southbend

A MIDDLEBY COMPANY

TECHNICAL MANUAL

WENDY'S RANGE

MODEL: C0300HT AND C0301 HT

This manual is intended for the use of Southbend Authorized Service Agencies and their

associates.

Service work should be performed only by a qualified technician who is experienced in, and

knowledgeable of, the operation of commercial gas, electric, and steam cooking

WARNING

Improper installation, service, or maintenance can cause property damage,

injury or death.

1100 Old Honeycutt Road • Fuquay-Varina, NC 27526 • (919) 552-9161 • FAX (919) 552-9798 • (800) 348-2558

Middleby Corp. Service Hot Line (800) 238-8444 (after hours)

WENDY'S RANGE

(MANUAL SECTION RR)

$18.00

NOTICE

Warranty will be void and the manufacturer is relieved of all liability if:

(A) Service work is performed by other than a qualified technician.

OR

(B)

Other than genuine Southbend replacement parts are installed.

TABLE OF CONTENTS:

FOR INSTALLATION AND OPERATION INSTRUCTIONS - CONSULT OPERATOR'S MANUAL

Safety Precautions ..................................................................................................................................

1

Specifications

..

..............

.......................

....................................................................................................

2

-

3

Adjustments..............................................................................................................................................

4-7

Troubleshooting ........................................................................................................................................

8

-

9

Performance Spec & Performance Check ...............................................................................................

10

Electrical Schematic Drawings .................................................................................................................

11-12

Parts List

....

..

............

................................................................................................................................

13

-

28

Location of serial and identification name plates:

The serial plate with all specifications is located below the oven door, behind the kick panel, attached to the frame base of the oven. There is also

a product identification plate that has only the model and serial number attached to the front left corner of the valve panel.

SAFETY PRECAUTIONS

The following symbols, found throughout this manual, alert you to potentially dangerous conditions to the operator, service

personnel, or to the equipment.

PAGE 1

This symbol warns of immediate hazards which will result in severe injury or death.

This symbol refers to a potential hazard or unsafe practice which could result in injury or

death.

This symbol refers to a potential hazard or unsafe practice which could result in injury,

product, or property damage.

This symbol refers to information that needs special attention or must be fully understood,

even though not dangerous.

DANGER

WARNING

CAUTION

NOTICE

southbend

A

MIDDLEBY COMPANY

1100

Old Honeycutt Road

Fuquay-Vanna. NC 27526

(919)552-9161

FAX (919) 552-9798

(800) 348-2558

NOTE: Not for Scale. For Dimensional Purposes Only.

WENDY'S GAS RANGE WITH CONVECTION OVEN MODEL CO-301HT-94A

DIMENSIONS: ( ) = Millimeters

EXTERIOR fl" GAS CONN.

ELECTRIC

MODEL

A

Width

B

Depth

C D E F G H I J K L M N 0

Cook

Top

P

Door

Opening

Q

Oven

Bottom

R

36.5" 41.00"

8" 30" 29.375" 4.250"

5" 45.5"

11.875"

28.750"

6" 9.500"

36" 12.5" 4.5" 36" 15.5" 13.5"

(927) (1042)

(203) (762) (746) (108) (127)

(1156)

(302) (730) (152)

(241) (914)

(315) (115)

(914)

(394) (345)

WENDY'S

GAS

RANGE

OVEN INTERIOR

BURNERS (BTU each)

CRATE SIZE

MODEL

Width Depth Height Hot Top Oven Griddle Width Depth Height

Cubic

Volume

Crated

Weight

WENDY'S

GAS

RANGE

26.125"

(664)

21.75"

(552)

14.25"

(362)

1

(20,000)

1

(25,000)

2

(30,000)

55"

(1397)

45.5"

(1156)

45"

(1143)

118 cu. ft.

3.33 cu. m.

705 lbs.

317kg.

UTILITY INFORMATION:

GAS-

Total 105,000 BTU. One 3/4" flex hose male connection.

(For location, see drawing above items "L" and "M").

Natural

Propane

Required operating pressure: Natural Gas

7

-

8"

W.C.

Propane Gas 11-12" W.C.

Incoming gas line and connections must not be smaller

than

3/4"

I.D.

ELECTRIC -

STANDARD: 115/60/1 - furnished with 5 ft. cord with 3-prong

plug. Total maximum amps 6.2.

OPTIONAL: 208/60/1 or for use on 3 (190 to 219 volts) - supply

must be wired to junction box with terminal block

located at rear. Total maximum amps 4.0.

OPTIONAL: 340/60/1 or for use on 3 (220 to 240 volts) - supply

must be wired to junction box with terminal block

located at rear. Total maximum amps 4.0.

PAGE 2

TOP VIEW

FRONT VIEW

SIDE VIEW

NOTE: Not for Scale. For Dimensional Purposes Only.

WENDY'S CHILI RANGE WITH CONVECTION OVEN MODEL CO-300HT-94A

TOP VIEW FRONT VIEW SIDE VIEW

DIMENSIONS: ( ) = Millimeters

EXTERIOR fl" GAS CONN.

ELECTRIC

MODEL

A

Width

B

Depth

C D E F G H I J K L M N 0

Cook

Top

P

Door

Opening

Q

Oven

Bottom

R

36.5"

41.00" 8" 30" 29.375"

4.250"

5" 45.5" 11.875"

28.750"

6" 9.500"

36" 12.5" 4.5" 36" 15.5” 13.5"

WENDY'S

GAS

RANGE

(927)

(1042) (203)

(762) (746) (108)

(127)

(1156)

(302) (730) (152)

(241) (914)

(315) (115) (914) (394) (345)

OVEN INTERIOR

BURNERS (BTU each)

CRATE SIZE

MODEL

Width Depth Height Hot Top Oven Width Depth Height

Cubic

Volume

Crated

Weight

WENDY'S

GAS RANGE

26.125"

(664)

21.75"

(552)

14.25"

(362)

3

(20,000)

1

(25,000)

55"

(1397)

45.5"

(1156)

45"

(1143)

118 cu. ft.

3.33 cu. m.

705 lbs.

317kg.

UTILITY INFORMATION:

GAS-

Total 85,000 BTU. One 3/4" flex hose male connection.

(for location, see drawing above items "L" and "M").

NATURAL

PROPANE

Required operating pressure: Natural Gas 4" W.C.

Propane Gas 10" W.C.

Incoming gas line and connections must not be smaller

than 3/4" I.D.

ELECTRIC -

STANDARD: 115/60/1 - furnished with 5 ft. cord w/ 3-prong

plug. Total maximum amps 6.2.

OPTIONAL: 208/60/1 or for use on 3 (190 to 219 volts) - supply

must be wired to junction box with terminal block located at

rear. Total maximum amps

4.0.

OPTIONAL: 240/60/1 or for use on 3 (220 to 240 volts) - supply

must be wired to junction box with terminal block located at

rear. Total maximum amps 4.0.

PAGE 3

ADJUSTMENTS

WARNING

De-energize all power to equipment before attempting to service or replace any

component of the equipment.

CAUTION

When changing motor or servicing unit, always verify that the blower wheel rotation

is as the illustration shows. (clock-wise when looking into oven cavity)

ONLY on units manufactured before serial numbers 91 H

Blower wheel must not be located over 1/8" from rear of

oven. This is critical for proper burner combustion.

A. MOTOR: The motor is serviceable from the front of the unit through the oven cavity. Remove the rear baffle. Disconnect

the motor mount plate by removing the eight hex nuts that secure it to the oven interior back. Pull the mount plate, with motor

attached, into the oven.

B. CONTROL PANEL ASSEMBLY COMPONENTS: The control panel assembly components are easily serviceable by

removing two screws (one at the top and at the bottom) of the control panel and then sliding out the control panel assembly.

C. THERMOSTAT: After sliding out the control box assembly, the thermostat can be completely removed by removing the

capillary bulb brackets from inside of the oven, and then sliding the capillary bulb out of the oven cavity into the control area.

CAUTION

Before sliding out control box for servicing, remove base panels below oven door and

remove the wire tie from the spark ignitor electrode wire (black wire).

To return control box to original position, push in slowly while lightly pulling the spark ignitor

wire (black wire) into the oven burner control area (below oven door). Re-attach a wire tie

in a similar fashion as before it was removed. Replace base panels.

PAGE 4

BLOWER

WHEEL

ROTATION

FIGURE 1

ADJUSTMENTS

THERMOSTAT ADJUSTMENT OVEN:

The calibration of the thermostat should not be changed until sufficient experience with cooking results have definitely proved that the

thermostat is not maintaining proper oven temperatures. Before any recalibration is attempted, the oven temperature should be checked

by the following procedure:

1.

The oven must be empty of all trays or pans.

2. Place a pyrometer thermocouple or a reliable mercury oven-type thermometer at the center of the middle rack.

3.

Turn on the blower.

4. Set the dial at 375° F.

5.

The red "Cooking Light will go out when the thermostat turns off the burners.

6.

Allow three such cycles for the temperature to stabilize.

7. Read the pyrometer or thermostat immediately after the light goes out for the third time and again immediately after it

comes on the next time.

8. If the average of these readings and the dial setting vary by more than 15°, recalibrate by following the instructions

outlined below:

TO RECALIBRATE:

NOTE: Recalibration should be attempted only by a

competent serviceman.

1. Remove knob from dial shaft (Item "B") from

figure 2.

2. Turn screw (Item "A") in figure 2 clockwise to

decrease and counterdockwise to increase

temperature.

3.

1/4

turn c

hanges the temperature 35°F.

4. Replace knob on dial shaft.

5. After the calibration is made, set the dial at

375°F and recheck the oven temperature using

the method outlined by steps 1 thru 7 of the

oven temperature checking procedure (as

stated above).

OVEN STANDING PILOT ADJUSTMENT:

The standing oven pilot flame can be adjusted by turning

the adjusting screw on the pilot line valve with a

screwdriver. The pilot line valve is located behind the front

panel below the oven door.

Remove the front panel to gain accessibility. The pilot flame is property adjusted when it is just large enough to maintain a

glowing red color on the flame switch capillary bulb.

OVEN BURNER FLAME ADJUSTMENT:

The oven burner orifice is of the fixed, type sized for the respective gas supply. The burner flame characteristics are

controlled by varying the primary air mixer cap. There should be a clear blue flame with a distinct inner cone at each port.

Excessive primary air can result in "blowing" or the flames leaving the ports. Lack of primary air causes soft or yellow

tipped flame.

THERMOSTAT REMOVAL AND REPLACEMENT:

(GRIDDLE DOESN'T HAVE TO BE REMOVED)

Refer to figures 3 and 4 for instructions below.

1.

Remove thermostat knob(s).

2.

Remove valve panel.

3.

Remove thermostat screw (Item "A") and

orifice bracket screws (Item "B").

4.

Pull thermostat assembly out to side and

remove the burner (Item "C") [this applies for

both sides].

PAGE 5

FIGURE 2

FIGURE 3

ADJUSTMENTS

THERMOSTAT REMOVAL AND REPLACEMENT: (Continued)

5. Loosen bolt(s) on bottom of griddle plate (Item "D") 1/2 inch then pull thermostat bulb out front.

NOTE: If bulb will not pull out loosen bolt (Item "D") further (DO NOT FORCE).

6. Reverse steps 3 thru 5 to install new thermostat.

NOTE: Snug bolt (Item "D") DO NOT over tighten, (this will damage capillary bulb causing incorrect sensing).

7. Make sure the excess capillary wire is stored in the cool zone under thermostat body in front of burners.

8. Replace valve panel.

9. Replace thermostat knob(s),

FIGURE 4

PRESSURE REGULATOR:

The pressure regulator is factory set a 7-8" W.C. for natural gas and 11-12" W.C. for propane gas. To check the manifold

pressure:

1. Turn all thermostats and burner valves to "OFF" position.

2. Turn main gas valve to entire unit off.

3. Remove valve panels and locate 1/8" plug in manifold.

4. Remove plug and install a fitting appropriate to connect a manometer.

5. Turn on main gas to unit and light pilots.

6. Turn all burners and ovens to full "ON" position and read manometer.

7. If manometer does not read 4" W.C. for natural gas,

or 10" W.C. for propane gas, adjust regulator (if gas pressure

is O.K. go to step 10)

8. Remove cap form top of regulator.

9. With a screwdriver rotate regulator adjustment screw

"Clockwise" to increase, or "counterclockwise" to decrease,

pressure until manometer shows correct reading.

10. Repeat steps 1 and 2.

11. Remove manometer fitting and replace plug in manifold.

12. Repeat step 5.

13. Replace valve panels.

FIGURE 5

PAGE 6

ADJUSTMENTS

THERMOSTAT CALIBRATION GRIDDLE:

To Check Calibration

1. Turn thermostat to the 300°F of marking see figure 5.

2. After burners have been on a minimum of 1 hour (if cold)

or 30 minutes (if already hot when set at 300°F). Place a

reliable thermometer or therm-couple with test instruments

in the center of the griddle and over the center of each

burner. See figure 6.

3. Continue to check temperatures at 5 minute intervals, until

you have two readings that are within 30° of each other.

4. The control should only be recalibrated if your reading is

not within 30° of the dial setting (300°F).

TO RECALIBRATE THERMOSTAT:

This control has been carefully calibrated at the factory. That is, it is adjusted

to match the actual griddle temperatures. Field calibration is seldom necessary

and it should NOT be done unless considerable experience with cooking and

temperatures definitely proves that the control is not maintaining the temperatures

to which the dial is set.

1. When recalibrating, check temperatures as instructed in

previous section (thermostat calibration)

2. Set temperature indicator knob to 300°F marking

3. Remove indicator knob (Item "A") from thermostat

(Item "B"). Refer to figure 7.

4. Using a screwdriver knock out silver insert

(Item "C"). Refer to figure 7.

5. Place knob back on the thermostat shaft.

6. With screwdriver inserted through center

of dial and in the calibration slot of screw push in

and hold - DO NOT rotate screw.

7. Rotate indicator mark until it points to actual temperature you are reading off the temperature sensing

device you placed over the center of the burners.

8. Turn thermostat to 300°P and check temperature again at 5 minute intervals.

9. Remove indicator knob and reinstall center insert.

10. If the griddle will not adjust to within 30°F this means that the sensing bulb is inoperative and the control

should be replaced.

PAGE 7

FIGURE 6

FIGURE

7

FIGURE 8

TROUBLESHOOTING GUIDE

Symptom Check or Replace

1) All burners and pilots in unit will not turn on A) Main gas supply to unit is "OFF".

A) Incorrect gas type supplied to unit. 2) All burners produce excessive carbon deposits

B) Incorrect supply pressure.

A) Incorrect orifices. 3) Only some burners in a unit produce excessive carbon

deposits

B) Primary air not adjusted properly.

A) Pilot gas not adjusted properly. 4) Only some pilots produce excessive carbon deposits

B) Incorrect pilot orifice.

A) Manual valve for top burner in "OFF" position. 5) Top burner (not oven) will not come on

B) Pilot out.

A) Pilot gas not adjusted property.

B) Clogged orifice.

C) Draft condition.

D) Improper ventilation system.

6) Top section pilot will not stay ignited

E) Air in gas line.

A) Main gas supply is "OFF".

B) Pilot not lit.

7) Unit will not heat up

C) Safety valve not "ON".

A) Incorrect gas type or orifice size.

B) Incorrect supply pressure.

C) Incorrect burner air mixer adjustment.

D) Burner orifice out of alignment with burner.

8) Burners produce excessive carbon deposits

E) Incorrect orifices.

A) Pilot gas not adjusted properly. 9) Pilot produces excessive carbon deposits

B) Incorrect pilot orifice.

A) Safety valve in "Pilot" position.

B) Pilot out.

10) Burner will not come on

C) Clogged burner - charge ports.

A) Pilot was not adjusted properly.

B) Clogged or dirty orifice.

11) Pilot will not stay lit

C) Draft condition.

PAGE 8

TROUBLESHOOTING GUIDE

Symptom Check or Replace

D) Improper ventilation systems.

E) Air in gas line.

F) Valve end of thermocouple corroded or loose.

G) Pilot shield needs to be moved closer to pilot.

H) Improper gas pressure.

I) Incorrect gas supply size (not enough volume).

CONVECTION OVEN ONLY

A) Is power cord plugged in?

B) Main supply fuses.

12) Unit does not come on when "Power Switch" is in the

"On" position.

C) Unit power switch.

A) Fan switch. 13) Motor will not run with fan switch in any position

B) Motor.

A) Door switch actuator.

14) Motor will not run in "Bake" position but runs in "Cool"

position.

B) Door switch.

A) Spark ignitor. 15) No spark at pilot

B) Wire to spark electrode broken or disconnected.

A) Gas supply to unit shut off.

B) Unit gas line shutoff in closed position.

C) Pilot line valve in closed position.

D) Pilot line solenoid.

16) Spark present but standing pilot will not light

E) Oven gas supply "Manual" valve off.

A) Main gas solenoid.

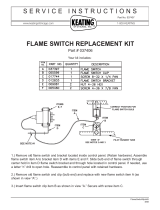

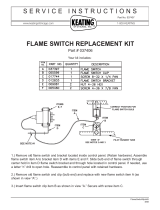

B) Flame switch bulb in incorrect position (Flame needs to

split bulb).

17) Pilot ignites but burners will not light when thermostat

calls for heat. Cook light on.

C) Flame switch.

18) Unit will function property for a period of time and then

shut down (oven circulating blower and oven burners).

Oven will begin to function properly again after it has

cooled down.

A) Motor overheating.

19) Pilot ignites but burners and cook light will not come on

when thermostat calls for heat.

A) Thermostat.

PAGE 9

PERFORMANCE CHECK:

The following items should be checked within the first 30 days of operation by a qualified service technician.

1. Verify equipment is level.

2. Verify proper electrical characteristics - voltage, cycle, phase.

3. Check thermostat operation; calibrate if required.

4. Check ventilation.

5. Check electrical connections - external and internal.

6. Check door for proper alignment, tension, seal, and adjustment.

7. Check timers, switches and motor for proper installation and operation.

8. Check for any damage to unit from shipping or installation.

9. Check for proper clearance from combustible materials.

10. Verify proper type of gas.

11. Verify gas supply and pressure. (Pressure regulator is already installed at factory.)

12. Check gas connection and check for leaks.

It is common for new products to require a bum-off time to dry out insulation and metal cooking surfaces.

PAGE 10

PAGE 11

PAGE 12

PARTS -- ACCESSORIES

NOTICE

INSTALLATION OF OTHER THAN GENUINE SOUTHBEND PARTS WILL VOID THE

WARRANTY ON THIS EQUIPMENT.

The serial plate with voltage, model, and serial information is located below oven door, behind the kick panel attached to

frame base of oven. There is also an Identification Plate mounted to the front left comer of the valve panel that will supply

model and serial number.

Replacement parts may be ordered either through a Southbend Authorized Parts Distributor or a Southbend

Authorized Service Agency.

When ordering parts, please supply the Model Number, Serial Number, Part Number, Description, Finish, and

Electrical Characteristics as applicable.

Consult the Southbend Authorized Parts/Service Distributor list for the Authorized Parts supplier in your area. If this list is

not available, call the Service Department at Southbend, 1-800-348-2558 for same.

Gas Conversion Kits for Wendy's 93A and 94A Series Models

4440422 - CO-300HT-93A - Propane to Natural

4440423 - CO-300HT-93A - Natural to Propane

4440424 - CO-301HT-93A - Propane to Natural

4440425 - CO-301HT-93A - Natural to Propane

C0300 with three hot tops or one solid top

4440051 Natural to Propane

4440050 Propane to Natural

REPLACEMENT PART INDEX

Legs, Casters Pages 14-15

Main Exterior Parts C0301HT & C0300HT Pages 16-17

Front Body Parts

Page 18

Control Panel Components Page 19

Oven Interior Parts

Pages 20-21

Oven Burner Compartment Pages 22-23

Manifold Components Page 24

Hot Top Manifold

Pages 25-26

Gas Supply Line Components Page 27

Flue Riser Body Parts Page 28

MISCELLANEOUS PARTS

PART NUMBER DESCRIPTION

1177047 Operator's Manual

4460004 Technical Manual

PAGE 13

FIGURE 9

Leg for Wendy's Ranges after August 1989

ITEM PART NUMBER DESCRIPTION QTY

A 1146201 1/4 x 20 x 3/4 Hex Head 16

B 1146500 1/4 Lock Washer 16

C 1172650 Leg Pad (3/4 x 10 hole) 4

D 1174259 S.S. Leg (3/4 stud) 4

* 1174260 Leg Package (set of 4) 1

* 1174262 Earth Quake Legs SS (set of 4) 1

FIGURE 9

Leg for Wendy's Ranges prior to August 1989

ITEM PART NUMBER DESCRIPTION

A 1034101 Leg Plated

B 1101000 Lock Nut 1-1/4"

* 1034111 Black Leg

FIGURE 10

PAGE 14

FIGURE 11

Leg for Wendy's Ranges after August 1989

ITEM PART NUMBER DESCRIPTION QTY

A 1146201 1/4 x 20 x 3/4 Hex Head 16

B 1146500 1/4 Lock Washer 16

C 1172650 Leg Pad (3/4 x 10 hole) 4

* 1174263 5" Swivel Caster Less Brake 2

D 1174264 5" Swivel Caster with Brake 2

* 1174265 Caster Package

Leg for Wendy's Ranges prior to August 1989

ITEM PART NUMBER DESCRIPTION

A 1101000 Lock Nut 1-1/4"

B 1167269 Caster Leg Weld Assembly

* 1167720 3/4 Flat Washer

1167721 3/4 Star Washer

E 1167545 4" Swivel Caster Less Brake

E 1167546 4" Swivel Caster with Brake

1167549

Caster Leg assembly without Break (includes

items A thru E)

* 1167550

Caster Leg assembly with Brake (includes

items A thru E)

PAGE 15

FIGURE

11

FIGURE

12

FIGURE 13 MAIN EXTERIOR PARTS FOR C0301HT

ITEM PART NUMBER DESCRIPTION

A

1176423

Flue Pan Deflector

B 1146304 #10 x 1/2 Phillips Screw

C 1176243 Hot Top 36" Assembly

D

C05

-

00093

Belly Bar Assembly

E 1166011 Hot Top Knob

F 4440000 Oven Door Handle Kit

G

1173578

Base Panel S/S

H

1176119

Direct Sparker

I 1165701 Thermostat Dial Knob

J

1173444

Timer Dial

K 1172748 Southbend Logo Plate

*

1165732

Rack Guide Assembly

* 1165652 Oven Rack (18 x 25 13/16)

* 1176866 Quick Disconnect Hose 36"

• 1176867 Restraining Device Kit (see pg. 11)

*

Legs

(see parts section in this manual)

• Casters (see parts section in this manual)

* Item not shown on drawing.

PAGE 16

FIGURE 14

MAIN EXTERIOR PARTS FOR C0300HT

ITEM

PART NUMBER

DESCRIPTION

A 1176423 Flue Pan Deflector

B 1146304 #10 x 1/2 Phillip Screw

C 1176168 Hot Top 12" Assembly

D 1176143 Grease Shield

E 1176145 Griddle Asm. 2ft.

F C05-00093 Belly Bar Assembly

G 1166011 Hot Top Knob

H 1176150 Grease Pan Assembly

I 4440000 Oven Door Handle Kit

J 1174762 Griddle Knob

K 1176119 Direct Sparker

L 1173578 Base Panel S/S

M 1165701 Thermostat Dial Knob

N 1173444 Timer Dial

0 1172748 Southbend Logo Plate

1165732 Rack Guide Assembly

* 1165652 Oven Rack (18 x 25 13/16)

• 1176866 Quick Disconnect Hose 36"

* 1176867 Restaining Device Kit

* Legs (see parts section in this manual)

• Casters (see parts section in this manual)

* Item not shown on drawing

PAGE 17

FIGURE 15

FRONT BODY PARTS

PART NUMBER

ITEM

C0300 C0301

DESCRIPTION QUANTITY

A 1176247 - Control Panel 1

B - 1176149 Control Panel 1

C 1176139 1176319 Control Panel Support Right 1

D 1176138 1176138 Control Panel Support Left 1

E - 1176137 Grease Pan Support 1

F - 1176150 Grease Pan Assembly 1

G C05-00093 C05-00093 Belly Bar Assembly 1

H 1173578 1173578 Right Base Panel SW Assy. S/S 1

I 1165967 1165967 Left Trim 1

J 1176175 1176175 Panel, Right Front 1

K 1176141 1176141 Cut Off Valve Cover 1

L 1168183 1168183 Bracket, Base Panel 2

PAGE 18

FIGURE 16

CONTROL PANEL COMPONENTS

PART NUMBER

ITEM

C0300 C0301

DESCRIPTION QUANTITY

A 1164503 1164503 Power Switch 1

B 1164504 1164504 Fan Switch 1

C 1161450 1161450 Neon Bulb, Red 125V 1

D 1165701 1165701 Thermostat Dial 1

E 1173444 1173444 60 Minute Timer Knob (1109866) 1

F 1160894 1160894 7/8" Plug 2

G 1173542 1173542 Thermostat (1161452) 1

H 1109850 1109850 60 Minute Timer 1

I 1165969 1165969 Control Panel Weld Assembly 1

J 1164809 1164809 Spark Ignitor Module 1

K 1165698 1165698 6 Pin Connector 1

L 1165700 1165700 4 Pin Connector 1

M 1165751 1165751 Poly Panel 1

* 1012510 1012510 Fuse 300V 15amp (for 208 & 236V only)

1

* 1161449 1161449 Power Relay 208/240V Only 1

* 1171891 1171891

Transformer, 100 VA (1165181)

(208/240 Volts Only)

1

* Item not shown on drawing.

NOTE: If voltage on control pane! is anything other than 120 Volt, Item F will be a 101-2596 fuse holder.

Cross Reference part numbers appear in parenthesis after description.

PAGE 19

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

-

13

13

-

14

14

-

15

15

-

16

16

-

17

17

-

18

18

-

19

19

-

20

20

-

21

21

-

22

22

-

23

23

-

24

24

-

25

25

-

26

26

-

27

27

-

28

28

-

29

29

-

30

30

Southbend CO-300HT-94A User manual

- Type

- User manual

- This manual is also suitable for

Ask a question and I''ll find the answer in the document

Finding information in a document is now easier with AI

Related papers

Other documents

-

Keating 2000 User manual

-

Keating 2000 User manual

-

pizzacraft PC6011 User manual

pizzacraft PC6011 User manual

-

Keating Of Chicago Flame Switch User manual

Keating Of Chicago Flame Switch User manual

-

Blodgett BPM Operating instructions

-

Patriot PT-R24 User manual

-

Patriot PT-R24 Installation guide

-

Bel Air Lighting MDN-1397 User manual

-

Lang GPO-1 User manual

-

Merco / Savory CG-30 User manual