Rinnai Commercial Water Heating Brochure Quick start guide

- Type

- Quick start guide

Rinnai Commercial Water Heating Brochure Below you will find brief product information for Rinnai Commercial Water Heating Brochure. This state-of-the-art system is engineered to meet the demands of even the most challenging commercial applications, delivering an endless supply of hot water while conserving energy and saving you money.

Here's a quick overview of its capabilities:

- Precisely engineered and irrefutably trusted, Rinnai Commercial Water Heaters are built to last and perform flawlessly.

- Featuring condensing technology, these water heaters maximize energy efficiency, reducing your operating costs.

Rinnai Commercial Water Heating Brochure Below you will find brief product information for Rinnai Commercial Water Heating Brochure. This state-of-the-art system is engineered to meet the demands of even the most challenging commercial applications, delivering an endless supply of hot water while conserving energy and saving you money.

Here's a quick overview of its capabilities:

- Precisely engineered and irrefutably trusted, Rinnai Commercial Water Heaters are built to last and perform flawlessly.

- Featuring condensing technology, these water heaters maximize energy efficiency, reducing your operating costs.

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

-

13

13

-

14

14

-

15

15

-

16

16

-

17

17

-

18

18

-

19

19

-

20

20

-

21

21

-

22

22

-

23

23

-

24

24

Rinnai Commercial Water Heating Brochure Quick start guide

- Type

- Quick start guide

Rinnai Commercial Water Heating Brochure Below you will find brief product information for Rinnai Commercial Water Heating Brochure. This state-of-the-art system is engineered to meet the demands of even the most challenging commercial applications, delivering an endless supply of hot water while conserving energy and saving you money.

Here's a quick overview of its capabilities:

- Precisely engineered and irrefutably trusted, Rinnai Commercial Water Heaters are built to last and perform flawlessly.

- Featuring condensing technology, these water heaters maximize energy efficiency, reducing your operating costs.

Ask a question and I''ll find the answer in the document

Finding information in a document is now easier with AI

Related papers

-

Rinnai MSB-C2 User manual

-

Rinnai RWMPB01 Installation guide

-

Rinnai V94XIN Operating instructions

-

Rinnai MC-100V-1-S User manual

-

Rinnai RWM101 Installation guide

-

Rinnai V53e (REU-VAM1620W-US) Quick start guide

-

Rinnai 790021 Installation guide

-

Rinnai RWM101 Installation guide

-

Rinnai RWM101 Dimensions Guide

-

Rinnai RHS199100SEiP Operating instructions

Other documents

-

EZ Tankless EZULTNG User manual

-

American Water Heater GTS-505-PE User manual

-

STIEBEL ELTRON MINI 6-2 User guide

-

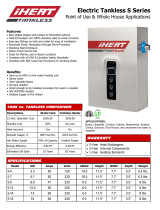

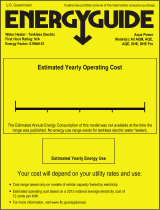

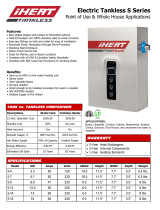

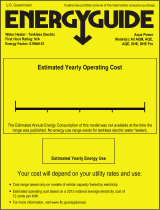

IHeat S-12 Specification

IHeat S-12 Specification

-

IHeat S-12 Specification

IHeat S-12 Specification

-

Worcester Greenstar 8000 Style Quick start guide

-

Maytag ATMOSPHERIC VENTED WATER HEATER User manual

-

Maytag ATMOSPHERIC VENTED WATER HEATER User manual

-

Rheem Tankless Mid-Efficiency 64 Direct Vent Indoor User manual

-

AquaPower AQM 2-1 User guide

AquaPower AQM 2-1 User guide