2

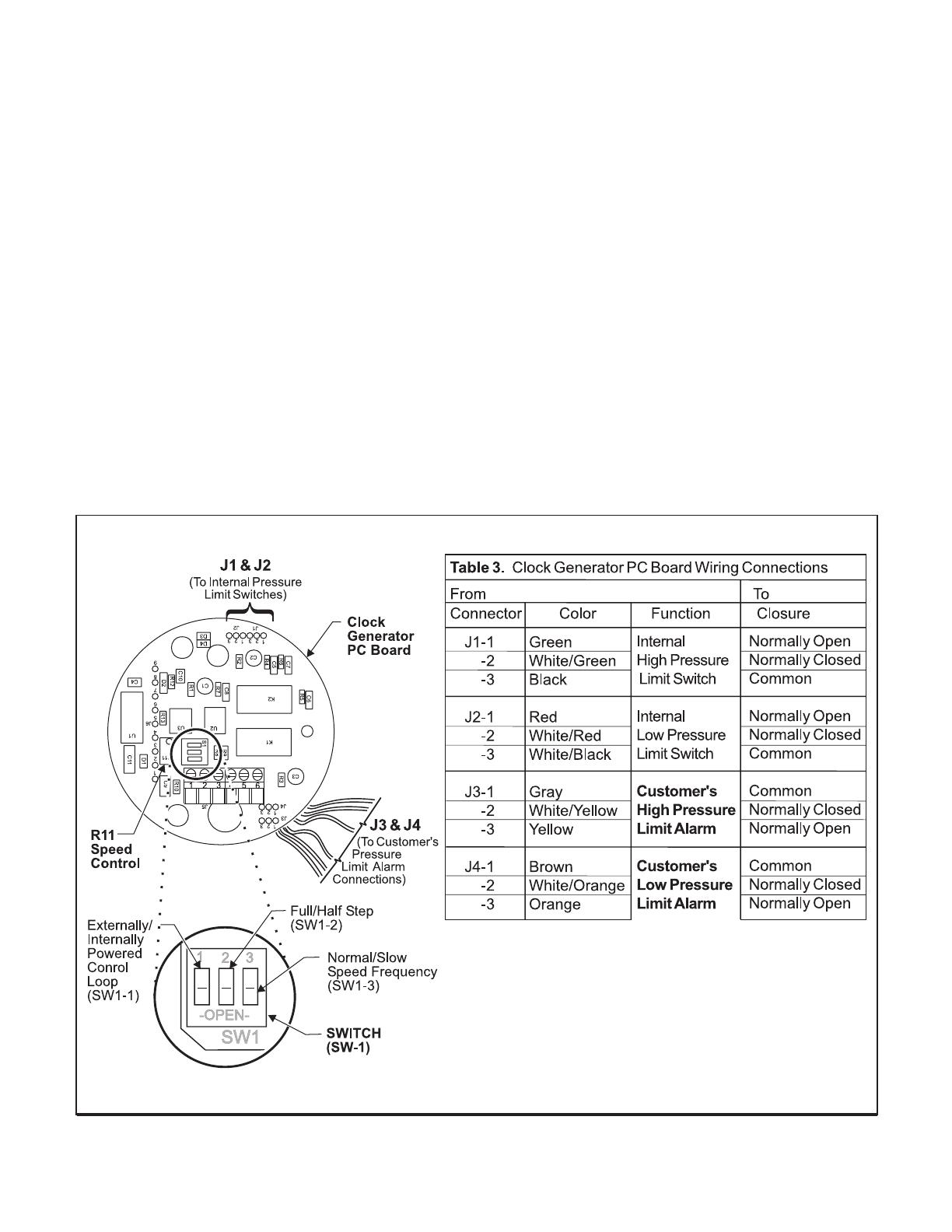

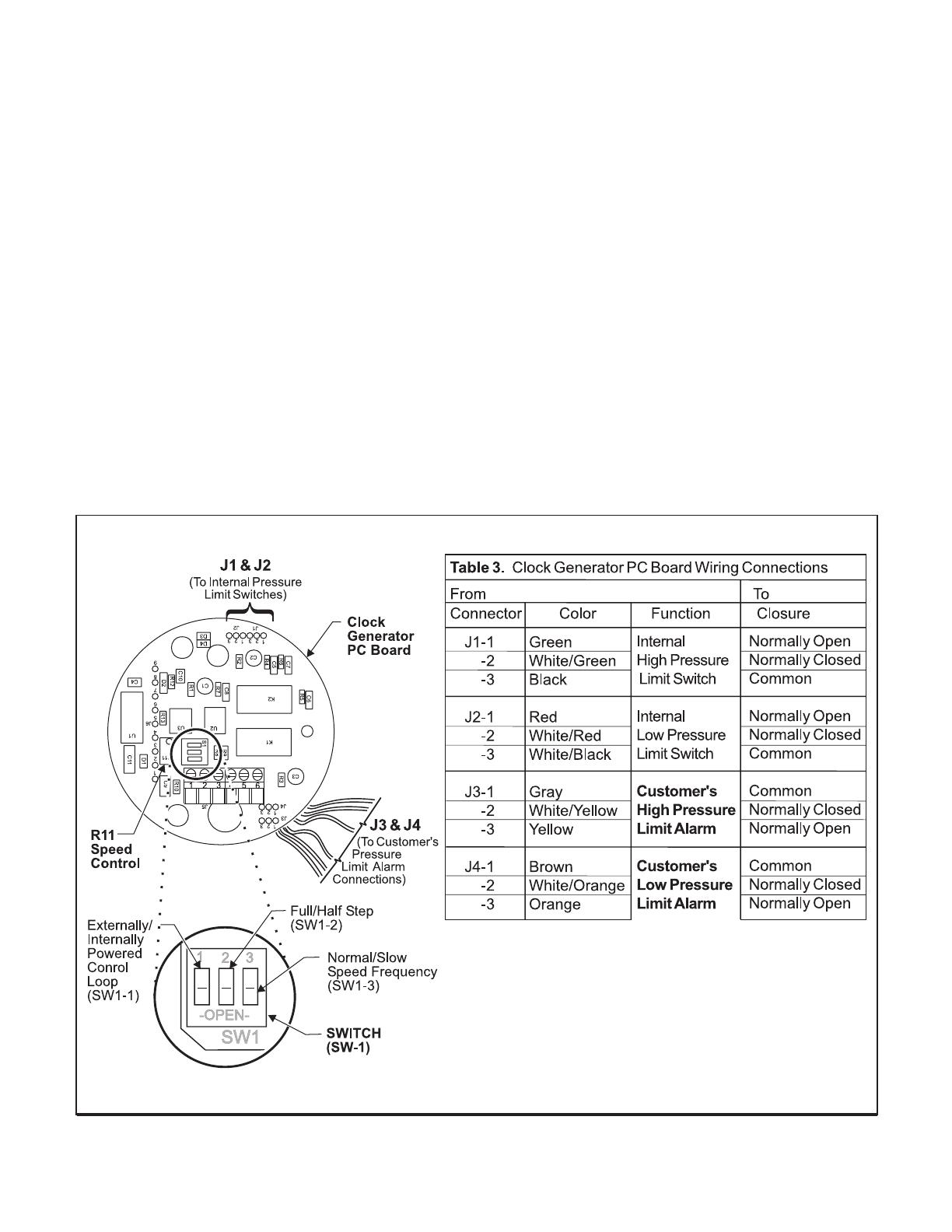

Figure 1. Clock Generator PC Assembly

Remove power from unit when changing

SW1-2 from half step mode to full step mode:

Switching from half step mode to full step

mode when the power is on can result in

motor operation at 1/2 its torque capability.

3.

4.

5.

6.

Turn the Normal/Slow Switch (SW1-3) to the Off/

Open position to achieve adjustment of pressure

over the full range when the stepper motor is

running at high speed.

Adjust the R11 Speed Control to fine-tune the

adjustment time. Refer to the column “High” of the

appropriate table on page 1 for the specific regula-

tor model and pressure range.

Turn the Normal/Slow Switch (SW1-3) to the On/

Closed position to achieve adjustment of pressure

over the full range when the stepper motor is

running at low speed.

Adjust the R11 Speed Control to fine-tune the

adjustment time. Refer to the column “Low” of the

appropriate table on page 1 for the specific regula-

tor model and pressure range.

ADJUSTMENTS

The following adjustments are provided:

•

•

•

•

Full/Half Step Mode Adjustment

NOTE:

1.

Normal/Slow Speed Frequency Selection

2.

Turn the Full/Half Step Switch (SW1-2) to the

Off/Open position for half step operation. Turn

the switch to the On/Closed position for full step

operation.

Refer to Tables 1. and 2. on page 1, to select the

required Full Range Adjustment Time.

Full/Half Step Mode

Normal/Slow Speed Frequency Selection

Externally/Internally Powered Control Loop

Limit Switch Adjustment