Page is loading ...

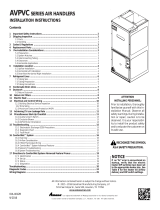

AMVT***P1400**

AIR HANDLERS INSTALLATION &

OPERATING INSTRUCTIONS

© 2022-2023 Daikin Comfort Technologies Manufacturing, L.P.

www.goodmanmfg.com - or - www.amana-hac.com

19001 Kermier Rd., Waller, TX 77484

P/N: IOG-4040B Date: February 2023

Contents

1 Important Safety Instructions .................................... 3

2 Shipping Inspection ................................................... 3

2.1 Parts ....................................................................... 3

2.2 Handling ................................................................. 3

2.3 Shipping Material Removal..................................... 3

3 Codes & Regulations ................................................. 3

4 Replacement Parts ..................................................... 3

5 Pre-Installation Considerations ............................... 3

5.1 Preparation ............................................................. 3

5.2 System Matches ..................................................... 3

5.3 Interconnecting Tubing ........................................... 3

5.4 Clearances ............................................................. 3

5.5 Horizontal Applications ........................................... 4

6 Installation Location ................................................... 4

4

...................... 5

6.3 Horizontal Right Installation ................... 5

6.4 Humid Environment Installations ............................ 5

6.4.1 All Installations – Humid Environments ............... 5

5

6.4.1.3 Horizontal Installations – Humid Environments 5

7 Refrigerant Lines ........................................................ 6

7.1 Tubing Size ............................................................. 6

7.2 Tubing Preparation ................................................. 6

7.3 Tubing Connections ................................................ 7

7.4 Thermal Expansion Valve System Adjustment ....... 9

8 Condensate Drain Lines ........................................... 10

9 Ductwork .................................................................... 11

9.1 Return Ductwork .................................................... 11

10 Return Air Filters ..................................................... 11

11 Electric Heat ............................................................. 11

12 Electrical and Control Wiring ................................. 14

12.1 Building Electrical Service Inspection .................. 14

WARNING

This device, which was assembled by Daikin Comfort Technologies

FCC: FCC ID QOQBGM111. And this international radiator has an

Industry Canada ID: IC 5123A-BGM111.

This device complies with Part 15 of the FCC’s Rules. Operation of this

device is subject to two conditions:

interference that may cause undesirable operation.

And this device meets the applicable Industry Canada technical

Silicon Laboratories Finland Oy, which can be contacted by calling

The FCC responsible party is Daikin Comfort Technologies

Manufacturing, L.P. may be contacted by calling 713-861-2500, or at

This equipment complies with FCC radiation exposure limits. To ensure

compliance, human proximity to the antenna shall not be less than

20 cm during normal operations.

®

is a registered trademark of Maytag Corporation or its related companies and is used under license. All rights reserved.

WARNING

2

12.2 Wire Sizing .......................................................... 14

............ 14

12.4 Electrical Connections – Supply Voltage ............. 14

........... 15

12.4.2 Air Handler - Non-Circuit Breaker Heat Kits ..... 15

12.4.3 Air Handler With Circuit Breaker Heat Kit ......... 15

12.5 Low Voltage Connections .................................... 15

12.5.1 Thermostats ...................................................... 15

13 CoolCloud HVAC Phone Menu ............................... 15

14 Quick Start Guide for Communication Outdoor Units 16

14.1 Charging .............................................................. 17

15 Quick Start Guide for Non-Communicating Outdoor

Units ...................................................................................... 17

..................................................... 19

............................................ 19

18 Start-Up Procedure.................................................. 19

............................................................... 19

.......................... 20

..................................................... 21

22 Electric Air Cleaner Warning .................................. 21

........................ 21

24 Start-up Procedure .................................................. 22

25 Regular Maintenance .............................................. 22

...................... 23

27 Air Handler Display ................................................. 25

............................................................ 27

29 Wiring Diagram ........................................................ 28

30 Start-Up Checklist ................................................... 31

RECOGNIZE SYMBOL THIS

AS A SAFETY PRECAUTION

NOTE: SPECIFICATIONS AND PERFORMANCE DATA LISTED

HEREIN ARE SUBJECT TO CHANGE WITHOUT NOTICE.

WARNING

HIGH VOLTAGE

-

-

WARNING

WARNING

-

DO NOT

CAUTION

WARNING

UNBROKEN

-

-

Carbon monoxide producing devices (such as an automobile, space

heater, gas water heater, etc.) should not be operated in enclosed areas

such as unvenlated garages, ulity rooms or parking areas because of

the danger of carbon monoxide (CO) poisoning resulng from the exhaust

emissions. If a furnace or air handler is installed in an enclosed area such

as a garage, ulity room or parking area and a carbon monoxide producing

device is operated therein, there must be adequate, direct outside

venlaon.

CARBON MONOXIDE POISONING HAZARD

Special Warning for In stallao n of Furnace or Air Handling Units in

Enclosed Areas su ch as Garages, Ulity Rooms or Parking Areas

This venlaon is necessary to avoid the danger of CO poisoning which

can occur if a carbon monoxide producing device connues to operate in

the enclosed area. Carbon monoxide emissions can be (re)circulated

throughout the structure if the furnace or air handler is operang in any

mode.

B10259-216

CO can cause serious illness including permanent brain

damage or death.

Los equipos ó aparatos que producen monóxido

(tal como automóvil, calentador de gas, calentador de

carbono (CO) que resulta de las

emisiones de gases de com busón.

gas, etc) no deben ser operados en áreas cerradas debido al riesgo

de envenenamiento por monóxido de

Si el equipo ó aparato se opera en

dichas áreas, debe exisr una adecuada venlación directa al exterior.

de carbono

agua por medio de

Advertencia especial para la instalación de calentadores ó manejadoras

de aire en áreas cerradas como estacionamientos ó cuartos de servicio.

B10259-216

RIESGO DE INTOXICACIÓN POR MONÓXIDO DE CARBONO

El monóxido de carbono puede causar enfermedades severas

como daño cerebral permanente ó muerte.

Las emisiones de monóxido de carbono pueden circular a través

del aparato cuando se opera en cualquier modo.

Averssement special au sujet de l'installaon d'appareils de chauffage

ou de traitement d'air dans des endroits clos, tets les garages, les

locaux d'entreen et les staonnements.

B10259-216

RISQUE D'EMPOISONNEMENT AUMONOXYDE DE CARBONE

Evitez de mere en marche les appareils produisant du monoxyde

de carbone (tels que les automobile, les appareils de chauffage

autonome,etc.) dans des endroits non venlés tels que les

d'empoisonnement au monoxyde de carbone. Si vous devez faire

fonconner ces appareils dans un endroit clos, assures-vous

qu'il y ait une venlaon directe provenant de l'exterier.

Le monoxyde de

des

carbone peut causer des maladies graves telles que

dommages permanents au cerveau et meme la mort.

Les émissions de monoxyde de carbone peuvent etre recircules dans les

endroits clos, si l'appareil de chauffage ou de traitement d'air sont

en marche.

Cee venlaon est nécessaire pour éviter le danger d'intoxicaon

au CO pouvant su rvenir si un appareil produisant du monoxyde

de carbone connue de fonconner au sein de la zone confinée.

Esta venlación es necesaria para evitar el peligro de envenenamiento

por CO, que puede ocurrir si un monóxido

de carbono sigue operando en el lugar cerrado.

disposivo que produc e

3

1 Important Safety Instructions

The following symbols and labels are used throughout this

manual to indicate immediate or potential safety hazards.

It is the owner’s and installer’s responsibility to read

and comply with all safety information and instructions

accompanying these symbols. Failure to heed safety

information increases the risk of personal injury, property

damage, and/or product damage.

2 Shipping Inspection

side or top during transit may cause equipment damage.

The installer should inspect the product upon receipt for

shipping damage and subsequent investigation is the

responsibility of the carrier. The installer must verify the

accessories are correct prior to installation. The distributor

or manufacturer will not accept claims from dealers for

transportation damage or installation of incorrectly shipped

units.

2.1 Parts

Inspect the unit to verify all required components are

present and intact. Report any missing components

immediately to the manufacturer or to the distributor. Use

Make sure to include the full product model number and

serial number when reporting and/or obtaining service

parts.

2.2 Handling

Use caution when transporting / carrying the unit. Do not

move unit using shipping straps. Do not carry unit with

hooks or sharp objects. The preferred method of carrying

the unit after arrival at the job site is to carry via a two-

wheel hand truck from the back or sides or via hand by

carrying at the cabinet corners.

2.3 Shipping Material Removal

IMPORTANT: All Shipping Material used to protect the

3 Codes & Regulations

This product is designed and manufactured to comply with

applicable national codes. Installation in accordance with

such codes and / or prevailing local codes / regulations

is the responsibility of the installer. The manufacturer

assumes no responsibility for equipment installed in

violation of any codes or regulations.

.

Should you have any questions please contact the local

gov.

4 Replacement Parts

When reporting shortages or damages, or ordering repair

parts, give the complete product model and serial numbers

as stamped on the product. Replacement parts for this

product are available through your contractor or local

distributor. For the location of your nearest distributor

consult the white business pages, the yellow page section

of the local telephone book or contact:

HOMEOWNER SUPPORT

DAIKIN COMFORT TECHNOLOGIES

MANUFACTURING, L.P.

19001 KERMIER ROAD

WALLER, TEXAS 77484

5 Pre-Installation Considerations

5.1 Preparation

Keep this document with the unit. Carefully read all

instructions for the installation prior to installing product.

Make sure each step or procedure is understood and

any special considerations are taken into account before

starting installation. Assemble all tools, hardware and

supplies needed to complete the installation. Some items

may need to be purchased locally. Make sure everything

needed to install the product is on hand before starting.

5.2 System Matches

listed. NOTE: Installation of unmatched systems is not

permitted.

5.3 Interconnecting Tubing

Give special consideration to minimize the length of

refrigerant tubing when installing air handlers. Refer to

Remote Cooling / Heat Pump Service Manual RS6200006,

and TP-107 Long Line Set Application R-410A for tubing

guidelines. If possible, allow adequate length of tubing such

5.4 Clearances

The unit clearance from a combustible surface may be

0”. However, service clearance must take precedence. A

minimum of 24” in front of the unit for service clearance

is required. Additional clearance on one side or top will

be required for electrical wiring connections. Consult all

clearances. When installing this unit in an area that may

sturdy, non-porous material. In installations that may lead

protective barrier to prevent such damage. Always install

4

5.5 Horizontal Applications

installed under the entire unit and its condensate drain line

must be routed to a location such that the user will see the

condensate discharge.

6 Installation Location

NOTE: These air handlers are designed for indoor

If the unit is located in an unconditioned area with high

ambient temperature and/or high humidity, the air handler

may be subject to nuisance sweating of the casing. On

with a vapor barrier is recommended. A secondary drain

pan below the unit is also recommended to protect the

installation site.

shown in Figures 3, 4, 5 and 6. The unit may be installed

6.1 Upflow and Downflow Installation

(Figure 3 & 4)

1. Remove blower access panel and coil access panel.

The coil access panel and tubing panel may remain

screwed together during this procedure. Remove and

the blower access panel to the cabinet.

2. Slide the coil assembly out from the cabinet. Use the

drain pan to pull the assembly from the cabinet.

IMPORTANT: Do not use manifolds, copper lines, or

do so may result in braze joint damage and leaks.

3. Removal of the center support is required on units

screws that secure the center support to the cabinet.

Remove the center support.

4. The horizontal drip shield, side drain pan, and drain

pan extension must be removed. Follow the “Side

Drain Pan and Extension Removal Instructions”.

5.

a. Using the drain pan to hold the coil assembly,

slide the coil assembly back into the cabinet.

b.

c. Reinstall the coil access panels and reinstall

blower access panel removed in Step 1 as shown

in Figure 9.

6.

a.

b. Using the drain pan to hold the coil assembly,

slide the coil assembly back into the cabinet on

c.

d. Reinstall the coil access panels and reinstall

blower access panel removed in Step 1 as shown

in Figure 10.

Side Drain Pan and Extension Removal Instructions

the drip shield support brackets to the condensate

from the bottom drain pan using a screwdriver or any small

lever. The side drain pan, drip shield brackets and the drain

pan extension may now be removed. From Figure 2, drain

condensate drain line must be attached to this drain port.

the side drain pan is removed, the drain port opening in the

access panel must be covered by the accessory drain port

Kit Number Application

DPK1 All Models

Side Drain Port Plug

Description

Drain Port Plug

SIDE DRAIN PAN

DPK1 DRAIN PLUG

COIL ACCESS PANEL

MAIN DRAIN PAN

5

6.2 Horizontal Left Installation (Figure 5)

Install unit as shown in Figure 5.

this application and condensate drain line must be attached

Remove red plugs from side drain pan before connecting

condensate drain pipes. Use removed plug to close drain

ports on vertical drain pan.

6.3 Horizontal Right Installation (Figure 6)

1. Before inverting the air handler, remove blower

access panel and coil access panel. The coil access

panel and tubing panel may remain screwed together

during this procedure. Remove and retain the seven

access panel to the cabinet.

2. Slide the coil assembly out from the cabinet. Use the

drain pan to pull the assembly from the cabinet.

3. Removal of the center support is required on units

screws that secure the center support to the cabinet.

Remove the center support.

4.

5. Remove side drain pan extension if present.

6. Using the drain pan to hold the coil assembly, slide the

brackets as shown in Figure 8.

7.

8. Reinstall the coil access panels and reinstall blower

access panel removed in Step 1 as shown in Figure 10.

9. Drain Connections for Horizontal Right Installation

a.

drain for this application and condensate drain line

b. Remove red plugs from side drain pan before

connecting condensate drain pipes. Use removed

plug to close drain ports on vertical drain pan.

must

6.4 Humid Environment Installations

to assist with condensation management in humid

6.4.1 ALL INSTALLATIONS – HUMID ENVIRONMENTS

Installations in areas where the return air environment

sees humidity levels above 65% relative humidity, a High

and Kit assignment.

HHK0004 HHK0005 HHK0006 HHK0007 HHK0008

AMVT24B

AMVT30B

AMVT36B

AMVT36C

AMVT42C

AMVT48C

AMVT48C AMVT48D AMVT48B

6.4.1.2 Downflow Installations – Humid

Environments

To prevent the coil pan “sweating”, the mandatory

for each model.

DFKE-02 DFKE-03

AMVT24B

AMVT30B

AMVT36B

AMVT36C

AMVT42C

AMVT48C

AMVT48D

AMVT60D

6

6.4.1.3 Horizontal Installations – Humid

Environments

where the air handler is installed in the horizontal position

humidity levels above 65% relative humidity, a Condensate

Applicable Kit and Model listing can be found in Table 4.

CMK0018 CMK0019 CMK0020

AMVT24B

AMVT36C

AMVT30B

AMVT36B

AMVT42C

AMVT48C

AMVT48D

AMVT60D

7

7 Refrigerant Lines

WARNING

THIS PRODUCT IS FACTORY-SHIPPED WITH R410A AND DRY

-

PRIATE SERVICE TOOLS AND FOLLOW THESE INSTRUC-

If the unit is located in an unconditioned area with

7.1 Tubing Size

condenser/heat pump.

7.2 Tubing Preparation

All cut ends are to be round, burr free, and clean. Failure

to follow this practice increases the chances for refrigerant

leaks. The suction line is spun closed and requires tubing

cutters to remove the closed end.

NOTE: The use of a heat shield is strongly

Heat trap or wet rags

WARNING

A QUENCHING CLOTH IS STRONGLY RECOMMENDED TO

PREVENT SCORCHING OR MARRING OF THE EQUIPMENT

CAUTION

APPLYING TOO MUCH HEAT TO ANY TUBE CAN MELT THE

-

OUS SIZES MUST BE PROPORTIONAL TO THE SIZE OF THE

7.3 Tubing Connections

An adjustable TXV with bulb is installed on the vapor tube

from the factory.

1.

panel.

2.

pressure indicates possible leak.

3. Replace the panel.

4. Remove the spin closure on both the liquid and

suction tubes using a tubing cutter.

5. Insert liquid line set into liquid tube expansion and

slide grommet about 18” away from braze joint.

6. Insert suction line set into suction tube expansion and

slide insulation and grommet about 18” away from

braze joint.

7. Braze joints. Quench all brazed joints with water or a

wet rag upon completion of brazing.

8

Upper Tie Plate

Control

Deck

Downflow

Bracket

Center

Support

Filter

Bracket

Filter

Access

Panel

Blower

Access

Panel

Coil

Access

Panel

UV

Knockout

Tubing

Panel

IMPORTANT NOTE: Ensure coil slides on the rails

Failure to do so will result in improper condensate

9

7.4 Thermal Expansion Valve System Adjustment

The following information for the indoor unit should be

necessary.

1. Total static pressure is .5” WC or less.

2.

3.

Sheet for Indoor Unit.

4.

in Service Manual RS6200006.

5. The outdoor temperature must be 60°F or higher.

6. Set the room thermostat to COOL, fan switch to

AUTO.

7. Set the temperature control well below room

temperature.

Superheat adjustments should not be made until indoor

ambient conditions have stabilized. This could take up to

24 hours depending on indoor temperature and humidity.

Before checking superheat run the unit in cooling for 10

minutes or until refrigerant pressures stabilize. Use the

following guidelines and methods to check unit operation

and ensure that the refrigerant charge is within limits.

1. Purge gauge lines. Connect service gauge manifold to

base-valve service ports.

2. Temporarily install a thermometer on the liquid

line at the liquid line service valve and 4-6” from

the compressor on the suction line. Ensure the

thermometer makes adequate contact and is insulated

for best possible readings. Use liquid line temperature

to determine subcooling and vapor temperature to

determine superheat.

3. Check subcooling and superheat. The system should

have a subcooling of 8°F +/- 1°F and two-stage

compressor systems should have a Subcooling of 6°F

+/- 1°F. and superheat of 8°F +/- 1°F. If subcooling

and superheat are low, adjust TXV to 8°F +/- 1°F

superheat, then check subcooling.

a. If subcooling is low and superheat is high,

add charge to raise subcooling to 8°F +/- 1°F.

Two-stage compressor systems should have a

Subcooling of 6°F +/- 1°F then check superheat.

b. If subcooling and superheat are high, adjust

TXV valve to 8°F +/- 1°F superheat, then check

subcooling.

1. Attach a pipe clamp thermometer near the suction line

service valve at the outdoor unit.

a. Ensure the thermometer makes adequate contact

for the best possible readings.

2. TXV-based systems should have a Superheat value of

8°F +/- 1°F.

3. Adjust Superheat by turning the TXV valve stem

clockwise to increase and counterclockwise to

decrease. Adjustments should be made opening or

closing the valve by no more than ¼ turn at a time.

Allow the system to stabilize 15 to 20 minutes before

making additional adjustments if necessary.

4. After adjustments are complete replace cap on

adjustment stem and tighten 1/6 turn.

5. Remove gauges and check the Schrader ports for

leaks and tighten valve cores if necessary. Install caps

SUCTION PRESSURE SATURATED SUCTION

PSIG R-410A

50 1

52 3

54 4

56 6

58 7

60 8

62 10

64 11

66 13

68 14

70 15

72 16

74 17

76 19

78 20

80 21

85 24

90 26

95 29

100 31

110 36

120 41

130 45

140 49

150 53

160 56

170 60

SATURATED SUCTION PRESSURE

TEMPERATURE CHART

SUBCOOL FORMULA =

SUPERHEAT FORMULA =

10

LIQUID PRESSURE

SATURATED LIQUID

TEMPERATURE °F

PSIG R-410A

200 70

210 73

220 76

225 78

235 80

245 83

255 85

265 88

275 90

285 92

295 95

305 97

325 101

355 108

375 112

405 118

415 119

425 121

435 123

445 125

475 130

500 134

525 138

550 142

575 145

600 149

625 152

SATURATED LIQUID PRESSURE

TEMPERATURE CHART

8 Condensate Drain Lines

The coil drain pan has a primary and a secondary drain

be hand tightened to a torque of no more than 37 in-lbs. to

prevent damage to the drain pan connection. An insertion

expected at this torque.

1. Ensure drain pan hole is not obstructed.

2. To prevent potential sweating and dripping on to

condensate drain line located inside the building. Use

A secondary condensate drain connection has been

provided for areas where the building codes require it.

free drainage. Provide required support to the drain line to

prevent bowing.

If the secondary drain line is required, run the line

separately from the primary drain and end it where

condensate discharge can be easily seen.

NOTE: Water coming from secondary line means the

coil primary drain is plugged and needs immediate

CAUTION

Insulate drain lines located inside the building or above

condensate trap to ensure proper drainage.

in other locations where damage from condensate

The installation must include a “P” style trap that is located

as close as is practical to the evaporator coil. See Figure

12 for details of a typical condensate line “P” trap.

NOTE: Units operating in high static pressure

Air Handler

2.75" MI

N.

POSITIVE LIQUID

SEAL REQUIRED

AT TRAP

Drain

Connection

2" MIN.

please refer to the requirements listed in the Uniform

A drain trap in a draw-through application prevents air

from being drawn back through the drain line during fan

operation thus preventing condensate from draining, and

if connected to a sewer line to prevent sewer gases from

being drawn into the airstream during blower operation.

Use of a condensate removal pump is permitted when

necessary. This condensate pump should have provisions

occur. A trap must be installed between the unit and the

condensate pump.

11

Tip: Priming the “P” trap may avoid improper draining at

the initial installation and at the beginning of the cooling

season.

9 Ductwork

This air handler is designed for a complete supply and

return ductwork system.

CAUTION

DO NOT OPERATE THIS PRODUCT WITHOUT ALL THE

To ensure correct system performance, the ductwork is to

be sized to accommodate 350-450 CFM per ton of cooling

with the static pressure not to exceed 0.5” in w.c. Refer to

ACCA Manual D, Manual S and Manual RS for information

on duct sizing and application. Flame retardant ductwork

is to be used and sealed to the unit in a manner that will

prevent leakage.

9.1 Return Ductwork

DO NOT LOCATE THE RETURN DUCTWORK IN

The return ductwork is to be connected to

10 Return Air Filters

may be performed at the air handler using the factory

11 Electric Heat

Refer to the installation manual provided with the electric

heat kit for the correct installation procedure. All electric

ONLY heat kits that are permitted to be used are the HKS

and HKTSD series. Refer to the air handler unit’s Serial

sheets to determine the heat kits compatible with a given

air handler. No other accessory heat kit besides the HKS

and HKTSD series may be installed in these air handlers.

The heating mode temperature rise is dependent upon the

Where: TR = Temperature Rise

kW = Heater Kit Actual kW

3412 = Btu per kW

1.08 = Constant

356810 15 19/20 25

800 12 19 23 31 37 56

1000 915 19 25 30 44

1200 812 15 21 25 37 49 62

1400 711 13 18 21 32 42 53

1600 6 9 12 15 19 28 37 46

1800 5 8 10 14 16 25 33 41

2000 57912 15 22 30 37

HEAT KIT NOMINAL kW

CFM

12

356810 15 19/20 25

800 11 18 22 30 35 54

1000 914 18 24 28 42

1200 712 15 20 24 35 47 56

1400 610 13 17 20 30 40 48

1600 6 9 11 15 18 27 35 42

1800 5 8 10 13 16 24 31 37

2000 47912 14 21 28 33

CFM

HEAT KIT NOMINAL kW

356810 15 19/20 25

800 10 17 21 28 33

1000 813 17 22 27 40

1200 711 14 19 22 33 45 56

1400 610 12 16 19 29 38 48

1600 5 8 10 14 17 25 33 42

1800 57912 15 22 30 37

2000 47811 13 20 27 33

CFM

HEAT KIT NOMINAL kW

Comfort Setting Menu Heater Kit Info

There are 6 options

available in the Comfort Setting Menu which impacts

system target run time and electric heat functionality.

Electric heat operation adjustments only apply if a

communicating heat pump is installed. Comfort Setting

Options 1 – 5 have set values for the System Target

Runtime and option 6 enables additional menus to

customize all comfort settings. See list below for the

satisfy the thermostat slower or faster based on the

selection where option 1, with a 10 minute Target Runtime,

is attempting to satisfy much faster than option 5, with a 30

minute Target Runtime.

System Target Runtime:

Runtime

Runtime

Runtime

Runtime

Runtime

This system will automatically

determine if the heat pump is capable of satisfying the

thermostat in the selected System Target Runtime. If the

heat pump is unable to satisfy in the selected time, electric

heat settings will determine how many attempts should be

given to the heat pump before temporarily locking it out

and using the furnace. These electric heat settings also

determine at what time the system should remove the

temporary heat pump lockout and run the heat pump again.

There are four adjustable items associated with back up

electric heat operation control. In the same way as the

System Target Time, each of these items have defaulted

values for Comfort Settings 1 – 5. Only when Comfort

Setting 6 is selected will each item be available for full

adjustment.

This

is a value that determines how far past the target

runtime the system should continue running the

heat pump before transitioning to the furnace. For

example, assume this menu was set to 20% with a

target runtime of 20 minutes. If the thermostat did

not remove the heating call after 20 minutes, the

system would allow for an additional 20% heat pump

up electric heat after 24 minutes if the thermostat call

was still present. Each time this occurs, the system

strike is important when looking at the Over Target

If the

heat pump has consecutively activated back up electric

heat for the selected Over Target Threshold amount

of times, meaning for this many consecutive cycles it

has been unable to satisfy the target time by itself, then

the heat pump will be temporarily locked out and the

furnace will become the primary heat source.

This only applies when the heat pump and back up

electric heat are activated on initial start-up. In this

case, the system will try to determine when the best

time to operate the heat pump individually again. To

determine this, the system looks at how easily the

air handler is able to satisfy the thermostat using the

heat pump with back up electric heat. Assume this

setting is 15% and the target time is 20 minutes If the

heat pump with back up electric heat can satisfy the

13

If

the air handler is able to satisfy the thermostat using

the heat pump with back up electric heat for the

selected number of consecutive cycles the electric

heat operation will be temporarily removed. The heat

pump will then be used during the next cycle. If the

heat pump can satisfy the thermostat in less than the

System Target Runtime the back up heat operation

will be completely removed and the heat pump will

become the primary heat source again. If it fails to do

so, the strike count against the furnace will be reset

and the furnace will remain the temporary primary

heat source until the Under Target Threshold is

reached again.

The system will automatically make adjustments in an

attempt to satisfy the thermostat as close to this target

runtime as possible. After a power cycle or mode change

thermostat call. Based on the selected target runtime and

how long the initial cycle takes to satisfy the thermostat,

the control algorithm will adjust the system stage times for

a 2 stage unit or the capacity demand percentage for an

inverter / modulating unit for the next cycle. NOTE: actual

run times may change depending on variations of load

throughout the day.

The following table shows the default values for all Comfort

Comfort

Setti ng

Opti on

Target

Ti me

(Minutes)

Stage Up

Percentage

(%)

Stage Down

Percentage

(%)

Over Target

Threshhold

(Strike Count)

Under Target

Threshhold

(Strike Count)

110 20 20 210

215 20 20 4 8

320 20 20 6 6

425 20 20 8 4

530 20 20 10 2

The following table shows the ranges for each of item when

the adjustable Comfort Setting Option 6 is selected. The

table shows the minimum value, the maximum value and

the defaulted value. All items can be adjusted up or down

to 60 and make sure the other menus are set to match

356810 15 19 20 25

AMVT24BP14 550 650 700 800 850 875

AMVT30BP14 550 650 700 800 875 1050

AMVT36BP14 630 650 700 800 875 1050

AMVT36CP14 735 810 935 1020 1145 1345

AMVT42CP14 735 810 935 1020 1145 1345

AMVT48CP14 880 880 1045 1200 1420 1480

AMVT48DP14 1040 1170 1260 1300 1595 1595

AMVT60DP14 1135 1265 1375 1455 1815 1860 1925

HEATER KIT (Kw)

Model

14

Menu Minimum Value Maximum Value Default Value

Target Time (t9t) 1 minute 240 minutes 60 minutes

Stage Up Percent (SUP) 0% 100% 20%

Stage Down Percent (SdP) 0% 100% 20%

Over Target Threshold (Ott) 1 strike 254 strikes 20 strikes

Under Target Threshold (Utt) 1 strike 254 strikes 20 strikes

12 Electrical and Control Wiring

WARNING

HIGH VOLTAGE

DISCONNECT ALL POWER BEFORE SERVIC-

WARNING

HIGH VOLTAGE!

AN

THE ELECTRICAL GROUND CIRCUIT MAY CONSIST OF AN

APPROPRIATELY SIZED ELECTRICAL WIRE CONNECTING

THE GROUND LUG IN THE UNIT CONTROL BOX TO THE

OTHER METHODS OF GROUNDING ARE PERMITTED IF PER-

FORMED IN ACCORDANCE WITH THE NATIONAL ELECTRIC

GROUNDING IS TO BE IN ACCORDANCE WITH THE CANADI-

12.1 Building Electrical Service Inspection

This unit is designed for single-phase electrical supply

only. DO NOT OPERATE ON A THREE-PHASE POWER

SUPPLY. Measure the power supply to the unit. The supply

voltage must be measured and be in agreement with the

unit nameplate power requirements and within the range

shown.

12.2 Wire Sizing

Wire size is important to the operation of your equipment.

Use the following check list when selecting the appropriate

wire size for your unit.

• Wire used must carry the Minimum Circuit Ampacity

•

sizing. The unit MCA for the air handler and the

optional electric heat kit can be found on the unit

Series and Rating Plate.

• Wire must be sized to allow no more than a 2%

voltage drop from the building breaker/fuse panel to

the unit.

•

have varying ampacities - be sure to check the

temperature rating used

Refer to the latest edition of the National Electric Code or in

Canada the Canadian Electric Code when determining the

correct wire size.

12.3 Maximum Overcurrent Protection (MOP)

check with local or state codes for any special regional

requirements.

Protection can be in the form of fusing or HACR style

circuit breakers. The Series and Rating Plate provides the

maximum overcurrent device permissible.

Nominal

Input

Minimum

Voltage

Voltage

208-230 VAC 197 253

12.4 Electrical Connections – Supply Voltage

CAUTION

FIRE HAZARD!

-

IMPORTANT NOTE: Use copper conductors only from

Knockouts are provided on the air handler top panel and

sides of the cabinet to allow for the entry of the supply

voltage conductors, as shown in Figure 13. Separate

knockouts must be used for two circuit heat kits. Unless

on the cabinet sides are used for electrical conduit, an

adapter ring must be used in order to meet UL1995 safety

requirements. An NEC or CEC approved strain relief is

to be used at this entry point. Some codes/municipalities

require the supply wire to be enclosed in conduit. Consult

your local codes.

15

Side of

Cabinet

Top of

Cabinet

12.4.1 Air Handler Only (Non-Heat Kit Models)

IMPORTANT: Installation of Air Handler must follow any

The building supply connects to the stripped black and red

wires contained in the air handler electrical compartment

cavity. A ground screw is also contained in this area.

Attach the Supply wires to the air handler conductors as

shown in the unit wiring diagram using appropriately sized

solderless connectors or other NEC or CEC approved

means.

12.4.2 Air Handler - Non-Circuit Breaker Heat Kits

A terminal block is provided with the HKS and HKTSD kit

to attach the power supply and air handler connections.

Follow the HKS and HKTSD Installation Manual and wiring

diagram for complete wiring details.

12.4.3 Air Handler With Circuit Breaker Heat Kit

The air handler has soft plastic cover on the upper access

panel and can be removed to allow the heater kit circuit

breaker to be installed. The circuit breakers have lugs

for power supply connection. See the HKS and HKTSD

Installation Instructions for further details.

12.5 Low Voltage Connections

Several combinations of low voltage schemes are possible,

depending on the presence of a heat kit and whether the

heat kit is single-stage or multi-stage, whether the outdoor

section is an air conditioner or heat pump, and whether

the outdoor section is single-stage or two-stage. The

24V-control voltage connects the air handler to the room

thermostat and condenser. Low voltage wiring must be

copper conductors. A minimum of 18AWG must be used

for installations up to 100 feet. Low voltage wiring must

be connected through the top of the cabinet or either side.

See the “Thermostat Wiring” section of this manual for

typical low voltage wiring connections.

12.5.1 Thermostats

Second-stage heat can be accomplished by a multi-stage

heating thermostat or the addition of an outdoor thermostat

as shown in wiring schematics on page 19. Follow the

thermostat manufacturer’s instructions for installation.

13 CoolCloud HVAC Phone Application

is no guarantee that interference will not occur in a

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and

receiver.

• Connect the equipment into an outlet on a

connected.

• Consult the dealer or an experienced radio/ TV

technician for help.

16

device being used.

1234567890

This air handler is Bluetooth ready and functions with the

CoolCloud HVAC phone application designed to improve

the contractor’s setup / diagnostic experience. Users can

error codes, observe system menu testing of all operational

phone application is also capable of directly updating the

air handler software anytime updates are available. The

application will automatically notify the user.

NOTE: The software update may take up to 20 minutes

14 Quick Start Guide for Communication

Outdoor Units

EXTREMELY IMPORTANT: For all cooling calls

the system only requires a single Y input from the

outdoor unit and to control single stage electric heat

heat pump control or multistage control may result in

1. Connect all necessary thermostat wires to the

thermostat connector on the air handler control as

instructed by the applicable wiring diagrams shown in

this section.

2. Connect the 1 & 2 wires between the indoor and

outdoor unit for communicating operation.

NOTE: Verify two stage outdoor units include a

Two stage outdoor units may not behave properly

without this 24 VAC transformer.

3. Download the Cool Cloud HVAC phone application for

17

Communication Software and Air Handler Control

14.1 Charging

1. Two-stage outdoor units using the Cool Cloud HVAC

application:

a. Using the cooling icon after entering the outdoor

unit menus, energize the outdoor unit at 49%

capacity or lower.

b. Charge the outdoor unit as required using the

charging information provided with the outdoor

equipment.

15 Quick Start Guide for Non-Communicating

Outdoor Units

When setting up a ComfortBridge air handler for use

with a Non-Communicating outdoor unit you must

EXTREMELY IMPORTANT: For two stage electric heat

Internal algorithms will control staging automatically

1. Use the wiring diagrams on the next page to connect

low voltage thermostat wires.

NOTE: When installing the air handler with a non-

communicating heat pump, wire directly to the “O”

terminal on the non-communicating heat pump. See

18

2. Download the Cool Cloud HVAC phone application.

NOTE: When new versions of Bluetooth

Communication Software and Air Handler Control

optional or mandatory and installed by using the

phone application. Ensure all mandatory software

updates have been installed. Review notes for

optional software updates and install if necessary.

3.

using the on board push buttons or the Cool Cloud

HVAC phone application. Select “” for single stage

Air Conditioners, “” for single stage Heat Pumps,

“” for two stage Air Conditioners and “” for 2

stage Heat Pumps.

4.

for the outdoor unit. See the following table.

NOTE: For the two stage non-communicating outdoor

stage operation.

Tonnage

Selecon Airow Tonnage

Selecon Airow Tonnage

Selecon Airow Tonnage

Selecon Airow

1 400 2.3 920 3.6 1440 4.9 1960

1.1 440 2.4 960 3.7 1480 5 2000

1.2 480 2.5 1000 3.8 1520 5.1 2040

1.3 520 2.6 1040 3.9 1560 5.2 2080

1.4 560 2.7 1080 4 1600 5.3 2120

1.5 600 2.8 1120 4.1 1640 5.4 2160

1.6 640 2.9 1160 4.2 1680 5.5 2200

1.7 680 3 1200 4.3 1720 5.6 2240

1.8 720 3.1 1240 4.4 1760 5.7 2280

1.9 760 3.2 1280 4.5 1800 5.8 2320

2 800 3.3 1320 4.6 1840 5.9 2360

2.1 840 3.4 1360 4.7 1880 6 2400

2.2 880 3.5 1440 4.8 1920

NOTE:

1.

place.

2. The cooling/heat pump speed tap should be selected

based on the AHRI rating. Otherwise, select a speed

tap that provides a minimum 350 CFM per outdoor

ton. For satisfactory operation, external static

pressure must not exceed 0.5” WC.

EXAMPLE: For a 2 ton outdoor, 1.6T 10% trim is the

1.5 22.5 33.5 4 5

Minimum

Cooling/Heating CFM

@ .5" WC ESP

525 700 875 1050 1225 1400 1750

Outdoor Unit Tonnage

3. Use the CFM adjustment factors of 0.98 for horizontal

orientations.

Model

AMVTC25B14

AMVTC29B14

AMVTC35B14

AMVTC37B14

1200

AMVTC33C14 1300

AMVTC31C14

AMVTC37C14

AMVTC39C14

1600

AMVTC37D14

AMVTC49C14

1800

AMVTC49D14

AMVTC59C14

1900

AMVTC59D14

AMVTC61D14

2100

4. Use the Cool Cloud HVAC phone application to

air handler operations.

NOTE: The phone application cannot test a non-

communicating outdoor unit

15.1 Electric Heater Kit Testing

1. Select the electric heat icon after entering the air

handler menus while using the Cool Cloud phone

application.

2. Select any value less than 50% for low stage

operation and any value greater than 50% for high

stage operation.

3.

properly for high stage operation.

MODEL NAME MAX CFM

AMVT24BP1400 1275

AMVT30BP1400 1450

AMVT36BP1400

AMVT36CP1400 1575

AMVT42CP1400

AMVT48CP1400 1700

AMVT48DP1400 1800

AMVT60DP1400 2200

19

blower to operate at a reduced speed during a combined

from the thermostat or humidistat. This lower blower

as it passes through the indoor coil. The control board

located on the thermostat wiring connector. The terminal

input is energized or de-energized. When using an external

dehumidistat, connect it between the R and DH terminals.

If the humidistat closes on humidity rise or the thermostat

” using

the push buttons or Cool Cloud HVAC phone application.

If the humidistat opens on humidity or the thermostat de-

set the Dehum Logic Menu to “” using the push buttons

or Cool Cloud HVAC phone application.

The control is equipped with a 24VAC Aux Alarm to be

connected AUX switch is normally closed and opens when

the water level in the evaporator coil base pan reaches

an undesirable level. The control responds by displaying

a “

unit. If the AUX switch is detected to be in the closed

position for 30 seconds, normal operation resumes and the

error message is no longer displayed.

18 Start-Up Procedure

The air handler includes three on-board push buttons

allowing users to navigate indoor and outdoor system

menus. The Right and Left buttons allow the user to

scroll through the main menus and to then scroll through

is used to enter into a main menu and to then permanently

select options within those menus.

NOTE: After scrolling to the desired option within a

function properly.

1. Make sure the installed 24VAC thermostat is capable

of controlling the accessory or accessories.

2. Connect the appropriate accessory control wires

to the accessory devices from the thermostat

3. If the thermostat is capable of providing a continuous

Make sure to connect the thermostat G terminal to

the G terminal on the indoor unit. Setup thermostat

to ensure G signal is energized during accessory

operation.

4.

accessory using the indoor unit push button menus or

the Cool Cloud HVAC phone application.

5. Using the thermostat, independently test each

accessory in addition to the independently testing

continuous fan mode.

20

Key Mitigations:

1. Full featured TS (dehum & overcool)

2. Connect G and dehum wire correctly

3. Dehumidistat

1) Install Dehum wire

and DO NOT install G

Wire

2) Install Dehumidistat

in living space or

return duct

Is there a setting in the

thermostat to enable

Dehum without fan? (G)

Yes

No

During a call for Dehum,

does the thermostat

provide 24V to Dehum, Y,

and G?

Yes No

Choose that setting

Wire the system and test

functionality

Yes No

Wire the system and

test functionality

Dehumidification Control Options

Dry Environment

Yes No

Install any 24VAC

thermostat on the

market - Use Y, W, G

signals

Thermostat has a Dehum or

Configurable terminal with

Dehum option

Yes

No

Does your thermostat have a

whole house Dehumidifier

setting?

Install Dehumidistat in

living space or return

duct

If the Dehumidistat

opens on a rise on

humidity, then you

will set Dehum logic

to Low via Coolcloud

app or push buttons

If the Dehumidistat

closes on a rise in

humidity, then you

will set Dehum logic

to High via Coolcloud

app or push buttons

Thermostat only sends Dehum + G on a

call for Dehum

A Dehumidistat needs to be installed in

the living space or return duct

If the Dehumidistat opens

on a rise on humidity,

then you will set Dehum

logic to Low via Coolcloud

app or push buttons

If the Dehumidistat closes on

a rise in humidity, then you will

set Dehum logic to High via

Coolcloud app or push buttons

/