

4.1 ImpulsePipingInstallationPrecautions ................... 35

4.2 ImpulsePipingConnectionExamples ..................... 37

4.3 ProcessPipingInstallationPrecautions(EJ115) 38

5. Wiring

5.1 Wiring Precautions ................................................... 40

5.2 ConnectionsofExternalWiringtoTerminalBox ...... 40

5.3 Wiring ....................................................................... 43

5.4 RTDCableConnection(EJX910A/EJX930A) ......... 45

5.5 Grounding ................................................................ 47

5.6 PowerSupplyVoltageandLoadResistance ........... 47

6. Operation

6.1 Preparation for Starting Operation ........................... 48

6.2 Zero Point Adjustment .............................................. 48

6.3 LocalParameterSetting .......................................... 49

7. Errors and Countermeasures

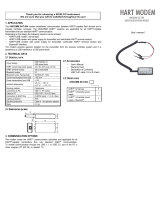

EJX and EJA-E Series

Differential Pressure and

Pressure Transmitters

Installation Manual

IM01C25A01-01E

IM01C25A01-01E

12thEdition

<1. Introduction> 1

IM01C25A01-01E

12thEdition:Feb.2017(YK)

AllRightsReserved,Copyright©2009,YokogawaElectricCorporation

1. Introduction

Thisinstallationmanualprovidesthebasicguidelines

forinstallationandwiringproceduresoftheDPharpEJX

seriesandEJA-EseriestransmitterswithBRAINand

HARTprotocolsandiscomposedoftheinformation

extractedfromtheproductusers’manualsaslistedin

Table1.1.Itdoesnotprovidetheinformationincluding

wiringproceduresofthetransmitterswithFOUNDATION

Fieldbus,ProbusandModbusprotocols,product

specicfunctionalspecicationsandexplanations,

operation,maintenanceandtrouble-shooting.

ForEJXC40ADigitalRemoteSensor,asthisInstallation

Manualdoesnotcovertheproduct,pleaserefertothe

dedicatedmanualforEJXC40A.

WARNING

Toensurecorrectandsafeuseoftheinstrument,

obtainthemanualsapplicabletodesignatedmodels

andspecicationsaslistedTable1.1,readthem

thoroughlyandfullyunderstandhowtooperatethe

instrumentbeforeoperatingit.

Users’manualforeachproductconsistsofahardware

manualdescribinginstallation,wiring,operation,

maintenanceandspecicationincludingdetailedmodel

andsufxcodeinformation,andacommunication

manualdescribinginformationspecictoeach

communicationprotocoltype,includingsafetymanualfor

safety instrumented system.

Thesemanualscanbedownloadedfromthewebsite

ofYokogawaorpurchasedfromtheYokogawa

representatives.

Websiteaddress:http://www.yokogawa.com/d/

Table 1.1 PDF Manual List and Applicable Style Code

[EJX series Hardware Manual]

Models Document No. Style

EJX110A

IM01C25B01-01E

S3

EJX120A S1

EJX130A,EJX310A,EJX430A

andEJX440A S2

EJX210A IM01C25C01-01E S2

EJX510AandEJX530A IM01C25F01-01E S2

EJX610AandEJX630A S1

EJX118AandEJX438A IM01C25H01-01E S2

EJX115A IM01C25K01-01E S1

EJX910A IM01C25R01-01E S2

EJX930A S1

EJXC80AandEJXC50A IM01C25W01-01EN —

EJXC40A IM01C25W05-01EN —

[EJX series Communication Manual]

Models Document No. Style

DPharpHART5/HART7

CommunicationType IM01C25T01-06EN —

DPharpFOUNDATIONFieldbus

CommunicationType IM01C25T02-01E —

DPharpBRAINCommunication

Type IM01C25T03-01E —

DPharpPROFIBUSPA

CommunicationType IM01C25T04-01EN —

EJX910AandEJX930AHART

CommunicationType IM01C25R02-01E —

EJX910AandEJX930A

FieldbusCommunicationType IM01C25R03-01E —

EJX910AandEJX930AModbus

CommunicationType IM01C25R05-01E —

[EJA-E series Hardware Manual]

Models Document No. Style

EJA110E,EJA120E

IM01C25B01-01E S1

EJA130E,EJA310E,EJA430E

andEJA440E

EJA210E IM01C25C01-01E S1

EJA510EandEJA530E IM01C25F01-01E S1

EJA118EandEJA438E IM01C25H01-01E S1

EJA115E IM01C25K01-01E S1

EJAC80EandEJAC50E IM01C25W01-01EN —

[EJA-E series Communication Manual]

Models Document No. Style

DPharpHART5/HART7

CommunicationType IM01C25T01-06EN —

DPharpFOUNDATIONFieldbus

CommunicationType IM01C25T02-01E —

DPharpBRAINCommunication

Type IM01C25T03-01E —

DPharpPROFIBUSPA

CommunicationType IM01C25T04-01EN —

Note:AnexclusiveUser’sManualmightbeattachedforthe

productswhosesufxcodesoroptionalcodescontain

code“Z”.Pleasereaditalongwiththestandardmanuals.

<1. Introduction> 2

IM01C25A01-01E

Regarding This Manual

• Thismanualshouldbepassedontotheenduser.

• Thecontentsofthismanualaresubjecttochange

withoutpriornotice.

• Allrightsreserved.Nopartofthismanualmaybe

reproducedinanyformwithoutYokogawa’swritten

permission.

• Yokogawamakesnowarrantyofanykindwithregard

tothismanual,including,butnotlimitedto,implied

warrantyofmerchantabilityandtnessforaparticular

purpose.

• Ifanyquestionarisesorerrorsarefound,orifany

informationismissingfromthismanual,pleaseinform

thenearestYokogawasalesofce.

• Thespecicationscoveredbythismanualarelimited

tothoseforthestandardtypeunderthespecied

modelnumberbreak-downanddonotcovercustom-

made instruments.

• Pleasenotethatchangesinthespecications,

construction,orcomponentpartsoftheinstrument

maynotimmediatelybereectedinthismanualat

thetimeofchange,providedthatpostponementof

revisionswillnotcausedifcultytotheuserfroma

functional or performance standpoint.

• Yokogawaassumesnoresponsibilitiesforthis

productexceptasstatedinthewarranty.

• Ifthecustomeroranythirdpartyisharmedbytheuse

ofthisproduct,Yokogawaassumesnoresponsibility

foranysuchharmowingtoanydefectsintheproduct

whichwerenotpredictable,orforanyindirect

damages.

• WhendescribingthemodelnamelikeEJ110

inthismanual,itshowstheapplicabilityforboth

EJX110AandEJA110E.Thesamerepresentations

areusedfortheothermodels,too.

• Thefollowingsafetysymbolmarksareusedinthis

manual:

WARNING

Indicatesapotentiallyhazardoussituationwhich,ifnot

avoided,couldresultindeathorseriousinjury.

CAUTION

Indicatesapotentiallyhazardoussituationwhich,ifnot

avoided,mayresultinminorormoderateinjury.Itmay

alsobeusedtoalertagainstunsafepractices.

IMPORTANT

Indicatesthatoperatingthehardwareorsoftwarein

thismannermaydamageitorleadtosystemfailure.

NOTE

Draws attention to information essential for

understandingtheoperationandfeatures.

Direct current

Functional grounding terminal

Caution

Thissymbolindicatesthattheoperatormust

refertoanexplanationintheuser’smanual

inordertoavoidtheriskofinjuryordeathof

personnelordamagetotheinstrument.

1.1 For Safe Use of Product

Fortheprotectionandsafetyoftheoperatorandthe

instrumentorthesystemincludingtheinstrument,please

besuretofollowtheinstructionsonsafetydescribed

inthismanualwhenhandlingthisinstrument.Incase

theinstrumentishandledincontradictiontothese

instructions,Yokogawadoesnotguaranteesafety.

Pleasegiveyourattentiontothefollowings.

(a) Installation

WARNING

• Theinstrumentmustbeinstalledbyanexpert

engineeroraskilledpersonnel.Theprocedures

describedaboutINSTALLATIONarenotpermitted

for operators.

• Incaseofhighprocesstemperature,careshould

betakennottoburnyourselfbecausethesurface

ofbodyandcasereachesahightemperature.

• Theinstrumentinstalledintheprocessisunder

pressure.Neverloosentheprocessconnector

boltstoavoidthedangerousspoutingofprocess

uid.

• Duringdrainingcondensatefromthepressure

detectorsection,takeappropriatecaretoavoid

contactwiththeskin,eyesorbody,orinhalation

ofvapors,iftheaccumulatedprocessuidmaybe

toxicorotherwiseharmful.

• Whenremovingtheinstrumentfromhazardous

processes,avoidcontactwiththeuidandthe

interiorofthemeter.

• Allinstallationshallcomplywithlocalinstallation

requirement and local electrical code.

<1. Introduction> 3

IM01C25A01-01E

(b) Wiring

WARNING

• Theinstrumentmustbeinstalledbyanexpert

engineeroraskilledpersonnel.Theprocedures

describedaboutWIRINGarenotpermittedfor

operators.

• Pleaseconrmthatvoltagesbetweenthepower

supplyandtheinstrumentbeforeconnectingthe

powercablesandthatthecablesarenotpowered

beforeconnecting.

(c) Operation

WARNING

• Wait5min.afterpoweristurnedoff,before

openingthecovers.

• Donotopenthecoverinwetweatherorhumid

environment.Ifthecoverisopened,stated

enclosureprotectionisnotapplicable.

(d) Maintenance

WARNING

• Pleasedonotcarryoutexceptbeingwritten

tomaintenancedescriptions.Whenthese

proceduresareneeded,pleasecontactnearest

YOKOGAWAofce.

• Careshouldbetakentopreventthebuildupof

drift,dustorothermaterialonthedisplayglass

andnameplate.Incaseofitsmaintenance,soft

anddryclothisused.

(e) Explosion Protected Type Instrument

WARNING

• Usersofexplosionproofinstrumentsshouldrefer

rsttosection2.4(InstallationofanExplosion

ProtectedInstrument)ofthismanual.

• ForTIISameprooftypeinstruments,besure

toread“INSTALLATIONANDOPERATING

PRECAUTIONSFORTIISFLAMEPROOF

EQUIPMENT”attheendofthismanual.

• Theuseofthisinstrumentisrestrictedtothose

whohavereceivedappropriatetraininginthe

device.

• Takecarenottocreatesparkswhenaccessingthe

instrumentorperipheraldevicesinahazardous

location.

(f) Modication

WARNING

• Yokogawawillnotbeliableformalfunctionsor

damageresultingfromanymodicationmadeto

thisinstrumentbythecustomer.

(g) Product Disposal

Theinstrumentshouldbedisposedofinaccordancewith

localandnationallegislation/regulations.

(h) Authorized Representative in EEA

InrelationtotheCEMarking,Theauthorized

representativeforthisproductintheEEA(European

EconomicArea)is:

YokogawaEuropeB.V.

Euroweg2,3825HDAmersfoort,TheNetherlands

<1. Introduction> 4

IM01C25A01-01E

(i) Control of Pollution Caused by the Product

Thisisanexplanationfortheproductbasedon“ControlofPollutioncausedbyElectronicInformation

Products”inthePeople’sRepublicofChina.TheinformationisvalidonlyinChina.

产品中有

型

EJX/

E

EJA/EJ

A

差压/压

FV

X

现场总线

网

○:表

×:表

环保使用

有

害物质或元

素

型

号

E

J

A

-E/

A

-A Series

压

力变送器

X

110

网

段指示器

表

示该部件的

所

表

示至少该部

件

期限:

该标识

注)该

素

的名称及

含

部件名

称

壳体

膜盒组

件

基板组

件

电源连接

线

壳体

基板组

件

电源连接

线

所

有均质材

料

件

的某些均

质

识

适用于 SJ /

T

该

年数为“环

保

含

量

称

铅

(P

×

件

×

件

×

线

×

×

件

×

线

×

料

中的有害物

质

质

材料中的有

害

T

11364 中所

述

保

使用期限”

铅

b)

汞

(H

g

×

○

×

○

×

○

×

○

×

○

×

○

×

○

质的含量均

在

害物质的含

量

述

,在中华人

,并非产品

有

汞

g

)

镉

(Cd

)

○

○

○

○

○

○

○

在

GB/T26572

量

均在 GB/T2

6

民共和国销

售

的质量保证

期

有

害物质

)

六价

铬

(Cr(VI

)

○

○

×

○

○

×

○

标准中所规

6

572 标准中

售

的电子电

气

期

。

铬

)

)

多溴联

苯

(PBB)

○

○

○

○

○

○

○

规

定的限量以

下

所规定的限

量

气

产品的环保

使

苯

多溴二苯

醚

(PBDE)

○

○

○

○

○

○

○

下

。

量

以上。

使

用期限。

醚

1.2 Warranty

• Thewarrantyshallcovertheperiodnotedonthe

quotationpresentedtothepurchaseratthetimeof

purchase.Problemsoccurredduringthewarranty

periodshallbasicallyberepairedfreeofcharge.

• Incaseofproblems,thecustomershouldcontactthe

Yokogawarepresentativefromwhichtheinstrument

waspurchased,orthenearestYokogawaofce.

• Ifaproblemariseswiththisinstrument,pleaseinform

usofthenatureoftheproblemandthecircumstances

underwhichitdeveloped,includingthemodel

specicationandserialnumber.Anydiagrams,

dataandotherinformationyoucanincludeinyour

communicationwillalsobehelpful.

• Responsiblepartyforrepaircostfortheproblems

shallbedeterminedbyYokogawabasedonour

investigation.

• ThePurchasershallbeartheresponsibilityfor

repaircosts,evenduringthewarrantyperiod,ifthe

malfunctionisdueto:

- Improperand/orinadequatemaintenancebythe

purchaser.

- Failureordamageduetoimproperhandling,use

orstoragewhichisoutofdesignconditions.

- Useoftheproductinquestioninalocation

notconformingtothestandardsspeciedby

Yokogawa,orduetoimpropermaintenanceofthe

installation location.

- Failureordamageduetomodicationorrepair

byanypartyexceptYokogawaoranapproved

representativeofYokogawa.

- Malfunctionordamagefromimproperrelocationof

theproductinquestionafterdelivery.

- Reasonofforcemajeuresuchasres,

earthquakes,storms/oods,thunder/lightening,

orothernaturaldisasters,ordisturbances,riots,

warfare,orradioactivecontamination.

Trademarks:

• ‘DPharp’,‘EJX’,‘EJA’,‘FieldMate’and‘BRAIN

TERMINAL’areregisteredtrademarksofYokogawa

ElectricCorporation.Companynamesandproduct

namesusedinthismaterialareregisteredtrademarks

ortrademarksoftheirrespectiveowners.

• Inthismanual,trademarksorregisteredtrademarks

arenotmarkedwith™or®.

<1. Introduction> 5

IM01C25A01-01E

1.3 ATEX Documentation

ThisisonlyapplicabletothecountriesinEuropeanUnion.

GB

DK

I

E

NL

SF

P

F

D

S

LT

LV

PL

EST

SLO

H

BG

RO

M

CZ

SK

GR

<2. Handling Cautions> 6

IM01C25A01-01E

2. Handling Cautions

Whenthetransmitterisdelivered,visuallycheckthem

tomakesurethatnodamageoccurredduringshipment.

Alsocheckthatalltransmittermountinghardwareshown

inFigure2.1isincluded.Ifthetransmitterwasordered

withoutthemountingbracketorwithouttheprocess

connector,thetransmittermountinghardwareisnot

included.

Table 2.1 Applicable Model Code for Mounting

Hardware

Applicable

model Sufxcode Part name Qty

EJ110

EJ120

EJ130

EJX910A

EJX930A

Process

connections

1,2,3and4

Processconnectorbolt 4

Process connector 2

Process connector

gasket 2

EJ210

EJ310

EJ430

EJ440

Process

connections

1,2,3and4

Processconnectorbolt 2

Process connector 1

Process connector

gasket 1

EJ110

EJ120

EJ130

EJ310

EJ430

EJ440

EJ118

EJ438

EJ115

EJX910A

EJX930A

Mountingbracket

B,D,G,J,Kand

M *

U-bolt 1

U-boltnut 2

Mountingbracket

(Lorattype) 1

Transmitter mounting

bolt 4

EJ110

Mounting

bracketM(For

measurement

spancodeother

thanF)

U-bolt 1

U-boltnut 2

Mountingbracket 1

Transmitter mounting

bolt 2

EJ510

EJ530

EJX610A

EJX630A

Mountingbracket

FandL

U-bolt(LandS) 1 ea.

U-boltnut(LandS) 2 ea.

Mountingbracket 1

EJX910A

EJX930A

External

temperature input

B,CandD RTDcable 1

External

temperature input

1,2,3and4 Cablegland 2

EJ210

EJ438Optioncode/TF1 Teonlm 1

Fluorinated oil 1

EJ118Optioncode/TF1 Teonlm 2

Fluorinated oil 2

*: FormeasurementspancodeF.

EJX910A

EJX930A -

1

2

3

4

1

2

3

4

B

C

D

-

B

D

G

J

K

M

EJ110

EJ120

EJ130

EJ310

EJ430

EJ440

-

1

2

3

4

-

B

D

G

J

K

M

- - B

J

EJ210

1

2

3

4

- -

EJ510

EJ530

EJX610A

EJX630A

EJ118

EJ438

F

L

- -

F0201.ai

B

D

J

K

EJ115 - -

Mounting bracket

(Flat type)

F0202.ai

Teflon film

Fluorinated oil

Bolt

Process connector

Process connector

Gasket

U-bolt nut

U-bolt

Mounting bracket

(L type)

Transmitter mounting bolt

Cable gland and RTD cable

(EJX910A and EJX930A only)

U-bolt nut (L)

Mounting bracket

U-bolt (L)

U-bolt (S)

U-bolt nut (S)

Figure 2.1 Transmitter Mounting Hardware

<2. Handling Cautions> 7

IM01C25A01-01E

2.1 ModelandSpecications

Check

Themodelnameandspecicationsareindicatedonthe

nameplateattachedtothecase.

F0203.ai

Figure 2.2 Name Plate

2.2 Selecting the Installation

Location

Thetransmitterisdesignedtowithstandsevere

environmentalconditions.However,toensurethatitwill

provideyearsofstableandaccurateperformance,take

thefollowingprecautionswhenselectingtheinstallation

location.

(a)AmbientTemperature

Avoidlocationssubjecttowidetemperaturevariations

orasignicanttemperaturegradient.Ifthelocationis

exposedtoradiantheatfromplantequipment,provide

adequatethermalinsulationand/orventilation.

(b)AmbientAtmosphere

Donotinstallthetransmitterinacorrosive

atmosphere.Ifthiscannotbeavoided,theremustbe

adequate ventilation as well as measures to prevent

theleakingofrainwaterandthepresenceofstanding

waterintheconduits.

(c)ShockandVibration

Althoughthetransmitterisdesignedtoberelatively

resistanttoshockandvibration,aninstallationsite

shouldbeselectedwherethisiskepttoaminimum.

(d)InstallationofExplosion-protectedTransmitters

Anexplosion-protectedtransmittersiscertiedfor

installationinahazardousareacontainingspecic

gastypes.Seesubsection2.4“Installationofan

Explosion-ProtectedInstrument.”

2.3 Pressure Connection

WARNING

• Neverloosentheprocessconnectorboltswhenan

instrumentisinstalledinaprocess.Thedeviceis

underpressure,andalossofsealcanresultina

suddenanduncontrolledreleaseofprocessuid.

• Whendrainingtoxicprocessuidsthathave

condensedinsidethepressuredetector,take

appropriatestepstopreventthecontactofsuch

uidswiththeskinoreyesandtheinhalationof

vaporsfromtheseuids.

Thefollowingprecautionsmustbeobservedinorderto

safelyoperatethetransmitterunderpressure.

(a)Makesurethattheprocessconnectorboltsare

tightenedrmly.

(b)Makesurethattherearenoleaksintheimpulse

piping.

(c) Neverapplyapressurehigherthanthespecied

maximumworkingpressure.

2.4 Installation of an Explosion-

Protected Instrument

Ifacustomermakesarepairormodicationtoan

intrinsicallysafeorexplosionproofinstrumentandthe

instrumentisnotrestoredtoitsoriginalcondition,its

intrinsicallysafeorexplosionproofconstructionmaybe

compromisedandtheinstrumentmaybehazardousto

operate.PleasecontactYokogawabeforemakingany

repairormodicationtoaninstrument.

CAUTION

Thisinstrumenthasbeentestedandcertiedas

beingintrinsicallysafeorexplosionproof.Please

notethatsevererestrictionsapplytothisinstrument’s

construction,installation,externalwiring,maintenance

andrepair.Afailuretoabidebytheserestrictionscould

maketheinstrumentahazardtooperate.

WARNING

Maintainingthesafetyofexplosionproofequipment

requiresgreatcareduringmounting,wiring,and

piping. Safety requirements also place restrictions on

maintenanceandrepair.Pleasereadthefollowing

sections very carefully.

<2. Handling Cautions> 8

IM01C25A01-01E

WARNING

Therangesettingswitchmustnotbeusedina

hazardousarea.

IMPORTANT

Forcombinedapprovaltypes

Onceadeviceofmultipleapprovaltypeisinstalled,

itshouldnotbere-installedusinganyotherapproval

types.Applyapermanentmarkinthecheckboxof

theselectedapprovaltypeonthecerticationlabelon

thetransmittertodistinguishitfromunusedapproval

types.

2.4.1 FM Approval

a. FM Intrinsically Safe/Nonincendive for

HART/BRAIN Protocol Type (Except for

EJX90A)

Note1. EJX/EJA-ESeriespressuretransmitterswith

optionalcode/FS1areapplicableforusein

hazardouslocations.

• ApplicableStandard:

Class3600:2011,Class3610:2010,

Class3611:2004,Class3810:2005

ANSI/ISA-60079-0:2009,ANSI/ISA-60079-11:2009

NEMA250:1991

• Rating

IntrinsicallySafefor

ClassI,II,IIIDivision1,

GroupsA,B,C,D,E,F,GT4

ClassIZone0AExiaIICT4

Nonincendivefor

ClassI,II,IIIDivision2

GroupsA,B,C,D,F,GT4

ClassI,Zone2GroupIICT4

• Ambienttemperature:–60to60°C

• Enclosure:Type4X

Note2. Installation

InstallationshouldbeinaccordancewithControl

DrawingIFM022-A12.

Note3. MaintenanceandRepair

• Theinstrumentmodicationorpartsreplacement

byotherthanauthorizedrepresentativeof

YokogawaElectricCorporationisprohibitedand

willvoidFactoryMutualIntrinsicallysafeand

NonincendiveApproval.

<2. Handling Cautions> 9

IM01C25A01-01E

b. FM Intrinsically Safe/Nonincendive for

Fieldbus Type (Except for EJX90A)

EJX/EJA-ESeriespressuretransmitterswithoptional

code/FS15areapplicableforuseinhazardous

locations.

Note1.

• ApplicableStandard:

Class3600:2011,Class3610:2010,

Class3611:2004,Class3810:2005

ANSI/ISA-60079-0:2009,ANSI/ISA-60079-11:2009

NEMA250:1991

• Rating

IntrinsicallySafewithEntity/FISCOfor

ClassI,II,IIIDivision1,

GroupsA,B,C,D,E,F,GT4

ClassIZone0AExiaIICT4

Nonincendiveeldwiring/FNICOfor

ClassI,IIDivision2

GroupsA,B,C,D,F,GT4

ClassIIIDivision1T4

ClassI,Zone2GroupIICT4

• Ambienttemperature:–40to60°C

• Enclosure:Type4X

• ElectricalConnection:

1/2NPTfemale,M20female

Note2. Installation

InstallationshouldbeinaccordancewithControl

DrawingIFM024-A12.

<2. Handling Cautions> 10

IM01C25A01-01E

c. FM Intrinsically Safe/Nonincendive for

Fieldbus Type for EJX90A

EJXmultivariabletransmitterwithoptionalcode

/FS15areapplicableforuseinhazardouslocations.

Note1.

• ApplicableStandard:

Class3600:2011,Class3610:2010,

Class3611:2004,Class3810:2005

ANSI/ISA-60079-0:2009,ANSI/ISA-60079-11:2009,

ANSI/ISA-60079-27:2006

NEMA250:1991

• Rating

IntrinsicallySafewithEntity/FISCOforClassI,II,III

Division1GroupsA,B,C,D,E,F,GT4

ClassIZone0AExiaIICT4

Nonincendiveeldwiring/FNICOforClassI,II

Division2GroupsA,B,C,D,F,GT4

ClassIIIDivision1T4

ClassI,Zone2GroupIICT4

• Ambienttemperature:–40to60°C

• Enclosure:Type4X

• ElectricalConnection:1/2NPTfemale,M20

female

Note2. Installation

InstallationshouldbeinaccordancewithControl

DrawingIFM026-A12.

<2. Handling Cautions> 11

IM01C25A01-01E

<2. Handling Cautions> 12

IM01C25A01-01E

d. FM Explosionproof

CautionforFMexplosionprooftype.

Note1. EJX/EJA-ESeriespressuretransmitterswith

optionalcode/FF1or/V1Fareapplicablefor

useinhazardouslocations.

• ApplicableStandard:FM3600,FM3615,FM3810,

ANSI/NEMA250

• ExplosionproofforClassI,Division1,GroupsB,C

and D.

• Dust-ignitionproofforClassII/III,Division1,

GroupsE,FandG.

• Enclosure:Type4X

• TemperatureClass:T6

• AmbientTemperature:–40to60°C

• SupplyVoltage:42Vdcmax.

32Vdcmax.(FOUNDATIONFieldbusand

PROFIBUSPAtype)

9to28Vdc,27mW(LowPowertype)

9to30Vdc,250mW(RS485Modbus

CommunicationType)

• Outputsignal:4to20mA

15 mA (FOUNDATIONFieldbusandPROFIBUSPA

type)

1to5V(LowPowertype)

RS485Modbus(RS485ModbusCommunication

Type)

Note2. Wiring

• AllwiringshallcomplywithNationalElectrical

CodeANSI/NFPA70andLocalElectricalCodes.

• WheninstalledinDivision1,“FACTORYSEALED,

CONDUITSEALNOTREQUIRED.”

• WiringconnectionforoutputsignalcodeQ(Low

Powertype)shallfollowthediagrambelow.

F0218.ai

Three-Wire Connection

Pressure Transmitters

Power Supply

Voltmeter

SUPPLY

+

SUPPLY

–

A

+

–

+

–

Four-Wire Connection

Pressure Transmitters

Power Supply

Voltmeter

SUPPLY

+

SUPPLY

–

A

+

–

+

–

<2. Handling Cautions> 13

IM01C25A01-01E

Note3. Operation

• Keepthe“WARNING”nameplateattachedtothe

transmitter.

WARNING:OPENCIRCUITBEFORE

REMOVINGCOVER.FACTORYSEALED,

CONDUITSEALNOTREQUIRED.INSTALLIN

ACCORDANCEWITHTHEUSERSMANUALIM

01C25.

• Takecarenottogeneratemechanicalsparking

whenaccessingtotheinstrumentandperipheral

devicesinahazardouslocation.

Note4. MaintenanceandRepair

• Theinstrumentmodicationorpartsreplacement

byotherthanauthorizedrepresentativeof

YokogawaElectricCorporationisprohibitedand

willvoidFactoryMutualExplosionproofApproval.

e. FM Intrinsically Safe and Explosion Proof

Combination for HART/BRAIN Protocol

Type

EJX/EJA-ESeriespressuretransmitterswith

optionalcode/FU1or/V1U1canbeselectedthe

typeofprotection(FMIntrinsicallySafeorFM

Explosionproof)foruseinhazardouslocations.

Note1. Fortheinstallationofthistransmitter,oncea

particulartypeofprotectionisselected,any

othertypeofprotectioncannotbeused.The

installationmustbeinaccordancewiththe

descriptionaboutthetypeofprotectioninthis

instruction manual.

Note2. Inordertoavoidconfusion,unnecessary

markingiscrossedoutonthelabelother

thantheselectedtypeofprotectionwhenthe

transmitter is installed.

2.4.2 CSACertication

a. CSA Intrinsically Safe for HART/BRAIN

Protocol Type (Except for EJX90A)

CautionforCSAIntrinsicallysafeandnonincendive

type.(Followingcontentsreferto“DOCNo.ICS013-

A13”)

Note1. EJX/EJA-ESeriespressuretransmitterswith

optionalcode/CS1areapplicableforusein

hazardouslocations.

Certicate:1606623

[ForCSAC22.2]

• ApplicableStandard:C22.2No.0,C22.2No.0.4,

C22.2No.25,C22.2No.94,C22.2No.157,

C22.2No.213,C22.2No.60079-0,

C22.2No.61010-1,C22.2No.61010-2-030

• IntrinsicallySafeforClassI,Division1,Groups

A,B,C&D,ClassII,Division1,GroupsE,F&G,

ClassIII,Division1

• NonincendiveforClassI,Division2,GroupsA,B,

C&D,ClassII,Division2,GroupsF&G,ClassIII,

Division 1

• Enclosure:Type4X

• Temp.Code:T4

• Amb.Temp.:–50*to60°C

*–15°Cwhen/HEisspecied.

• ProcessTemperature:120°Cmax.

[ForCSAE60079]

• ApplicableStandard:CAN/CSAE60079-11,

CAN/CSAE60079-15,IEC60529:2001

• ExiaIICT4,ExnLIICT4

• AmbientTemperature:–50to60°C

• Max.ProcessTemp.:120°C

• Enclosure:IP66/IP67

Note2. EntityParameters

• Intrinsicallysaferatingsareasfollows:

MaximumInputVoltage(Vmax/Ui)=30V

MaximumInputCurrent(Imax/Ii)=200mA

MaximumInputPower(Pmax/Pi)=0.9W

MaximumInternalCapacitance(Ci)=10nF

MaximumInternalInductance(Li)=0µH

• Type"n"orNonincendiveratingsareasfollows:

MaximumInputVoltage(Vmax/Ui)=30V

MaximumInternalCapacitance(Ci)=10nF

MaximumInternalInductance(Li)=0µH

• InstallationRequirements

Uo≤Ui,Io≤Ii,Po≤Pi,

Co≥Ci+Ccable,Lo≥Li+Lcable

Voc≤Vmax,Isc≤Imax,

Ca≥Ci+Ccable,La≥Li+Lcable

Uo,Io,Po,Co,Lo,Voc,Isc,CaandLaare

parametersofbarrier.

Note3. Installation

• Inanysafetybarreirusedoutputcurrentmust

belimitedbyaresistor'R'suchthatIo=Uo/Ror

Isc=Voc/R.

• ThesafetybarriermustbeCSAcertied.

• Inputvoltageofthesafetybarriermustbeless

than250Vrms/Vdc.

• InstallationshouldbeinaccordancewithCanadian

ElectricalCodePartIandLocalElectricalCode.

• Dust-tightconduitsealmustbeusedwhen

installedinClassIIandIIIenvironments.

• Theinstrumentmodicationorpartsreplacement

byotherthanauthorizedrepresentativeof

YokogawaElectricCorporationandYokogawa

CorporationofAmericaisprohibitedandwill

voidCanadianStandardsIntrinsicallysafeand

nonincendiveCertication.

<2. Handling Cautions> 14

IM01C25A01-01E

F0206.ai

Class I, II, III, Division 1,

Groups A, B, C, D, E, F, G

Pressure Transmitters Safety Barrier

Supply

Hazardous Location Nonhazardous Location

General

Purpose

Equipment

+

–

+

–

+

–

+

–

[Intrinsically Safe]

Group IIC, Zone 0

F0207.ai

Pressure Transmitters

Supply

Hazardous Location Nonhazardous Location

+

–

+

–

Class I, II, Division 2,

Groups A, B, C, D, F, G

Class III, Division 1.

Not Use

Safety Barrier

[Nonincendive]

CSA Certified

Equipment

([nL] or

nonincendive)

Group IIC, Zone 2

b. CSA Intrinsically Safe for Fieldbus Type

(Except for EJX90A)

EJX/EJA-ESeriespressuretransmitterswithoptional

code/CS15areapplicableforuseinhazardous

locations.

• Certicate:1689689

• Applicablestandard:C22.2No.0,C22.2No.0.4,

C22.2No.25,C22.2No.94,C22.2No.157,

C22.2No.213,C22.2No.61010-1,

C22.2No.61010-2-030,C22.2No.60079-0,

CAN/CSAE60079-0,CAN/CSAE60079-11,

CAN/CSAE60079-15,IEC60529

• CSAIntrinsicallySafeApproval

ClassI,Division1,GroupsA,B,C,&D;ClassII,

Division1,GroupsE,F&G;ClassIII;ExiaIICT4

AmbientTemperature:–40*to60°C(–40*to

140°F)Encl.Type4X,IP66/IP67

*–15°Cwhen/HEisspecied.

• CSANonincendiveApproval

ClassI,Division2,GroupsA,B,C,&D;ClassII,

Division2,GroupsF&G;ClassIII;ExnLIICT4

AmbientTemperature:–40*to60°C(–40*to

140°F)Encl.Type4X,IP66/IP67

*–15°Cwhen/HEisspecied.

Caution for CSA Intrinsically Safe Type.

(Following Contents Refer to “DOC. No.

ICS018)

Installation Diagram for Intrinsically Safe

(Division 1 Installation)

Non-Hazardous Location

Hazardous Location

F0229.ai

Terminator

Safety Barrier

Field Instruments

Pressure

Transmitter

Field Instruments

+

–

+

–

+

–

Terminator

+

–

+

–

Note1. ThesafetybarriermustbeCSAcertied.

Note2. Inputvoltageofthesafetybarriermustbeless

than250Vrms/Vdc.

Note3. Installationshouldbeinaccordancewith

CanadianElectricalCodePartIandlocal

ElectricalCode.

Note4. Donotalterdrawingwithoutauthorizationfrom

CSA.

Electrical Data:

•Rating1(Entity)

ForGroupsA,B,C,D,E,F,andGorGroupIIC

Ui(vmax)=24Vdc

Ii(Imax)=250mA

Pi(Pmax)=1.2W

Ci=3.52nF

Li=0μH

or

•Rating2(FISCO)

ForGroupsA,B,C,D,E,F,andGorGroupIIC

Ui(vmax)=17.5Vdc

Ii(Imax)=380mA

Pi(Pmax)=5.32W

Ci=3.52nF

Li=0μH

or

<2. Handling Cautions> 15

IM01C25A01-01E

• Rating3(FISCO)

ForGroupsC,D,E,F,andGorGroupIIB

Ui(vmax)=17.5Vdc

Ii(Imax)=460mA

Pi(Pmax)=5.32W

Ci=3.52nF

Li=0μH

Installationrequirements;

Po≤PiUo≤UiIo≤Ii,

Co≥Ci+CcableLo≥Li+Lcable

Vmax≥VocImax≥Isc

Ca≥Ci+CcableLa≥Li+Lcable

Uo,Io,Po,Co,Lo,Voc,Isc,CaandLaareparameters

ofbarrier.

Caution for CSA Non-incendive Type.

(Following contents refer to “DOC. No.

ICS018)

Installation Diagram for Non-incendive or Type of

protection “n” (Division 2 Installation)

Non-Hazardous location

Hazardous location

F0230.ai

Terminator

CSA Certified

Equipment [nL]

Pressure

Transmitter

SUPPLY

Terminator

+

–

Transmitter

+

–

Transmitter

+

–

+ –

+ –

Note1. Installationshouldbeinaccordancewith

CanadianElectricalCodePartIandlocal

ElectricalCode.

Note2. Dust-tightconduitsealmustbeusedwhen

installedinclassIIandIIIenvironments.

Note3. Donotalterdrawingwithoutauthorizationfrom

CSA.

Electrical Data:

•Rating(includingFNICO)

UiorVmax=32V

Ci=3.52nF

Li=0μH

c. CSA Explosionproof Type

CautionforCSAexplosionprooftype.

Note1. EJX/EJA-ESeriespressuretransmitterswith

optionalcode/CF1or/V1Fareapplicablefor

useinhazardouslocations.

• Certicate:2014354

• ApplicableStandard:C22.2No.0,

C22.2No.0.4,C22.2No.0.5,C22.2No.25,

C22.2No.30,C22.2No.94,C22.2No.61010-1,

C22.2No.61010-2-030,C22.2No.60079-0,

C22.2No.60079-1

• Explosion-proofforClassI,GroupsB,CandD.

• Dustignition-proofforClassII/III,GroupsE,Fand

G.

• Enclosure:Type4X

• TemperatureCode:T6...T4

• ExdIICT6...T4

• Enclosure:IP66/IP67

• MaximumProcessTemperature:120°C(T4),

100°C(T5),85°C(T6)

• AmbientTemperature:–50*to75°C(T4),

–50*to80°C(T5),–50*to75°C(T6)

*–15°Cwhen/HEisspecied.

• SupplyVoltage:42Vdcmax.

32Vdcmax.(FOUNDATIONFieldbusand

PROFIBUSPAtype)

9to28Vdc,27mW(LowPowertype)

9to30Vdc,250mW(RS485Modbus

CommunicationType)

• OutputSignal:4to20mAdc

15 mA (FOUNDATIONFieldbusandPROFIBUSPA

type)

1to5V(LowPowertype)

RS485Modbus(RS485ModbusCommunication

Type)

Note2. Wiring

• AllwiringshallcomplywithCanadianElectrical

CodePartIandLocalElectricalCodes.

• Inhazardouslocation,wiringshallbeinconduitas

showninthegure.

• WARNING:

ASEALSHALLBEINSTALLEDWITHIN50cmOF

THEENCLOSURE.

UNSCELLEMENTDOITÊTREINSTALLÉÀ

MOINSDE50cmDUBOÎTIER.

• WARNING:

WHENINSTALLEDINCL.I,DIV2,SEALNOT

REQUIRED.

UNEFOISINSTALLÉDANSCLI,DIV2,AUCUN

JOINTN'ESTREQUIS.

<2. Handling Cautions> 16

IM01C25A01-01E

Non-hazardous

Location Equipment

42 V DC Max.

4 to 20 mA DC

Signal

Non-Hazardous

Locations

Hazardous Locations Division 1

50 cm Max.

Sealing Fitting Conduit

Transmitter

F0208.ai

Non-Hazardous

Locations

Hazardous Locations Division 2

Non-hazardous

Location Equipment

42 V DC Max.

4 to 20 mA DC

Signal

Sealing Fitting

Transmitter

F0209.ai

• Allwiringshallcomplywithlocalinstallation

requirements and local electrical code.

• Inhazardouslocations,thecableentrydevices

shallbeofacertiedameprooftype,suitablefor

theconditionsofuseandcorrectlyinstalled.

• Unusedaperturesshallbeclosedwithsuitable

ameproofcertiedblankingelements.(Theplug

attachedisameproofcertied.)

• WiringconnectionforoutputsignalcodeQ(Low

Powertype)shallfollowthediagrambelow.

F0219.ai

Three-Wire Connection

Pressure Transmitters

Power Supply

Voltmeter

SUPPLY

+

SUPPLY

–

A

+

–

+

–

Four-Wire Connection

Pressure Transmitters

Power Supply

Voltmeter

SUPPLY

+

SUPPLY

–

A

+

–

+

–

Note3. Operation

• WARNING:

AFTERDE-ENERGIZING,DELAY5MINUTES

BEFOREOPENING.

APRÉSPOWER-OFF,ATTENDRE5MINUTES

AVANTD'OUVRIR.

• WARNING:

WHENAMBIENTTEMPERATURE≥65°C,USE

THEHEAT-RESISTINGCABLES≥90°C.

QUANDLATEMPÉRATUREAMBIANTE≥65°C,

UTILISEZDESCÂBLESRÉSISTANTESÁLA

CHALEUR≥90°C.

• Takecarenottogeneratemechanicalsparking

whenaccessingtotheinstrumentandperipheral

devicesinahazardouslocation.

Note4. MaintenanceandRepair

• Theinstrumentmodicationorpartsreplacement

byotherthanauthorizedrepresentativeof

YokogawaElectricCorporationandYokogawa

CorporationofAmericaisprohibitedandwillvoid

CanadianStandardsExplosionproofCertication.

d. CSA Intrinsically Safe and Explosion-proof

Combination for HART/BRAIN Protocol

Type (Except for EJX90A)

EJX/EJA-ESeriespressuretransmitterswith

optionalcode/CU1or/V1U1canbeselectedthe

typeofprotection(CSAIntrinsicallySafeorCSA

Explosionproof)foruseinhazardouslocations.

Note1. Fortheinstallationofthistransmitter,oncea

particulartypeofprotectionisselected,any

othertypeofprotectioncannotbeused.The

installationmustbeinaccordancewiththe

descriptionaboutthetypeofprotectioninthis

instruction manual.

Note2. Inordertoavoidconfusion,unnecessary

markingiscrossedoutonthelabelother

thantheselectedtypeofprotectionwhenthe

transmitter is installed.

2.4.3 ATEXCertication

(1) Technical Data

a. ATEX Intrinsically Safe for HART/BRAIN

Protocol Type (Except for EJX90A)

CautionforATEXIntrinsicallysafetype.

Note1. EJX/EJA-ESeriespressuretransmitterswith

optionalcode/KS21forpotentiallyexplosive

atmospheres.

• No.DEKRA11ATEX0228X

• ApplicableStandard:

EN60079-0:2012+A11:2013

EN60079-11:2012

<2. Handling Cautions> 17

IM01C25A01-01E

• TypeofProtectionandMarkingcode:

ExiaIICT4Ga

ExiaIIICT85ºCT100ºCT120ºCDb

• Group:II

• Category:1G,2D

• AmbientTemperatureforEPLGa:

–50to60°C

• AmbientTemperatureforEPLDb:

–30*to60°C

*–15°Cwhen/HEisspecied.

• ProcessTemperature(Tp.):120°Cmax.

• MaximumSurfaceTemperatureforEPLDb:

T85°C(Tp.:80°C)

T100°C(Tp.:100°C)

T120°C(Tp.:120°C)

• Enclosure:IP66/IP67

TosatisfyIP66orIP67,applywaterproofglandsto

theelectricalconnectionport.

Note2 ElectricalData

• IntypeofexplosionprotectionintrinsicsafetyExia

IICorExiaIIIC,onlyforconnectiontoacertied

intrinsicallysafecircuitwithfollowingmaximum

values:

Ui=30V

Ii=200mA

Pi=0.9W

(LinearSource)

Maximuminternalcapacitance;Ci=27.6nF

Maximuminternalinductance;Li=0µH

Whenthelightningprotectoroptionisspecied,

theapparatusisnotcapableofwithstandingthe

500VinsulationtestrequiredbyEN60079-11.This

mustbetakenintoaccountwheninstallingthe

apparatus.

Note3. Installation

• Refertothecontroldrawing.Allwiringshallcomply

withlocalinstallationrequirements.

Pressure Transmitters

Supply Safety Barrier *1

Nonhazardous Location

[Control Drawing]

Hazardous Location

+

–

+

–

F0210.ai

*1:Anysafetybarriersmustbealinearpowersource

whoseoutputcurrentisresistivelylimited.

Note4. MaintenanceandRepair

• Theinstrumentmodicationorpartsreplacement

byotherthanauthorizedrepresentativeof

YokogawaElectricCorporationisprohibitedand

willvoidDEKRAIntrinsicallysafeCertication.

Note5. SpecialConditionsforSafeUse

WARNING

• WhentheenclosureofthePressureTransmitter

ismadeofaluminum,ifitismountedinanarea

wheretheuseofcategory1Gequipmentis

required,itmustbeinstalledsuch,that,evenin

theeventofrareincidents,ignitionsourcesdueto

impactandfrictionsparksareexcluded.

• Electrostaticchargesonthecoatedpartsof

PressureTransmittershallbeavoided.

• Electrostaticchargemaycauseanexlosion

hazard.Avoidanyactionsthatcausethe

generationofelectrostaticcharge,suchasrubbing

withadryclothoncoatingfaceoftheproduct.

• IncaseoftheenclosureofthePressure

Transmitterwithpaintlayers,ifitismountedinan

areawheretheuseofcategory2Dequipmentis

required,itshallbeinstalledinsuchawaythatthe

riskfromelectrostaticdischargesandpropagating

brushdischargescausedbyrapidowofdustis

avoided.

b. ATEX Intrinsically Safe for Fieldbus Type

(Except for EJX90A)

CautionforATEXIntrinsicallysafetype.

Note1. EJX/EJA-Eseriespressuretransmitterswith

optionalcode/KS26areapplicableforusein

hazardouslocations.

• No.KEMA04ATEX1116X

• ApplicableStandard:

EN60079-0:2012+A11:2013

EN60079-11:2012

Note2. Ratings

TypeofProtectionandMarkingCode:

ExiaIIC/IIBT4Ga

ExiaIIICT85°CT100°CT120°CDb

Group:II

Category:1G,2D

AmbientTemperatureforEPLGa:–40to60°C

AmbientTemperatureforEPLDb:–30*to60°C

*–15°Cwhen/HEisspecied.

MaximumProcessTemperature(Tp.):120°C

MaximumSurfaceTemperatureforEPLDb.

T85°C(Tp.:80°C)

T100°C(Tp.:100°C)

T120°C(Tp.:120°C)

AmbientHumidity:

0to100%(Nocondensation)

DegreeofProtectionoftheEnclosure:

IP66/IP67

<2. Handling Cautions> 18

IM01C25A01-01E

Electrical Data

• WhencombinedwithTrapezoidalandRectangular

outputcharacteristicFISCOmodelIICbarrier

Ui=17.5V,Ii=380mA,Pi=5.32W,

Ci=3.52nF,Li=0μH

• WhencombinedwithLinearcharacteristicbarrier

Ui=24V,Ii=250mA,Pi=1.2W,

Ci=3.52nF,Li=0μH

• WhencombinedwithTrapezoidalorRectangular

outputcharacteristicFISCOmodelIIBbarrier

Ui=17.5V,Ii=460mA,Pi=5.32W,

Ci=3.52nF,Li=0μH

Note3. Installation

• Allwiringshallcomplywithlocalinstallation

requirements.(Refertotheinstallationdiagram)

Note4. MaintenanceandRepair

• Theinstrumentmodicationorpartsreplacement

byotherthanauthorizedrepresentativeof

YokogawaElectricCorporationisprohibitedand

willvoidDEKRAIntrinsicallysafeCertication.

Note5. SpecialConditionsforSafeUse

WARNING

• InthecasewheretheenclosureofthePressure

Transmitterismadeofaluminium,ifitismounted

inanareawheretheuseofcategory1G

apparatusisrequired,itmustbeinstalledsuch,

thatevenintheeventofrareincidents,ignition

sourcesduetoimpactandfrictionsparksare

excluded.

• Electrostaticchargemaycauseanexplosion

hazard.Avoidanyactionsthatcausethe

generationofelectrostaticcharge,suchasrubbing

withadryclothoncoatingfaceoftheproduct.

• InthecasewheretheenclosureofthePressure

Transmitterismadeofaluminum,ifitismountedin

anareawheretheuseofcategory2Dapparatusis

required,itshallbeinstalledinsuchawaythatthe

riskfromelectrostaticdischargesandpropagating

brushdischargescausedbyrapidowofdustis

avoided.

• TosatisfyIP66orIP67,applywaterproofglandsto

theelectricalconnectionport.

• Whenthelightningprotectoroptionisspecied,

theapparatusisnotcapableofwithstandingthe

500VinsulationtestrequiredbyEN60079-11.

Thismustbetakenintoaccountwheninstalling

theapparatus.

Note6. InstallationInstructions

Non-Hazardous Location

Hazardous Location

F0231.ai

Terminator

Safety Barrier

Transmitter

Pressure

Transmitter

Transmitter

+

−

+

−

+

−

Terminator

+

−

+

−

[Installation Diagram]

SUPPLY

• Intherating1(*1),theoutputcurrentofthebarrier

mustbelimitedbyaresistor‘Ra’suchthatIo=Uo/

Ra.

• Intherating2(*2),theoutputofthebarriermustbe

thecharacteristicsofthetrapezoidortherectangle

andthistransmittercanbeconnectedtoFieldbus

equipmentwhichareinaccordingtotheFISCO

model.

• Theterminatorsmaybebuiltinbyabarrier.

• Morethanonetransmittermaybeconnectedto

thepowersupplyline.

• Theterminatorandthesafetybarriershallbe

certied.

Electricaldata:

MaximumInputVoltageUi:24V

*1:

Rating 1

MaximumInputCurrentIi:250mA

MaximumInputPowerPi:1.2W

MaximumInternalCapacitanceCi:3.52nF

MaximumInternalInductanceLi:0μH

or

MaximumInputVoltageUi:17.5V

*2:

Rating 2

MaximumInputCurrentIi:380mA

MaximumInputPowerPi:5.32W

MaximumInternalCapacitanceCi:3.52nF

MaximumInternalInductanceLi:0μH

or

MaximumInputVoltageUi:17.5V

MaximumInputCurrentIi:460mA

MaximumInputPowerPi:5.32W

MaximumInternalCapacitanceCi:3.52nF

MaximumInternalInductanceLi:0μH

<2. Handling Cautions> 19

IM01C25A01-01E

c. ATEX Intrinsically Safe for Fieldbus Type

for EJX90A

CautionforATEXIntrinsicallysafetype.

Note1. EJXmultivariabletransmitterwithoptional

code/KS26areapplicableforuseinhazardous

locations:

• No.KEMA06ATEX0278X

• ApplicableStandard:

EN60079-0:2012+A11:2013

EN60079-11:2012

Note2. Ratings

TypeofProtectionandMarkingCode:

ExiaIIC/IIBT4Ga

ExiaIIICT85°CT100°CT120°CDb

Group:II

Category:1G,2D

AmbientTemperatureforEPLGa:

–40to60°C

AmbientTemperatureforEPLDb:

–30*to60°C

*–15°Cwhen/HEisspecied.

MaximumProcessTemperature(Tp.):120°C

MaximumSurfaceTemperatureforEPLDb.

T85°C(Tp.:80°C)

T100°C(Tp.:100°C)

T120°C(Tp.:120°C)

AmbientHumidity:

0to100%(Nocondensation)

DegreeofProtectionoftheEnclosure:

IP66/IP67

Electrical Data

• WhencombinedwithTrapezoidalorRectanglar

outputcharacteristicFISCOmodelIICbarrier

[Supplycircuit(terminals+and-)]

Ui=17.5V,Ii=380mA,Pi=5.32W,

Ci=3.52nF,Li=0µH

[Sensorcircuit]

Uo=7.63V,Io=3.85mA,Po=0.008W,

Co=4.8µF,Lo=100mH

• WhencombinedwithLinearcharacteristicbarrier

[Supplycircuit(terminals+and-)]

Ui=24V,Ii=250mA,Pi=1.2W,

Ci=3.52nF,Li=0µH

[Sensorcircuit]

Uo=7.63V,Io=3.85mA,Po=0.008W,

Co=4.8µF,Lo=100mH

• WhencombinedwithTrapezoidalorRectanglar

outputcharacteristicFISCOmodelIIBbarrier

[Supplycircuit(terminals+and-)]

Ui=17.5V,Ii=460mA,Pi=5.32W,

Ci=3.52nF,Li=0µH

[Sensorcircuit]

Uo=7.63V,Io=3.85mA,Po=0.008W,

Co=4.8µF,Lo=100mH

Note3. Installation

• Allwiringshallcomplywithlocalinstallation

requirements.(Refertotheinstallationdiagram)

Note4. MaintenanceandRepair

• Theinstrumentmodicationorpartsreplacement

byotherthanauthorizedrepresentativeof

YokogawaElectricCorporationisprohibitedand

willvoidDEKRAIntrinsicallysafeCertication.

Note5. SpecialConditionsforSafeUse

WARNING

• InthecasewheretheenclosureofthePressure

Transmitterismadeofaluminium,ifitismounted

inanareawheretheuseofcategory1Gapparatus

isrequired,itmustbeinstalledsuch,thatevenin

theeventofrareincidents,ignitionsourcesdueto

impactandfrictionsparksareexcluded.

• Electrostaticchargemaycauseanexplosion

hazard.Avoidanyactionsthatcausethe

generationofelectrostaticcharge,suchasrubbing

withadryclothoncoatingfaceoftheproduct.

• InthecasewheretheenclosureofthePressure

Transmitterismadeofaluminum,ifitismountedin

anareawheretheuseofcategory2Dapparatusis

required,itshallbeinstalledinsuchawaythatthe

riskfromelectrostaticdischargesandpropagating

brushdischargescausedbyrapidowofdustis

avoided.

• TosatisfyIP66orIP67,applywaterproofglandsto

theelectricalconnectionport.

• Whenthelightningprotectoroptionisspecied,

theapparatusisnotcapableofwithstandingthe

500VinsulationtestrequiredbyEN60079-11.

Thismustbetakenintoaccountwheninstalling

theapparatus.

Note6. Installationinstructions

Non-Hazardous Location

Hazardous Location

F0232.ai

Terminator

Safety Barrier

Transmitter

Pressure

Transmitter

Transmitter

+

−

+

−

+

−

Terminator

+

−

+

−

SUPPLY

RTD

Pt100.3wire

[Installation Diagram]

/