Applications

Meat Dishes

Vegetables

Soups

Sauces

Pasta

Rice

Pie Fillings

Gravies

Poultry

Seafood

Stainless Steel

2/3 Steam Jacketed

Kettle

Floor Mounted

Tilting

Self-Contained

Gas Heated

20, 40 or 60-

Gallon Capacity

Short Form

Groen Model DH (specify

gallons), self-contained,

gas heated (specify natural,

propane, butane, or mixture)

tilting, steam jacketed kettle.

All stainless steel construction

with reinforced bar rim,

butterfly shaped pouring lip

and smooth action mechanical

tilt. Patented fin tube burner

assembly is 62-65% efficient,

with electronic ignition

standard. NSF listed, A.S.M.E.

code constructed for 50 PSI

and A.G.A. design certified

(Natural & Propane gas only).

Requires 1/2” IPS gas line

and 115 volt electric service.

Made in USA.

Model DH-40 shown with optional No. 51 cover

Groen Floor Kettles, Page 6

144242D

Revised 07/10

Floor Kettles

model DH

Description

Kettle shall be a Groen Model DH (specify 20, 40, or 60)

gallon stainless steel steam jacketed unit, operating with

a self-contained gas heated steam source contained

within the unit.

Construction

Kettle interior shall be of type 316 stainless steel, solid

one-piece welded construction. The console and all

exposed surfaces shall be stainless steel. All controls

shall be mounted on the front panel except the thermostat,

which is mounted on the trunnion support arm.

The kettle body shall be mounted in a heavy-duty

stainless steel combination kettle support tilt trunnion,

which in turn, is supported by the stainless steel enclosed

base. The base shall be provided with stainless steel

tubular legs with adjustable bullet feet. The enclosed

support base shall contain a smooth operating, self

locking tilt mechanism, and shall be of sanitary, drip-

proof construction, with interior readily accessible for

installation or maintenance.

The unit shall be furnished with a heavy reinforced bar

rim with a welded in butterfly shaped pouring lip for

maximum sanitation and durability. Faucet mounting

bracket is standard.

Finish

Kettle interior shall be polished to a 180 emery grit

finish. Exterior of kettle shall be finished to a bright high

buff finish, ensuring maximum ease in cleaning and

maintaining brilliant appearance.

A.S.M.E. Code, A.G.A. Design Certified

Unit shall be A.S.M.E. shop inspected, stamped and

registered with the National Board for operation up to

a maximum working pressure of 50 PSI. Unit shall be

design certified by the American Gas Association. (Natural

and Propane only.)

Sanitation

Unit shall be designed and constructed to meet NSF and

known health department and sanitation codes. and be

NSF listed.

Drawoff

A 2” tangent drawoff is optional. (Add “T” to model

designation DHT). If drawoff is specified, outlet shall be

equipped with removable 1/4” perforated stainless steel

strainer.

Self-contained Steam Source

Kettle shall have a gas-heated (natural, butane,

propane) self-contained steam source to provide kettle

temperatures of 150 to approximately 295˚F. Unit shall

be factory charged with chemically-pure water and rust

inhibitors to ensure long life and minimum maintenance.

Controls

Controls shall include a thermostat, pressure gauge,

safety valve, pressure limit control, water sight glass, low

water cut off, a gas regulator valve and electronic ignition

module. Power ON switch, Power ON indicator light, LOW

WATER indicator light, and HEATING light are mounted on

the kettle support side console. Gas supply shall shut off

automatically when unit is tilted.

Performance Features

Patented fin tube burner assembly delivers 62-65%

efficient combustion, depending on size, 20 Gallon Model

has 72,000 BTU/HR firing rate with 44,140 BTU/HR into the

product; 40 Gallon Model has 100,000 BTU/HR firing rate

with 65,000 BTU/HR into the product, and 60 Gallon Model

has 150,000 BTU/HR firing rate with 93,000 BTU/HR into

the product.

Electronic ignition to standing pilot is standard on all models.

Unit shall be thermostatically controlled to automatically

shut off when desired temperature is reached and turn on

when product temperature drops below setting.

Installation

Specify natural, propane, butane, or specific propane/

butane mixture. Unit requires 1/2” IPS gas line connection

and 115 volt electrical connection. No remote steam

source required.

Options/Accessories

2” tangent draw-off valve with

1/4” perforated disk strainer

Basket inserts (TRI-BC)

Lift-off cover

Hinged cover kit

Pan carrier (40 and 60-gallon)

Kettle brush kit

Double and single pantry faucets

Lip strainers

1/8” perforated disk strainer

1/4” perforated disk strainer

Solid disk strainer

Contour measuring strips

Gallon etch marks

Origin of Manufacture

Kettle shall be designed and manufactured in the United

States.

1055 Mendell Davis Drive, Jackson, MS 39272

888-994-7636, unifiedbrands.net

Please reference our website for the most

updated product information and specifications.

P/N 128113 REV A

Model DH

MM

1194

749

673

879

654

40 GAL/152 LITRES

CAPACITY (GALLONS/LITRES)

TABLE OF DIMENSIONS

463

1095

711

349

787

1537

743

INCOMING GAS PRESSURE TABLE

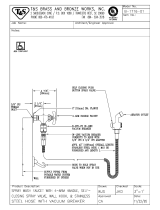

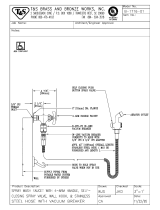

G

F

7/8" DIA. HOLE

ELECTRICAL CONNECTION

B

J

POUR PATH MAX.

6" MIN. (152)

7-1/2" MAX.

2-3/16"

6"

H

POSITION

KETTLE IN

FULL TILT

POUR PATH MIN.

M

L

K

(241)

6-1/2"

CLEARANCE

WALL

6" MIN.

LEFT SIDE

(46)

1-13/16"

4-5/8"

A

ID

2" (51)

TYP.

2"

65425 29

C

DH/1-40 & DH-60 KETTLES.

DH-20 & DH/1-40 KETTLES.

4. FAUCET WITH SWING SPOUT

3. HINGED COVER MODEL # 51 FOR

2. LIFT OFF COVER MODEL # 31 FOR

1. 2" TANGENT SANITARY DRAW-OFF

OPTIONAL EXTRA COST FEATURES :

OPERATING GAS PRESSURE

KETTLE TILT

HANDLE

OPTIONAL

2" (51)

TANGENT

DRAWOFF

12-5/8"

6-1/8"

3-1/2"

29"

NOTES :

FAUCET

3.5 W.C.

NATURAL

FAUCET BRACKET

FURNISHED AS

STANDARD

MIN. REAR

CLEARANCE

(254)

WALL

NATURAL

PROPANE

4.5 W.C.

11.0 W.C.

K

M

L

10.0 W.C.

PROPANE

H

J

G

E

F

D

1

/

768

1295

686

TYPE OF GAS

51

/

1

30

27

4

MIN. SUPPLY

GAS PRESSURE

31

60

29

1

2

/

4

787

832

457

1000

660

397

26

15

/

3

39

8

32

18

31

4

43

13

28

4

/

3

/

8

1

26

34

18

/

1

FIRING RATE

FOR BOTH NATURAL AND LP

OPTIONAL

GAS INLET

1/2" NPT

DH/20

DH/1-40

DH/60

100,000

150,000

72,000

(BTU/HR)

A

B

20 GAL/76 LITRES

889

505

INCHES

19

35

47

25

INCHES

MM

78430

14.0 W.C.

14 W.C.

806

889

1562

MAX. SUPPLY

GAS PRESSURE

61

31

35

1

/

2

3

4

/

902

1089

483

314

1175

28

12

46

711

8

/

3

/

4

1

42

19

35

762

1194

60 GAL/228 LITRES

INCHES

47

30

MM

5. DIMENSIONS IN BRACKETS ( ) ARE MM

ADJUSTABLE FEET

SCALE: .05"=1"

DO NOT SCALE DRAWING

# 51 SHOWN

OPTIONAL

COVER

6"

115/1/60, 5 AMPS

3

4

/

/

2

1

5

8

/

/

2

/

7

8

1

D

(152)

(56)

(152)

(191)

10"

9-1/2"

(152)

TYP.

(117)

(321)

(156)

(737)

(89)

(165)

(51)

37

1

/

4

2

N

P

946

51

36

/

1

8

5

/

16

7

918

138

/

1

43

8

/

1

7

2

1095

191

E

P

3

/

4

2

1

/

7

/

8

7

/

8

3

/

4

5

/

8

N

R

C

6. HEAT LIGHT IS ON WHEN MAIN BURNER IS ON.

1-2 LOW HEAT (SIMMER), 8-9 HIGH HEAT (BOIL)

TO STOP

2. SET POWER SWITCH TO "OFF".

1. SET THERMOSTAT TO "OFF".

2. CHECK FOR WATER IN KETTLE. LEVEL MUST BE ABOVE "MINIMUM".

b. LIFT SAFETY VALVE LEVER TO VENT KETTLE.

1. READ AND UNDERSTAND OPERATORS MANUAL.

5. ROTATE THERMOSTAT UNTIL HEAT LIGHT IS ON.

*** WARNING *** ESCAPING STEAM CAN CAUSE SEVERE BURNS !!

a. HEAT KETTLE UNTIL PRESSURE GAUGE SHOWS 5 PSI.

BETWEEN 20" Hg to 30" Hg WHEN KETTLE IS COLD.

3. CHECK FOR VACUUM IN KETTLE. PRESSURE GAUGE SHOULD READ

TO START

4. SET POWER SWITCH TO "ON",

3. OPEN GAS SUPPLY VALVE.

2. SET THERMOSTAT TO "OFF".

4. IF REQUIRED, ESTABLISH VACUUM.

BEFORE OPERATION

1. SET POWER SWITCH TO "OFF".

c. ALLOW LEVER TO SNAP CLOSED.

LOW WATER

HEAT

OFF

ON

POWER

30

30

40

50

60

FRONT VIEW RIGHT SIDE VIEW

TOP VIEW

P/N 128113 REV A

1055 Mendell Davis Drive, Jackson, MS 39272, 888-994-7636, unifiedbrands.net

© 2009 Unified Brands. All Rights Reserved. Unified Brands is a wholly-owned subsidiary of

Dover Corporation.

-

1

1

-

2

2

Groen DH-60 Datasheet

- Type

- Datasheet

Ask a question and I''ll find the answer in the document

Finding information in a document is now easier with AI

Related papers

Other documents

-

Blodgett 40G-KLT Datasheet

-

T & S Brass & Bronze Works B-1716-01 Datasheet

T & S Brass & Bronze Works B-1716-01 Datasheet

-

Unified Brands GROEN Steam Jacketed Kettles User manual

Unified Brands GROEN Steam Jacketed Kettles User manual

-

Blodgett 40GS-KLT Datasheet

-

Blodgett 80G-KLS Datasheet

-

Crown GC-12 Owner's manual

-

Southbend KTLG-20 Datasheet

-

Blodgett 40GS-KLS Datasheet

-

Southbend KSLG-40 Datasheet

-

LoLo LKS-45G User manual

LoLo LKS-45G User manual