Page

CONTENTS

1. PRODUCT NAME .............................................................................................................................. 1

2. MARKETING OBJECTIVE ................................................................................................................ 1

3. APPLICATIONS ................................................................................................................................. 1

4. SELLING POINTS ............................................................................................................................. 1

4-1. Selling Point Descriptions ...................................................................................................................2

5. SPECIFICATIONS ............................................................................................................................. 4

6. COMPARISONS WITH SIMILAR PRODUCTS ................................................................................. 5

7. PRECAUTIONS IN SALES PROMOTION ........................................................................................ 6

7-1. Instruction Manual ..............................................................................................................................6

7-2. Warning Labels and Caution Labels ...................................................................................................6

7-3. Relative Standards .............................................................................................................................8

7-4. Laser Marker (Only Model C 10FCH) .................................................................................................8

7-5. Ambient illuminance and Visibility of Laser Line (Only Model C 10FCH) ...........................................9

8. ADJUSTMENT AND OPERATION PRECAUTIONS ....................................................................... 10

8-1. Position Adjustment of Laser Line (Only Model C 10FCH) ............................................................... 10

8-2. How to Use the Vise Assembly ......................................................................................................... 11

8-3. Confirmation for Use of Sub Fence (Standard accessory) ............................................................... 12

8-4. Cutting Operation ..............................................................................................................................13

9. ADJUSTMENT OF COMPONENTS ................................................................................................ 17

9-1. Bevel Angle Adjustment ....................................................................................................................17

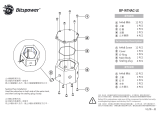

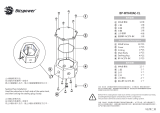

10. PACKING ....................................................................................................................................... 17

11. PRECAUTIONS IN DISASSEMBLY AND REASSEMBLY............................................................ 19

11-1. Precautions in Disassembly and Reassembly of the Laser Marker (Only Model C 10FCH) ..........19

11-2. Disassembly ....................................................................................................................................19

11-3. Reassembly ....................................................................................................................................26

11-4. Wiring Diagram ...............................................................................................................................27

11-5. No-load Current...............................................................................................................................30

11-6. Reassembly Requiring Adjustment .................................................................................................30

11-7. Lubrication.......................................................................................................................................31

11-8. Product Precision ............................................................................................................................31

11-9. Adjustment of Laser Marker Accuracy (Model C 10FCH only) .......................................................32

11-10. Tightening Torque ..........................................................................................................................35