Page is loading ...

S

e

r

vic

e

N

o

.

St

o

c

k Mo

d

u

l

e

Iden

t

ific

a

tion P

la

t

e

2

0

8

2

6

4

Mod

u

l

e

N

o

.

Pr

o

d

u

c

t

V

O

L

T

S

Easto

n

Pen

n

s

y

l

va

n

ia

M

A

X

.

B

R

A

N

C

H

C

I

R

C

U

I

T

F

U

S

E

S

I

Z

E

M

I

N

.

B

R

A

N

C

H

C

I

R

C

U

I

T

A

M

P

A

C

I

T

Y

M

O

T

O

R

C

O

M

P

R

E

S

S

OR THE

R

MA

L

L

Y

P

R

O

T

E

CTED

D

ES

I

G

N

P

R

ES

S

U

R

E

HI

G

H

S

I

D

E

C

H

A

R

GE

H

Z

PA

R

T

N

O

A

M

P

S

A

M

P

S

N

S

F

R

U

L

OZ

PSIG

MADE IN

THE USA

C

SINGLE

PH

A

SE

R

L

O

W

SID

E

L

U

MODE

L

R

EF

R

I

G

ER

A

N

T

F

U

L

L

L

O

A

D

A

M

P

S

CORPO

R

A

TI

O

N

SER

IA

L

N

O

00117259R04

801 Church Lane • Easton, PA 18040, USA

Toll free (800) 523-9361 • (610) 252-7301

Fax (610) 250-0696 • www.follettice.com

Following installation, please forward this manual

to the appropriate operations person.

Follett Maestro

™

Chewblet

®

400 Series

Icemaker and Top Kit

for Remcor/Cornelius Countertop ice and beverage dispensers

Installation, Operation and Service Manual

Order parts online

www.follettice.com

Welcome to Follett Corporation

Important cautions

Specifications

Installation

Operation

Cleaning

Replacement Parts

Models MTC22SC, MSC22SC

Models MTC24SC, MSC24SC

Models MTC30SC, MSC30SC

Model MSC44SC

2

Table of contents

Follett Corporation

Equipment Return Policy

Follett equipment may be returned for credit under the following conditions:

1. The equipment is new and unused.

2. A return authorization number has been issued by customer service within 30 days after shipment.

3. Follett receives the equipment at the factory in Easton, PA within 30 days after issuance of the return authorization number.

4. The equipment must be returned in Follett packaging. If the packaging has been damaged or discarded, Follett will forward, at the customer’s expense,

new packaging.

Note: Return freight charges are the responsibility of the customer. If equipment is returned and is damaged because of improper packaging,

Follett Corporation will not be held responsible.

Credit will be issued when:

The equipment has been inspected by Follett and deemed suitable to be returned to stock.

Note: A 15% restocking charge will be deducted from the credit. If the cost to return the product to stock exceeds 15%, the actual cost will be deducted.

3

3

4

6

14

14

16

16

17

18

19

Welcome to Follett

Follett equipment enjoys a well-deserved reputation for excellent performance, long-term reliability and

outstanding after-the-sale support. To ensure that this equipment delivers that same degree of service, we

ask that you review the installation portion of this manual before beginning to install the unit. Our installation

instructions are designed to help you achieve a trouble-free installation. Should you have any questions or

require technical help at any point, please call our technical service group at (800) 523-9361 or (610) 252-7301.

Before you begin

After uncrating and removing all packing material, inspect the equipment for concealed shipping damage. If

damage is found, notify the shipper immediately and contact Follett Corporation so that we can help in the filing

of a claim, if necessary.

Check your paperwork to determine which model you have. Follett model numbers are designed to provide

information about the type and capacity of Follett equipment. Following is an explanation of the different model

numbers in the series.

3

MSC22SC

Icemaker configuration

SC = self-contained

Dispenser size

22 = 22" wide

24 = 24" wide

30 = 30" wide

44 = 44" wide

Dispenser manufacturer

C = Cornelius

L = Lancer

S = SerVend

Icemaker mounting

MT = Maestro top mount

MS = Maestro Satellite-fill

Important cautions

Dispenser bin area contains mechanical, moving parts. Keep hands and arms clear of this

area at all times. If access to this area is required, power to unit must be disconnected first.

Follett recommends a Follett water filter system (part# 00130229 for the 400 series) be

installed in the icemaker inlet water line.

Ice is slippery. Maintain counters and floors around dispenser in a clean and ice-free condition.

Ice is food. Follow recommended cleaning instructions to maintain cleanliness of delivered ice.

!

Specifications

4

Electrical

Model number Full load amps Max. fuse size

MC400 series icemaker 115/60/1 11.0 amps 20 amps

Ambient specifications

Air temperature 100˚F/38˚C max. 50˚F/10˚C min. (best performance below 80˚F/27˚C)

Water temperature 90˚F/32˚C max. 40˚F/4˚C min. (best performance below 70˚F/21˚C)

Water pressure 70 P.S.I. max.(482kPA) 10 P.S.I min. (89kPA)

Plumbing

Your new icemaker is equipped with a drain line to simplify draining the evaporator and float reservoir. The tube

labeled “float/evap drain” is for SERVICE USE ONLY and must NOT be connected to the icemaker drain.

Water line sizes Make up water (inlet to float) 1/4" min.

Condenser (water-cooled only) 3/8" min.

Drain line sizes Icemaker drain 3/4" min.

Condenser (water-cooled only) 3/8" min.

Slope to drain 1/4" per foot (6mm per 30.4cm run) 1/2" min.

• Water shut-off recommended within 10 feet (3m), drain to be hard-piped and insulated

• Separate drains for icemaker and condenser. To prevent back flow, do NOT connect drains.

• Follett recommends installation of a Follett water filter system (part# 00130229) in icemaker inlet water line

Field Wiring: countertop dispensers with Satellite-fill icemakers

Consult enclosed D400A/W, R400A/W, MCD400A/W manual.

20.75" (527mm)

22.75" (578mm)

13.00"

(331mm)

4.875"

(124mm)

2.375"

(61mm)

1.875" (48mm)

7.00" (178mm)

A

A

B

B

F

F

D

E

C

A

B

C

C

17.00"

(432mm)

Front view — air-cooled

Satellite-fill

Side view — air-cooled and water-cooled

top mount and Satellite-fill

Satellite-fill air-cooled units only

Back view — air-cooled

top mount

Front view — water-cooled

Satellite-fill

Back view — water-cooled

top mount

12.875"

(327mm)

4.75"

(121mm)

8.375"

(213mm)

2.25"

(57mm)

1.875" (48mm)

Front view — air-cooled

top mount

Icemaker plug

configuration

NEMA 5-20

6.875"

(175mm)

2"

(51mm)

5

Dimensions and clearances

Required clearances – MCD400 series

Entire front of icemaker clear of obstruction/connections to allow removal.

12" (305mm) above icemaker for service

6" (153mm) minimum between louvered (exhaust) side of icemaker and any adjacent equipment.

MCD400AHS – 18" (457mm) minimum, 10 ft (3m) maximum between discharge and air intake grilles.

A – 3/4" MPT drain

B – 3/8" OD push-in water inlet

C – Electrical cord

D – 3/8" FPT condenser inlet

E – 3/8" FPT condenser drain

Installation

1. Install Cornelius ice dispenser according to

manufacturer’s specifications.

Note: We recommend that the dispenser

back be mounted at least 1" (26mm) from wall to

allow water, drain and electric lines from top-mount

icemakers to be concealed behind dispenser.

2. Disconnect power to dispenser.

3. Remove front panel/merchandiser from the dispenser.

4. Adjust the agitation timer located on Cornelius PC

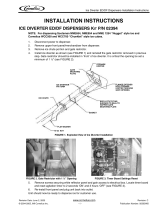

board to 1 second on – 1 hour off (Fig. 1).

Fig. 1

5. Install supplied

nugget ice diverter at

dispenser opening.

a) Disassemble

chute assembly

and discard gate

restrictor (Fig. 2.1).

b) Reassemble with

supplied ice

diverter as shown

(Fig. 2.2).

6. Reinstall front panel.

ON

OFF

agitation

timer

Fig. 2

storage hopper

gate

restrictor

plate

flange extends

into storage

hopper through

gate opening

apply RTV to this

surface to seal to

hopper gate

mounting plate

gasket

flat washer

10-32 nut

ice chute

ice diverter

(supplied)

gate

mounting

plate

1

2

6

8. Install supplied stainless steel top with access opening toward

front of dispenser (Fig. 4).

For dispensers with top mounted icemakers

Proceed with steps 9 through 17.

For dispensers with Satellite-fill icemakers

Go directly to step 18.

Fig. 4

Fig. 3

7. Remove existing plastic top from dispenser and install supplied

gasket around perimeter of dispenser top (Fig. 3).

Note: Sanitize dispenser before proceeding.

gasket

7

S

e

r

v

i

c

e

N

o

.

Sto

c

k

Mo

d

u

l

e

I

d

en

t

i

fi

c

a

t

i

on

P

l

a

t

e

2

0

8

2

6

4

Mod

u

l

e

N

o

.

Pr

o

d

u

ct

V

O

L

T

S

Eas

t

o

n P

en

n

s

y

l

va

n

ia

MA

X

.

B

R

A

NC

H

CIR

C

U

IT F

U

SE

S

I

Z

E

M

I

N

.

B

R

A

N

C

H

C

I

R

C

U

IT

A

M

P

A

C

I

T

Y

MO

T

O

R COM

P

RES

S

OR

T

HERMA

L

L

Y

P

RO

T

ECT

E

D

D

E

S

IG

N

P

R

ES

S

U

R

E

H

IGH

S

IDE

C

H

A

R

GE

H

Z

PA

R

T

N

O

AM

P

S

AM

P

S

N

S

F

R

U

L

O

Z

PSI

G

M

A

D

E IN

T

HE

USA

C

SINGL

E

PH

A

S

E

R

L

O

W

S

I

DE

L

U

MODEL

REF

R

IGE

R

A

NT

F

U

L

L

L

O

AD A

M

P

S

C

O

R

POR

A

T

ION

S

E

R

IA

L

N

O

Fig. 5

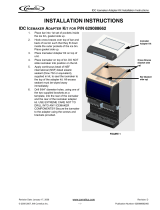

Top mounted icemaker installation

9. Position Follett MCD400AHT icemaker on perimeter gasket

of stainless steel top. Icemaker should be oriented with A/C

condenser facing front (Fig 5).

8

Fig. 6

10. Use pliers to compress and remove cage nut at front

of condenser on icemaker base (Fig. 6.1).

11. Install filter and grille. Lock in place using four

mounting screws (Fig. 6.2).

Fig. 7

9

M

o

d

u

l

e

N

o

.

M

o

d

u

l

e

N

o

.

P

r

o

d

u

c

t

P

r

o

d

u

c

t

S

t

o

c

k

M

o

d

u

l

e

I

d

e

n

t

i

f

i

c

a

t

i

o

n

P

l

a

t

e

S

t

o

c

k

M

o

d

u

l

e

I

d

e

n

t

i

f

i

c

a

t

i

o

n

P

l

a

t

e

2

0

8

2

6

4

2

0

8

2

6

4

S

e

r

v

i

c

e

N

o

.

S

e

r

v

i

c

e

N

o

.

M

I

N

.

B

R

A

N

C

H

C

I

R

C

U

I

T

A

M

P

A

C

I

T

Y

M

I

N

.

B

R

A

N

C

H

C

I

R

C

U

I

T

A

M

P

A

C

I

T

Y

D

E

S

I

G

N

PR

ESS

U

R

E H

IGH

S

IDE

D

E

S

I

G

N

PR

ES

S

U

R

E H

IGH

S

IDE

M

A

X

.

B

R

A

N

C

H

C

I

R

C

U

I

T

F

U

S

E

S

I

Z

E

M

A

X

.

B

R

A

N

C

H

C

I

R

C

U

I

T

F

U

S

E

S

I

Z

E

A

IR

OU

T

A

IR

OU

T

VO

LT

S

VO

LT

S

E

as

ton

P

en

n

s

y

l

va

ni

a

E

as

ton

P

en

n

s

y

l

va

ni

a

M

OT

OR

CO

M

P

R

ES

S

O

R

T

H

ER

M

AL

L

Y

PR

O

T

E

C

T

E

D

M

OT

OR

CO

M

P

R

ES

S

O

R

T

H

ER

M

AL

L

Y

PR

O

T

E

C

T

E

D

T

H

E

U

SA

T

H

E

U

SA

M

A

D

E

I

N

M

A

D

E

I

N

S

I

N

GLE

S

I

N

GLE

L

O

W

S

ID

E

L

O

W

S

ID

E

CH

A

R

G

E

CH

A

R

G

E

O

Z

O

Z

P

S

I

G

P

S

I

G

C

C

R

R

R

R

P

H

A

S

E

P

H

A

S

E

A

MP

S

A

MP

S

H

Z

H

Z

PA

RT

N

O

PA

RT

N

O

A

M

P

S

A

M

P

S

F

U

LL

LO

AD

AM

PS

F

U

LL

LO

AD

AM

PS

C

O

R

P

O

R

A

T

ION

C

O

R

P

O

R

A

T

ION

R

E

FR

I

G

E

R

A

N

T

R

E

FR

I

G

E

R

A

N

T

S

E

R

IA

L N

O

S

E

R

IA

L N

O

M

O

D

E

L

M

O

D

E

L

AI

R

I

N

AI

R

I

N

U

U

U

U

L

L

L

L

N

SF

N

SF

1

filter

grille

2

2

Power

115V

A

B

C

Back view – air-cooled

top mount

3/8" OD

water inlet

Drain

3/4" MPT

12. Make water, drain and electric connections

to icemaker (Fig. 7).

Note: Water connection accepts 3/8" OD

copper or plastic tubing. Push tubing in

until it stops. Use supplied 90˚ push-in

water inlet fitting if there is not enough

clearance behind icemaker to install

water tubing without kinking tubing or

putting stress on fitting.

Note: Follett recommends the installation

of a Follett water filter system

(par# 00130229) on supply water

inlet.

Fig. 8

10

13. Remove icemaker top panel and

louvered side panel.

14. Insert ice transport tube to a 1/2"

(13mm) depth through mounting

bracket (Fig 8 and 9.1) and secure

transport tube away from condenser

fan under float reservoir bracket

(Fig. 9.2).

15. Tighten clamp screw(s) on icemaker

base securely (Fig. 9.3).

16. Uncoil capillary tube from bin

thermostat and route through hole in

gasket to mounting bracket and secure

as shown (Fig. 8).

17. Reinstall icemaker louvered side panel

and top panel.

GO TO STARTUP – STEP 27.

ice transport tube

bin thermostat

capillary tube

1/2"

2"

Fig. 9

2

1

3

tighten

clamp

screw

insert ice

transport

tube

Satellite-fill icemaker installation

18. Ice transport tube chase may be located

behind or to either side of the dispenser

(Fig. 10 and 11). Using the chase

mounting bracket (Fig. 12) as a template

mark the counter for the ice transport

tube(s) in one of the locations shown in

Fig. 10 and 11. Within the template outline

drill one 2.25" (58mm) to 2.375" (61mm)

hole for each ice transport tube. Secure

the chase mounting bracket to the counter

using supplied screws (Fig. 12).

Fig. 10 – Single ice tube dispensers

Fig. 11 – Double ice tube dispensers

11

2.25" (57mm) -

2.375" (61mm)

dia. hole

typical

1.25

(32mm)

1.25" (32mm)

1.25"

(32mm)

1.50" (38mm)

1.50" (38mm)

front

side entry

chase

side entry

chase

rear entry chase

4.50" (115mm)

4.50" (115mm)

A

B

6"

(153mm)

2.25" (57mm) -

2.375" (61mm)

dia. hole

typical

1.25

(32mm)

1.25" (32mm)

1.25"

(32mm)

3" (77mm)

3" (77mm)

front

side entry

chase

side entry

chase

rear entry chase

A

B

6"

(153mm)

Fig. 12

Dimension A Dimension B

Single tube – Fig. 10

22" (559mm) dispenser 11.00" (280mm) 8.00" (242mm)

24" (607mm) dispenser 12.00" (312mm) 9.00" (299mm)

30" (762mm) dispenser 15.00" (762mm) 12.00" (343mm)

Double tube – Fig. 11

22" (559mm) dispenser 9.50" (242mm) 8.00" (204mm)

24" (607mm) dispenser 10.50" (273mm) 9.00" (242mm)

30" (762mm) dispenser 13.50" (343mm) 12.00" (305mm)

44" (1118mm) dispenser 20.50" (521mm) 19.00" (483mm)

21. Route the bin signal cord from the 4" x 4" (102mm x 102mm)

junction box through the top knockout (Fig. 13.1) and

countertop hole. Attach the bin signal connector to the two

lead plug on the icemaker.

22. Route the ice transport tube(s) from the icemaker(s) through

counter cutout and knock out into dispenser top by following

the same routing as the bin signal cord (Fig. 13.2).

19. Remove lid from dispenser top (Fig. 13.). Remove the

knockout from the Harmony top (Fig. 13.2) corresponding to

selected chase location. Line the edges of the opening with

the supplied gasket material (Fig. 13.2).

20. Follow the “Satellite-fill icemaker installation procedure”

found in the Symphony MCD400 Icemaker Manual 208600

to install your Follett icemaker.

12

1

1

2

2

2

1

Fig. 13

23. Connect the ice transport tube(s) to the dispenser:

a) Drill 3/16" (5mm) holes through both sides of the tube

1/2" (13mm) from the tube end.

b) Collapse tube and insert through gasketed hole (Fig. 14.1).

c) Match tube holes to bracket tabs.

24. Route bin thermostat capillary tube from the 4" x 4"

(102mm x 102mm) junction box into bin alongside the ice

transport tube. Secure capillary tube into bracket (Fig. 8).

25. Reinstall the dispenser cover with supplied screws (Fig. 14).

26. Install telescoping chase.

a) Mount lower chase section to chase bracket on counter

with supplied screws (Fig. 15.1).

b) Position upper chase section over lower chase section.

Align top of upper section to top of stainless dispenser top

and secure with screw (Fig. 15.2).

c) Drill pilot holes on both sides of chase and secure with

supplied screws (Fig. 15.3).

27. Turn icemaker power and water on.

28. After icemaker has made ice for approximately 15 minutes

complete the following start-up checks:

a) Dispense ice.

b) Hold ice on bin thermostat and make sure

icemaker shuts off.

c) Remove ice from bin thermostat and make sure

icemaker restarts.

Note: Icemaker has a 20 minute restart delay.

Fig. 15

13

2

3

1

Fig. 14

1

14

Operation

Weekly exterior evaporator unit care

The exterior may be cleaned with a stainless cleaner such as 3M Stainless Steel Cleaner & Polish or equivalent.

Recommended semi-annual icemaker/evaporator unit cleaning (every 6 months)

1

3

2

Fig. 16

Solution A – Sanitizing solution: Prepare 2 gallons (9L)

Combine 1 oz (250ml) bleach with 2 gal (8L) hot water or use

200ppm of Ecolab Mikro-chlor Cleaner or equivalent 5.25% sodium

hypochlorite solution.

Solution B – Ice machine cleaner: Prepare one gallon (3.8L)

of Follett SafeCLEAN

™

Ice Machine Cleaner (one 7 oz packet) or

equivalent. Solution temperature must be at least 120° F

(48.9° C).

Warning: Most ice machine cleaners contain citric or phosphoric

acid that can cause skin irritation. Read caution label on product

and follow instructions carefully.

1. Remove icemaker panels required to gain access to water

reservoir components (Fig. 16) and electrical control box.

2. Locate icemaker electrical box and turn compressor switch off.

3. Dispense all ice from dispenser.

4. Shut off water to icemaker.

5. Drain water from reservoir through float/evaporator drain line

(Fig. 16.3). Reinsert hose into hose clip (Fig. 16.1).

6. Fill reservoir (Fig. 16.2) with Solution B.

7. Restart icemaker and allow gearmotor to run with the

compressor off for 15 minutes.

8. While waiting 15 minutes, follow steps 8a through 8c.

a) Remove ice compression nozzles (Fig. 17.1). Soak in

Solution B.

b) Descale drain pans (Fig. 17.2) by grasping firmly and

gently bending up and down. Vacuum residue out.

c) Inspect all drain lines. Clean as necessary with Solution B.

9. Turn icemaker power off.

10. Drain Solution B through float/evaporator drain line

(Fig. 16.3). Rinse evaporator by filling reservoir (Fig. 16.2) with

potable water and draining evaporator through float/evaporator

drain line (Fig. 16.3) three times. Reinsert hose into hose clip

and plug into end of drain line (Fig. 16.1).

11. Connect ice transport tubes (Fig. 17.3) directly to evaporator

outlet ports (without ice compression nozzle) (Fig. 17.4).

12. Fill reservoir (Fig. 16.2) with Solution A.

13. Turn icemaker power on (to allow gearmotor to run).

14. Wait 10 minutes. Turn compressor switch on.

15. Keep reservoir (Fig. 16.2) full of Solution A while making ice for

20 minutes.

16. Turn compressor switch off.

1

2

3

4

Fig. 17

17. Rinse ice compression nozzles (Fig. 17.1) with water

and reinstall.

18. Drain any remaining sanitizing solution from reservoir through

float/evaporator drain line (Fig. 16.1).

19. Fill reservoir (Fig. 16.2) with 120˚F (49˚C) water. Empty water

through float/evaporator drain line (Fig. 161). Repeat 3 times.

20. Turn on water to icemaker.

21. Turn compressor switch on.

22. Replace reservoir cover and any panels removed to

clean icemaker.

23. Make ice for 30 minutes. Dispense and discard all ice.

15

9

10

2

4

3

13

12

1

M

A

X

.

B

R

A

N

C

H

C

I

R

C

U

I

T

F

U

S

E

S

I

Z

E

M

I

N

.

B

R

A

N

C

H

C

I

R

C

U

I

T

A

M

P

A

C

I

T

Y

S

to

c

k

M

o

d

u

le

Id

en

tif

ic

a

t

io

n

P

l

a

te

S

e

r

v

ic

e

N

o

.

2

0

8

2

6

4

P

ro

d

u

c

t

M

o

d

u

l

e

N

o

.

V

O

L

T

S

E

a

s

t

o

n

P

e

n

n

s

y

l

v

a

n

i

a

D

E

S

I

G

N

P

R

E

S

S

U

R

E

H

I

G

H

S

I

D

E

M

O

T

O

R

C

O

M

P

R

E

S

S

O

R

T

H

E

R

M

A

L

L

Y

P

R

O

T

E

C

T

E

D

H

Z

C

H

A

R

G

E

P

A

R

T

N

O

A

M

P

S

A

M

P

S

P

S

I

G

O

Z

C

L

U

R

N

S

F

T

H

E

U

S

A

M

A

D

E

I

N

U

L

L

O

W

S

I

D

E

R

P

H

A

S

E

S

I

N

G

L

E

CO

R

P

O

R

A

T

I

O

N

M

O

D

E

L

F

U

L

L

L

O

A

D

A

M

P

S

R

E

F

R

I

G

E

R

A

N

T

S

E

R

I

A

L

N

O

11

12

8

14

15

6

5

Service

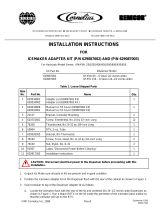

Replacement parts

Top kit models MTC22SC, MSC22SC

Reference # Description Part #

1 Base, top mount 00113506

1 Base, Satellite-fill 00113266

2 Cabinet 00113324

3 Cover 00113357

4 Chase, upper 00113381

5 Chase, lower 00113399

6 Collar 00113407

8 Deflector, single 501616

9 Lid, access 00113423

10 Box, thermostat 00113449

11 Gasket, top, Harmony 00113464

12 Gasket, ice entry 502824

13 Socket, bin signal 502334

14 Kit, ice entry, MCD400 00120279

15 Plate, ice tube mounting, MCD400 307071

Not shown Thermostat, bin level 500514

Not shown Diverter, ice 307277

Not shown Plate, blank, ice entry 00113498

16

17

Top kit models MTC24SC, MSC24SC

9

10

2

4

3

13

12

1

M

A

X

.

B

R

A

N

C

H

C

I

R

C

U

I

T

F

U

S

E

S

I

Z

E

M

I

N

.

B

R

A

N

C

H

C

I

R

C

U

I

T

A

M

P

A

C

I

T

Y

S

to

c

k

M

o

d

u

l

e

Id

e

n

t

i

f

ic

a

t

io

n

P

la

te

S

erv

ic

e

N

o

.

2

0

8

2

6

4

P

ro

d

u

c

t

M

o

d

u

le

N

o

.

V

O

L

T

S

E

a

s

t

o

n

P

e

n

n

s

y

l

v

a

n

i

a

D

E

S

I

G

N

P

R

E

S

S

U

R

E

H

I

G

H

S

I

D

E

M

O

T

O

R

C

O

M

P

R

E

S

S

O

R

T

H

E

R

M

A

L

L

Y

P

R

O

T

E

C

T

E

D

H

Z

C

H

A

R

G

E

P

A

R

T

N

O

A

M

P

S

A

M

P

S

P

S

I

G

O

Z

C

L

U

R

N

S

F

T

H

E

U

S

A

M

A

D

E

I

N

U

L

L

O

W

S

I

D

E

R

P

H

A

S

E

S

I

N

G

L

E

C

O

R

P

O

R

A

T

I

O

N

M

O

D

E

L

F

U

L

L

L

O

A

D

A

M

P

S

R

E

F

R

I

G

E

R

A

N

T

S

E

R

I

A

L

N

O

11

12

8

14

15

6

5

Reference # Description Part #

1 Base, top mount 00119495

1 Base, Satellite-fill 00119487

2 Cabinet 00119503

3 Cover 00119511

4 Chase, upper 00113381

5 Chase, lower 00113399

6 Collar 00113407

8 Deflector, single 501616

9 Lid, access 00113423

10 Box, thermostat 00113449

11 Gasket, top, Harmony 00113464

12 Gasket, ice entry 502824

13 Socket, bin signal 502334

14 Kit, ice entry, MCD400 00120279

15 Plate, ice tube mounting, MCD400 307071

Not shown Thermostat, bin level 500514

Not shown Diverter, ice 307277

Not shown Plate, blank, ice entry 00113498

Top kit models MTC30SC, MSC30SC

S

e

r

v

i

c

e

N

o

.

S

to

c

k

M

o

d

u

l

e

I

d

e

n

t

i

f

i

c

a

t

i

o

n

P

l

a

t

e

2

0

8

2

6

4

M

o

d

u

l

e

N

o

.

P

r

o

d

u

c

t

V

O

L

T

S

E

a

s

t

on

P

e

n

n

s

y

l

v

a

n

i

a

M

A

X

.

B

R

A

N

C

H

C

I

R

C

U

I

T

F

U

S

E

S

I

Z

E

M

I

N

.

B

R

A

N

C

H

C

I

R

C

U

I

T

A

M

P

A

C

I

T

Y

M

O

T

O

R

C

O

M

P

R

E

S

S

O

R

T

H

E

R

M

A

L

LY

P

R

O

T

E

C

T

E

D

D

E

S

I

G

N

P

R

E

S

S

U

R

E

H

I

G

H

S

I

D

E

C

H

A

R

G

E

H

Z

P

A

R

T

N

O

A

M

P

S

A

M

P

S

NS

F

R

U

L

O

Z

P

S

I

G

M

A

D

E

I

N

T

H

E

U

S

A

C

S

I

NG

L

E

P

H

A

S

E

R

L

O

W

S

I

D

E

L

U

C

O

R

P

O

R

A

T

I

O

N

M

O

D

E

L

R

E

F

R

I

G

E

R

A

N

T

F

U

L

L

L

O

A

D

A

M

P

S

S

E

R

I

AL

N

O

1

14

9

11

8

12

12

8

5

6

9

10

2

1

4

3

13

12

15

18

Reference # Description Part #

1 Base, top mount 00113282

1 Base, Satellite-fill 00113274

2 Cabinet 00113332

3 Cover 00113365

4 Chase, upper 00113381

5 Chase, lower 00113399

6 Collar 00113407

8 Deflector, single 501616

9 Lid, access 00113423

10 Box, thermostat 00113449

11 Gasket, top, Harmony 00113464

12 Gasket, ice entry 502824

13 Socket, bin signal 502334

14 Kit, ice entry, MCD400 00120279

15 Plate, ice tube mounting, MCD400 307071

Not shown Thermostat, bin level 500514

Not shown Diverter, ice 307277

Not shown Plate, blank, ice entry 00113498

Top Kit models MSC44SC

9

10

2

4

3

13

12

1

5

6

11

8

Reference # Description Part #

1 Base, Satellite-fill 00113290

2 Cabinet 00113340

3 Cover 00113373

4 Chase, upper 00113381

5 Chase, lower 00113399

6 Collar 00113407

8 Deflector, single 501616

9 Lid, access 00113423

10 Box, thermostat 00113449

11 Gasket, top, Harmony 00113464

12 Gasket, ice entry 502824

13 Socket, bin signal 502334

Not shown Thermostat, bin level 500514

Not shown Diverter, ice 307277

Not shown Plate, blank, ice entry 00113498

00117259R04

09/05

801 Church Lane • Easton, PA 18040, USA

Toll free (800) 523-9361 • (610) 252-7301

Fax (610) 250-0696 • www.follettice.com

Chewblet is a registered trademark of Follett Corporation, registered in the US.

/