Page is loading ...

8

88

8

PROBLEM 1: THE UNIT HAS NO POWER

1. Check if the unit is switched ON.

2. Check the fuse. Replace with the same type if fuse is blown.

3. Check the power cord.

4. Verify that the unit is properly connected to the power source.

PROBLEM 2: TEMPERATURE DISPLAY IS ALWAYS ABOVE 400

o

C

Description: Constant display of above 400

o

C temperature from the panel

then displays “Err” on the panel after a few minutes.

SOLUTION:

The thermal sensor may be broken and needs to be replaced.

PROBLEM 3: TEMPERATURE DISPLAY IS ALWAYS BELOW 60

o

C

Description: Constant display of below 60

o

C temperature from the panel

then displays “Err” on the panel after a few minutes.

SOLUTION:

Turn OFF unit and then ON again. If Display still shows “Err” then the

Heating element may be broken and needs to be replaced.

PROBLEM 4: DISPLAY PANEL SHOWS UNRECOGNIZABLE

CHARACTERS

SOLUTION : Switch unit OFF, wait a few seconds and ON again. If problem

persists contact vendor

OTHER PROBLEMS NOT MENTIONED:

Contact the vendor.

OPERATING GUIDELINES

Automated Hot Bar

Soldering System

INSTRUCTION MANUAL

Thank you for purchasing the AOYUE 8011

Automated Hot Bar Soldering System.

Please read this manual before operating the equipment.

Keep manual in accessible place for future reference.

8011

2

22

2

Main Station

Power input: 220V

Station Dimensions: 400(w)x580(h)x580(d)mm

Power consumption: 500W peak

Temperature range: 100°C - 350°C

The 8011 Automated Hot Bar Soldering System is equipped

with a three way micro adjust system two Powerful magnified

camera and LCD screen for precise movement adjustment.

Its CPU controlled timer and temperature controls provide

precise timing and temperature stability. Finally its automated

pneumatic system provides accurate and easy repeatability .

SPECIFICATIONS

Specifications are subject to change without prior notice

PRODUCT DESCRIPTION

TABLE OF CONTENTS

Product Description ———————————–— 2

Specifications ————————————–——— 2

Safety Precautions ———————–—————— 3

Initial Setup ————————–———————— 3

Control Panel Guide ———–-————————— 4

Operating Guidelines ————————--—- 5 — 7

Basic Troubleshooting Guide ————–—–———

8

7

77

7

7. Upon finishing one complete automated cycle the previously entered

temperature and timer settings will be saved to the CPU memory.

Note: The Emergency stop button can be used to stop the hot bar tool from

automatically descending. (see “Emergency stop button” for details)

5. MANUAL CONTROL

1. Automatic or Manual Control can be selected by pressing the

SELECT button. (“10” from control panel guide).

2. When the RED Lamp is lighted it means the system is currently in

Manual control mode.

3. If the Green Lamp is lighted the system is in automatic control

mode, push the SELECT button to switch to manual control mode.

4. During the manual control mode the manual control buttons(“11

and 12” from control panel guide) will be activated.

5. Pressing the In/Out button (“12” from control panel guide) will

control the platform movement.

6. Pressing the UP/Down button (“11” from control panel guide) will

control the Hot Bar Tool movement.

7. The Platform can only be controlled when the Hot bar tool is at the

up position.

6. EMERGENCY STOP BUTTON

1. In case of immediate requirement to stop the automated soldering

cycle the Emergency Stop Button can be pushed. (“15” from

control panel guide)

2. When emergency stop button is engaged the hot bar soldering tool

would move to the “up” position while the platform would move into

the “in” position. The system would be locked to manual control

mode.

3. The Platform and hot bar tool can then be manually adjusted to the

adequate position.

4. To disengage Emergency stop mode , unlock the Emergency stop

button by turning it clockwise.

OPERATING GUIDELINES

6

66

6

IMPORTANT: Never allow temperature setting above 300 degrees Celsius

for pro-longed period. Temperature setting at lower temperature will

preserve heater life.

5. The Timer can be adjusted by pushing the “+” and “-” buttons of

the Timer control buttons. (“9” from control panel guide).

6. The Timer display (“8” from control panel guide) will show the

current set timer settings.

7. Timer settings can only be adjusted during automated control

mode.

Note: The Set Temperature and Timer settings will automatically be saved

into the CPU memory once one complete cycle of the automated

procedure is finished.

4. AUTOMATIC CONTROL

1. Automatic or Manual Control can be selected by pressing the

SELECT button. (“10” from control panel guide).

2. When the Green Lamp is lighted it means the system is currently

in Automatic control mode.

3. If the Red Lamp is lighted the system is in manual control mode,

push the SELECT button to switch to automatic control mode.

4.

To initiate the automatic soldering procedure push both start

buttons simultaneously (“13,16” from control panel guide).

5. The automatic soldering cycle:

●

The platform moves in

●

If platform is completely in, the hot bar soldering tool would

descend.

●

When the hot bar soldering tool has reached the platform count

down timer would commence.

●

With Count down completed, hot bar tool would move back up.

●

The platform slides out to original position.

6. The automatic soldering cycle can be repeated by pressing both

start buttons again.

OPERATING GUIDELINES

3

33

3

CAUTION: Improper usage can cause serious injury to personnel and/or damage

to equipment. For personnel safety, please follow these precautions:

●

Check each component after opening the package to make sure everything

is in good condition. Do not use item if visible damage is seen, report the

issue to your vendor.

●

Power off unit and unplug the device when moving the device from one loca-

tion to another.

●

Do not subject the main unit to physical shock

- Never drop or sharply jolt the unit.

- Contains delicate parts that may break if the unit is dropped.

●

Always connect power to a grounded receptacle.

●

Tip temperature may reach as high as 350°C when switched ON.

●

Disconnect from power source if the unit will not be used for a long periods.

●

Use only genuine replacement parts.

●

Soldering process produces smoke — use on well ventilated place.

●

Do not try to alter or repair unit, bring to qualified service center for repairs.

●

Never insert body parts between the paths of the moving platforms.

1. Place unit on top of a flat and stable work table.

2. LCD Monitor — Pull out the LCD Monitor mounting bracket on each

side of the unit. Mount both LCD monitors. Attach the 5 pin LCD moni-

tor connectors to the base of the upper control box and its other ends

to the LCD monitor.

3. Air compressor** — Attach Air compressor tube to the unit. Turn

off the main valve at the air compressor. Switch on the air compressor

when gauge at the air compressor reaches 0.2 MPA turn on the main

valve.

4. Make sure power switch is turned OFF before plugging the device to

the main power source.

Note: In order for pneumatic system to function, Compressed air should

be fed into system. ** Air compressor is sold separately.

SAFETY PRECAUTIONS

Initial Setup

4

44

4

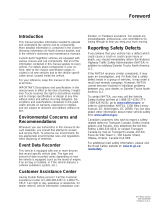

LEGEND:

1 — Pressure Adjustment Knob

2 — Pressure Gauge

3 — 8 pin camera input socket

4 — Brightness adjustment of Lower Lamp

5 — Brightness adjustment of Upper Lamp

6 — Temperature display.

“C” denotes actual Temperature, “c” Denotes Set Temperature

7 — Temperature Adjustment Buttons. “+” increase. “-” decrease.

8 — Timer Display

9 — Timer Adjustment Buttons.“+” increase. “-” decrease.

10 — Mode Selection Button.

Green lamp –Automatic control. Red lamp– Manual control

11 — Hot Bar module Descend and Ascend Button.

For use only in Manual Control.

12 — Adjustment Platform In/Out Button. For use only in Manual Control.

13 , 16 — Start Automation Button.

14 — Reserved Button.

15 — Emergency Stop Button for use during Automatic control.

AIR PRESSURE

CONTROL

TEMPERATURE

+ -

AUTO-

MATIC

CONTROL

MANUAL

CON-

TROL

SELECT

UP /

DOWN

IN/ OUT

MANUAL CONTROL

AOYUE

8011

AUTOMATED HOT BAR

SOLDERING SYSTEM

®

BRIGHTNESS

ADJUSTMENT

UPPER LOWER

Camera

Input

0010

-

--

-

+

++

+

1

2

3

4 5

6

7

8

9

10

11

12

START

EMERGENCY

START

VAC

13

14 15

16

CONTROL PANEL GUIDE

TIMER

+ -

5

55

5

Please refer to the CONTROL PANEL GUIDE page for buttons and display

panel directory.

1. INITIAL PROCEDURES

1. Make sure power switch (Located at the back of the unit) is turned

OFF before plugging the device to the main power source.

2. Switch ON the main power switch (Located at the back of the unit).

3. Display panels, 6 and 8 will display “C100” and “0010” default

parameters.

2. ADJUSTING PRESSURE

1. Adjust to desire pressure level using the Air pressure control Knob,

“1” from control panel guide. Pull on the knob to unlock it before

adjusting pressure level. Push knob back in to lock into place.

2. If Higher pressure is needed the pressure control knob located at

the left side of the unit can be adjusted for higher pressure level,

then use the Air pressure control Knob (“1” from control panel

guide) to fine adjust the pressure to desired level.

3. ADJUSTING TEMPERATURE AND TIMER

1. During automated control mode. Green lamp lighted.

2. Adjust to desire temperature settings using the temperature control

buttons. (“7” from control panel guide).

3. The Temperature display window (“6” from control panel guide).

Will initially display a number with the Capital letter “C” at the

beginning. This indicates the number displayed is the actual

temperature. Upon pressing the temperature control buttons. The

display will change to small letter “c” indicating the temperature is

being set and the number shown is the current set temperature for

the Hot bar soldering tool.

4. The heating element can be temporarily turned OFF and ON by

simultaneously pressing the “+” and “-” buttons of the temperature

adjustment buttons. The Display would show “OFF” to indicate the

heater is currently turned off.

OPERATING GUIDELINES

/