Allen-Bradley MicroLogix 1200 Reference guide

- Category

- Processors

- Type

- Reference guide

This manual is also suitable for

MicroLogix™ 1200

and MicroLogix 1500

Programmable

Controllers

(Bulletins 1762 and 1764)

Instruction Set

Reference Manual

Important User

Information

Because of the variety of uses for the products described in this

publication, those responsible for the application and use of this control

equipment must satisfy themselves that all necessary steps have been

taken to assure that each application and use meets all performance and

safety requirements, including any applicable laws, regulations, codes

and standards.

The illustrations, charts, sample programs and layout examples shown in

this guide are intended solely for purposes of example. Since there are

many variables and requirements associated with any particular

installation, Rockwell International Corporation does not assume

responsibility or liability (to include intellectual property liability) for

actual use based upon the examples shown in this publication.

Rockwell Automation publication SGI-1.1, Safety Guidelines for the

Application, Installation and Maintenance of Solid-State Control

(available from your local Rockwell Automation office), describes some

important differences between solid-state equipment and

electromechanical devices that should be taken into consideration when

applying products such as those described in this publication.

Reproduction of the contents of this copyrighted publication, in whole or

part, without written permission of Rockwell Automation, is prohibited.

Throughout this manual we use notes to make you aware of safety

considerations:

Attention statements help you to:

•

identify a hazard

•

avoid a hazard

•

recognize the consequences

PLC-5 is a registered trademark; and MicroLogix, SLC 500, RSLogix, and RSLinx are trademarks of Rockwell Automation.

Modbus is a trademark of Schneider Electric Incorporated.

DeviceNet is a trademark of Open DeviceNet Vendor Association (ODVA).

ATTENTION

!

Identifies information about practices or circumstances

that can lead to personal injury or death, property

damage or economic loss

IMPORTANT

Identifies information that is critical for successful

application and understanding of the product.

3 Publication 1762-RM001C-EN-P - November 2000

Summary of Changes

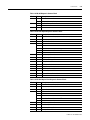

The information below summarizes the changes to this manual since

the last printing as publication 1762-RM001B-US-P, April 2000.

To help you locate new and updated information in this release of the

manual, we have included change bars as shown to the right of this

paragraph.

Firmware Revision History

Features are added to the controllers through firmware upgrades. Use

the listing below to be sure that your controller’s firmware is at the

level you need. Firmware upgrades are not required, except to allow

you access to the new features.

MicroLogix 1200

Catalog

Number

Series

Letter

Revision

Letter

Firmware

Release No.

Release Date Enhancement

1762-L24AWA

1762-L24BWA

1762-L40AWA

1762-L40BWA

A A FRN1 March 2000 Initial product release.

1762-L24AWA

1762-L24BWA

1762-L40AWA

1762-L40BWA

A B FRN2 May 2000 The trim pots (trimming potentiometers) on the controller

operated in reverse of the ladder logic. Corrected.

1762-L24AWA

1762-L24BWA

1762-L40AWA

1762-L40BWA

B A FRN3 November 2000 MicroLogix 1200 controllers now offer:

•

Full ASCII (read/write)

•

PTO Controlled Stop

•

PWM Ramping

•

RTC and String Messaging

•

Static Data File Protection

•

Comms Reset Pushbutton Bit

1762-L24BXB

1762-L40BXB

B A FRN3 November 2000 Initial product release. Supports all the features listed above

for the 1762-L24xWA and 1762-L40xWA controllers.

Publication 1762-RM001C-EN-P - November 2000

Summary of Changes 4

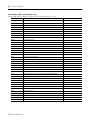

MicroLogix 1500

Catalog

Number

Series

Letter

Revision

Letter

Firmware

Release No.

Release Date Enhancement

1764-LSP A B FRN2 February 1999 Initial product release.

1764-LSP A C FRN3 October 1999 MicroLogix 1500 Controllers with 1764-LSP Processor can now

be used with Compact I/O (Bulletin 1769) Expansion Cables and

Power Supplies.

1764-LSP B A FRN4 April 2000 MicroLogix 1500 Controllers with 1764-LSP Processor can now

use:

•

String Data File Type

•

ASCII Instruction Set Support

•

Modbus RTU Slave protocol

•

Ramping, when using PWM outputs

•

Static Data File Protection

•

RTC Messaging

1764-LRP B A FRN4 April 2000 Initial product release. MicroLogix 1500 Controllers with

1764-LRP Processor has all the features of the 1764-LSP, plus:

•

Second communications port (isolated RS-232)

•

Data Logging capability

1764-LSP B B FRN5 October 2000 For both the 1764-LSP and LRP processors:

•

When using the PTO feature, the controller can now

perform a controlled stop when using PTO outputs. The

deceleration phase of the PTO can be initiated early via

ladder logic.

•

Enhanced program compare bit functionality in the Memory

Module.

1764-LRP B B FRN5 October 2000

Publication 1762-RM001C-EN-P - November 2000

Summary of Changes 5

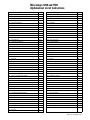

New Information

The table below lists sections that document new features and

additional information about existing features.

For This New Information See

Added MicroLogix 1200 1762-L24BXB and 1762-L40BXB Controllers Chapter 1, 5, 6

Added configuration information for several new I/O modules:

•

1762-IQ16, -OA8, -OB8, -OB16, -OW16, -IF4

•

1769-OB16P and -IT6

Chapter 1

Added section on Configuring Expansion I/O Using RSLogix 500 Chapter 1

Made minor changes to clarify data file numbering. Chapter 2

Modified section on Writing Data to the Real-Time Clock Chapter 3

In the Communications Status File, General Channel Status Block, Bit 15,

the Comms Toggle Push Button Bit, is now valid for MicroLogix 1200 and

MicroLogix 1500 (previously was only the MicroLogix 1500).

Chapter 3

Added IMPORTANT notes about using the High-Speed Counter (HSC). Chapter 5

Added IMPORTANT notes about using the High-Speed Outputs (PTO and

PWM).

Chapter 6

Modified text that describes the PWM Accel/Decel Delay (ADD)

parameter.

Chapter 6

Added PTO Controlled Stop (CS) parameter (MicroLogix 1500 only). Chapter 6

Modified text that describes the Scale (SCL) instruction. Chapter 10

Corrected text for the PID Reset Term (Ti). The last sentence now reads:

“A value of 1 adds the maximum integral term into the PID equation.”

(previously said that “a value of 1 adds the minimum integral term...”)

Chapter 19

MicroLogix 1200 Series B Controllers can use the entire set of ASCII

instructions

Chapter 20

Added section on Programming ASCII Instructions with information on

how to prevent communications shut-down when using ASCII

instructions.

Chapter 20

Added Ctrl-characters to the ASCII Character Set chart. Chapter 20

Added MSG File Element description. Chapter 21

The ASCII String Manipulation Error bit (S:5/15) now applies to

MicroLogix 1200 Series B Controllers as well as the MicroLogix 1500.

Appendix C

Added Fault Classification (non-user, recoverable, non-recoverable) to the

Fault Messages troubleshooting table.

Appendix D

Added new Error Code:

001A - User Program Incompatible with OS at Power-Up

Appendix D

Added alphabetical list of instructions for easy reference. Inside Back

Cover

ASCII Protocol can be used by MicroLogix 1200 Series B Controllers as

well as the MicroLogix 1500.

Appendix E

Updated Instruction Execution Times Appendix A

and B, and

throughout

manual

Publication 1762-RM001C-EN-P - November 2000

Summary of Changes 6

i Publication 1762-RM001C-EN-P

Table of Contents

Preface Who Should Use this Manual . . . . . . . . . . . . . . . . . . . . . . . . P-1

Purpose of this Manual. . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-1

Common Techniques Used in this Manual. . . . . . . . . . . . . . . P-2

Rockwell Automation Support . . . . . . . . . . . . . . . . . . . . . . . P-3

Chapter 1

I/O Configuration Embedded I/O. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

MicroLogix 1200 Expansion I/O . . . . . . . . . . . . . . . . . . . . . . 1-3

MicroLogix 1200 Expansion I/O Memory Mapping. . . . . . . . . 1-4

MicroLogix 1500 Compact™ Expansion I/O. . . . . . . . . . . . . . 1-7

MicroLogix 1500 Compact™ Expansion I/O Memory Mapping 1-9

I/O Addressing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-13

I/O Forcing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-14

Input Filtering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-14

Latching Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-15

Configuring Expansion I/O Using RSLogix 500 . . . . . . . . . . 1-18

Chapter 2

Controller Memory and File

Types

Controller Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Data Files. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Protecting Data Files During Download. . . . . . . . . . . . . . . . . 2-6

Static File Protection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Password Protection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Clearing the Controller Memory . . . . . . . . . . . . . . . . . . . . . 2-10

Allow Future Access Setting (OEM Lock). . . . . . . . . . . . . . . 2-10

Chapter 3

Function Files Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Real-Time Clock Function File . . . . . . . . . . . . . . . . . . . . . . . 3-3

Trim Pot Information Function File . . . . . . . . . . . . . . . . . . . . 3-5

Memory Module Information Function File . . . . . . . . . . . . . . 3-6

DAT Function File (MicroLogix 1500 only) . . . . . . . . . . . . . . 3-9

Base Hardware Information Function File . . . . . . . . . . . . . . 3-12

Communications Status File . . . . . . . . . . . . . . . . . . . . . . . . 3-13

Input/Output Status File . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-18

Chapter 4

Programming Instructions

Overview

Instruction Set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Using the Instruction Descriptions. . . . . . . . . . . . . . . . . . . . . 4-2

Publication 1762-RM001C-EN-P

Table of Contents ii

Chapter 5

Using the High-Speed

Counter

High-Speed Counter (HSC) Function File . . . . . . . . . . . . . . . 5-2

High-Speed Counter Function File Sub-Elements Summary . . 5-4

HSC Function File Sub-Elements. . . . . . . . . . . . . . . . . . . . . . 5-5

HSL - High-Speed Counter Load . . . . . . . . . . . . . . . . . . . . . 5-26

RAC - Reset Accumulated Value . . . . . . . . . . . . . . . . . . . . . 5-27

Chapter 6

Using High-Speed Outputs PTO - Pulse Train Output. . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Pulse Train Output Function. . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Pulse Train Outputs (PTO) Function File. . . . . . . . . . . . . . . . 6-6

Pulse Train Output Function File Sub-Elements Summary . . . 6-7

PWM - Pulse Width Modulation . . . . . . . . . . . . . . . . . . . . . 6-18

PWM Function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-18

Pulse Width Modulation (PWM) Function File . . . . . . . . . . . 6-19

Pulse Width Modulated Function File Elements Summary . . 6-20

Chapter 7

Relay-Type (Bit) Instructions XIC - Examine if Closed

XIO - Examine if Open . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

OTE - Output Energize. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

OTL - Output Latch, OTU - Output Unlatch . . . . . . . . . . . . . 7-4

ONS - One Shot. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-5

OSR - One Shot Rising, OSF - One Shot Falling. . . . . . . . . . . 7-6

Chapter 8

Timer and Counter

Instructions

Timer Instructions Overview . . . . . . . . . . . . . . . . . . . . . . . . 8-1

TON - Timer, On-Delay . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-4

TOF - Timer, Off-Delay . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-5

RTO - Retentive Timer, On-Delay . . . . . . . . . . . . . . . . . . . . . 8-6

How Counters Work . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-7

CTU - Count Up, CTD - Count Down . . . . . . . . . . . . . . . . . . 8-9

RES - Reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-10

Chapter 9

Compare Instructions Using the Compare Instructions . . . . . . . . . . . . . . . . . . . . . . 9-2

EQU - Equal, NEQ - Not Equal . . . . . . . . . . . . . . . . . . . . . . . 9-3

GRT - Greater Than, LES - Less Than . . . . . . . . . . . . . . . . . . 9-4

GEQ - Greater Than or Equal To, LEQ - Less Than or Equal To 9-5

MEQ - Mask Compare for Equal . . . . . . . . . . . . . . . . . . . . . . 9-6

LIM - Limit Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-7

Publication 1762-RM001C-EN-P

Table of Contents iii

Chapter 10

Math Instructions Using the Math Instructions . . . . . . . . . . . . . . . . . . . . . . . . 10-2

Updates to Math Status Bits . . . . . . . . . . . . . . . . . . . . . . . . 10-3

ADD - Add, SUB - Subtract . . . . . . . . . . . . . . . . . . . . . . . . . 10-4

MUL - Multiply, DIV - Divide . . . . . . . . . . . . . . . . . . . . . . . 10-5

NEG - Negate. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-6

CLR - Clear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-6

SCL - Scale. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-7

SCP - Scale with Parameters . . . . . . . . . . . . . . . . . . . . . . . . 10-8

SQR - Square Root . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-9

SWP - Swap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-10

Chapter 11

Conversion Instructions Using Decode and Encode Instructions . . . . . . . . . . . . . . . . 11-1

DCD - Decode 4 to 1-of-16. . . . . . . . . . . . . . . . . . . . . . . . . 11-2

ENC - Encode 1-of-16 to 4 . . . . . . . . . . . . . . . . . . . . . . . . . 11-3

FRD - Convert from Binary Coded Decimal (BCD). . . . . . . . 11-4

TOD - Convert to Binary Coded Decimal (BCD) . . . . . . . . . 11-8

Chapter 12

Logical Instructions Using Logical Instructions. . . . . . . . . . . . . . . . . . . . . . . . . . 12-1

Updates to Math Status Bits . . . . . . . . . . . . . . . . . . . . . . . . 12-2

AND - Bit-Wise AND . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-3

OR - Logical OR. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-4

XOR - Exclusive OR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-5

NOT - Logical NOT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-6

Chapter 13

Move Instructions MOV - Move . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-1

MVM - Masked Move . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-3

Chapter 14

File Instructions COP - Copy File. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-2

FLL - Fill File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-3

BSL - Bit Shift Left . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-4

BSR - Bit Shift Right . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-6

FFL - First In, First Out (FIFO) Load . . . . . . . . . . . . . . . . . . 14-8

FFU - First In, First Out (FIFO) Unload . . . . . . . . . . . . . . . 14-11

LFL - Last In, First Out (LIFO) Load. . . . . . . . . . . . . . . . . . 14-14

LFU - Last In, First Out (LIFO) Unload. . . . . . . . . . . . . . . . 14-17

Publication 1762-RM001C-EN-P

Table of Contents iv

Chapter 15

Sequencer Instructions SQC- Sequencer Compare . . . . . . . . . . . . . . . . . . . . . . . . . 15-2

SQO- Sequencer Output. . . . . . . . . . . . . . . . . . . . . . . . . . . 15-5

SQL - Sequencer Load . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-8

Chapter 16

Program Control Instructions JMP - Jump to Label. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16-1

LBL - Label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16-2

JSR - Jump to Subroutine . . . . . . . . . . . . . . . . . . . . . . . . . . 16-2

SBR - Subroutine Label. . . . . . . . . . . . . . . . . . . . . . . . . . . . 16-3

RET - Return from Subroutine. . . . . . . . . . . . . . . . . . . . . . . 16-3

SUS - Suspend . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16-4

TND - Temporary End . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16-4

END - Program End . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16-5

MCR - Master Control Reset . . . . . . . . . . . . . . . . . . . . . . . . 16-5

Chapter 17

Input and Output Instructions IIM - Immediate Input with Mask . . . . . . . . . . . . . . . . . . . . 17-1

IOM - Immediate Output with Mask . . . . . . . . . . . . . . . . . . 17-3

REF- I/O Refresh . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17-4

Chapter 18

Using Interrupts Information About Using Interrupts . . . . . . . . . . . . . . . . . . 18-2

User Interrupt Instructions . . . . . . . . . . . . . . . . . . . . . . . . . 18-7

INT - Interrupt Subroutine . . . . . . . . . . . . . . . . . . . . . . . . . 18-7

STS - Selectable Timed Start . . . . . . . . . . . . . . . . . . . . . . . . 18-8

UID - User Interrupt Disable. . . . . . . . . . . . . . . . . . . . . . . . 18-9

UIE - User Interrupt Enable . . . . . . . . . . . . . . . . . . . . . . . 18-10

UIF - User Interrupt Flush . . . . . . . . . . . . . . . . . . . . . . . . 18-11

Using the Selectable Timed Interrupt (STI) Function File . . 18-12

Using the Event Input Interrupt (EII) Function File . . . . . . 18-17

Chapter 19

Process Control Instruction The PID Concept . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19-1

The PID Equation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19-2

PD Data File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19-2

PID - Proportional Integral Derivative . . . . . . . . . . . . . . . . . 19-3

Input Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19-4

Output Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19-7

Tuning Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19-8

Runtime Errors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19-16

Analog I/O Scaling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19-17

Application Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19-18

Application Examples. . . . . . . . . . . . . . . . . . . . . . . . . . . . 19-22

Publication 1762-RM001C-EN-P

Table of Contents v

Chapter 20

ASCII Instructions General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20-1

ASCII Instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20-1

Instruction Types and Operation. . . . . . . . . . . . . . . . . . . . . 20-2

Protocol Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20-4

String (ST) Data File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20-5

Control Data File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20-6

ACL - ASCII Clear Buffers . . . . . . . . . . . . . . . . . . . . . . . . . . 20-7

AIC - ASCII Integer to String . . . . . . . . . . . . . . . . . . . . . . . . 20-8

AWA - ASCII Write with Append. . . . . . . . . . . . . . . . . . . . . 20-9

AWT - ASCII Write . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20-11

ABL - Test Buffer for Line. . . . . . . . . . . . . . . . . . . . . . . . . 20-14

ACB - Number of Characters in Buffer. . . . . . . . . . . . . . . . 20-15

ACI - String to Integer . . . . . . . . . . . . . . . . . . . . . . . . . . . 20-16

ACN - String Concatenate . . . . . . . . . . . . . . . . . . . . . . . . . 20-18

AEX - String Extract . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20-19

AHL - ASCII Handshake Lines. . . . . . . . . . . . . . . . . . . . . . 20-20

ARD - ASCII Read Characters . . . . . . . . . . . . . . . . . . . . . . 20-22

ARL - ASCII Read Line . . . . . . . . . . . . . . . . . . . . . . . . . . . 20-23

ASC - String Search. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20-25

ASR - ASCII String Compare . . . . . . . . . . . . . . . . . . . . . . . 20-26

Timing Diagram for ARD, ARL, AWA, and AWT Instructions 20-28

Using In-line Indirection. . . . . . . . . . . . . . . . . . . . . . . . . . 20-29

ASCII Instruction Error Codes . . . . . . . . . . . . . . . . . . . . . . 20-30

ASCII Character Set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20-31

Chapter 21

Communications Instructions Messaging Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21-1

MSG - Message . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21-3

The Message File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21-4

Local Messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21-7

Configuring a Local Message. . . . . . . . . . . . . . . . . . . . . . . . 21-9

Remote Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21-16

Configuring a Remote Message . . . . . . . . . . . . . . . . . . . . . 21-18

MSG Instruction Error Codes. . . . . . . . . . . . . . . . . . . . . . . 21-21

Timing Diagram for the MSG Instruction . . . . . . . . . . . . . . 21-23

SVC - Service Communications . . . . . . . . . . . . . . . . . . . . . 21-26

MSG Instruction Ladder Logic . . . . . . . . . . . . . . . . . . . . . . 21-28

Local Messaging Examples . . . . . . . . . . . . . . . . . . . . . . . . 21-29

Publication 1762-RM001C-EN-P

Table of Contents vi

Chapter 22

Data Logging

(MicroLogix 1500 1764-LRP

Processor only)

Queues and Records . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22-2

Configuring Data Log Queues . . . . . . . . . . . . . . . . . . . . . . 22-6

DLG - Data Log Instruction. . . . . . . . . . . . . . . . . . . . . . . . . 22-8

Data Log Status File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22-9

Retrieving (Reading) Records . . . . . . . . . . . . . . . . . . . . . . 22-11

Accessing the Retrieval File . . . . . . . . . . . . . . . . . . . . . . . 22-11

Conditions that Will Erase the Data Retrieval File . . . . . . . 22-13

Appendix A

MicroLogix 1200 Memory

Usage and Instruction

Execution Time

Programming Instructions Memory Usage and Execution Time A-1

MicroLogix 1200 Scan Time Worksheet. . . . . . . . . . . . . . . . . A-7

Appendix B

MicroLogix 1500 Memory

Usage and Instruction

Execution Time

Programming Instructions Memory usage and Execution Time B-1

MicroLogix 1500 Scan Time Worksheet. . . . . . . . . . . . . . . . . B-6

Appendix C

System Status File Status File Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-2

Status File Details. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-3

Appendix D

Fault Messages and Error

Codes

Identifying Controller Faults . . . . . . . . . . . . . . . . . . . . . . . . . D-1

Contacting Rockwell Automation for Assistance. . . . . . . . . . . D-9

Appendix E

Protocol Configuration DH-485 Communication Protocol . . . . . . . . . . . . . . . . . . . . . E-2

DF1 Full-Duplex Protocol. . . . . . . . . . . . . . . . . . . . . . . . . . . E-5

DF1 Half-Duplex Protocol . . . . . . . . . . . . . . . . . . . . . . . . . . E-6

Modbus™ RTU Slave Protocol . . . . . . . . . . . . . . . . . . . . . . . E-9

ASCII Driver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-13

Glossary

Index

MicroLogix 1200 and 1500 Alphabetical List of Instructions

1 Publication 1762-RM001C-EN-P

Preface

Read this preface to familiarize yourself with the rest of the manual. It

provides information concerning:

•

who should use this manual

•

the purpose of this manual

•

related documentation

•

conventions used in this manual

•

Rockwell Automation support

Who Should Use this

Manual

Use this manual if you are responsible for designing, installing,

programming, or troubleshooting control systems that use MicroLogix

1200 or MicroLogix 1500 controllers.

You should have a basic understanding of electrical circuitry and

familiarity with relay logic. If you do not, obtain the proper training

before using this product.

Purpose of this Manual

This manual is a reference guide for MicroLogix 1200 and MicroLogix

1500 controllers. It describes the procedures you use to program and

troubleshoot your controller. This manual:

•

gives you an overview of the file types used by the controllers

•

provides the instruction set for the controllers

•

contains application examples to show the instruction set in use

Publication 1762-RM001C-EN-P

Preface 2

Related Documentation

The following documents contain additional information concerning

Rockwell Automation products. To obtain a copy, contact your local

Rockwell Automation office or distributor.

Common Techniques

Used in this Manual

The following conventions are used throughout this manual:

•

Bulleted lists such as this one provide information, not procedural

steps.

•

Numbered lists provide sequential steps or hierarchical information.

•

Italic type is used for emphasis.

•

Change bars appear beside information that has been changed or

added since the last revision of this manual. Change bars appear in

the margin as shown to the right of this paragraph.

For Read this Document Document Number

Information on understanding and applying micro controllers. MicroMentor 1761-MMB

Information on mounting and wiring the MicroLogix 1200 Programmable

Controller, including a mounting template and door labels.

MicroLogix 1200 Programmable

Controllers Installation Instructions

1762-IN006C-MU-P

Detailed information on planning, mounting, wiring, and troubleshooting

your MicroLogix 1200 system.

MicroLogix 1200 Programmable

Controllers User Manual

1762-UM001B-EN-P

Information on mounting and wiring the MicroLogix 1500 Base Units,

including a mounting template for easy installation

MicroLogix 1500 Programmable

Controllers Base Unit Installation

Instructions

1764-IN001A-ML-P

Detailed information on planning, mounting, wiring, and troubleshooting

your MicroLogix 1500 system.

MicroLogix 1500 Programmable

Controllers User Manual

1764-UM001A-US-P

A description on how to install and connect an AIC+. This manual also

contains information on network wiring.

Advanced Interface Converter (AIC+) User

Manual

1761-6.4

Information on how to install, configure, and commission a DNI DeviceNet™ Interface User Manual 1761-6.5

Information on DF1 open protocol. DF1 Protocol and Command Set

Reference Manual

1770-6.5.16

In-depth information on grounding and wiring Allen-Bradley

programmable controllers

Allen-Bradley Programmable Controller

Grounding and Wiring Guidelines

1770-4.1

A description of important differences between solid-state programmable

controller products and hard-wired electromechanical devices

Application Considerations for

Solid-State Controls

SGI-1.1

An article on wire sizes and types for grounding electrical equipment National Electrical Code - Published by the National Fire

Protection Association of Boston, MA.

A complete listing of current documentation, including ordering

instructions. Also indicates whether the documents are available on

CD-ROM or in multi-languages.

Allen-Bradley Publication Index SD499

A glossary of industrial automation terms and abbreviations Allen-Bradley Industrial Automation

Glossary

AG-7.1

Publication 1762-RM001C-EN-P

Preface 3

Rockwell Automation

Support

Rockwell Automation offers support services worldwide, with over 75

Sales/Support Offices, 512 authorized Distributors and 260 authorized

Systems Integrators located throughout the United States alone, plus

Rockwell Automation representatives in every major country in the world.

Local Product Support

Contact your local Rockwell Automation representative for:

•

sales and order support

•

product technical training

•

warranty support

•

support service agreements

Technical Product Assistance

If you need to contact Rockwell Automation for technical assistance,

please review the Fault Messages and Error Codes on page D-1 and the

Troubleshooting appendix in your controller’s User Manual first. Then call

your local Rockwell Automation representative. Rockwell Automation

phone numbers appear on the back of this manual.

Your Questions or Comments on this Manual

If you find a problem with this manual, or you have any suggestions for

how this manual could be made more useful to you, please contact us at

the address below:

Rockwell Automation

Control and Information Group

Technical Communication, Dept. A602V

P.O. Box 2086

Milwaukee, WI 53201-2086

or visit our internet page at:

http://www.ab.com/micrologix

or http://www.rockwellautomation.com

Publication 1762-RM001C-EN-P

Preface 4

1 Publication 1762-RM001C-EN-P

Chapter

1

I/O Configuration

This section discusses the various aspects of Input and Output features of

the MicroLogix 1200 and MicroLogix 1500 controllers. Each controller

comes with a certain amount of embedded I/O, which is physically located

on the controller. The controller also allows for adding expansion I/O.

This section discusses the following I/O functions:

•

Embedded I/O on page 1-1

•

MicroLogix 1200 Expansion I/O on page 1-3

•

MicroLogix 1200 Expansion I/O Memory Mapping on page 1-4

•

MicroLogix 1500 Compact™ Expansion I/O on page 1-7

•

MicroLogix 1500 Compact™ Expansion I/O Memory Mapping on

page 1-9

•

I/O Addressing on page 1-13

•

I/O Forcing on page 1-14

•

Input Filtering on page 1-14

•

Latching Inputs on page 1-15

Embedded I/O

The MicroLogix 1200 and 1500 provide discrete I/O that is built into the

controller as listed in the following table. These I/O points are referred to as

Embedded I/O.

Controller Family Inputs Outputs

Quantity Type Quantity Type

MicroLogix 1200

Controllers

1762-L24BWA 14 24V dc 10 relay

1762-L24AWA 14 120V ac 10 relay

1762-L24BXB 14 24V dc 10 5 relay

5 FET

1762-L40BWA 24 24V dc 16 relay

1762-L40AWA 24 120V ac 16 relay

1762-L40BXB 24 24V dc 16 8 relay

8 FET

MicroLogix 1500

Base Units

1764-24BWA 12 24V dc 12 relay

1764-24AWA 12 120V ac 12 relay

1764-28BXB 16 24V dc 12 6 relay

6 FET

Publication 1762-RM001C-EN-P

1-2 I/O Configuration

AC embedded inputs have fixed input filters. DC embedded inputs have

configurable input filters for a number of special functions that can be

used in your application. These are: high-speed counting, event

interrupts, and latching inputs. The 1764-28BXB has two high-speed

outputs for use as pulse train output (PTO) and/or pulse width

modulation (PWM) outputs. The 1762-L24BXB and -L40BXB each have

one high-speed output.

Publication 1762-RM001C-EN-P

I/O Configuration 1-3

MicroLogix 1200

Expansion I/O

If the application requires more I/O than the controller provides, you can

attach I/O modules. These additional modules are called expansion I/O.

Expansion I/O Modules

MicroLogix 1200 expansion I/O (Bulletin 1762) is used to provide discrete

and analog inputs and outputs and, in the future, specialty modules. For

the MicroLogix 1200, you can attach up to six additional I/O modules.

The number of 1762 I/O modules that can be attached to the MicroLogix

1200 is dependent on the amount of power required by the I/O modules.

See your MicroLogix 1200 User Manual, publication 1762-UM001A-US-P

for more information on valid configurations.

Addressing Expansion I/O Slots

The figure below shows the addressing for the MicroLogix 1200 and its

I/O.

The expansion I/O is addressed as slots 1 through 6 (the controller’s

embedded I/O is addressed as slot 0). Modules are counted from left to

right as shown below.

NOTE

Visit the MicroLogix web site (http://www.ab.com/

micrologix.) for the MicroLogix 1200 Expansion I/O

System Qualifier.

NOTE

In most cases, you can use the following address format:

X:s/b (X = file type letter, s = slot number, b = bit number)

See I/O Addressing on page 1-13 for complete

information on address formats.

Expansion I/O

Embedded I/O = Slot 0

Slot 1

Slot 2

Publication 1762-RM001C-EN-P

1-4 I/O Configuration

MicroLogix 1200

Expansion I/O Memory

Mapping

Discrete I/O Configuration

1762-IA8 and 1762-IQ8 Input Image

For each input module, the input data file contains the current state of the

field input points. Bit positions 0 through 7 correspond to input terminals

0 through 7.

r = read only, x = not used, always at a 0 or OFF state

1762-IQ16 Input Image

For each input module, the input data file contains the current state of the

field input points. Bit positions 0 through 15 correspond to input

terminals 0 through 15.

r = read only

1762-OA8, 1762-OB8, and 1762-OW8 Output Image

For each output module, the output data file contains the

controller-directed state of the discrete output points. Bit positions 0

through 7 correspond to output terminals 0 through 7.

r/w = read and write, 0 = always at a 0 or OFF state

1762-OB16 and 1762-OW16 Output Image

For each output module, the output data file contains the

controller-directed state of the discrete output points. Bit positions 0

through 15 correspond to output terminals 0 through 15.

r/w = read and write

Word

Bit Position

1514131211109876543210

0xxxxxxxxrrrrrrrr

Word

Bit Position

1514131211109876543210

0rrrrrrrrrrrrrrrr

Word

Bit Position

1514131211109876543210

000000000r/wr/wr/wr/wr/wr/wr/wr/w

Word

Bit Position

1514131211109876543210

0 r/w r/w r/w r/w r/w r/w r/w r/w r/w r/w r/w r/w r/w r/w r/w r/w

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

-

13

13

-

14

14

-

15

15

-

16

16

-

17

17

-

18

18

-

19

19

-

20

20

-

21

21

-

22

22

-

23

23

-

24

24

-

25

25

-

26

26

-

27

27

-

28

28

-

29

29

-

30

30

-

31

31

-

32

32

-

33

33

-

34

34

-

35

35

-

36

36

-

37

37

-

38

38

-

39

39

-

40

40

-

41

41

-

42

42

-

43

43

-

44

44

-

45

45

-

46

46

-

47

47

-

48

48

-

49

49

-

50

50

-

51

51

-

52

52

-

53

53

-

54

54

-

55

55

-

56

56

-

57

57

-

58

58

-

59

59

-

60

60

-

61

61

-

62

62

-

63

63

-

64

64

-

65

65

-

66

66

-

67

67

-

68

68

-

69

69

-

70

70

-

71

71

-

72

72

-

73

73

-

74

74

-

75

75

-

76

76

-

77

77

-

78

78

-

79

79

-

80

80

-

81

81

-

82

82

-

83

83

-

84

84

-

85

85

-

86

86

-

87

87

-

88

88

-

89

89

-

90

90

-

91

91

-

92

92

-

93

93

-

94

94

-

95

95

-

96

96

-

97

97

-

98

98

-

99

99

-

100

100

-

101

101

-

102

102

-

103

103

-

104

104

-

105

105

-

106

106

-

107

107

-

108

108

-

109

109

-

110

110

-

111

111

-

112

112

-

113

113

-

114

114

-

115

115

-

116

116

-

117

117

-

118

118

-

119

119

-

120

120

-

121

121

-

122

122

-

123

123

-

124

124

-

125

125

-

126

126

-

127

127

-

128

128

-

129

129

-

130

130

-

131

131

-

132

132

-

133

133

-

134

134

-

135

135

-

136

136

-

137

137

-

138

138

-

139

139

-

140

140

-

141

141

-

142

142

-

143

143

-

144

144

-

145

145

-

146

146

-

147

147

-

148

148

-

149

149

-

150

150

-

151

151

-

152

152

-

153

153

-

154

154

-

155

155

-

156

156

-

157

157

-

158

158

-

159

159

-

160

160

-

161

161

-

162

162

-

163

163

-

164

164

-

165

165

-

166

166

-

167

167

-

168

168

-

169

169

-

170

170

-

171

171

-

172

172

-

173

173

-

174

174

-

175

175

-

176

176

-

177

177

-

178

178

-

179

179

-

180

180

-

181

181

-

182

182

-

183

183

-

184

184

-

185

185

-

186

186

-

187

187

-

188

188

-

189

189

-

190

190

-

191

191

-

192

192

-

193

193

-

194

194

-

195

195

-

196

196

-

197

197

-

198

198

-

199

199

-

200

200

-

201

201

-

202

202

-

203

203

-

204

204

-

205

205

-

206

206

-

207

207

-

208

208

-

209

209

-

210

210

-

211

211

-

212

212

-

213

213

-

214

214

-

215

215

-

216

216

-

217

217

-

218

218

-

219

219

-

220

220

-

221

221

-

222

222

-

223

223

-

224

224

-

225

225

-

226

226

-

227

227

-

228

228

-

229

229

-

230

230

-

231

231

-

232

232

-

233

233

-

234

234

-

235

235

-

236

236

-

237

237

-

238

238

-

239

239

-

240

240

-

241

241

-

242

242

-

243

243

-

244

244

-

245

245

-

246

246

-

247

247

-

248

248

-

249

249

-

250

250

-

251

251

-

252

252

-

253

253

-

254

254

-

255

255

-

256

256

-

257

257

-

258

258

-

259

259

-

260

260

-

261

261

-

262

262

-

263

263

-

264

264

-

265

265

-

266

266

-

267

267

-

268

268

-

269

269

-

270

270

-

271

271

-

272

272

-

273

273

-

274

274

-

275

275

-

276

276

-

277

277

-

278

278

-

279

279

-

280

280

-

281

281

-

282

282

-

283

283

-

284

284

-

285

285

-

286

286

-

287

287

-

288

288

-

289

289

-

290

290

-

291

291

-

292

292

-

293

293

-

294

294

-

295

295

-

296

296

-

297

297

-

298

298

-

299

299

-

300

300

-

301

301

-

302

302

-

303

303

-

304

304

-

305

305

-

306

306

-

307

307

-

308

308

-

309

309

-

310

310

-

311

311

-

312

312

-

313

313

-

314

314

-

315

315

-

316

316

-

317

317

-

318

318

-

319

319

-

320

320

-

321

321

-

322

322

-

323

323

-

324

324

-

325

325

-

326

326

-

327

327

-

328

328

-

329

329

-

330

330

-

331

331

-

332

332

-

333

333

-

334

334

-

335

335

-

336

336

-

337

337

-

338

338

-

339

339

-

340

340

-

341

341

-

342

342

-

343

343

-

344

344

-

345

345

-

346

346

-

347

347

-

348

348

-

349

349

-

350

350

-

351

351

-

352

352

-

353

353

-

354

354

-

355

355

-

356

356

-

357

357

-

358

358

-

359

359

-

360

360

-

361

361

-

362

362

-

363

363

-

364

364

-

365

365

-

366

366

-

367

367

-

368

368

-

369

369

-

370

370

-

371

371

-

372

372

-

373

373

-

374

374

-

375

375

-

376

376

-

377

377

-

378

378

-

379

379

-

380

380

-

381

381

-

382

382

-

383

383

-

384

384

-

385

385

-

386

386

-

387

387

-

388

388

-

389

389

-

390

390

-

391

391

-

392

392

-

393

393

-

394

394

-

395

395

-

396

396

-

397

397

-

398

398

-

399

399

-

400

400

-

401

401

-

402

402

-

403

403

-

404

404

-

405

405

-

406

406

-

407

407

-

408

408

-

409

409

-

410

410

-

411

411

-

412

412

-

413

413

-

414

414

-

415

415

-

416

416

-

417

417

-

418

418

-

419

419

-

420

420

-

421

421

-

422

422

-

423

423

-

424

424

Allen-Bradley MicroLogix 1200 Reference guide

- Category

- Processors

- Type

- Reference guide

- This manual is also suitable for

Ask a question and I''ll find the answer in the document

Finding information in a document is now easier with AI

Related papers

-

Allen-Bradley 1747–PT1 User manual

-

Allen-Bradley micrologix 1500 User manual

-

Allen-Bradley SLC 500 Reference guide

-

Allen-Bradley micrologix 1500 User manual

-

Allen-Bradley MicroLogix 1100 User manual

-

Allen-Bradley MicroLogix 1400 User manual

-

Allen-Bradley MicroLogix 1200 User manual

-

Allen-Bradley 1762-OF4 Installation Instructions Manual

-

Allen-Bradley SLC 500 Series User manual

-

Allen-Bradley 1763-L16BBB Instruction Set Reference Manual

Other documents

-

Mitsubishi Electric MELSEC iQ-R Programming Manual

-

Spectrum Controls 1762sc-IF4OF4 User guide

-

Rockwell Automation 1763-L16BBB Installation Instructions Manual

-

ProSoft Technology MVI69E-GSC User manual

ProSoft Technology MVI69E-GSC User manual

-

ProSoft Technology MVI69-DFNT User manual

ProSoft Technology MVI69-DFNT User manual

-

Novus DigiRail-4C Communications Manual

-

ProSoft Technology MVI69-S3964R User manual

ProSoft Technology MVI69-S3964R User manual

-

ProSoft Technology MVI69-DNPSNET User manual

-

ProSoft Technology MVI69-DNP User manual

ProSoft Technology MVI69-DNP User manual

-

Rockwell Automation 2711C-T6C Quick start guide

Rockwell Automation 2711C-T6C Quick start guide