Page is loading ...

6245 State Rd. Telephone 215-624-4800

Philadelphia, PA 800-344-4802 19135-2996

Fax:215-624-6966

www.insingermachine.com

TECHNICAL MANUAL

FOR

DOOR TYPE

DISHWASHING

MACHINE

MODELS

COMMANDER 18-5

COMMANDER 18-5C

COMMANDER 18-5H CS

5 CS-5C

TECHNICAL MANUAL

including Installation, Operation, and Maintenance Instructions

FOR

DOOR TYPE DISHMACHlNES

MODELS

Commander 18-5

Commander 18-5C

Commander 18-5H

CS-5

CS-5C

rlsd: 1/97

s:\wp51\manual\mnll841

6245 State Road Telephone 215.624.4800

Philadelphia FAX: 215 624 6966

PA 19135-2996

Thank you for Purchasing this quality Insinger product.

On the space provided please record the Model and Serial Number of this unit:

Model: ______________________

Serial Number: _______________

When referring to this equipment please have these numbers available.

Each piece of equipment at Insinger is carefully tested before shipment for proper operation.

If the need for service should arise please contact your local Authorized Insinger Service

Company. A Service Network Listing is provided within this manual. Check this list for your

local authorized servicer.

For proper activation of the Insinger Limited Warranty a SureFire™ Start-up should be completed

on your machine. Refer to the Introduction section in this manual for an explanation of

Insinger's SureFire™ Start-up and Check-out Program.

Please read the Insinger Limited Warranty and all installation and operation instructions

carefully before attempting to install or operate your new Insinger product.

To register your machine for warranty by phone, fax, or the internet or for answers to questions

concerning installation, operation, or service contact our Technical Services Department:

Toll-Free 800.344.4802

Fax 215.624.6966

Email service@insingermachine. com

World-Wide Web http://WWW.insingermachine.corn

Thank you.

Insinger Machine Company

S:\WP51\MANUAL\INTRO

DOOR TYPE DISHMACHINES MODEL:

Commander 18-5 & CS Series

Table of Contents

Part 1 - Technical Information

• Section A, Introduction

• Catalogue Cut-sheet and Installation Drawing

• Warranty

• Authorized Service Agency Network Listing

Part 2 - Installation and Operation Instructions

• Section A, Installation Instructions

• Section B, Operation and Cleaning Instructions

• Part 3 - Maintenance and Repair Procedures

• Section A, Maintenance and Repair Procedures

• Basic Service Guide

Part 3 - Electrical Schematics and Replacement Parts

• Machine Wiring Diagrams

• Control Panel Layout and Component Drawing

Part 4 - Replacement Parts

• Overall Assembly Drawing for:

Commander 18-5, 18-5H, CS-5

Commander 18-5C, CS-5C

• Drain Assembly

• Motor Assembly, 1HP

• Pump, Motor & Suction Assembly

• Level Float Installation

• Electric Heater, Diode and Level float

• Steam Injectors, Steam Coils and Steam Booster Assembly's

• Final Rinse Assembly

• Final Rinse Assembly (self-contained booster)

• Electric Booster Assembly

• Self Contained Booster Assembly

• Gas-heated Machines •

Parts Listing

Troubleshooting

Sequence of Operations

rlsd: 1/97, 10/98

s:\wp51\manual\mnl185

COMMANDER 18-5 Series & CS Series

TECH MANUAL INTRODUCTION

Part 1, Section A

1.A. INTRODUCTION

I.A.I Purpose

The purpose of this Tech Manual is to provide installation, operation, cleaning and maintenance directions. A

section is provided for replacement parts.

1.A.2 Scope

This manual contains all pertinent information to assist in the proper installation, operation, cleaning,

maintenance, and parts ordering for the Commander 18-5 series and CS-5 series dishwashers. The installation

instructions are intended for qualified equipment installers. The operation and cleaning instructions are

intended for the daily users of the equipment. The maintenance and parts sections are intended for qualified

service and/or maintenance technicians. Replacement parts may be ordered directly from our factory or from

your local Insinger Authorized Service Agency. For the name of your local Insinger Authorized Service

Agency please reference the Service Network Listing in Section 1 of this manual. You can also speak to the

Insinger Technical Services Department, 800/344-4802, or e-mail us at [email protected].

When calling for warranty information or replacement parts please provide the model and serial number of

your Insinger equipment. These important numbers should be noted in this manual on the spaces provided on

the opening page.

1.A.3 Surefire™ Start-Up Program

Insinger is proud to offer our exclusive Surefire™ Start-up & Check-out Program to our commercial

customers. This service is included in the purchase price of your new Insinger dishwasher. We will provide an

authorized factory service technician for the initial start-up of your new Insinger dishwasher to ensure it is

running correctly. Please call the factory or your local Insinger Sales or Service Representative to schedule

this service.

1.A.4 Definitions

Throughout this guide you will find the following terms: WARNING, CAUTION, & NOTE. When used,

these terms will be outlined in a box to draw attention:

WARNING indicates potential physical danger.

CAUTION indicates potential equipment damage.

NOTE indicates helpful operating hints or tips.

rlsd: 1/97, 10/98

s:\wp51\manual\mnl 185

Item #

COMMANDER 18-5

AUTOMATIC SINGLE TANK

DOOR TYPE DISHWASHER

DESIGN

Automatic door type, single tank dishwasher with timed wash and

rinse cycle. Fully automatic operation with power on/off button.

Capacity is 60 - 20" X 20" racks per hour, or 1500 dishes per hour.

Cycle starts when doors are closed. Designed for straight through

operation. Corner model available for right angle operation.

• Elevated top-mounted control panel

(NEMA12)

• Easily-cleaned crowned hood top

• "Easy Clean" front-mounted wash tank

• Capillary thermometer for wash

• In-line thermometer for final rinse

• Manifold cleanout brush

• Inspection door

• S/S frame, legs and feet

• Automatic tank fill

• Low water protection

• Override switch for de-liming or extended

wash cycle

• Vent fan connection provision

OPTIONAL ACCESSORY EQUIPMENT

·

Pressure reduction valve

·

Remote electric booster

and line strainer

·

Security package

·

Stainless steel steam coil

·

Totally enclosed motor

tank heat

•

Door activated drain closer

·

Gas tank heat

·

Plastic 20" x 20" racks

·

Steam booster (plate or silver)

·

Built-in electric booster

·

S/S front panel

6245 State Road

Philadelphia,PA19135-2996

215/624-4800

215/624-6966 FAX

800/344-4802

www.insingermachine.com

STANDARD EQUIPMENT

• Space saving compact design

• Door safety switch

• Detergent connection provision

• Fully automatic operation

• Single scrap screen design

• Non-proprietary commercially

available pump motor

• Easily removable pump suction

strainer

• Tank heat: 3KW electric immersion

heater or steam injector

• SureFire™ Start-Up and Check-Out

Service

• Vacuum breaker

COMMANDER 18-5

Note: For all rough in connections see Installation and Layout Detail Drawing.

SPECIFICATIONS

CONSTRUCTION-Hood and tank constructed of 16 gauge 18-8 type 304 S/S. Hood unit of all welded seamless construction. S/S frame, legs and

feet. All internal castings are non-corrosive lead free nickel alloy or bronze.

DOORS-a front inspection/cleanout door and two simultaneously opening operating doors. Operating doors have fingertip control, balanced by

externally mounted springs. (Corner model available with 2 doors at right angles.) Extra large die formed 18-8 type 304 S/S doors ride in all S/S

channels. A triple ply leading edge on the door channels made of S/S with no plastic or nylon sleeves or liners used.

PUMP-Centrifugal type "packless" pump with a brass petcock drain. Construction includes ceramic seal and a balanced cast impeller on a precision

ground stainless steel shaft. All working parts mounted as an assembly and removable as a unit without disturbing pump housing. One 1 HP motor,

standard frame, horizontal C-faced, drip proof, squirrel-cage, induction run type, 3400 RPM, internally cooled with ball-bearing construction.

CONTROLS-Top-mounted control cabinet, NEMA 12 rated, housing motor controls and overload protection, transformer, contactors and all

dishwasher integral controls. All controls safe low voltage 24 VAC.

SPRAY SYSTEM- Wash and rinse spray systems made of 18-8 type 304 stainless steel pipe threaded into cast hub assemblies. Upper

and lower wash and rinse spray assemblies are removable without the use of tools.

WASH- 2 power spinning wash arms above and 2 power spinning wash arms below. On top, each wash arm is designed with 8 nozzles (16 total).

On the bottom, each wash arm is designed with 4 slots (8 total). The slots are precision milled for water control and produce a fan spray.

FINAL RINSE-2 power spinning rinse arms above and 2 power spinning rinse arms below. On top, each rinse arm is designed with 2 nozzles (4

total). On the bottom, each rinse arm is designed with 4 nozzles (8 total). The nozzles produce a fan spray reducing water consumption, maximizing

heat retention.

DRAIN-Drain valve externally controlled. Overflow assembly with skimmer cap is removable without use of tools for drain line inspection. Heater

protected by low water level control.

Capacity Tank capacity Motor size Electric usage Steam Final rinse

per hour

3 kw wash tank

consumption at

20

psi min.

peak flow

at 20 psi min.

60

racks

13.5

kw b.i.booster

40°

or

70°

rise

18lbs./hr

tank

1500

dishes

6

kw rem. booster

40°

rise

24

lbs./hr booster

40°

rise

75-150 meals 6.4 gals. 1 hp (wash) 12 kw rem. booster 70° rise 42 lbs./hr booster 70° rise

3.25 gals./min.

Exhaust hood

requirement

Current draw

amps

115/1/60

Steam/gas

.

17

Electric w/o

booster

42

Electric w/

built-in booster

n/a

208/3/60

5

1

3

51

240/1/60

9

23

84

240/3/60

4

12

44

380/3/50

3

8

n/a

Final rinse

consumption at

20 psi min.

60 gals./hr. 1.0

gals./rack

100CFM

Peak rate

drain flow

9 gals./min.

Shipping

weight

550 Ibs.

480/3/60 2 6 22

3M 9.97 PRINTED IN USA

INSINGER'S FULL LINE SPECIFICATION AVAILABLE IN FIRST PLACE™ and AutoQuotes™

File: STD/18

-

5

*

ADD 3 KW FOR ELECTRIC HEA T, PLUS

13.5 KW FOR BUILT-IN ELECT. BOOSTER.

** 10 KW FURNISHED WHEN SPECIFIED.

? FOR HOT WATER TO BOOSTER 140' F

STANDARD / 110' F SPECIAL

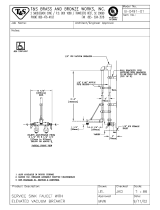

NOTES:

1. WASH TANK IS FILLED THRU THE FINAL RINSE

LINE.

2. FOR GAS HEATED MACHINE SEE DWG 18-5G.

INSTALLATION

AND LAYOUT

DETAIL

INSTALLATION CONNECTIONS

LTR

DESCRIPTION SIZE

A HOT WATER TO FINAL RINSE - 180' F 1/2 FIPS

B HOT WATER TO REMOTE ELEC. BOOSTER? 1/2 FIPS

C HOT WATER TO STEAM BOOSTER ? 1/2 F!PS

D STEAM TO TANK 1/2 FIPS

E STEAM TO STEAM BOOSTER 1/2 FIPS

F DRAIN CONNECTION

1 1/2

FIPS

G CONDENSATE RETURN - STEAM BOOSTER 1/2 FIPS

H CONDENSATE RETURN - COIL ONLY 2/8 FIPS

J ELECTRICAL CONNECTION - MOTORS 1 HP *

K ELECTRICAL CONNECTION-REMOTE BOOSTER

6 KW **

L HOT WATER TO B.I. ELEC. BOOSTER

?

1/2 FIPS

COMMANDER

18

-

5

AUTOMATIC DISHWASHING MACHIHE

6245

State Rd. Tel.

215

-

624

-

4800

Philadelphia FAX: 215-624-6966

PA 19135-2996

DWG. NO.

18-5

SCALE: 3/4" =

1’

-

0"

DRAWN: EMM 7.21.98

APPROVED: EBA 7.21.98

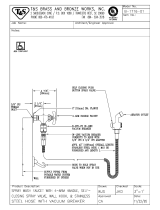

INS TALLA TION CONNEC TIONS

LTR

DESCRIPTION SIZE

A HOT WATER TO FINAL RINSE - 180° F 1/2 FIPS

B HOT WATER TO REMOTE ELEC. BOOSTER ? 1/2 FIPS

C HOT WATER TO STEAM BOOSTER ? 1/2 FIPS

D STEAM TO TANK 1/2 FIPS

E STEAM TO BOOSTER 1/2 FIPS

F DRAIN CONNECTION 1 1/2 FIPS

G CONDENSATE RETURN - STEAM BOOSTER 1/2 FIPS

H CONDENSATE RETURN - COIL ONL Y 3/8 F!PS

J ELECTRICAL CONNECTION - MOTORS 1 HP *

K ELECTRICAL CONNECTION-REMOTE BOOSTER

6 KW **

L HOT WATER TO B.I. ELECT. BOOSTER? 1/2 FIPS

*

AD

D 3KW FOR ELECTRIC HEAT, PLUS

13.5 KW FOR BUILT-IN ELECT. BOOSTER.

** 10 KW FURNISHED WHEN SPECIFIED.

? FOR HOT WATER TO BOOSTER 140' F

STANDARD / 110' SPECIAL

NOTES:

1. WASH TANK IS FILLED THRU THE FINAL RINSE

LINE.

2. FOR GAS HEATED MACHINE SEE DWG. 18-5CG

COMMANDER 18

-

5C

AUTOMATIC DISHWASHING MACHINE

6245 State Rd. Tel. 215

-

624

-

4800

Philadelphia FAX; 215-624-6966

PA 19135-2996

DWG. NO.

18-5C

SCALE: 3/4" =1'

-

0"

DRAWN: EMM 7.21.98

APPROVED: EBA 7.21.98

COMMANDER

18

-

5

(GAS)

AUTOMATIC DISHWASHING MACHINE

6245

State Rd. Tel.

215

-

624

-

4800

Philadelphia TWX: 710-670-1233

PA 19135-2996 FAX: 215-624-6966

DWG. NO.

18-5G

scale 3/4"

=

1'

-

0"

DRAWN: EMM 7.22.98

APPROVED: EBA 7.22.98

NOTE:

1. WASH TANK IS FILLED THRU THE FINAL

RINSE TANK.

* 2. ALLOW 2 FEET MINIMUM FROM A

VERTICAL COMBUSTIBLE WALL.

INS TALLATION CONN EC TIONS

LTR

DESCRIPTION SIZE

A HOT WATER TO FINAL RINSE - 180° F 1/2 FIPS

B DRAIN CONNECTION 1 1/2 FIPS

C GAS CONNECTION 3/4 FIPS

D ELECTRICAL CONNECTION 1 HP

E FLUE 1 3/4x5

INSTALLATION CONNECTIONS

LTR

DESCRIPTION SIZE

A HOT WATER TO FINAL RINSE - 180° F ½ FIPS

DRAIN CONNECTION 1 1/2 FIPS

B

C

GAS CONNECTION 3/4 FIPS

D ELECTRICAL CONNECTION 1 HP

E FLUE 1 3/4x5

NOTES:

1. WASH TANK IS FILLED THRU THE FINAL

RINSE LINE.

*2. ALLOW 2 FEET MINIMUM FROM A

VERTICAL COMBUSTIBLE WALL.

COMMANDER 18-5C (GAS)

AUTOMATIC DISHWASHING MACHINE

6245

State Rd. Tel. 215

-

624

-

4800

PhiladelphIa FAX: 215-624-6966

PA 19135-2996

DWG. NO.

18-5CG

SCALE:

¾ “

-

1'

-

0"

DRAWN: EMM 7.22.98

APPROVED: EBA 7.22.98

Item #________

COMMANDER 18-5H

AUTOMATIC SINGLE TANK DOOR TYPE

WAREWASHER & TRAY/UTENSIL

WASHER

DESIGN

Automatic door type, single tank dishwasher with timed wash and rinse cycle.

Fully automatic operation with power on/off button. Capacity is 60 - 20" X 20"

racks per hour, or 1500 dishes per hour. The 18-5H can also handle mixer

agitators, 18" X 26" sheet pans, utensils and mixing bowls up to 60 quarts!

Cycle starts when doors are closed. Designed for straight through operation.

Corner model available for right angle operation.

STANDARD EQUIPMENT

• Space saving compact design • Top-mounted control panel

• Door safety switch (NEMA 12)

• Detergent connection provision • "Easy Clean" front-mounted

• Fully automatic operation wash tank

• Single scrap screen design • Capillary thermometer for wash

• Non-proprietary commercially • In-line thermometer for final rinse

available pump motor • Manifold cleanout brush

• Easily removable pump • Inspection door

suction strainer •S/S frame, legs and feet

• Tank heat: 5KW electric • Automatic tank fill

immersion heater or • Low water protection

steam injector • Override switch for de-liming

• SureFire™ Start-Up and or extended wash cycle

Check-Out Service • Vent fan connection provision

• Vacuum breaker

OPTIONAL ACCESSORY EQUIPMENT

• Pressure reduction valve • Remote electric booster

and line strainer • Security package

• Stainless steel steam coil • Totally enclosed motor

tank heat • Door activated drain closer

• Gas tank heat • Plastic 20" x 20" racks

• Steam booster (plate or silver)

• Built-in electric booster • S/S front panel

6245 State Road

Philadelphia, PA 19135-2996

215/624-4800

215/624-6966 FAX

800/344-4802

www.insingermachine.com

CSI-11400

COMMANDER 18-5H

Note: For all rough in connections see Installation and Layout Detail Drawing.

SPECIFICATIONS

CONSTRUCTION-Hood and tank constructed of 16-gauge 18-8 type 304 S/S. Hood unit of all welded seamless construction. S/S frame, legs and feet.

All internal castings are non-corrosive lead free nickel alloy or bronze.

DOORS-A front inspection/cleanout door and two simultaneously opening operating doors. Operating doors have fingertip control, balanced by

externally mounted springs. (Corner model available with 2 doors at right angles.) Extra large die formed 18-8 type 304 S/S doors ride in all S/S

channels. A triple ply leading edge on the door channels made of S/S with no plastic or nylon sleeves or liners used.

PUMP-Centrifugal type "packless" pump with a brass petcock drain. Construction includes ceramic seal and a balanced cast impeller on a precision

ground stainless steel shaft. All working parts mounted as an assembly and removable as a unit without disturbing pump housing. One 2 HP motor,

standard frame, horizontal C-faced, drip proof, squirrel-cage, induction run type, 3400 RPM, internally cooled with ball-bearing construction.

CONTROLS-Top-mounted control cabinet, NEMA 12 rated, housing motor controls and overload protection, transformer, contactors and all

dishwasher integral controls. All controls safe low voltage 24 VAC.

SPRAY SYSTEM- Wash and rinse spray systems made of 18-8 type 304 stainless steel pipe threaded into cast hub assemblies. Upper and

lower wash and rinse spray assemblies are removable without the use of tools.

WASH- 2 power spinning wash arms above and 2 power spinning wash arms below. On top, each wash arm is designed with 8 nozzles (16 total). On

the bottom, each wash arm is designed with 4 slots (8 total). The slots are precision milled for water control and produce a fan spray.

FINAL RINSE-2 power spinning rinse arms above and 2 power spinning rinse arms below. On top, each rinse arm is designed with 2 nozzles (4 total).

On the bottom, each rinse arm is designed with 4 nozzles (8 total). The nozzles produce a fan spray reducing water consumption, maximizing heat

retention.

DRAIN-Drain valve externally controlled. Overflow assembly with skimmer cap is removable without use of tools for drain line inspection. Heater

protected by low water level control.

Capacity per hour Tank capacity Motor size

Electric usage

5 kw wash tank

Steam consumption

at 20 psi min.

Final rinse peak

flow at 20 psi min.

60 racks

13.5 kw b.i.booster 40°

or 70° rise

70°rise

18lbs./hr tank

1500 dishes

6 kw rem. booster 40° rise

24 lbs./hr booster 40°

rise

75-150 meals 6.4 gals. 2 hp (wash) 12 kw rem. booster 70° rise

42 lbs./hr booster 70°

rise

3.25 gals./min.

Final rinse

consumption

Current draw

amps

208/3/60

Steam/gas

8

Electric Electric w/

w/o booster built-in booster

21.9 59. 9

240/1/60 13 33.8 94.8

240/3/60 7 2 19.2 51.2

380/3/50 4.4 12 n/a

480/3/60 3.6 9.6 25.6

60 gals./hr.

1.0gal./rack

Exhaust hood

requirement

100CFM

Peak rate

drain flow

9 gals./min.

Shipping

weight

600 Ibs.

3M 9.97 PRINTED IN USA

INSINGER’S FULL LINE SPECIFICATION AVAILABLE N FIRST PLACE™ and AutoQuotes™

CSI- 11400

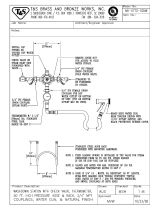

INSTALLATION CONNECTIONS

LTR

DESCRIPTION SIZE

A HOT WATER TO FINAL RINSE - 180° F 1/2 FIPS

B HOT WATER TO REMOTE ELEC. BOOSTER ?

1/2 FIPS

C HOT WA TER TO STEAM BOOSTER

?

1/2 FIPS

D STEAM TO TANK 1/2 FIPS

E STEAM TO STEAM BOOSTER 1/2 FIPS

F DRAIN CONNECTION 1 1/2 FIPS

G CONDENSATE RETURN - STEAM BOOSTER 1/2 FIPS

H CONDENSATE RETURN - COIL ONL Y 3/8 FIPS

J ELECTRICAL CONNECTION - MOTORS 2 HP *

K ELECTRICAL CONNECTION-REMOTE BOOSTER

6 KW **

L HOT WATER TO B.I. ELEC. BOOSTER

?

1/2 FIPS

* ADD

5

K

W FOR ELECTRIC HEAT, PLUS

13.5 KW FOR BUILT-IN ELECT. BOOSTER.

** 10 KW FURNISHED WHEN SPECIFIED.

? FOR HOT WATER TO BOOSTER 140° F

STANDARD / 110° F SPECIAL.

NOTE:

1. WASH TANK IS FILLED THRU THE FINAL

RINSE LINE.FILE: STD\18-5H

COMMANDER 18-5H

AUTOMATIC DISHWASHING MACHINE

6245

State Rd. Tel.

215

-

624

-

4800

Philadelphia FAX: 215-624-6966

PA 19135-2996

DWG. NO.

18-5H

SCALE:

3/4

"

=

1'

-

0"

DRAWN: Y.G. 12.17.9

APPROVED:

21

,

INSTALLATION CONNECTIONS

LTR

DESCRIPTION SIZE

A HOT WATER TO FINAL RINSE -180° F 1/2 FIPS

B HOT WATER TO REMOTE ELEC. BOOSTER? 1/2 FIPS

C HOT WATER TO STEAM BOOSTER

?

1/2 FIPS

D STEAM TO TANK 1/2 FIPS

E STEAM TO STEAM BOOSTER 1/2 FIPS

F DRAIN CONNECTION 1 1/2 FIPS

G CONDENSATE RETURN - STEAM BOOSTER 1/2 FIPS

H CONDENSATE RETURN - COIL ONL Y 3/8 FIPS

J ELECTRICAL CONNECTION - MOTORS 2 HP *

K ELECTRICAL CONNECTION-REMOTE BOOSTER

6 KW **

L HOT WATER TO B.I. EL EC. BOOSTER

?

1/2 FIPS

*ADD

5

KW FOR ELECTRIC HEAT, PLUS

13.5 KW FOR BUILT-IN ELECT. BOOSTER.

** 10 KW FURNISHED WHEN SPECIFIED.

? FOR HOT WATER TO BOOSTER 140° F

STANDARD / 110° F SPECIAL.

NOTE:

1. WASH TANK IS FILLED THRU THE FINAL RINSE

LINE.

FILE: STD\18-5CH

COMMANDER 18-5CH

AUTOMATIC DISHWASHING MACHINE

6245

State Rd. Tel.

215

-

624

-

4800

Philadelphia FAX: 215-624-6966 PA

19135-2996

DWG. NO.

18-5CH

SCALE: 3/4" = 1'-0""

DRAWN: PG 2.13.98

APPROVED:

CS

-

4

AUTOMATIC SINGLE TANK

CHEMICAL SANITIZING DOOR

TYPE DISHWASHER

DESIGN

Automatic door type, single tank dishwasher with a timed wash and

rinse cycle. Fully automatic operation with power on/off button.

Capacity is 80 racks per hour for light soil (60 racks per hour for normal

soil) - 20" x 20" racks. Cycle starts when doors are closed. Designed

for straight through operation. Corner model available for right angle

operation.

STANDARD EQUIPMENT

OPTIONAL ACCESSORY EQUIPMENT

·

Pressure reduction valve and

line strainer

• Stainless steel steam coil

tank heat

6245 State Road

Philadelphia, PA 19135-2996

215/624-4800

215/624-6966 FAX

800/344-4802

http://www.insingermachine.com

•

Tank heat:

3

KW electric

immersion heater or steam

injector

• NSF approved sanitizer injector

pump

• Capillary thermometer for wash

• In-line thermometer for final rinse

• Vacuum breaker

• Manifold cleanout brush

• Inspection door

• S/S frame, legs and feet

• Automatic tank fill

• Low water protection

•

Deterg

ent connection provision

• Space saving compact design

• Fully automatic operation

• Top mounted control panel

(NEMA12)

• Simplified scrap screen design

• Door safety switch

• Interchangeable upper & lower

wash arms

• Standard frame drip proof motor

• Override switch for de-liming

•

Gas tank heat

·

Security package

• Totally enclosed motors

·

Door activated drain closer

Note: For all rough in connections see Installation and Layout Detail Drawing.

SPECIFICATIONS

CONSTRUCTION-Hood and tank constructed of 16 gauge 18-8 type 304 S/S. Hood unit of all welded seamless construction. S/S

frame, legs and feet. All internal castings are non-corrosive nickel alloy, bronze or S/S investment.

DOORS-a front inspection/cleanout door and two simultaneously opening operating doors. Operating doors have fingertip control,

balanced by externally mounted springs. (Corner model available with 2 doors at right angles.) Extra large die formed 18-8 type 304

S/S doors ride in all S/S channels. A triple ply leading edge on the door channels made of S/S with no plastic or nylon sleeves or liners

used.

PUMP-Centrifugal type "packless" pump with a brass petaock drain. Construction includes ceramic and a balanced cast impeller on a

precision ground stainless steel shaft. All working parts mounted as an assembly and removable as a unit without disturbing pump

housing. One 1 HP motor, standard frame, horizontal C-faced, drip proof, squirrel-cage, induction run type, internally cooled with ball-

bearing construction.

CONTROLS-Top-mounted control cabinet, NEMA 12 rated with heat insulation provided between hood and control cabinet, housing

motor controls and overload protection, transformer, contactors and all dishwasher integral controls. All controls safe low voltage 24

VAC.

SPRAY SYSTEM- Wash and rinse spray systems made of 18-8 type 304 S/S pipe threaded into cast hub assemblies. Upper and lower

wash spray assemblies are interchangeable and are removable without the use of tools.

WASH-2 power spinning wash arms above and 2 power spinning wash arms below each designed with 8 high pressure action

cleansing slots. The slots are precision milled for water control producing a fan spray.

FINAL RINSE-2 power spinning rinse arms above and 2 power spinning rinse arms below each designed with 2 nozzle assemblies.

Nozzle assemblies produce a cone spray reducing water consumption, maximizing heat retention. The final rinse piping is chlorinate

poly vinyl chloride.

DRAIN-

Drain valves

externally

controlled.

Tank capacity Motor size Electric usage Steam consumption

at 20 psi min.

Final rinse peak

flow at 20 psi

min.

1500 dishes

75-150 meals 6.4 gals. 1 hp 3 kw wash tank 11 Ibs/hr tank 3.1 gals./min.

Final rinse

consumption

Exhaust hood

requirements

Peak rate drain

flow

Shipping weight

Current draw

amps

115/1/60

Steam

17

Electric w/o

booster

42

208/3/60

5 13

230/1/60

9 23

41 gals./hr.

230/3/60

4 12

380/3/60

3 8

0.51 gals./rack 100CFM 9 gals./min. 550 Ibs.

460/3/60

2 6

3M 3.98 PRINTED IN USA INSINGER'S FULL LINE SPECIFICATION AVAILABLE IN FIRST PLACE™

CS

-

4

FILE: STD\CS-5

CS

-

5

AUTOMATIC CHEMICAL SANITIZING DISHWASHING

MACHINE

6245

State Rd. Tel.

215

-

624

-

4800

Philadelphia

PA 19135-2996 FAX: 215-624-6966

DWG. NO.

CS-5

SCALE: ¾”

=

1'

-

0"

DRAWN: EMM 10.5.98

APPROVED: EBA 10.5.93

NOTES:

1. WASH TANK IS FILLED THRU THE FINAL

RINSE LINE.

2. CHEMICAL SANITIZER INJECTOR PUMP

FURNISHED.

INS TALLATION CONN EC TIONS

LTR

DESCRIPTION SIZE

A HOT WATER 70 FINAL RINSE - 140' F 1/2 FIPS

B STEAM TO TANK COIL 1/2 FIPS

C DRAIN CONNECTION 1 1/2 FIPS

D CONDENSATE RETURN - TANK COIL 3/8 FIPS

E ELECTRICAL CONNECTION 1 HP *

*

ADD

3

KW FOR ELECTRIC HEAT.

INSTALLATION CONNECTIONS

LTR DESCRIPTION SIZE

A HOT WATER TO FINAL RINSE- 140° F 1/2 FIPS

B STEAM TO TANK COIL 1/2 FIPS

C DRAIN CONNECTION 1 1/2 FIPS

D CONDENSATE RETURN - TANK COIL 3/8 FIPS

E ELECTRICAL CONNECTION 1 HP *

*

ADD

3

KW FOR ELECTRIC HE

AT

.

1.

WASH TANK IS FILLED THRU THE FINAL

RINSE LINE.

2. CHEMICAL SANITIZER INJECTOR PUMP

FURNISHED.

CS

-

5C

AUTOMATIC CHEMICAL SANITIZING DISHWASHING MACHINE

6245

Stole Rd. Tel.

215

-

624

-

4800

Philadelphia

PA 19135-2996 FAX: 215-624-6966

DWG. NO.

CS-5C

SCALE: 3/4"=

1'

-

0"

DRAWN: EMM 9.5.98

APPROVED: EBA 9.5.98

COMMANDER 18-5 Series & CS Series

INSTALLATION INSTRUCTIONS

Part 2, Section A

2.A.1 PLACEMENT

2.A. 1.1 Carefully uncrate machine. Take caution to not damage components which may be mounted on the

top or sides of the machine.

2.A. 1.2 Set unit in place and adjust the feet to level the machine.

2.A. 1.3 Fasten the tables to the load and unload side of the machine. Most installations require fastening the

turn-down lip of the dish tables to the side of the machine with flathead counter-sunk screws. The table design

should provide horizontal clearance of 30" for servicing.

2.A.2 ELECTRICAL CONNECTIONS

2.A.2.1 Connect electrical lines sized for the correct voltage, current and phase of the machine.

These should agree with machine requirements indicated on the nameplate and labels in control

panel.

2.A.2.2 A single-point electrical connection is provided for the pumps, control circuit, and wash

tank heater.

2.A.2.3 If an electric water booster is provided connect the power directly to the booster. If the

Insinger Self-Contained booster is provided the machine comes standard with a Single-Point

Connection (to include the booster).

CAUTION

Connections must be made to a circuit breaker or fused disconnect as provided

by the end-user and required by local codes. A laminated wiring diagram is

inside the control panel

Fuse Sizing Chart

Model 208VAC/30 230VAC/30 380VAC/30 460VAC/30 220VAC/10

18-5(C)

steam heat

6A 6A 6A 6A 15A

18-5(C)

electric heat

15A 15A 10A 10A 25A

18-5(C)

electric heat

Insinger SCB

60A 45A 30A 25A 90A

18-5H

steam heat

10A 10A 6A 6A 20A

18-5H

electric heat

25A 25A 15A 15A 40A

rlsd: 1/97, 10/98

s:\wp51\manual\mnl185

/