Page is loading ...

INSTALLATION INSTRUCTIONS

Centerline & Ecoline Incoming Power Wiring Conversion For Door Type High

Temp Machine

CDH AND EDH WIRING CONVERSION

These instructions are only intended for use by properly trained and qualified service technicians.

If you do not have technical training for this product, you should read the following procedure, in its entirety, to

determine if you have the necessary tools, instruments and skills required to perform the procedure. Procedures for

which you do not have the necessary tools, instruments and skills should be performed by a trained Hobart Service

technician.

The reproduction, transfer, sale or other use of this manual, without the express written consent of Hobart Service,

is prohibited.

INCOMING POWER CONVERSIONS COVERED:

240V Wired Machine (Factory Default) to 208V Wired Machine

CDH and EDH 3PH to 1PH Wiring Conversion

240V Wired Machine (Factory Default) to 208V Wired Machine

3TB JUMPER

NOTE: Incoming voltage must be correctly wired for proper transformer function.

NOTE: Follow the Instructions below to convert a 240V wired machine (Factory Default) to a 208V wired machine.

NOTE: Reverse directions below to convert 208V wiring to 240V wiring.

WARNING

Disconnect the electrical power to the machine and follow lockout / tagout procedures.

1. Remove LOWER FRONT PANEL.

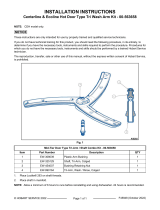

2. Loosen/Remove screws on 3TB locations 1, 2 and 3 (1, Fig. 1).

Fig. 1

© HOBART SERVICE 2022 Page 1 of 8 F45912 Rev. A (August 2022)

3. Move jumper (2, ) from 240V position (3TB-1 and 3TB-2) to 208V position (3TB-2 and 3TB-3) (2, Fig. 2).

Fig. 2

4. Reinstall/Tighten screws on 3TB locations 1, 2 and 3 (1, Fig. 2). Tighten all screws to 17.5 in*lbs.

5. Turn on machine and test unit for proper operation.

6. Reinstall any removed panels.

CDH and EDH 3PH to 1PH Wiring Conversion

NOTE: WIRING CHANGES REQUIRED: 1TB Wiring 4TB WIRING BOOSTER HEATER WIRING - JUMPER

BAR

NOTE: Follow the Instructions below to convert a Three (3) Phase (3 Hot + Ground) wired machine (Factory Default)

to a Single (1) Phase (2 Hot + Ground) wired machine.

NOTE: Reverse directions below to convert Single Phase to 3 Phase wiring.

1TB Wiring

WARNING

Disconnect the electrical power to the machine and follow lockout / tagout procedures.

1. Remove LOWER FRONT PANEL.

2. Move wire labeled ‘1TB-1 (3PH) -4 (1PH)' from 1TB-1 (Fig. 3) to 1TB-4 (Fig. 4).

F45912 Rev. A (August 2022) Page 2 of 8

Fig. 9

Fig. 10

4. Contrinue to Booster Heater Wiring - Jumper Bar.

BOOSTER HEATER WIRING - JUMPER BAR

1. Remove red cover used for protecting the booster heater connections.

2. Remove the nuts currently clamping down wire and jumper bar at wire labeled ‘BSTR-HTR2’ (Terminal C) and

bar connection to Terminal A (Fig. 12).

F45912 Rev. A (August 2022) Page 6 of 8

Fig. 11

Fig. 12

3. Remove Wire labeled ‘BSTR-HTR2’ from Terminal C.

4. Remove jumper bar connecting Terminal C and Terminal A.

5. Reattach Wire and Nut labeled ‘BSTR-HTR2’ to Terminal C that it was previously attached to (Fig. 14).

NOTE: Tighten nut to 16 in*lbs. Use 7 mm wrench to hold back nut when tightening.

Fig. 13

Fig. 14

6. Remove nut and wire labeled ‘BSTR-HTR1’ currently housed on Terminal B (Fig. 12).

7. Install jumper bar to connect Terminal A (where jumper bar was previously attached) and Terminal B (where

wire labeled ‘BSTR-HTR1’ was previously attached). Have the slotted side of the jumper bar facing out (Fig.

15).

Page 7 of 8 F45912 Rev. A (August 2022)

Fig. 15 Fig. 16

8. Reattach nut clamping down jumper bar at Terminal A (Fig. 14).

NOTE: Verify distances between both jumper bars. There MUST be a minimum 1.6mm (1/16") gap (Fig. 16). Use

stainless steel BOOSTER HEATER GAUGE provided in new machine documentation package. Gauge should slide

freely between jumper bars. If gauge is not present, 1/16" allen wrench may be used as gauge.

NOTE: Tighten nut to 16 in*lbs. Use 7 mm wrench to hold back nut when tightening.

9. Reattach wire labeled ‘BSTR-HTR1’ and nut at Terminal B where previously attached (Fig. 14).

NOTE: Tighten nut to 16 in*lbs. Use 7 mm wrench to hold back nut when tightening.

10. Reattach the red cover used for protecting the booster heater connections.

11. Test unit for proper operation.

12. Reinstal any removed panels and place into service.

F45912 Rev. A (August 2022) Page 8 of 8

/