Page is loading ...

Installation and user’s guide

H-2000-5124-12-A

Original instructions – translation of these original instructions are available on request

HPRA

high-precision removable arm

EN

Publications for this product are available

by scanning the barcode or visiting

www.renishaw.com/hpra.

DE

Für dieses Produkt stehen weitere Informationen zur

Verfügung. Scannen Sie dazu den Barcode oder besuchen Sie

www.renishaw.de/hpra.

ES

Para acceder a las publicaciones sobre este producto

escanee el código de barras o visite

www.renishaw.es/hpra.

FR

Les documentations pour ce produit sont disponibles en

scannant le code barres ou en visitant

www.renishaw.fr/hpra.

IT

Le pubblicazioni relative a questo prodotto sono disponibili

scansionando il codice a lato oppure visitando il sito:

www.renishaw.it/hpra.

日本語

www.renishaw.jp/hpra

Renishaw part no: H-2000-5124-12-A

Issued: 12.2020

NL

Publicaties voor dit product zijn te verkrijgen

door de barcode te scannen of te gaan naar

www.renishaw.nl/hpra.

PT

As publicações sobre este produto estão disponíveis

pelo código de barras ou visitando

www.renishaw.com.br/hpra.

RU

Если вас интересует информация об этом продукте,

отсканируйте штрих-код или посетите сайт

www.renishaw.ru/hpra.

中文

(繁體)

可透過下列方式獲得此產品的出版物

透過掃描條碼,或造訪

www.renishaw.com.tw/hpra。

中文

(简体)

可通过以下方式获得此产品的相关文档:

扫描二维码,或访问

www.renishaw.com.cn/hpra。

한국어

본 제품에 대한 간행물은

바코드를 스캔하거나 다음을 방문하여 확인하실 수있습니다

www.renishaw.co.kr/hpra.

This page is intentionally left blank.

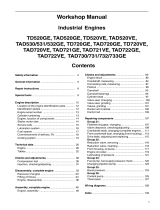

1

Before you begin ...........................................................................................................4

Safety .............................................................................................................4

Glossary of terms .......................................................................................................... 6

System kit .......................................................................................................................7

Specication ..................................................................................................................8

System installation ........................................................................................................9

HPRA installation ............................................................................................9

Mounting details ...........................................................................................10

Cover removal ..............................................................................................10

Side view ......................................................................................................11

Front view .....................................................................................................11

Standard arms dimension table ....................................................................12

Stylus dimensions by tool size ......................................................................13

Fitting the probe to the arm .......................................................................... 15

Stylus tting ..................................................................................................15

Stylus coarse adjustment .............................................................................15

Stylus ne adjustment ..................................................................................16

Mounting the base ........................................................................................ 17

TSI 2 or TSI 2-C installation ........................................................................................20

Standard mounting .......................................................................................20

Alternative mounting .....................................................................................20

TSI 2 installation and operation .................................................................................21

Wiring diagram .............................................................................................21

Interface connections ...................................................................................22

Probe trigger delay .......................................................................................23

Standard wiring for probe output ..................................................................24

Probe select inputs ....................................................................................... 25

Probe inhibit ..................................................................................................26

Inhibit inputs .................................................................................................27

Contents

2

Contents

TSI 2 specication ....................................................................................................... 28

Input specication .........................................................................................28

Output specication ...................................................................................... 28

TSI 2-C installation and operation .............................................................................29

Wiring diagram .............................................................................................29

Interface connections ...................................................................................30

Probe trigger delay .......................................................................................31

Standard wiring for probe output ..................................................................32

Probe inhibit ..................................................................................................33

Inhibit inputs .................................................................................................34

TSI 2-C specication ...................................................................................................35

Input specication .........................................................................................35

Output specication ...................................................................................... 35

Maintenance and fault-nding ....................................................................................36

HP Arms app ................................................................................................ 36

Maintenance .................................................................................................................37

Base removal ................................................................................................ 37

RP3 probe removal ....................................................................................... 38

Stylus and break stem removal .................................................................... 38

Break stem and stylus tting .........................................................................38

RP3 probe care ............................................................................................39

Cleaning and diaphragm inspection .............................................................39

Base inspection and cleaning .......................................................................40

HPRA inspection ..........................................................................................40

Tool setting denitions ...............................................................................................41

Probe datuming ............................................................................................41

Tool setting ...................................................................................................41

3

Contents

Setting tools .................................................................................................................42

Static tool length setting ...............................................................................42

Rotating tool length setting (for driven tools) ................................................42

Rotating diameter setting (for driven tools) ...................................................42

Tool breakage detection and calibration ................................................................... 43

Tool breakage detection ...............................................................................43

Calibrating the tool setting probe .................................................................. 43

Fault-nding ................................................................................................................. 44

Parts list .......................................................................................................................46

General information ....................................................................................................47

Disclaimer .....................................................................................................47

Trade marks .................................................................................................. 47

Warranty .......................................................................................................47

China RoHS ..................................................................................................48

Changes to equipment .................................................................................48

CNC machines .............................................................................................48

EU declaration of conformity ........................................................................48

REACH regulation ........................................................................................48

FCC Information to user (USA only) .............................................................49

WEEE directive .............................................................................................49

Chinese Safety .............................................................................................50

Notes .............................................................................................................................51

4

Before you begin

Safety

Information for the user

In all applications involving the use of machine tools or CMMs, eye protection is recommended.

Remove power before performing any maintenance operations.

It is the machine supplier’s responsibility to ensure that the user is made aware of any hazards

involved in operation, including those mentioned in Renishaw product documentation, and to

ensure that adequate guards and safety interlocks are provided.

Under certain circumstances the probe signal may falsely indicate a probe seated condition. Do

not rely on probe signals to stop machine movement.

The expected method of providing an emergency stop for Renishaw products is to remove power.

Information for the machine supplier/installer

The high-precision removable arm (HPRA) system must be installed by a competent person,

observing relevant safety precautions. Before starting work, ensure that the machine tool is in

a safe condition with the power switched OFF and the power supply to the TSI 2 or TSI 2-C

disconnected.

Equipment operation

If this equipment is used in a manner not specied by the manufacturer, the protection provided by

the equipment may be impaired.

5

Before you begin

<8 mm (0.315 in)

>8 mm (0.315 in)

6

Glossary of terms

Abbreviation Denition

HPRA High-precision removable arm

CNC Computer numerical control

TSI Tool setting interface

ARO Arm ready output

MRO Machine ready output

AWG American wire gauge

INH Inhibit input

SEL Select input

NO Normally open

NC Normally closed

GND Ground

SCR Screen

OCT Open collector transistor

SSR Solid state relay

COM Common

PELV Protective extra-low voltage

LED Light-emitting diode

SFPD Styli and Fixturing Product Division

8

Specication

Variant Standard rear exit Standard side exit

Principal application Tool measuring on 2-axis and 3-axis CNC lathes.

Transmission type Hard-wired transmission

Weight ≈ 3.1kg (109 oz)

Probe RP3

1 2

Compatible interfaces TSI 2 or TSI 2-C

Cable

(to interface)

Specication Ø4 mm (0.16 in), 2-core screened cable, each core

7 × 0.2 mm

Length 3 m (9.8 ft), 5.5 m (18 ft),

10 m (32.8 ft), 12 m (39.4 ft)

3 m (9.8 ft)

Sense directions ±X, ±Y, (probe), ±X, ±Z, (machine)

Typical positional repeatability

(machine)

3

5 μm (197 μin) 2σ X/Z (arms for machines with 6 in to 15in

chucks)

8 μm (315 μin) 2σ X/Z (arms for machines with 18 in to

24in chucks)

Stylus trigger force (probe)

4 5

XY low force

XY high force

+Z direction

1.5N, 153gf (5.4ozf)

3.5N, 357gf (12.59ozf)

12N, 1224gf (43.16ozf)

Sealing IPX8, BS EN 60529:1992+A2:2013

(IEC 60529:1989+A1:1999+A2:2013)

Mounting M6 bolts (× 3)

Operating temperature +5 °C to +55 °C (+41 °F to +131 °F)

Storage temperature −25 °C to +70 °C (−13 °F to +158 °F)

1

Where the RP3 is to be used in the probe’s Z-axis (the lathe Y-axis), a ve-faced stylus is available to order from

Renishaw’s Styli and Fixturing Products Division (SFPD), or from our Web shop at www.renishaw.com/shop.

2

Performance specication is tested at a standard test velocity of 480 mm/min (18.9 in/min) with a 35 mm stylus.

Signicantly higher velocity is possible depending on application requirements.

3

Test conditions: Stylus length:

Stylus velocity:

Stylus force:

22mm (0.87in)

36mm/min (1.42in/min)

Factory settings

4

Trigger force, which is critical in some applications, is the force exerted on the stylus by the tool when the probe

triggers. The maximum force applied will occur after the trigger point (overtravel). The force value depends on related

variables including measuring speed and machine deceleration.

5

These are the factory settings; manual adjustment is not possible.

9

System installation

HPRA installation

For best performance of the HPRA, the following installation guidelines are recommended:

• The HPRA is ideally mounted on a solid xed part of the machine tool, such as a

casting. If mounting brackets or plates are used, these must be designed to maximise

stiffness with minimal joints. If mounted onto a moving part of the machine tool,

repeatability may be adversely affected.

• The HPRA is sealed to IPX8 and designed for the harsh environments inside

a machine tool. However, high-pressure jets and reected jets can exceed this

specication and must not spray directly onto the HPRA base. If it is not possible to

position the HPRA base away from these jets, the base should be protected with

suitable guarding. Guarding is not supplied by Renishaw.

• Like all metrology systems, repeatability can be adversely affected by thermal effects

on the machine tool. Renishaw recommends thermal compensation routines are

incorporated into the measurement software cycles to counteract these effects.

10

System installation

Mounting details

Cover removal

Base

Cover

Lathe X axis

PCD Ø72 (2.84)

M6 (× 3)

Ø30 (1.18)

16 (0.63)

120°

120°

Ø85 (3.35)

13 (0.51)

25.3

(1.0)

11

System installation

Side view

Dimensions given in mm (in)

A*

Ø38.1 (1.50)

Ø85 (3.35)

* A variety of rear and side exit, standard size arms are available. See the table on page 12 for further information.

69.1 (2.72)

28.4 (1.12)

Front view

Dimensions given in mm (in)

B*

83 (3.27)

* A variety of rear and side exit, standard size arms are available. See the table on page 12 for further information.

60 (2.36)

S*

12

Standard arms dimension table

Chuck size Tooling size Arm size S*

A B

6 in 16 mm

20 mm

25 mm

32 mm

250

(9.84)

211

(8.31)

36 (1.42)

41 (1.61)

51 (2.01)

56 (2.20)

8 in 16 mm

20 mm

25 mm

32 mm

280

(11.02)

241

(9.49)

36 (1.42)

41 (1.61)

51 (2.01)

56 (2.20)

10 in 16 mm

20 mm

25 mm

32 mm

40 mm

325

(12.80)

290

(11.42)

36 (1.42)

41 (1.61)

51 (2.01)

56 (2.20)

61 (2.40)

12 in 16 mm

20 mm

25 mm

32 mm

40 mm

50 mm

355

(13.98)

290

(11.42)

36 (1.42)

41 (1.61)

51 (2.01)

56 (2.20)

61 (2.40)

71 (2.80)

15 in 20 mm

25 mm

32 mm

40 mm

50 mm

455

(17.91)

335

(13.19)

41 (1.61)

51 (2.01)

56 (2.20)

61 (2.40)

71 (2.80)

18 in 25 mm

32 mm

40 mm

50 mm

510

(20.08)

375

(14.76)

51 (2.01)

56 (2.20)

61 (2.40)

71 (2.80)

24 in 25 mm

32 mm

40 mm

50 mm

580

(22.83)

450

(17.72)

51 (2.01)

56 (2.20)

61 (2.40)

71 (2.80)

Dimensions given in mm (in)

* Stylus height, S, is adjustable. See “Stylus coarse adjustment” on page 15.

System installation

13

Stylus dimensions by tool size

20 mm

72.2 (2.84)

34

(1.34)

9

(0.35)

S = 51 (2)

25 mm

16 mm

19.1 (0.75)

S = 35.7 (1.4)

56.9 (2.24)

62.2 (2.45)

S = 41 (1.6)

24

(0.94)

Dimensions given in mm (in)

Dimensions given in mm (in)

Dimensions given in mm (in)

30°

3.1 (0.12)

6.6 (0.26)

2.7 (0.11)

Ø25

(0.98)

30°

6.6 (0.26)

Ø32

(1.26)

4.5 (0.18)

30°

6.6 (0.26)

Ø50

(1.97)

4.5 (0.18)

4 (0.16)

9 (0.35)

System installation

14

50 mm

40 mm

32 mm

77.2 (3.04)

39

(1.53)

9

(0.35)

S = 56 (2.2)

30°

6.6 (0.26)

Ø60

(2.36)

4.5 (0.18)

7 (0.27)

82.2 (3.24)

44.4

(1.75)

9

(0.35)

S = 61 (2.4)

30°

6.6 (0.26)

Ø60

(2.36)

9.5 (0.37)

4.4 (0.17)

92.2 (3.63)

54.4

(2.14)

9

(0.35)

S = 71 (2.8)

30°

Ø60

(2.36)

19.5 (0.77)

4.4 (0.17)

Dimensions given in mm (in)

Dimensions given in mm (in)

6.6 (0.26)

Dimensions given in mm (in)

System installation

15

System installation

Stylus tting

Fitting the probe to the arm

Lubricate O-ring only

(for example Hellerine lubricant)

2.5 mm A/F

2 Nm (1.48 lbf.ft)

1. Loosen grub

screws (× 2)

2. Insert probe

3. Tighten grub

screws (× 2)

Stylus coarse adjustment

Set approximately parallel with X-Z axes

±2°

1.1 Nm

(0.81 lbf. ft)

2 mm A/F

Y

For 16 mm and 20 mm

stylus ±0.8 mm

For 25 mm, 32 mm, 40 mm

and 50 mm stylus ±1.3 mm

Z

X

3 Nm

(2.21 lbf.ft)

1.1 Nm

(0.81 lbf.ft)

1

2

3

1. Fit the free end of the captive link

over the threaded end of the break

stem (1).

2. Fit the break stem inside the stylus

and secure it by tightening the two

M3 grub screws (2).

3. Using a 2 mm hexagonal key tted

through the hole in the break stem

(3), t the stylus to the probe.

16

Stylus ne adjustment

2 Nm

(1.48 lbf.ft)

>5 µm

>5 µm

>5 µm

<5 µm <5 µm

System installation

×

/