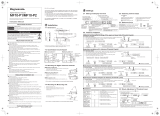

8.1 Menu structure and parameter description............................................ 24

8.1.1 Main display level and main menu......................................... 24

8.1.2 Measurement menu group..................................................... 25

8.1.3 I/O interface menu group: Q1 output..................................... 26

8.1.4 I/O interface menu group: Q2/Qa output, In1 input............. 27

8.1.5 Device menu group.................................................................. 28

8.1.6 Communication menu group.................................................. 28

8.1.7 Info menu group...................................................................... 28

8.2 Main display level..................................................................................... 28

8.3 Measurement............................................................................................ 29

8.3.1 Application settings................................................................. 29

8.3.2 Default settings........................................................................ 34

8.4 I/O interface.............................................................................................. 39

8.4.1 Q1 output................................................................................. 39

8.4.2 Q

2

/ Q

a

output..........................................................................

46

8.4.3 In1 input................................................................................... 48

8.5 Device........................................................................................................ 53

8.5.1 User level.................................................................................. 53

8.5.2 Reset........................................................................................ 53

8.5.3 Saving customer settings........................................................ 54

8.5.4 Language.................................................................................. 54

8.5.5 Display settings........................................................................ 54

8.5.6 Measurement laser................................................................. 55

8.6 Communication......................................................................................... 55

8.7 Info............................................................................................................. 55

8.7.1 Firmware verification............................................................... 55

8.7.2 Serial number.......................................................................... 56

8.7.3 Sensor operating hours........................................................... 56

8.7.4 Laser operating hours............................................................. 56

8.7.5 Sensor status........................................................................... 56

8.7.6 Part number............................................................................. 56

9 Operation via IO-Link........................................................................ 58

9.1 Process data............................................................................................. 58

9.2 Device data............................................................................................... 58

10 Operation via SOPAS ET................................................................... 59

11 Maintenance...................................................................................... 61

11.1 Cleaning..................................................................................................... 61

11.2 Maintenance plan..................................................................................... 61

12 Troubleshooting................................................................................. 62

12.1 General faults, warnings, and errors....................................................... 62

12.2 Detecting and displaying errors............................................................... 62

12.3 Information for service cases.................................................................. 63

CONTENTS

4

O P E R A T I N G I N S T R U C T I O N S | OD1000 8019642/18JN/2020-07-01 | SICK

Subject to change without notice