3227447

Rev. A

AUGUST 2012

RNP SERIES

REFRIGERATED COMPRESSED AIR DRYERS

OPERATOR

MANUAL

RNP25 RNP35 RNP50

2

GENERAL SAFETY INFORMATION

1. PRESSURIZED DEVICES:

This equipment is a pressure containing

device.

• Donotexceedmaximumoperating

pressure as shown on equipment

serial number tag.

• Makesureequipmentisdepressurizedbefore

workingonordisassemblingitforservice.

2. ELECTRICAL:

This equipment requires electricity to

operate.

• Installequipmentincompliancewith

all applicable electrical codes.

• Standardequipmentissuppliedwithelectrical

enclosuresnotintendedforinstallationinhazardous

environments.

• Disconnectpowersupplytoequipmentwhen

performinganyelectricalservicework.

3. BREATHING AIR:

• Airtreatedbythisequipmentmay

notbesuitableforbreathingwithout

furtherpurication.

Refertoapplicablestandardsand

specicationsfortherequirements

forbreathingqualityair.

RECEIVING, MOVING, AND UNPACKING

A. RECEIVING

Thisshipmenthasbeenthoroughlychecked,packedand

inspectedbeforeleavingourplant.Itwasreceivedin

goodconditionbythecarrierandwassoacknowledged.

CheckforVisibleLossorDamage.Ifthisshipmentshows

evidenceoflossordamageattimeofdeliverytoyou,

insistthatanotationofthislossordamagebemadeon

the delivery receipt by the carrier’s agent.

B. UNPACKING

Checkforconcealedlossordamage.Whenashipment

hasbeendeliveredtoyouinapparentgoodorder,but

concealeddamageisfounduponunpacking,notifythe

carrier immediately and insist on his agent inspecting

the shipment. Concealed damage claims are not our

responsibilityasourtermsareF.O.B.pointofshipment.

C. MOVING

Inmovingortransportingdryer,donottipdryerontoits

side.

D. STORAGE

IMPORTANT:Donotstoredryerintemperaturesabove

130°F (54.4°C).

3

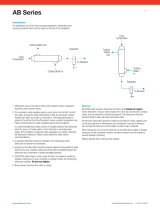

Compressor

Oil Removal

Filter

Aftercooler

Automatic Drain

Dryer

Separator

Receiver

TYPICAL COMPRESSED AIR SYSTEM

INSTALLATION

Ambient Air Temperature

Locatethedryerindoorswheretheambientairtemperature

willbebetween40°Fand100°F.Intermittentoperationat

ambient temperatures up to 113°F will not damage the dryer

but may result in a higher dew point or dryer shutdown

duetohighrefrigerantdischargepressure(seeFieldService

Guide).

Donotoperateair-cooleddryersatambientairtemperatures

below40°F.Suchoperationmayresultinlowsuction

pressure,causingfreeze-up.

Callyourlocaldistributorifprolongedoperationatambient

temperatures above 100°F or below 40°F is unavoidable.

Location and Clearance

Mountthedryeronalevelbase.Installthedryerinaclean,

well-ventilatedareatoreducefoulingofthecondensercoils

with dirt and dust.

Vaporsandcontaminantscorrosivetocopperandaluminum

mustnotbeintheareaofthedryeroraircompressorintake.

Allowatleast6inchesclearancefromthefrontandfromthe

condensercoilserviceaccess.Installthedryerwiththeframe

level.Anchorboltsarenotrequired.

System Arrangement

Liquidwaterintheinletairwilladverselyaffectthe

performanceofthedryer.Installthedryerdownstreamofan

aftercoolerorseparatorsothatthetemperatureofthedryer

inletairdoesnotexceed120°Fandtheinletairdoesnot

contain any liquid water.

Mostcompressedairsystemsrequireltersforremoval

ofsolidandliquidcontaminants.Whenanoil-removal

lterisused,itshouldbeinstalleddownstreamofthe

refrigerateddryer.Thedryerwillremovesomeentraineddirt,

extendingthelifeofthereplaceablelterelement.Outlet

air temperature may be 10 to 30 degrees higher than inlet

airtemperature.Thisisnormal.Consultyourdistributorifa

lower outlet air temperature is required.

Piping and Connections

Pipingmustbefurnishedbytheuserunlessotherwise

specied.Connectionsandttingsmustberatedforthe

maximumoperatingpressuregivenonthedryerdataplate

andmustbeinaccordancewithapplicablecodes.Support

allpiping;donotallowtheweightofanypipingtostressthe

dryerorlters.Inletandoutletshutoffvalvesandabypass

valvearerecommended.Pipingshouldbeatleastthesizeof

theinletandoutletconnectionstominimizepressuredrop

intheairsystem.SeeEngineeringDatasectionfordryerinlet

and outlet connections.

Removing Condensate

Aseparatorwithanautomaticdrainvalveissuppliedwith

each dryer. The user must install a separate discharge line

atthedrainconnectiontocarryoffcondensatetoan

environmentally approved condensate collection/disposal

system.Securelyanchordrainlinetopreventwhipping.

Ifcloggingoftheautomaticdrainisaproblem,installa

particulatelterbeforethedryertokeepsolidparticlesfrom

enteringthedryer.Contactyourlocaldistributorforthe

appropriateparticulatelter.

Electrical Connections (See Figure 1)

Dryerisdesignedtooperateonthevoltage,phaseand

frequencylistedontheserialnumbertag.Referencetag

priortomakingelectricalconnection.Dryersaresupplied

withacordandplug.Installinreceptacleofpropervoltage.

Operationofdryerswithimproperlinevoltage

constitutesabuseandcouldaffectthedryerwarranty.

4

INSTRUMENTATION

ON/OFF Switch

ThedryerisequippedwithanON/OFFswitchonthefront

panel.Alightsignalswhenthedryerison.

Color Indicator

Alldryersareequippedwithacolorindicatorwhichindicates

dryerconditionsasfollows:

Itisnormalfortheindicatorcolortobeintheredzonewhen

thedryerisrstturnedonandthenmovetothegreenzone

whenthedryerreachesitsnormaloperatingtemperature.If

thisindicatorisintheredzoneduringnormaloperation,turn

thedryerofftoavoidcompressordamage.RefertotheField

ServiceGuideforadditionalinformation,orcallyourlocal

distributor.

DRAIN VALVES

Anelectronicdrainvalveissuppliedtoautomatically

dischargecondensatefromthedryer.Thedrainvalveand

itscontrolsareaccessiblefromtherearofthedryer.The

electronic drain valve has two indicators and a test button to

helpverifyoperation.Pushingthetestbuttoncausesthe

drainporttoclickopen.Ifeitherindicatorfailstoturnon

atthepropertime,refertothemaintenancesectionofthis

manual.Drainvalveoperationiscontrolledbyanelectronic

timer.Thedrainopeningcanbesetfrom0.5secto10sec.

Thedraincyclecanbesetfrom0.5minto45min.

Drain Valve Adjustment

Tominimizeairlosses,thedraintimershouldbeadjusted

toopenthedrainportjustlongenoughtodischarge

accumulatedcondensate.Setthetimersothatonlyair

dischargesattheendoftheopenperiod.

Recommended Drain Settings

Time

ModelSCFM Open(Sec) Closed(Min)

25 2 10

35 2 10

50 2 10

NOTE:Ifliquiddischargesastheportisclosing,setthetimerfora

shortercycleoralongeropening.Theamountofcondensatewill

vary as ambient conditions and inlet flow rates change.

START-UP/OPERATION

Follow the procedure below to start your dryer. Failure

tofollowtheprescribedstart-upprocedurewillinvalidate

thewarranty.Ifproblemsariseduringstart-up,callyour

distributor.

RefertoSerialNumberTagfordryeroperating

capacity.Donotexceedrecommendedcapacity.

Drainconnectionsmustbemadebeforethedryercanbe

operated.Thedryersarefullyautomaticandrequireno

auxiliarycontrols.

1. Connectinletandoutletlinestothedryer.Reference

dryerindentationsandinstructiontagforappropriate

inlet and outlet connections.

2. Routedrainconnectionstoacondensateseparatoror

approved collection point.

3. Turntheon/offswitchtoon.Doublecheckconnections.

4. Afterthedryerhasbeenrunningfor30minutes:

a. Checkthaton/offlightedswitchisglowing.Iflight

isnotglowing,unplugunitandrefertoFieldService

Guideforadditionalinformationorcallyourlocal

distributor.

b. ChecktheColorIndicator.IftheIndicatorisinthe

redzone,unplugthedryer.RefertotheField

ServiceGuideforadditionalinformation,orcallyour

local distributor.

c. Conrmthatcondensateisdischargingfromthe

drain. This can only be done when there is air flow

through the dryer.

ReferenceSerialNumberTagforappropriate

powerrequirement/connectionrating.Makeotherdryer

connections prior to connecting power source.

Thedryerisdesignedtoruncontinuously.Letthedryerrun

evenwhenthedemandforcompressedairisinterrupted;

thedryerwillnotfreezeup.

Operating Check Points

1. Powerlightison,lightisilluminated.

2. Condensateisdischargingproperly.

3. ColorIndicatorisintheGreenZone.

SHUTDOWN

Whenthedryermustbeshutdownformaintenanceorother

reasons,usethefollowingprocedure:

1. Turnthepoweron/offswitchtooff.

2. Disconnectthemainpowersupply.

Ifmechanicalrepairsaretobemadeorserviceisperformed,

venttheinternalpressureofthedryertoatmospheric

pressure.Restartthedryeraccordingtothestart-up

instructions.

Disconnectpowersupplyanddepressurize

dryerbeforeservicing.Dismantlingorworkingonany

componentofthecompressedairsystemunderpressure

maycauseequipmentfailureandseriouspersonalinjury.

5

MAINTENANCE

Thedryersrequirelittlemaintenanceforsatisfactory

operation.Gooddryerperformancecanbeexpectedifthe

followingroutinemaintenancestepsaretaken.

Disconnectpowersupplyanddepressurize

dryerbeforeperforminganymaintenance.

General

Forcontinuedgoodperformanceofyourrefrigerateddryer,

allrefrigerationsystemmaintenanceshouldbeperformedby

acompetentrefrigerationmechanic.

NOTE:Beforecorrectivemaintenanceisdoneduringthe

warrantyperiod,callyourlocaldistributorandproceed

accordingtoinstructions.Refertothewarrantyforlimitsof

your coverage.

Daily Maintenance

Checktheseparatorforcondensatedischarge.Ifno

dischargeisevident,depressurizeandperformthefollowing:

1. ElectricDrain-Cleanstrainerand/orclean/replace

solenoid valve.

Monthly Maintenance

Inspectthecondensercoils.Removeaccumulateddustand

dirtwithasoftbrushorwithairfromanOSHAapproved

compressedairnozzlethatlimitsthedischargepressureto

30 psig.

Electronic Drain Valve Disassembly and Servicing

Donotdisassembledrainvalvetimerorattempt

torepairelectricalparts.Replacetimerifdefective.

Thedrainvalvedischargecondensatethroughafull-port

drain opening. The valve body may need to be cleaned under

conditionsofgrossparticulatecontamination.

Todisassemblethedrainvalvebodyforcleaningandother

maintenance:

1. Turnpowerswitchoff.

2. Disconnectmainpowersupplytodryer.

3. Depressurizeunit.

4. LockoutandtagpowersupplyinaccordancewithOSHA

requirements.

Ifpowersupplyisnotconnectedandunitis

notdepressurizedbeforedisassembly,seriouspersonalinjury

and valve damage may result.

5. Removescrewandwasherfromfrontofthedrainvalve.

6. Removethepowersupplyconnectorandgasket(with

thetimerassemblyifattached)fromthesolenoidcoil

housing.Donotdamageorlosethegasket.

7. Removecoilxingnutandspringwasherfromtopof

solenoid coil housing.

8. Liftsolenoidcoilhousingoffsolenoidcoreinvalvebody.

9. Unscrewsolenoidcorefromvalvebody.

Oncethedrainvalveisdisassembled,thefollowing

maintenancecanbeperformed.

1. Inspectinternalpartsofvalvebody;cleanorreplaceas

required.

NOTE:Replacesolenoidvalveifcomponentdamageis

observed.

2. Removedebrisfromvalvebody.

3. Wipesolenoidcorecomponentswithacleanclothor

blowoutdebriswithcompressedairfromanOSHA-

approvedairnozzlethatlimitsitsdischargepressureto

30 psig.

4. Checkthattheplungerassemblyiscleanandmoves

freelyinhousing.

5. Iftimerisattachedtovalvebody,checkelectrical

continuity across timer assembly.

Toreassemblethedrainvalve,reversethesequence

oftheprecedingsteps.Afterthedrainvalveis

reassembled,connectthemainpowersupplytothe

dryer.Whenthedryerisreturnedtoservice,check

thedrainvalveforairorcondensateleaks;tighten

connectionsasrequiredtocorrectleaks.Checkthedrain

cycle;adjustthetimeraccordingtotheprocedureinthe

drainvalveadjustmentsection.

Returns to Manufacturer

Ifthedryeroracomponentofthedryermustbereturnedto

themanufacturer,rstcallyourlocaldistributorforareturn

authorizationnumberandshippingaddress.Yourdistributor

willinformyouwhetherthedryeroronlyacomponentmust

bereturned.Markthepackagewiththereturnauthorization

numberandshipfreightprepaidasdirectedbyyourlocal

distributor.

6

FIELD SERVICE GUIDE

Problemsmostfrequentlyencounteredwithrefrigerated

dryersarewaterdownstreamofthedryerandexcessive

pressuredrop.Mostcausescanbeidentiedandremedied

byfollowingthisguide.

Closedrefrigerationsystemsarepotentially

dangerous.Workontherefrigerationsystemmustbedone

onlybyacompetentrefrigerationmechanic.Donotrelease

uorocarbonrefrigerantstotheatmosphere.Allrefrigerants

mustberecoveredperEPArequirements.Donotsmoke

whenarefrigerationleakissuspected.Burningmaterials

maydecomposerefrigerants,formingatoxicgasoracids

thatmaycauseseriousinjuryandpropertydamage.Before

dismantlinganypartofthedryerorcompressedairsystem,

completely vent the internal pressure to the atmosphere.

PROBLEM SYMPTOM POSSIBLE CAUSE REMEDY

Water Downstream of

Dryer

Refrigerantcompressornot

running.

Leakinrefrigerationsystem. Contact your local distributor.

Compressor overheated. Turndryeroff,wait30minutes;turndryeron.

(Motorthermostatself-starting)

Compressor burned out. Contact your local distributor.

Nocondensatedischargingfrom

dryer.

Failureofdrain. Dismantleandcleanstrainer.Repairorreplace

solenoid valve.

Dryerinletairtemperaturetoo

high.

Aftercoolermalfunction. Checkaftercoolerdischargetemperatureand

reducetodryerdesigncondition(120°Fmax)

Excessive Pressure

Drop Across Dryer

Lowoutletpressure. Dryerundersized(mayalsocause

waterdownstreamofdryer)

Checkairowanddryercapacity.Reduceairowor

resizeandreplacedryer.

Dryericingup.(checkatseparator) Contact your local distributor.

Color Indicator Out of

Green Zone

Indicatorinredzone. Inletairtemperaturetoohigh. Reduceaftercoolerdischargetemperaturetodesign

conditions(SeeEngineeringData).

Condenserfouledorclogged. Clean or replace condenser.

Inletairtemperaturetoohigh. Reduceaftercoolerdischargetemperaturetodesign

conditions.(SeeEngineeringData)

Highambienttemperature. Ventilatearea.

Improperadjustmentofexpansion

valve.

Removecapfromtheexpansionvalveandturnthe

screwuntiltheindicatorisinthegreenzone.

Indicatorinbluezone. Improperadjustmentofexpansion

valve.

Adjusttheexpansionvalveuntiltheindicatorisin

thegreenzone.

Lowambienttemperature. Increaseambienttemperaturetodesignconditions.

7

ENGINEERING DATA

MODEL 25 35 50

SPECIFICATIONS

Rated Capacity

a

-(scfm) 25 35 50

Inlet/OutletConnections-(inches) 3/4 3/4 3/4

Dimensions

Height-(inches) 22.2 22.2 22.2

Length-(inches) 15.5 15.5 19.7

Width-(inches) 14.5 14.5 19.7

PowerSupply-(V/Ph/Hz) 115/1/60 115/1/60 115/1/60

RefrigerantCompressorRating-(hp) 1/4 1/4 1/3

InputPower-(kW) 0.47 0.47 0.63

RefrigerantType

b

R-134a R-134a R-134a

a

Rating conditionsare100°Finlettemperature,100psiginletpressure,100%inletrelativehumidity,100°Fambienttemperature@60Hz.PerCAGIADF-100.

b

Refertodryerdataplateforrefrigerantcharge.

MODEL 25, 35, 50

MINIMUM - MAXIMUM OPERATING CONDITIONS

Min.-Max.InletAirPressure(compressedairatinlettodryer) 30-250psig

Min.-Max.InletAirTemperature(compressedairatinlettodryer) 40°F-120°F

Min.-Max.AmbientTemperature 40°F-110°F

NOTE:Continuousoperationintheabovemaximumandminimumoperationconditionsisnotallowable.

8

ELECTRICAL SCHEMATICS

ON/OFF SWITCH

WITH RUNNING LAMP

R

25

6

PTC STARTER

S

M

COMP.

1PH

C

OVERLOAD

PROTECTOR

DRAIN SOL.

VALVE TIMER

T

Figure 1

25-50 scfm models

9

AIR AND REFRIGERANT FLOW SCHEMATICS

Figure 2

25-50 scfm models

HEAT EXCHANGER

REHEATER

AIR OUTLET

AUX. CONDENSER

CONDENSER

REF. COMPRESSOR

ELECTRONIC

DRAIN

VALVE

LIQUID RECEIVER

FILTER DRYER

CONSTANT PRESSURE

EXPANSION VALVE

DRAIN OUTLET

COLOR INDICATOR

C.I.

CHILLER

EVAPORATOR

AIR INLET

10

REPLACEMENT PARTS

Item 25 35 50

RefrigerantCompressor 3149273 3146980 3149274

Condenser 3149275 3149275 3149275

LiquidReceiver/FilterDryer 1283369 1283369 1283369

ConstantPress.ExpansionValve 3041489 3041489 3041489

ElectronicDrainValve 3149293 3149293 3149293

ColorIndicator 3041493 3041493 3041493

On/OffSwitch 3041494 3041494 3041494

HeatExchanger 3149278 3149279 3149280

MaintenanceKits RNPJMK2 RNPJMK2 RNPJMK2

AUTHORIZATION FROM THE SERVICE DEPARTMENT IS NECESSARY BEFORE MATERIAL IS

RETURNED TO THE FACTORY OR IN-WARRANTY REPAIRS ARE MADE.

WARRANTY

Themanufacturerwarrantstheproductmanufacturedbyit,whenproperlyinstalled,operated,applied,andmaintainedinaccordancewithproce-

duresandrecommendationsoutlinedinmanufacturer’sinstructionmanuals,tobefreefromdefectsinmaterialorworkmanshipforaperiodas

speciedbelow,providedsuchdefectisdiscoveredandbroughttothemanufacturer’sattentionwithintheaforesaidwarrantyperiod.

Themanufacturerwillrepairorreplaceanyproductorpartdeterminedtobedefectivebythemanufacturerwithinthewarrantyperiod,provided

suchdefectoccurredinnormalserviceandnotasaresultofmisuse,abuse,neglectoraccident.Normalmaintenanceitemsrequiringroutinereplace-

mentarenotwarranted.Thewarrantycoverspartsandlaborforthewarrantyperiodunlessotherwisespecied.Repairorreplacementshallbemade

atthefactoryortheinstallationsite,atthesoleoptionofthemanufacturer.Anyserviceperformedontheproductbyanyoneotherthanthemanu-

facturermustrstbeauthorizedbythemanufacturer.

Unauthorizedservicevoidsthewarrantyandanyresultingchargeorsubsequentclaimwillnotbepaid.Productsrepairedorreplacedunderwarranty

shallbewarrantedfortheunexpiredportionofthewarrantyapplyingtotheoriginalproduct.

Theforegoingistheexclusiveremedyofanybuyerofthemanufacturer’sproduct.Themaximumdamagesliabilityofthemanufactureristheoriginal

purchasepriceoftheproductorpart.

THEFOREGOINGWARRANTYISEXCLUSIVEANDINLIEUOFALLOTHERWARRANTIES,WHETHERWRITTEN,ORAL,ORSTATUTORY,ANDISEXPRESSLYINLIEU

OFTHEIMPLIEDWARRANTYOFMERCHANTABILITYANDTHEIMPLIEDWARRANTYOFFITNESSFORAPARTICULARPURPOSE.THEMANUFACTURERSHALL

NOTBELIABLEFORLOSSORDAMAGEBYREASONOFSTRICTLIABILITYINTORTORITSNEGLIGENCEINWHATEVERMANNERINCLUDINGDESIGN,MANUFAC-

TUREORINSPECTIONOFTHEEQUIPMENTORITSFAILURETODISCOVER,REPORT,REPAIR,ORMODIFYLATENTDEFECTSINHERENTTHEREIN.

THEMANUFACTURER,HISREPRESENTATIVEORDISTRIBUTORSHALLNOTBELIABLEFORLOSSOFUSEOFTHEPRODUCTOROTHERINCIDENTALORCONSE-

QUENTIALCOSTS,EXPENSES,ORDAMAGESINCURREDBYTHEBUYER,WHETHERARISINGFROMBREACHOFWARRANTY,NEGLIGENCEORSTRICTLIABILITY

INTORT.

Themanufacturerdoesnotwarrantanyproduct,part,material,component,oraccessorymanufacturedbyothersandsoldorsuppliedinconnection

withthesaleofmanufacturer’sproducts.

Warranty Period

Partsandlaborfortwo(2)yearsfromthedateofshipmentfromthefactory;heatexchangersarecovered(partsonly)foranadditionalthree(3)

years(totalofve[5]).Onunitsthatmanufacturerrequestsbereturnedtothefactory,aonetimeremoval/reinstallationlaborallowanceasnotedin

theServiceWarrantyPoliciesandProceduresHandbookwillapply.Freighttothefactoryfromtheinstallationsiteandtotheinstallationsitefromthe

factorywillbepaidbythemanufacturer;meansoftransportationtobespeciedbymanufacturer.

SERVICE DEPARTMENT: (724) 746-1100

Curtis-Toledo, Inc.

1905 Kienlen Avenue, St. Louis Missouri 63133

WWW.FSCURTIS.COM

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

FS-Curtis RNP50 User manual

- Type

- User manual

- This manual is also suitable for

Ask a question and I''ll find the answer in the document

Finding information in a document is now easier with AI

Related papers

Other documents

-

Champion CRN75 User manual

-

PSB G5C 0250 User manual

-

AT&T D-320 User manual

-

Ingersoll-Rand IRN 20HP Operation and Maintenance Manual

-

Ingersoll-Rand RD1600A Installation, Operation & Maintenance Manual

-

Deltech Fitness PYRAMID 8DM25 User manual

Deltech Fitness PYRAMID 8DM25 User manual

-

Ingersoll-Rand SSR UP6-15c Operation and Maintenance Manual

-

Thermal Transfer AB Series Datasheet

Thermal Transfer AB Series Datasheet

-

Quincy Compressor QSI 1500 User manual

-

Ingersoll-Rand HRD30 Operator's Instruction Manual