Page is loading ...

INSTRUCTION MANUAL

99916070 REV 9 © 2015 Greenlee Textron Inc. 4/15

Read and understand all of the instructions and

safety information in this manual before operating

or servicing this tool.

Register this product at www.greenlee.com

H4670

Submersible Trash Pump

Serial Code GLW

Español ............... 11

Français .............. 21

H4670 Submersible Trash Pump

Greenlee / A Textron Company 4455 Boeing Dr. • Rockford, IL 61109-2988 USA • 815-397-7070

2

Description

The Greenlee Utility H4670 Submersible Trash Pump is

intended for pumping water with solids in any type of

non-explosive environment. This pump operates with

either open-center or closed-center hydraulic systems.

The quiet, self-priming pump mechanism operates

efciently and features a rugged, direct-drive, gear-type

hydraulic motor. Oil-lubricated seals prevent damage

when the pump is unintentionally run dry.

Safety

Safety is essential in the use and maintenance of

Greenlee Utility tools and equipment. This instruction

manual and any markings on the tool provide informa-

tion for avoiding hazards and unsafe practices related to

the use of this tool. Observe all of the safety information

provided.

Purpose of this Manual

This manual is intended to familiarize all personnel with

the safe operation and maintenance procedures for the

following Greenlee Utility tool:

H4670 (42192) Submersible Trash Pump

Serial Code GLW

Keep this manual available to all personnel.

Replacement manuals are available upon request

at no charge at www.greenlee.com.

Other Publications

SAE Standard J1273 (Hose and Hose Assemblies):

Publication 99930323

All specications are nominal and may change as design

improvements occur. Greenlee Textron Inc. shall not be liable for

damages resulting from misapplication or misuse of its products.

Loctite is a registered trademark of Henkel Corp.

Mobilgrease is a registered trademark of Mobil Oil Corp.

KEEP THIS MANUAL

Table of Contents

Description .................................................................... 2

Safety ............................................................................ 2

Purpose of this Manual ................................................. 2

Other Publications ......................................................... 2

Important Safety Information .....................................3–4

Identication .................................................................. 5

Specications ................................................................ 6

Hoses and Fittings ........................................................ 7

Hose Connections ......................................................... 7

Typical Setup ................................................................. 7

Operation ....................................................................... 8

Maintenance .................................................................. 8

Troubleshooting ............................................................. 9

Español ................................................................... 11–19

Français .................................................................. 21–29

Deutsch .................................................................. 31–39

Italiano .................................................................... 41–49

SERVICE

Disassembly ................................................................. 31

Inspection ..................................................................... 31

Assembly ...................................................................... 32

Illustrations and Parts Lists .................................... 33–35

H4670 Submersible Trash Pump

Greenlee / A Textron Company 4455 Boeing Dr. • Rockford, IL 61109-2988 USA • 815-397-7070

3

IMPORTANT SAFETY INFORMATION

SAFETY

ALERT

SYMBOL

This symbol is used to call your attention to hazards

or unsafe practices which could result in an injury or

property damage. The signal word, dened below,

indicates the severity of the hazard. The message

after the signal word provides information for pre-

venting or avoiding the hazard.

Immediate hazards which, if not avoided, WILL result

in severe injury or death.

Hazards which, if not avoided, COULD result in

severe injury or death.

Hazards or unsafe practices which, if not avoided,

MAY result in injury or property damage.

Read and understand all of the

instructions and safety information

in this manual before operating or

servicing this tool.

Failure to observe this warning

could result in severe injury or death.

Wear eye protection when operating

or servicing this tool.

Failure to wear eye protection could

result in serious eye injury from

ying debris or hydraulic oil.

Skin injection hazard:

• Do not use hands to check for

leaks.

• Do not hold hose or couplers

while the hydraulic system is

pressurized.

• Depressurize the hydraulic system

before servicing.

Oil under pressure easily punc-

tures skin, causing serious injury,

gangrene, or death. If you are

injured by escaping oil, seek medical

attention immediately.

Pump water only.

• Do not use to pump drinking water.

• Do not use to extinguish res.

Failure to observe these warnings could result in

severe injury or death.

Keep away from the pump outlet/discharge hose

during operation. Liquid and debris will be thrown by

the pump.

Failure to observe this warning could result in severe

injury or death.

Do not operate the pump if the impeller blades are

exposed. Do not operate the pump without the base

legs and base plate in place.

Failure to observe this warning could result in severe

injury or death.

H4670 Submersible Trash Pump

Greenlee / A Textron Company 4455 Boeing Dr. • Rockford, IL 61109-2988 USA • 815-397-7070

4

IMPORTANT SAFETY INFORMATION

Do not exceed the following hydraulic power source

maximums:

• Hydraulic ow: 34.1 l/min (9 gpm)

• Pressure relief: 138 bar (2000 psi)

• Back pressure: 13.8 bar (200 psi)

Failure to observe this warning could result in severe

injury or death.

Do not disconnect tool, hoses, or ttings while

the power source is running or if the hydraulic uid

is hot. Hot hydraulic uid can cause serious burns.

Do not reverse hydraulic ow. Operation with

hydraulic ow reversed can cause tool malfunction.

Connect the pressure (supply) hose and tank (return)

hose to the proper ports.

Failure to observe this warning could result in severe

injury or death.

Do not change accessories, inspect, adjust, or

clean tool when it is connected to a power source.

Accidental startup can result in serious injury.

Hydraulic oil can cause skin irritation.

• Handle the tool and hoses with care to prevent skin

contact with hydraulic oil.

• In case of accidental skin contact with hydraulic oil,

wash the affected area immediately to remove the

oil.

Failure to observe these precautions may result in

injury.

• Inspect tool before use. Replace any worn or

damaged parts. A damaged or improperly

assembled tool can malfunction, injuring nearby

personnel.

• Inspect the hydraulic hoses and couplings every

operating day. Repair or replace if leakage, crack-

ing, wear, or damage is evident. Damaged hoses

or couplings can fail, resulting in injury or property

damage.

• Use this tool for manufacturer’s intended use only.

Use other than that which is described in this

manual could result in injury or property damage.

• Make sure all bystanders are clear of the work

area when handling, starting, and operating the

tool. Nearby personnel can be injured by ying

debris or by ying parts in the event of a tool

malfunction.

Procedure for connecting or disconnecting hydraulic

hoses, ttings, or components:

1. Move the ow lever on the hydraulic power

source to the OFF position.

2. Stop the hydraulic power source.

3. Follow the sequence under “Hose Connections”

to prevent pressure buildup. In case some

pressure has built up, loosen hoses, ttings, or

components slowly.

Note: Keep all decals clean and legible, and replace

when necessary.

H4670 Submersible Trash Pump

Greenlee / A Textron Company 4455 Boeing Dr. • Rockford, IL 61109-2988 USA • 815-397-7070

5

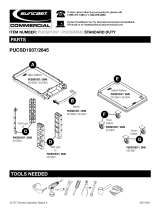

Identification

1

8

2

3

7

6

4

5

1. Serial Number Tag

2. Hydraulic Motor

3. Hydraulic Pressure Port “P” (supply)

4. Hydraulic Tank Port “T” (return)

5. Handle

6. Discharge Port

7. Housing

8. Base Legs and Base Plate

H4670 Submersible Trash Pump

H4670 Submersible Trash Pump

Greenlee / A Textron Company 4455 Boeing Dr. • Rockford, IL 61109-2988 USA • 815-397-7070

6

Specifications

H4670

Type of Hydraulic System: Open-center

or closed-center

Hydraulic Ports:

Pressure (supply): 1/2" male NPT

Tank (return): 1/2" male NPT

Output: Refer to the “Performance Chart” below

Mass/Weight: 26.8 kg (59 lb)

Width (diameter): 368 mm (14.5")

Height (with handle): 400 mm (15.75")

Maximum Trash Diameter: 76.2 mm (3")

Pump Inlet Port: 102 mm (4")

Pump Discharge Port: 4" male NPT

Performance Chart

0

0

Pump Discharge Flow — l/min (gpm)

3025

(800)

3405

(900)

2645

(700)

2270

(600)

1890

(500)

1510

(400)

1135

(300)

755

(200)

375

(100)

3 m (10 ft)

6 m (20 ft)

9 m (30 ft)

12 m (40 ft)

Total Discharge Head of Water

34.1 l/min

(9 gpm)

26.5 l/min

(7 gpm)

22.7 l/min

(6 gpm)

18.9 l/min

(5 gpm)

30.3 l/min

(8 gpm)

3785

(1000)

15 m (50 ft)

Hydraulic Power Source

Do not exceed the following hydraulic power source

maximums:

• Hydraulic ow: 34.1 l/min (9 gpm)

• Pressure relief: 138 bar (2000 psi)

• Back pressure: 13.8 bar (200 psi)

Failure to observe this warning could result in severe

injury or death.

Type of Hydraulic System: Open-center

or closed-center

Flow:

Minimum: 19 l/min (5 gpm)

Recommended: 26.5 l/min (7 gpm)

Maximum: 34.1 l/min (9 gpm)

Filtration: 10 micron (nominal)

Pressure Relief Setting: 138 bar (2000 psi)

Back Pressure (maximum*): 13.8 bar (200 psi)

* 13.8 bar (200 psi) is the maximum agreed standard back pressure

for the HTMA (Hydraulic Tool Manufacturers Association).

Greenlee Utility tools will operate satisfactorily at this standard.

1. Maximum hydraulic uid temperature must not

exceed 60 °C (140 °F). A sufcient oil cooling

capacity is needed to limit the hydraulic uid

temperature.

2. Hydraulic ow must not exceed 34.1 l/min (9 gpm).

Install a ow meter in the return line to measure the

rate of hydraulic ow before using the tool.

3. Pressure relief valve setting must not exceed

138 bar (2000 psi) at your tool’s maximum ow.

Locate the pressure relief valve in the supply circuit

to limit excessive hydraulic pressure to the tool.

Hydraulic Schematic

FILTER

(10 MICRON)

COOLER

RELIEF

VALVE

138 bar

(2000 psi)

CONTROL

VALVE

FLOW METER

T

P

TOOL

RESERVOIR

PUMP

POWER SOURCE

Recommended Hydraulic Fluids

Use any nondetergent, petroleum-based hydraulic

uid which meets the following specications or HTMA

specications.

S.U.S. @:

38 °C (100 °F): 140 to 225

99 °C (210 °F): 40 minimum

Flash Point: 170 °C (340 °F) minimum

Pour Point: –34 °C (–30 °F) minimum

Hydraulic Power Source (cont’d)

H4670 Submersible Trash Pump

Greenlee / A Textron Company 4455 Boeing Dr. • Rockford, IL 61109-2988 USA • 815-397-7070

7

Hoses and Fittings

Installation and Maintenance

Refer to publication 99930323, SAE J1273

(Hose and Hose Assemblies).

Replacement

Refer to a Greenlee Utility catalog or publication

99910322, Low Pressure Quick Couplers, Adapters, and

Hoses.

Do not disconnect tool, hoses, or ttings while

the power source is running or if the hydraulic uid is

hot. Hot hydraulic uid can cause serious burns.

Hose Connections

Tool Port Identification

Three methods are used to identify the pressure (supply)

and tank (return) ports of Greenlee Utility tools. Match

the markings on your tool to this table.

Pressure Port (supply) Tank Port (return)

P T

or

In Out

or

9/16–18 O-ring Boss

(smaller port)

9/16–16 O-ring Boss

(larger port)

Connecting Hoses

1. Move the ow lever on the hydraulic power source

to the OFF position.

2. Stop the hydraulic power source.

3. Connect the tank hose to the tank (return) port on

the hydraulic power source, and then to the tank

port on the tool.

4. Connect the pressure hose to the pressure port on

the tool, and then to the pressure (supply) port on

the hydraulic power source.

Disconnecting Hoses

1. Move the ow lever on the hydraulic power source

to the OFF position.

2. Stop the hydraulic power source.

3. Disconnect the pressure hose from the hydraulic

power source, and then from the tool.

4. Disconnect the tank hose from the tool, and then

from the hydraulic power source.

5. Install dust caps over the ports to prevent

contamination.

Typical Setup

H4670 Submersible Trash Pump

Greenlee / A Textron Company 4455 Boeing Dr. • Rockford, IL 61109-2988 USA • 815-397-7070

8

Operation

Keep away from the pump outlet/discharge hose

during operation. Liquid and debris will be thrown by

the pump.

Failure to observe this warning could result in severe

injury or death.

Do not change accessories, inspect, adjust, or

clean tool when it is connected to a power source.

Accidental startup can result in serious injury.

Wear eye protection when operating

or servicing this tool.

Failure to wear eye protection could

result in serious eye injury from

ying debris or hydraulic oil.

Skin injection hazard:

• Do not use hands to check for

leaks.

• Do not hold hose or couplers

while the hydraulic system is

pressurized.

• Depressurize the hydraulic system

before servicing.

Oil under pressure easily punc-

tures skin, causing serious injury,

gangrene, or death. If you are

injured by escaping oil, seek medical

attention immediately.

1. Connect the discharge hose to the discharge port.

2. Start the hydraulic power source.

Note: Allow the power source to run for a few

minutes to warm the hydraulic fluid.

Do not use the hydraulic hoses to lower or lift the

pump. This will weaken or damage the hoses or

ttings, and could cause a hydraulic uid leak.

Failure to observe this precaution may result in

property damage.

3. Attach a rope or other device to the handle of the

pump. Lower the pump into the material to be

pumped.

4. Actuate the control valve of the power source to

start the ow of hydraulic uid.

5. When nished pumping, actuate the control valve to

stop the ow of hydraulic uid.

Maintenance

Use this maintenance schedule to maximize the tool’s

service life.

Note: Keep all decals clean and legible, and replace

when necessary.

Daily

1. Wipe all tool surfaces clean.

2. Inspect the hydraulic hoses and ttings for signs

of leaks, cracks, wear, or damage. Replace if

necessary.

3. Install dust caps over the hydraulic ports when the

tool is disconnected.

Monthly

1. Perform a thorough inspection of the hydrau-

lic hoses and ttings as described in publication

99930323, SAE J1273 (Hose and Hose Assemblies).

2. Remove and clean the base legs and base plate.

Remove any material that may have accumulated

near the inlet port.

H4670 Submersible Trash Pump

Greenlee / A Textron Company 4455 Boeing Dr. • Rockford, IL 61109-2988 USA • 815-397-7070

9

Problem Probable Cause Probable Remedy

Tool does not operate. Improper power source. Verify that the power source meets

the specications. Refer to the

“Specications” section of this manual.

Hydraulic uid level low. Check the uid level. Check system for

leaks.

Incorrect hydraulic uid viscosity. Use hydraulic uid with the correct

viscosity. Refer to the “Specications”

section of this manual.

Debris stuck in the impeller. Remove debris from the impeller.

Tool operates slowly or

erratically.

Hydraulic uid cold. Allow uid to warm to the operating

temperature. Actuate the tool intermit-

tently to reduce the warming time.

Power source not adjusted

correctly.

Refer to the power source operator’s

manual. Set the ow and pressure to

correspond with the tool.

Hydraulic uid level low. Check the uid level. Check system for

leaks.

Air in the hydraulic system. Refer to the power source manufac-

turer’s instructions for removing air from

the system.

Incorrect hydraulic uid viscosity. Use hydraulic uid with the correct

viscosity. Refer to the “Specications”

section of this manual.

Tool operates backwards. Hose connections at tool reversed. Depressure the hydrauic system. Switch

the hose connections.

Tool operates, but discharge

islow.

Inlet port plugged. Remove debris from the area around the

base legs and base plate.

Discharge hose plugged. Remove and clean hose.

Troubleshooting

Before troubleshooting, determine whether the problem

is in the tool, the hoses, or the power source. Substitute

a tool, hoses, or power source known to be in good

working order to identify the item that is not operating.

If the problem is in the tool, refer to the troubleshoot-

ing table below. If the problem is in the power source,

refer to the troubleshooting section of the power source

instruction manual.

H4670 Submersible Trash Pump

Greenlee / A Textron Company 4455 Boeing Dr. • Rockford, IL 61109-2988 USA • 815-397-7070

10

Bomba sumergible para residuos y sedimentos H4670

Greenlee / A Textron Company 4455 Boeing Dr. • Rockford, IL 61109-2988 USA • 815-397-7070

20

Pompe à déchets submersible H4670

Greenlee / A Textron Company 4455 Boeing Dr. • Rockford, IL 61109-2988 USA • 815-397-7070

30

H4670 Submersible Trash Pump

Greenlee / A Textron Company 4455 Boeing Dr. • Rockford, IL 61109-2988 USA • 815-397-7070

31

SERVICE

Disassembly

Complete disassembly of the tool is not recommended.

If a complete overhaul is necessary, return the tool to

your nearest Greenlee Utility Authorized Service Center.

The disassembly procedure is divided into sections of

the tool. Disassemble only the section(s) necessary to

complete the repair.

Disassemble the tool on a at, clean surface. Take care

not to lose or damage any parts that may fall free during

disassembly.

Base Plate, Base Legs, and Inlet Plate

Note: Mating surfaces of inlet plate (4) and impeller (21)

are critical. Disassemble and handle with care to prevent

damage of these parts.

1. Remove three hex head cap screws (8), lock

washers (9), hex nut (10) and base plate (7).

2. Remove six hex head cap screws (6), three base

legs (5) and inlet plate (4).

Discharge Coupling, Handle, and Volute Housing

1. Remove discharge coupling (34) from volute

housing (1) if necessary.

2. Remove two wing nuts (25) and handle (31) from

volute housing (1).

3. Remove four wing nuts (25). Remove volute

housing (1) from case adapter assembly (11).

4. Remove shim(s) (24) from volute housing (1).

5. Remove six socket head cap screws (2) and lock

washers (3) from volute housing (1), if necessary.

Impeller

Lock impeller (21) in place by inserting a screw driver

between the blades of impeller. Remove hex cap nut

(23), wrought washer (22) and impeller (21) from case

adapter shaft (12). Remove Woodruff key (20) from case

adapter shaft.

Motor and Case Adapter

Remove two socket head cap screws (29). Remove

motor (28) from case adapter (11).

Case Adapter

Note: On later models only, remove O-ring (26) from

case adapter (11).

1. Remove retaining ring (14). Using a plastic head

mallet, tap on threaded end of drive shaft (12) to

drive shaft and bearings (13) out of case adapter.

Pull bearings (13) off drive shaft (12), if necessary.

2. Remove V-ring (17), insert (16) and seal (15) from

case adapter (11).

3. Remove six socket head cap screws (19) to remove

plate (18) from case adapter (11), if necessary.

Motor

Remove 90° elbows (32) and adapters (30 and 36) from

motor (28) pressure port P and tank port T. Remove

O-rings (31) from adapters.

Note: Disassembly of motor (28) is not recommended.

Motor components are not available.

Inspection

Clean all parts with solvent and dry them thoroughly.

Inspect each component as follows:

• Bearings: Insert shaft into bearing. Spin shaft. If shaft

does not spin smoothly, replace the bearings and the

shaft.

• Inspect all disassembled components for cracks,

grooves, chips, or nicks.

H4670 Submersible Trash Pump

Greenlee / A Textron Company 4455 Boeing Dr. • Rockford, IL 61109-2988 USA • 815-397-7070

32

Assembly

Refer to the Illustration and Parts List for correct

orientation and placement of parts.

Replace any O-rings, V-rings, seals, and gaskets on

parts that have been disassembled. Apply hydraulic

uid or O-ring lubricant to all O-rings and all metal

surfaces which they must slide over. When installing

an O-ring which must slide over sharp surfaces, use a

rolling motion and be careful not to damage the O-ring.

Wherever the assembly results in metal-to-metal

contact, coat the surfaces with hydraulic uid or O-ring

lubricant.

Motor

1. Install O-rings (31) on adapters (30 and 36).

2. Apply a thread sealant compatible with hydrau-

lic system oil to the male pipe threads of the 90°

elbows (32). Install adapters and elbows in motor

(28) pressure port and tank port. Tighten ttings

securely.

Case Adapter

1. Apply Loctite

®

271 Threadlocker, or equivalent,

to threads of six socket head cap screws (19), if

removed. Follow the manufacturer’s instructions for

curing. Install plate (18) to case adapter (11) using

the six socket head cap screws. Tighten securely.

2. Fill groove of seal (15) and liberally coat V-ring (17)

with Mobilgrease

®

HP, or equivalent. Install seal (15),

insert (16) and V-ring (17) into case adapter (11).

3. Pack bearings (13) with Mobilgrease HP, or equiva-

lent. If bearings (13) were removed from drive shaft

(12), press the two bearings onto the drive shaft.

Press drive shaft and bearing assembly into case

adapter (11). Be careful not to cut or damage seal

(15) and V-ring (17). Secure using retaining ring (14).

Motor and Case Adapter

1. Install O-ring (26) on the pilot diameter of motor (28)

and install key (37) into keyway on motor shaft (see

below).

372611 28

2. Install motor (28) onto case adapter (11). Align the

key (37) with the keyway in shaft (12). Be careful not

to damage O-ring (26).

3. Install lock washer (38), at washer (39), and two

socket head screws (29) and tighten securely.

Impeller

Install Woodruff key (20) in case adapter shaft (12).

Install impeller (21), wrought washer (22) and cap nut

(23) on case adapter shaft (12). Lock impeller in place by

inserting a screwdriver between the blades of impeller.

Tighten cap nut (23) securely.

Discharge Coupling, Volute Housing,

Impeller Clearance, and Handle

1. Apply Loctite 271 Threadlocker, or equivalent, to the

six socket head cap screws (2), if removed. Follow

manufacturer’s instructions for curing. Install with

the lock washers (3) in volute housing (1). Tighten

securely.

2. Install one shim (24) on volute housing (1). Install

motor, case adapter and impeller assembly in volute

housing. Install inlet plate (4) on volute housing (1).

Check clearance between bottom of impeller (21)

and top of inlet plate (4). Install as many shims (24)

as required (maximum of three), to prevent impeller

from making contact with inlet plate. Impeller must

not make contact with inlet plate. Remove inlet

plate (4).

3. Secure volute housing (1) and handle (33)

to case adapter (11) using six wing nuts (25).

Tighten securely.

4. Install discharge coupling (34) to volute housing (1),

if removed. Tighten securely.

Base Plate, Base Legs, and Inlet Plate

1. Use six hex head cap screws (6) to fasten inlet plate

(4) and three base legs (5) to volute housing (1).

Tighten securely.

2. Use three hex head cap screws (8), lock washers

(9) and hex nuts (10) to fasten base plate (7) to base

legs (5). Tighten securely.

H4670 Submersible Trash Pump

Greenlee / A Textron Company 4455 Boeing Dr. • Rockford, IL 61109-2988 USA • 815-397-7070

33

Illustration

28

29

26

14

13

12

15

16

17

32

30

4

19

21

1

6

5

7

8,9,10

18

2

22

23

20

3

33

11

25

24

31

36

Liberally coat

with grease.

Fill the groove

with grease.

Apply locking compound

to the threads.

Apply locking compound

to the threads.

Use shims (24), maximum

quantity of three, to prevent

impeller (21) from contacting

the plate (4).

34

35

37

38

39

H4670 Submersible Trash Pump

Greenlee / A Textron Company 4455 Boeing Dr. • Rockford, IL 61109-2988 USA • 815-397-7070

34

Parts List

UPC No.

Key 78-3310- Part No. Description Qty

1 Volute housing ....................................................................... 1

2 Screw, cap, 1/4–20 x 1.250 socket head ............................... 6

3 Washer, lock, 1/4 ................................................................... 6

4 41166 50411662 Inlet plate ............................................................................... 1

5 43320 50433202 Base leg ................................................................................. 3

6 Screw, cap, 1/4–20 x .625 hex head...................................... 6

7 43931 50439316 Base plate .............................................................................. 1

8 Screw, cap, 1/4–20 x .750 hex head...................................... 3

9 Washer, lock, .254 x .489 x .062 ........................................... 3

10 Nut, hex, 1/4–20 .................................................................... 3

11 49141 50491415 Case adapter ......................................................................... 1

12† 51350 52026627 Shaft ....................................................................................... 1

13† 43176 50431765 Bearing, .984 x 2.440 x .669 .................................................. 2

14 43939 50439391 Retaining ring, 2.437 .............................................................. 1

15

*

† Seal ........................................................................................ 1

16 43347 50433474 Insert ...................................................................................... 1

17

*

† V-ring ...................................................................................... 1

18 41165 50411652 Plate ....................................................................................... 1

19 Screw, machine, 1/4–20 x .500 at head .............................. 6

20 43972 50439723 Woodruff key, .187 x .625 ...................................................... 1

21 41132 50411324 Impeller .................................................................................. 1

22 Washer, at, .562 x 1.375 x .109 ............................................ 1

23 Nut, hex, 1/2–20 Acorn .......................................................... 1

24 41161 50411613 Shim, .063 (use maximum of three, as required) ................... 1

25 Wing nut, 1/2 stainless steel .................................................. 6

26

*

† O-ring, 3.250 x 3.375 x .062–70 ............................................ 1

28† 26376 52055063 Motor with key (includes item 37) .......................................... 1

29 Screw, cap, 3/8–16 x 1.000 socket head ............................... 2

30† 50141 90501411 Adapter, 1/2 F NPT x 1-1/16 M STR ...................................... 1

31

*

O-ring, .924 x 1.156 x .116–90 .............................................. 2

32 43186 50431862 90° Elbow, 1/2 M NPT x 1/2 M NPT ...................................... 2

33 43138 50431382 Handle .................................................................................... 1

34 43452 52000876 Coupling, 4 F NPT ................................................................. 1

35 41547 50415471 Decal, Greenlee Utility ............................................................ 1

36† 44135 50441353 Adapter, 1/2 FNPT x 7/8-14 M STR ....................................... 1

37 Key (included with item 28) .................................................... 1

38 Lock washer, 3/8 stainless steel ............................................ 2

39 Flat washer, 3/8 stainless steel .............................................. 2

Repair Kits

*

43113 50431137 Packing kit (includes items marked with an asterisk)

† 26303 52055703 Motor retrot kit (for units preceding serial code GLW)

(includes items marked with †)

H4670 Submersible Trash Pump

Greenlee / A Textron Company 4455 Boeing Dr. • Rockford, IL 61109-2988 USA • 815-397-7070

35

Accessories

3 421

UPC No.

Key 78-3310- Part No. Description Qty

41189 50411891 Hose assembly, heavy-duty discharge

1 42091 50420912 Coupling, cam lock ................................................................ 1

2 Clamp, hose, 4.5" .................................................................. 4

3 Hose, discharge, 4" x 25'....................................................... 1

4 Coupling, male ....................................................................... 1

4455 Boeing Drive • Rockford, IL 61109-2988 • USA • 815-397-7070

An ISO 9001 Company • Greenlee Textron Inc. is a subsidiary of Textron Inc.

USA Tel: 800-435-0786

Fax: 800-451-2632

Canada Tel: 800-435-0786

Fax: 800-524-2853

International Tel: +1-815-397-7070

Fax: +1-815-397-9247

www.greenlee.com

/