Yamato Scientific PDC100 is a plasma treatment system designed to clean and activate surfaces, preparing them for subsequent processes like bonding, coating, and printing. It utilizes argon gas to generate plasma, which is directed at the surface to remove contaminants and modify its chemical composition. The system features an intuitive touch panel interface for easy operation and monitoring of treatment parameters like time, power, and gas flow rate.

Yamato Scientific PDC100 is a plasma treatment system designed to clean and activate surfaces, preparing them for subsequent processes like bonding, coating, and printing. It utilizes argon gas to generate plasma, which is directed at the surface to remove contaminants and modify its chemical composition. The system features an intuitive touch panel interface for easy operation and monitoring of treatment parameters like time, power, and gas flow rate.

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

-

13

13

-

14

14

-

15

15

-

16

16

-

17

17

-

18

18

-

19

19

-

20

20

-

21

21

-

22

22

-

23

23

-

24

24

-

25

25

-

26

26

-

27

27

-

28

28

-

29

29

-

30

30

-

31

31

-

32

32

-

33

33

-

34

34

-

35

35

-

36

36

Yamato Scientific PDC100 is a plasma treatment system designed to clean and activate surfaces, preparing them for subsequent processes like bonding, coating, and printing. It utilizes argon gas to generate plasma, which is directed at the surface to remove contaminants and modify its chemical composition. The system features an intuitive touch panel interface for easy operation and monitoring of treatment parameters like time, power, and gas flow rate.

Ask a question and I''ll find the answer in the document

Finding information in a document is now easier with AI

Related papers

-

Yamato Scientific PDC200 Operating instructions

Yamato Scientific PDC200 Operating instructions

-

Yamato Scientific PDC610 Operating instructions

-

Yamato Scientific DP200/300/410/610 Operating instructions

Yamato Scientific DP200/300/410/610 Operating instructions

-

Yamato Scientific PR300 Operating instructions

Yamato Scientific PR300 Operating instructions

-

Yamato Scientific BM110/210 Operating instructions

Yamato Scientific BM110/210 Operating instructions

-

Yamato Scientific PR500 Operating instructions

Yamato Scientific PR500 Operating instructions

-

Yamato Scientific DP23/33/43/63 Operating instructions

Yamato Scientific DP23/33/43/63 Operating instructions

-

Yamato Scientific BM100/200 Operating instructions

Yamato Scientific BM100/200 Operating instructions

-

Yamato Scientific BF200/400/500/600 Operating instructions

Yamato Scientific BF200/400/500/600 Operating instructions

Other documents

-

SEVERIN BAG SEALER Dimensions

-

Hitachi R-W550PDX User manual

-

PRECISION DIGITAL PD138, PDS178 User manual

PRECISION DIGITAL PD138, PDS178 User manual

-

Schneider Electric PD100 Partial discharge monitoring User guide

-

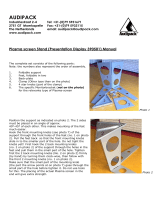

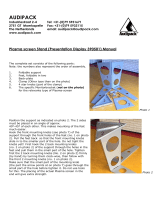

Audipack 390501 User manual

Audipack 390501 User manual

-

Alpine SWX-1243D Owner's manual

-

JVC KD-AVX11 Compatibility Chart

-

Jackery by Honda HLS290 User manual

Jackery by Honda HLS290 User manual

-

Aerco KC Series Operation and Maintenance Manual

-

Generac MTP8 Operating instructions