Kenmore Elite 79046623502 Installation guide

- Category

- Cookers

- Type

- Installation guide

INSTALLATION AND SERVICEMUST BE PERFORMED BY A QUALIFIED INSTALLER.

iMPORTANT: SAVE FOR LOCAL ELECTRICALiNSPECTOR'S USE.

READ AND SAVE THESE INSTRUCTIONS FOR FUTUREREFERENCE.

_][_[_ Jf the information in this manual is not followed exactly, a fire or explosion

may result causing property damage, personal injury or death,

FOR YOUR SAFETY:

,@

-- Do not store or use gasoline or other flammable vapors and liquids [n the v[dn[ty of this or any

other appliance.

-- WHATTO DO IFYOU SMELLGAS:

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any phone in your building.

• Immediately call your gas supplier from a neighbor's phone. Follow the gas supplier's instructions.

• tf you cannot reach your gas supplier, call the fire department.

-- Installation and service must be performed by a qualified installer, service agency or the gas supplier.

_Njx_

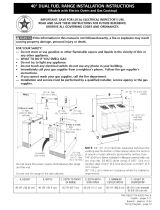

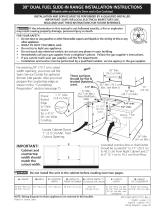

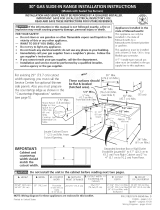

30" Min.

(76.2 cm Min.

These surfaces

meveled (hatched area).

Shave

Raised

Edge

to Clear

Space

fora 31_z"

(81 cm) Wide

Cooktop.

1 Y2" Max.

(3.8 cm Max.

should be flat &

m?'_W_.\30" Min. (76.2

1/2'

3"

18" Min. (33 cm)5

rL

12.7 cm Min

n Wal! E (45.7 cm) Min.

Locate Cabinet Doors

1" (2.5 cm) Min. from

Cutout Opening.

Grounded Jonction Box or Wall Outlet

Should Be Located 8" to 17" (203 cm

to 433 cm) From Right Cabinet and 2"

to4" (5.1 cm to 103 cm) From Floor.

24" Min.

(61 cm Min.)

For existing 29" (73.7 cm) cutout width opening, you must call the Sears Service

Center for optional thinner side panels. Also you must prepare the countertop edge

as shown in the "Countertop Preparation" section (see page 6).

[ [ \!V!D!kt' FRONT OF RANGE (Counte<top and <abinet, o DEPTH . OF COUNIERTOP

355/8" 1905cm)- 30" (76,2 crrl) 31Y2"(80cm) 28 5116" /71,9cm) 30±1116"

36 518" (9_ crn) (76,2±0,15 cm)

NOTE: Wiring diagram for these appliances are enclosed in this booklet.

Printed in United States

21 3/4" (55,2 cm) Min. 365/8" (93 cm) Max

22 1/8" (56,2cm) Max 35 518" 1905cm) Min

24" 161 cm) Min with

backguard

P/N 318201670 (05101 Rev C

English - pages 1-12

Espai_ol - p_ginas 13-25

Wiring Diagrams - pages 28

NOTE:

1.Do not pinch the power supply cord or the flexible gas conduit between the range and the wall.

2. Do not seal the range to the side cabinets.

3.24" (61 cm) minimum clearance between the cooktop and the bottom of the cabinet when the

bottom of wood or metal cabinet is protected by not less than X" (0.64 cm) flame retardant

milIboard covered with not lessthan No. 28 MSG sheet metal, 0.015"(0.4 mm) stainless steel,

0.024"(0.6 mm) aluminum, or 0.020" (0.5 ram) copper.

30" (76.2 cm) minimum clearance when the cabinet is unprotected.

4. For cutouts below 22 7/8"(58.1 cm), appliance will slightly show out of the cabinet.

5. Allow at least 19 X" (48.9 cm) clearance for door depth when it is open.

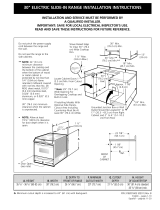

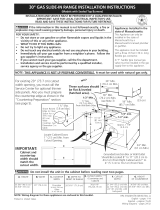

FRONT OF

CABINET

22 7/8"(581 cm) rnim

23 1/4"(5905 cm) max

_-- (see Note 4) -_

I

1 118"

Ref.

Door Open

A

Side Panel

IMPORTANT: Cabinet and

countertop width should match

the cutout width.

E

E

*** IMPORTANT: To avoid cooktop glass

breakage for cutout width (E dimension)

of more than 30 1/16" (76.4 cm), make

sure the appliance is centered in the

counter opening while pushing into it.

Raise leveling legs at maximum position,

insert the appliance in the counter anod

then level. Make sure the unit ms

supported by the leveling legs not by the

cooktop glass itself.

B

D, DEPTH TO

FRONT OF RANGE

35 5/8" (905cm)- 30" (76,2 cm)

36 518" (93 cm)

3IY2" (80 cm) 28 5/16" (71,9 cm) 30+_II16" 21 3/4" (55,2 crn) Min

(76,2+_0,15 cm) 22 I18" (56,2 cm) Max

24" (61 cm) Min with

backgua/d

36 518" (93 cm) Max

35 518" (905 crn) Min

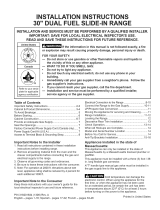

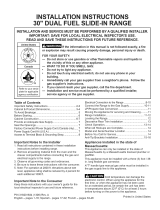

Important Notes to the Installer

1. Read all instructions contained in these installation

instructions before installing range.

2. Remove all packing material from the oven

compartments before connecting the gas and electrical

supply to tile range.

3. Observe all governing codes and ordinances.

4. Be sure to leavethese instructions with the consumer.

Important Note to the Consumer

Keep these instructions with your Use& Care Guide for future

reference.

IMPORTANT SAFETY

[NSTRU S

Installation of this range must conform with local codes

or, in the absence of local codes, with the National Fuel

Gas Code ANS! Z223. l--latest edition.

This range has been design certified by CSA

international. As with any appliance using gas and

generating heat, there are certain safety precautions you

should follow. You will find them in the Use and Care

Guide, read it carefully.

• Be sure your range is instai[ed and grounded

properly by a qualified installer or service

technician.

• This range must be electrically grounded in

accordance with toca[ codes or, in their absence,

with the National EJectrica[ Code ANSJ/NFPA No.

7O--Jatest edition. See Grounding Instructions on

page 6.

• The installation of appliances designed for

manufactured (mobile) home installation must conforra

with Manufactured Home Construction and Safety

Standard, title 24CFR, part 3280 [Formerly the Federal

Standard for Mobile Home Construction and Safety,

title 24, HUD (part 280)] or when such standard is not

applicable, the Standard for Manufactured Home

Installation 1982 (Manufactured Home Sites,

Communities and Setups), ANSI Z225.1/NFPA 501A-

latest edition or with local (.odes.

To reduce

All ranges

cantip.

Injuryto

persons could

result.

Installanti-tip

device

packed with

range.

the risk of tipping of tile

range, the range must be

secured by properly

installed anti-tip bracket

provided with the range.

To check if the bracket is

installed properly, grasp

the top rear edgge of the

range and carefully tilt it

forward to make sure the

range isanchored.

Make sure the wa

Power Suppmy Cord Kit

The user is responsible for connecting tile power supply

cord to tile connection block located behind tile back

panel access (:over.

This appliance may be connected by means of

permanent "hard wiring" (flexible armored or

nonmetallic shielded copper cable), or by means of a

power supply cord. Only a power supply cord kit rated at

125/250 volts minimum, 40 amperes minimum and

marked for use with ranges shall be used. See chart

(below) for cord kit connection opening size rating

information. Cord must have either 3 or 4 conductors.

For mobile homes, new installations, recreational

vehicles, or areas where local codes do not permit

grounding through neutral, a 4 conductor power supply

cord kit rated at 125/250 volts minimum, 40 amperes

and marked for use with ranges should be used (see

Figure 4).

Terminals on end of wires must be either closed loop or

open-end spade lugs with upturned ends. Cord must

have strain-relief (.lamp.

Range Connection Opening Size Chart

Refer to chart below for proper range conr_ectior_ operfing size ant

power supply cord kit ampere rating information. See serial plate

on range for kilowatt rating

See Serial Plate on Range

for KW Rating

data.

120/240 Volts 120/208 Volts

0-16.5 Kw 0-12.5 Kw 40 Amp

16.6-22,5 Kw 12.6-18,5 Kw 50 Amp

Minimum

Cord kit

Ampere

Rating

Diameter (inches)of Range

Conrlectiorl Opening

Direct

Cord Kit Connection

1-3/8 in. I-1/8 in.

1-://8 in. I-:_/8 in.

Figure 1

NOTE: Dual fuel Slide-in Range isshipped from factory

with ! 1/8" dia. hole asshown on figure 3. If a larger hole

is required, punch out the knockout.

Risk of fire or e[ectrka[ shock exists [f

the incorrect amperage cord [s used, the

installation instructions are not followed, or the

strain relief bracket is discarded (see Figure 3).

Do not [oosen the nuts which secure

the factory-installed range wiring to terminal block

while connecting range. Electrical failure or loss of

electrical connection may occur.

Electrical Connection to the Range

This appliance is manufactured with the neutral terminal

connected to the frame.

Note: Refer to the wiring diagram in the center pages of

this manual.

Electrical Shock Hazard

• Electrical ground is required on this appliance.

• Do not connect to the electrical supply until

appliance is permanently grounded.

• Disconnect power to the circuit breaker or fuse

box before making the electrical connection.

• This appliance must be connected to a

grounded, metallic, permanent wiring system,

or a grounding connector should be connected

to the grounding terminaJ or wire [ead on the

appliance.

• Do not use the gas supply line for grounding

the appliance.

Failure to do any of the above could result in a

fire, personal injury or electrical shock.

Three Conductor Wire Connection to Range

(The 3-conductor cord or (able must be replaced with a

4-conductor cord or (able where grounding through the

neutral conductor is prohibited in new installations,

mobile homes, recreational vehicles or in other areas

where local codes do not permit neutral grounding)

If local codes permit connection of the frame grounding

conductor to the neutral wire of the copper power supply

cord (see Figure 3):

1. Remove the 3 screws at the lower end of the rear

wire (:over, then bend the lower end of the rear wire

(over (access cover) upward to expose range

terminal connection block (see Figure 2).

BEND REARWIRE COVER HERE

FORACCESS TO TERMINAL BLOCK

Figure 2

2. Removethe3loosenuts(afteryouremovethe

rubberband)ontheterminalblockusinga3/8"nut

driverorsocket.

3. Connect tile neutral white wire of the copper power

supply cord to the center silver-colored terminal of

the terminal block, and connect the other wires to

tile outer terminals. Match wires and terminals by

color (red wires connected to the right terminal,

black wires connected to the left terminal).

4. Replace the 3 nuts on the terminal block. (See

Figure 3)

5. Lower tile terminal cover and replace the 3 screws.

Silver colored Terminal

5. Connect the neutral of the copper power supply cord

to the center silver-colored terminal of the terminal

block, and connect the other wires to the outer

terminals. Match wires and terminals by color (red

wires connected to the right terminal, black wires

connected to the left terminal).

6. Replace the 3 nuts on the terrainal block (see Figure

4).

7. Lower the terminal cover and replace the 3 screws.

Block

Terminal

Red

Wire

Terminal

Block

wire

A strain relief

supplied by the user 1-1/8" Dia. Direct

must be installed at Connection Hole. Punch

this location To 240 V out knockout for

receptacle 1-3/8" Dia. Cord Kit Hole

Figure 3

Four Conductor Wire Connection to Range

(mobile homes)

1. Remove the 3 screws at the lower end of the rear

wire (:over, then raise the lower end of the rear wire

(.over (access cover) upward to expose range

terminal connection block (see figure 2).

2. Remove the 3 loose nuts (after you remove the

rubber band) on the terminal block using a 3/8" nut

driver or socket.

3. Remove the grounding strap from the terminal block

and from the appliance frame.

4. Connect the ground wire (green) of the copper

power supply cord to the frame of tile appliance

with the ground screw, using the hole in the frame

where tile ground strap was removed (see Figure 4).

1-118"

Direct

Connection

Hole. Punch

out knockout

for 1-3/8" Dia.

Cord Kit Hole

A strainrdief

supplied by the user

must be installed at

this location

NOTE: Be sure to remove the supplied

grounding strap

Figure 4

Direct Electrical Connection to the Circuit

Breaker, Fuse Box or Junction Box

If the appliance is connected directly to the circuit

breaker, fuse box or junction box, use flexible, armored

or nonmetallic sheathed copper cable (with grounding

wire). Supply a U.L listed strain-relief at each end of the

cable. At the appliance end, tile cable goes through tile

Direct Connection Hole (see Figure 4) on the Cord

Mounting Plate. Wire sizes (copper wire only} and

connections must conform to tile rating of tile appliance.

Where local codes permit connecting the appliance-

grounding conductor to the neutral (white) wire

(see Figure 5):

(The 3-conductor cord or cable must be replaced with a

4<onductor cord or cable where grounding through tile

neutral conductor is prohibited in new installations,

mobile homes, recreational vehicles or in other areas

where local codes do not permit neutral grounding)

1. Disconnect tile power supply.

2. In the circuit breaker, fuse box or junction box

connect the appliance and residence cable wires as

shown in Figure 5.

White Wire

(Neutra0

Cable from

Residence

Bmack

Wires--

Box

White Wire

(Neutram)

Green U.L°=hsted

(or Bare Copper) cable from Conduit

Wire Connector

Range (or CSA misted)

Figure 5

3-Wire (Grounded Neutra0 ElectrkaJ System

(ExampJe: Junction Box)

Where tocaJ codes DO NOT permit connecting the

appliance-grounding conductor to the neutral

(white) wire, or if connecting to 4-wire electrical

system (see Figure 6):

1. Disconnect the power supply.

2. Separate the green (or bare copper) and white

appliance cable wires.

3. In the circuit breaker, fuse box or junction box:

connect appliance and residence cable wires as

shown in figure 6.

Cabmefrom

Green Residence Junction

(or Bare Copper) Box

[wi

(Got;Bare Copper)_e

Wire __:d ra')

Cable from Conduit

Appbance Connector

(or CSA misted)

Figure 6 - 4-Wire Electrical System

(Example: Junction Box)

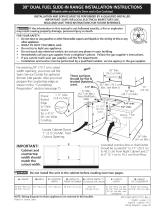

Cabinet Construction

To eliminate the risk of cabinet burns or

fire do not have cabinet storage space above the range.

If there is cabinet storage space above range, reduce risk

by installing a range hood that projects horizontally a

minimum of 5" (12.7 cm) beyond the bottom of tile

cabinet.

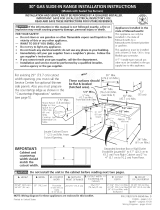

Countertop Preparation

• The cooktop sides of tile range fit over the cutout edge

of your countertop.

• If you have a square finish (flat) countertop, no

countertop preparation is required. Cooktop sides lay

directly on edge of countertop.

Formed front-edged countertops must have molded

edge shaved flat 3/4" (1.9 cm) from each front corner

of opening (Figure 7).

Tile countertops may need trim cut back 3/4"(1.9

cm) from each front corner and/or rounded edge

flat :ened (Hgure

[vlin.

Cutout

WMth

(1.9 cm)

(1.9cm)

311/2,_

(81cm)

/ Formed or tile countertop

trimmed %" (1.9 cm) back at

front corners of countertop

opening.

Figure 7

tf the existing cutout width is greater than

30-1/15" (76,4 cm), reduce the 3A" (1.9 cm)

dimension.

For existing cutout width of 29" (73.7 cm) (Figure 8):

2 3/15"

cm)

You must also clear 2 3/

16" (5.56 cm) of materia_

from front of countertop.

(3.2 cm)

• Countertop must be level Place a level

on the countertop, first side to side, then

front to back. If the countertop is not level,

the range will not be level. The oven must

be level for satisfactory baking results, 11/,,

Cooktop sides of range fit over edges of (3.2cm)

countertop opening, I

30'o_ _

(75.2 cm) 311/_" _.::.,:::::::,

_. (80 cm)

_Formed or tile countertop trimmed

_'_"_ 11/4" (3.2 cm) back at front corners of

countertop opening.

Figure 8

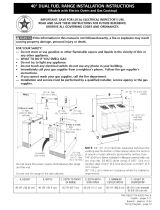

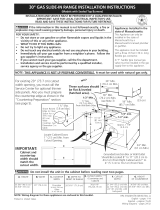

Gas Suppmy- Installation

When shipped from the factory, this unit isdesigned to

operate on 4"(!0,16 cm) water column (! .0 kPa)Natural

gas manifold pressure. A convertible pressure regulator is

connected to the range manifold and MUST be connected

in serieswith the gas supply line. To accesstile regulator,

remove the drawer.

For proper operation, the maximum inlet pressure to

the regulator should be no more than 14"(35,56 cm)of

water column pressure (3.5 kPa).

The inlet pressure to the regulator must be at least I " (.25

kPa)greater than the regulator manifold pressure setting.

The regulator isset for 4" (10,16 cm)water column (1.0

kPa) Natural gas manifold pressure; the inlet pressure must

be at least 5"(12.60 era)water column (1.25 kPa) Natural

gas. For LP/Propanegas, the regulator must be set for

10"(25,4 era)water column (2.5 kPa)manifold pressure; tile

inlet pressure must be at least 11"(27,9 cm)water column

(2.75 kPa).

The supply line should be equipped with an approved

shutoff valve (see Figure 11). This valve should be located

in the same room asthe range and should be in a location

that allows easeof opening and closing. Do not block

accessto the shutoff valve. The valve isfor turning on or

shutting off gasto tile appliance.Open the shutoff valve in

the gas supply line. Wait a few minutes for gasto move

through the gas line.

The gas supply between the shutoff valve and tile regulator

may be connected by rigid piping or by A.G.A./C.G.A.-

approved flexible metallic,union-connected piping where

local codes permit use.

The gas supply piping can be through the side wall of the

right cabinet. The right side cabinet isan ideal location for

the main shutoff valve.

Connection to Pressure Regulator

The regulator is already installed on the appliance.

Do not make the connection too tight. The

regulator isdie cast.Overtightening may crackthe regulator

resulting in a gasleakand possiblefire or explosion.

ManuaH GAS FLOW Pressure

Shutoff Hare _ Hare

VaHve Union Union

,-r ..........'T

On_ NiPple t --

J

Flexible Nipple I .........

Access

Off Connector

Cap

All connections must be wrench4ightened

Figure 10

Assemble the flexible connector from the gas supply pipe

to the pressure regulator in the following order:

1. manual shutoff valve (not supplied)

2. 1/2" nipple (not supplied)

3. 1/2" flare union adapter (not supplied)

4. flexible connector (not supplied)

5. 1/2" flare union adapter (not supplied)

6. 1/2" nipple (not supplied)

7. pressure regulator (supplied)

The gas supply line to the shutoff valve should be

1/2"(1,27 cm) or 3/4"(I .9 cm) solid pipe.

The user must know the location of the main shutoff

valve and have easy access to it.

When using flexible gas conduit on the range, allow

sufficient slack to pull the range outside the cutout for

cleaning or servicing.

NOTF: Do not allow the flexible conduit to get pinched

between the wall and the range. To visually check,

remove the range drawer.

Use pipe-joint compound made for usewith Natural and

LP/Propane gas to seal all gas connections. If flexible

connectors are used, be certain connectors are not kinked.

t_

PRESSUREREGULATOR LOCATION

Figure 9

Shutoff Valve -

Open position

Figure 11

The supply line must be equipped with an approved

manual shutoff valve. This valve should be located in the

same room as the range and should be in a location that

allows ease of opening and closing. Do not block access

to the shutoff valve. The valve is for turning on or

shutting off gas to the appliance.

Onceregulatorisinplace,opentheshutoffvalveinthe

gassupplyline.Waitafewminutesforgasto move

throughthegasline.

Leaktestingof theapplianceshallbeconducted

accordingto themanufacturer'sinstructions.

CheckforJeaks.A_terconnectingtherangetothegassupply,

checkthesystemforleakswithamanometer.Ifamanometer

isnotavailable,turnonthegassupplyandusealiquidleak

detectoratalljointsandconnectionstocheckforleaks.

Donotuseaflameto checkforleaks

fromgasconnections.Checkingforleakswithaflame

mayresultinafireorexplosion.

Allopeningsinthewallorfloorwheretherangeistobe

installedmustbesealed.

Tightenallconnectionsif necessaryto preventgas

leakageinthe(ooktoporsupplyline.

Disconnectthisrangeandits individualshutoff

valvefromthegassupplypipingsystemduringany

pressuretestingofthesystemattestpressuresgreater

than1/2psig(3.5kPaor14"(35,56era)watercolumn).

tsoJatetherangefromthegassupplypipingsystem

byclosingitsindividualmanualshutoffvalveduringany

pressure testing of the gas supply piping system at test

pressures equal to or less than 1/2 psig (3.5 kPa or

14"(35,56 cm) water column).

LPiPropane Gas Conversion

Thisapplian(e (an be used with Natural gasor LP/Propane

gas. It isshippedfrom the factory for usewith natural gas.

If you wish to convert your range for use with LP/Propane

gas, use the supplied fixed orifices located in a bag

containing tile literature marked "FOR LP/PROPANEGAS

CONVERSION." Follow the instructions packaged with

the orifices.

The conversion must be performed by a qualified service

technician in accordance with the manufacturer's

instructions and all local codes and requirements. Failure

to follow these instructions could result in serious injury

or property damage. The qualified agency performing

this work assumes responsibility for the conversion.

Failure to make the appropriate

conversion can result in personal injury and property

damage.

Moving the Appliance for

Servicing and Cleaning

Turn off the range line fuse or circuit breakers at the main

power source, and turn off the manual gas shut-off valve.

Make sure tile range is cold. Remove tile service drawer

(warmer drawer on some models) and open the oven door.

Lift the range at the front and slide it out of tile cut-out

opening without creating undue strain on tile flexible gas

conduit. Make sure not to pinch the flexible gas conduit at

the back of the range when replacing the unit into tile cut-

out opening. Replace the drawer, close the door and switch

on the electrical power and gas to the range.

Range JnstaJJation

mportant Note: Door removal is not a requirement for

installation of tile range, but is

an added convenience.

Refer to the Use and Care

Guide for oven door

removal instructionso

Standard Installation

1. The range cooktop

overlaps tile countertop at

the sides and the range

rests on the floor. The cooktop is 31 I/2"(1,27

cm)(81 cm) wide.

2. Install base cabinets 30" (76.2 cm) apart. Make sure

they are plumb and level before attaching cooktop.

Shave raised countertop edge to clear 31 1/2 "(1,27

cm)wide range top rim.

3. Install cabinet doors 31 " (78.7 cm) min. apart so

they will not interfere with range door opening.

4. Cutout countertop exactly as shown on page 1.

5. A backguard kit can be ordered through Sears

Service Center.

6. When you unpack the range, the leveling devices

at rear are at the highest position they can be. Make

sure the front leveling legs are also at their highest

position.

7. _ Install the anti-tip bracket at this

point before placing the range at its finaJ

position. Follow tile installation instructions on page

12 or on the anti-tip bracket template supplied with

tile range.

8. To provide an optimum installation, the top surface

of the countertop must be level and flat (lie on the

same plane) around the 3 sides that are adjacent to

range cooktop. Proper adjustments to make the top

flat should be made or gaps between the countertop

and tile range cooktop may occur.

9. _ To reduce the risk of damaging your

appliance, do not handle or manipulate it by tile

ceramic glass. Manipulate with care.

10. Position range in front of the cabinet opening.

11. Make sure that the cooktop glass which overhangs

tile countertop clears tile countertop. If necessary,

raise tile unit by lowering the leveling legs.

12. Slide the range into the cutout opening.

13. Level the range (see section 8). The floor where the

range isto be installed must be level. Follow the

instructions under "Leveling tile Range - Models

Equipped with Leveling Device".

14. Adjust leveling legs so that the underside of the

cooktop is sitting on the countertop.

15. Carefully screw in the back leveling leg until the

cooktop glass overhang touches slightly the

countertop (refer to "Leveling tile range: Models

equipped with Leveling Device"). The cooktop

glass must not support the unit,

16.Then carefully screw in the front two leveling legs

(similar to 15) until the cooktop glass overhang

touches slightly the countertop.

Installation For 29" Existing Cutout Width Opening

1. You must replace the original side panels with new and

thinner side panels. These new side panels can be

ordered through a SearsService Center.

2. Follow instructions supplied with your new side panels to

replace tile original side panels with the new ones.

3. Check if the countertop isprepared for 29" cutout wide

opening in "Countertop Preparation" sectionat page 5.

4. Install range as in the "Standard installation" section

above.

Installation With Backguard

Tile cutout depth of (21 3/4" (55.2 cm)Min., 22 1/8"

(56.2cm) Max.) needs to be increased to 24"(10,16

cm)(61 cm) when installing a backguard.

installation With End PaneJ

A End Panel kit can be ordered through a Sears Service

Center.

[nstaJJation With Side Panels

A Side Panels kit can be ordered through a Sears Service

Center.

Install cabinet doors 31 " (78.7 cm) min. apart so as not

to interfere with range door opening.

Leveling the Range -

Level the range after installation in the cutout opening.

1. Open the range drawer. The leveling screws control

the height of the rear leg.

2. Adjust the appliance legs asfollows until tile underside

of the cooktop surface issitting level on the countertop

(Figure 12).

Font

L_,,_n_----_ Figure 12

Leg

LOWER

RAISE

1. To adjust the front leveling legs, use a wrench and turn

counterclockwise to lower or clockwise to raise.

2. To adjust tile rear leveling screws, use a ratchet or a

nutdriver and turn counterdockwise to lower or

clockwise to raise.

3. Checkiftherangeislevelbyinstallinganovenrackin

the(.enteroftheovenandplacingalevelontherack

(Figure13)

4. Take2readingswiththelevelplaceddiagonallyin

onedirectionandthentheother.Leveltherange,if

necessary,byadjustingthelevelinglegs.

5. Iftherangeisnotlevel,contactacarpentertocorrect

saggingorslopingfloor.

Check Operation

Refer to the Use and Care Guide packaged with the

range for operating instructions and for (.are and (.leaning

of your range.

Do not touch the elements or burners. They may be hot

enough to cause burns.

Remove all packaging from the oven before testing.

1.[nstaJ[ Burner Bases and Burner Caps

This range is equipped with sealed burners as

shown (see Figure 15).

1. Unpack burner bases and burner caps.

2. Placeburner bases over each gas opening.

3. Make sure the burner is properly aligned and leveled.

Placeburner caps over appropriate burner bases.

Burner Cap

J /

Figure 13

Decorative Rear Trim lnstaJJation

(if required)

1. Disconnect the power from the range.

2. Make sure tile range is leveled.

3. Pull range toward you.

4. Measure the distance between the floor and the

surface underneath the cooktop frame.

5. Mark that distance on the wall where the decorative

trim will be installed.

6. Draw a line.

7. Place the top of the decorative trim under that line.

8. Using the screws provided fix the decorative trim into

the wall.

9. Slide the range back into position asfar as it will go

and reconnect tile power source.

Trim

underneath the

Figure 14

Figure 15 Electrode

NOTE: There are no burner adjustments necessary on this

range.

2.Turn on Electrical Power and Open Main Shutoff

Gas VaIve

3.Check the Igniters

Operation of electric: igniters should be checked after

range and supply line connectors have been carefully

checked for leaks and range has been connected to

electric power. To check for proper lighting:

1.Push in and turn a surface burner knob to the LITE

position. You will hear the igniter sparking.

2. The surface burner should light when gas is available

to the top burner. Each burner should light within four

(4) seconds in normal operation after air has been

purged from supply lines. Visually check that burner

has lit.

3.Once the burner lights, the control knob should be

rotated out of the LITEposition.

There are separate ignition devices for each burner. Try

each knob separately until all burner valves have been

checked.

10

4.Adjustthe "LOW"Settingof SurfaceBurner

Valves(seeFigure16)

Figure!6%

1.PushinandturneachcontroltoLITEuntilburnerignites.

2.QuicklyturnknobtoLOWESTPOSITION.

3.Ifburnergoesout,readjustvalveasfollows:

ResetcontroltoOFF.Removethesurfaceburnercontrol

knob,insertathin-bladedscrewdriverintothehollowvalve

stemandengagetileslottedscrewinside.Flamesizecanbe

increasedordecreasedwiththeturnofthescrew.Adjust

flameuntilyoucanquicklyturnknobfromLITEtoLOWEST

POSITIONwithoutextinguishingtheflame.Flameshouldbe

assmallaspossiblewithoutgoingout

5. Operationof OvenElements

Theovenisequippedwithanelectronicovencontrol.Each

oftilefunctionshasbeenfactorycheckedbeforeshipping.

However,itissuggestedthatyouverifytheoperationof

theelectronicovencontrolsoncemore.Refertothe

ElectronicOvenControlGuideforoperation.Followthe

instructionsfortheClock,Timer,Bake,Broil,Convection

(somemodels)andCleanfunctions.

Bake-Aftersettingtheovento350%(177°C)forbaking,

thelowerelementintheovenshouldbecomered.

Broil-WhentheovenissettoBROIL,theupperelement

intheovenshouldbecomered.

Clean-Whentheovenissetforaself<leaningcycle,the

upperelementshouldbecomeredduringthepreheat

portionofthecycle.Afterreachingtheself<leaning

temperature,thelowerelementwill becomered.

Convection(somemodels)-Whentheovenissetto

CONV.BAKE/ROASTat350%(177°C),tile convection

elementcyclesonandoff andtheconvectionfanturns.

Theconvectionfanwillstopturningwhentileovendoor

isopenedduringconvectionbakingorroasting.

WarmerDrawer(somemodels)-Setthecontrolknob

to HIandcheckto seethedrawerisheating.

When All Hookups are Complete

Make sure all controls are left on the OFF position.

Make sure the flow of combustion anf ventilation air to tile

range isunobstructed.

Model and Serial Number Location

The serial plate is located on the oven front frame

behind the oven door (some models or on the drawer

side frame (some models).

When ordering parts for or making inquiries about your

range, always be sure to include the model and serial

numbers and a lot number or letter from tile serial plate

on your range.

Your serial plate also tells you the rating of the burners,

the type of fuel and the pressure tile range was adjusted

for when it left tile factory.

Before You Call for Service

Read tile Before You Call Checklist and operating

instructions in your Use and Care Guide. It may save

you time and expense. The list includes common

occurrences that are not the result of defective

workmanship or materials in this appliance.

Refer to your Use & Care Guide for Sears service phone

numbers or call 1-800-4-MY-HOME ®.

11

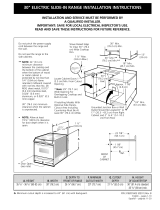

Anti-Tip Brackets JnstaJJation

instructions

To reduce tile risk of tipping of the range,

the range must be secured to the floor by properly installed

anti-tip bracket and screws packed with the range, Those

parts are located in the oven, Failure to install the anti-tip

bracket will allow the range to tip over if excessiveweight

is placed on an open door or if a child climbs upon it,

Serious injury might result frora spilled hot liquids or from

the range itself,

Follow the instructions below to install tile anti-tip

brackets.

If range is ever moved to a different location, the anti-tip

brackets must also be moved and installed with the

range.

Tools Required:

Adjustable Wrench

Ratchet

Drill & I/8"(0,32 cm) bit

5/I 6" (0,79 cm) Nutdriver

Level

Kitchen

Cabinet

Toe

Door

Cabinet

S

Figure 17

BACK

The anti-tip bracket attaches to the floor at the back of

the range to hold range rear center leg. When fastening

bracket to the floor, be sure that screws do not

penetrate electrical wiring or plumbing. The screws

provided will work in either wood or concrete.

1. Draw a center line (CL) on the floor where the range

should be installed. Also draw a line on the floor at

the range back position if there is no wall.

2. Unfold paper template and place it flat on the floor

positioned exactly on the intersection of the center

and back lines you just drew before. (Use the diagram

below to locate brackets if template is not available

(Figure 17)).

3. Mark on the floor the location of the 4 mounting

holes shown on the template. For easier installation,

3/16"(0,48 cm) diameter pilot holes 1/2"(!,27 cm)

deep can be drilled into the floor.

4. Remove template and place bracket on floor. Line

up holes in bracket with marks on floor and attach

with 4 screws provided. Bracket must be secured to

solid floor (Figure 18). If attaching to concrete floor,

first drill 3/16"(0,48 cm) dia. pilot holes using a

masonry drill bit.

5. Be sure the leveling legs and leveling device are at

the highest position they can be.

6. Slide range into place making sure rear center leg is

trapped by the anti-tip bracket (Figure 17). Lower

tile range by adjusting the leveling legs and leveling

device until the underside of the cooktop is sitting

leveled on the (ountertop. Refer to "Leveling tile

Range" section.

7. After installation, verify that the anti-tip bracket is

engaged by grasping the top rear edge of the range

and carefully attempt to tilt it forward to make sure

range isproperly anchored.

C

Screws

Figure 18

12

LA INSTALAaON Y EL SERVlaO DEBEN SER EFECTUADOS POR UN INSTALADOR CAUNCADO.

IMPORTANTE: GUARDE ESTAS INSTRUCaONES PARA USO DEL INSPECTOR LOCAL DE ELECTRlaDAD.

LEA Y GUARDE ESTAS INSTRUCaONES PARA REFERENaA FUTURA.

Si [a informad6n contenida en este manuaJ no es seguida exactamente,

puede ocurrk un incendio o exptosi6n causando da_os materiales, tesi6n personaJ o ta muerte.

PARA SU SEGURDAD:

-- No almacene ni utilice gasolina u otros vapores y t_q@dos inflamables en [a proximidad

de _ste o de cua[q@er otto artefacto.

-- QUE DEBE HACER SJPERCtBE OLOR A GAS:

• No trate de encender ningQn artefacto.

• No toque ningun interruptor e[_ctrico; no use ningQn te[_fono en su edificio.

, L[ame a su proveedor de gas desde e[ te[_fono de un vecino. Siga [as instrucciones de[ proveedor de gas.

• S[ no [ogra comunkarse con su proveedor de gas, [lame a[ departamento de bomberos.

-- La [nsta[ad6n y e[ serv[c[o de manten[m[ento deben set efectuados pot un [nsta[ador ca[[f[cado, [a

agenda de servk[o o e[ proveedor de gas.

***JMPORTANTE: Para el

torte a 1oancho (dimensi6n

E)de m&s de 30 1/15" (76,4

cm) para evitar que se

rompa e[ vidrio, asegQrese

que el artefacto est&

centrado en [a abertura de

[a mesada m[entras [o

presiona. Levante [as patas

de n[ve[ad6n hasta [a

poski6n m&xima; inserte el

artefacto en [a mesada y

[uego nivele. As_::jurese

de que la unidad est_

apoyada en [as patas

de nive[aci6n y no en

La superfk[e debe estar piana y

niveiada (area sombreada).

1 Y2" M_x.

(3.8 cm M_x,)

Acepille el

borde

subido a

que deje

espacio

para un

borde 31 1/2" (81

cm) de anchura de

estufa

Localise las puertas del

armario 1"(2,5 cm) rain del

hueco de la abertura,

NOTA: Para la abertura amplia de corle de 29" (73,7

cm), tiene que [larnar al Centro de Servkios Sears y

solkitar paneles laterales opcionales, Despejar el

reborde ancho de la cocina tal como se muestra en la

section "Preparacion de la Mesada "(vet pagina 16)

E

30" Min.

(76.2 cm Mln,)

30" Min,

18" Min.

(45.7 cm) Min,

I3"

(33 cm)

24" Min,

(61 cm Min,)

caja de empahnes o el enchufe con puesta a

tierra deberia situarse de 8" a 17" (20.3 cm a

43.2 cm) del armario derecho y de 2" a 4" (5.1

cm a 10.2 cm) del suelo,

IMPORTANTE: El ancho de la

cubierta y e[ armario debe de

set igua[ a[ ancho de[ torte.

B._,r,_cHoc.ANcH0H LAD.PROFUNDDADA

: RLANCHA DE LA FRENTEDE LA

" COCINAR ° ESTUFA

:_B5/8" (905 cm) -- :_0" (76,2 cm) 31/2" (80 cm) 28 B/16" (71,9 cm)

:_65/8" (g:_cm)

B

E, ANCHO G, ALTURA DEL

DE RECORTADO*** RECORTADO ' M©SIRADOR

(cubierta yarmario)

_0±1/I6" 2I :V4" 65,2 cm) Min. 36 B/8" (93 cm) Max

(76,2±0,15 cm) 22 I/8" (56,2 cm) Max 35 5/8" (905 cm) rain

24" 61 cm) Min con un

protector trasero_

NOTA: Se adjunta el diagrama de cables de esta codna a[ final de este [ibreta. P/N 318201670 (0510) Rev C

Imprimido en los Estados Unidos English - pages 1-12

Espai_o[ - p_ginas 13-25

Diagrama de la instalaci6n alambrica - p_ginas 28

1, No pellizque el cordon electrico o e! conducto flexible de gas entre la estufa y la pared,

No selle la estufa a los armarios de lado,

3_

cuando e! fondo deI armario de madera

o metal est,1protegido pot no menos de

1/4" (0,64 cm) de madera resistente aI

fuego cubierta pot una I_imina met_ilica

de MSG, n0mero 28, 0,015" (0.4 ram)

de acero inoxidable, 0.024" (0.6 ram) de

aluminio, 6 0.02" (0,5 ram) de cobre,

Un espacio mfnimo de 30" (76.2 cm)

cuando el armario no est,1protegido,

Un espacio mfnimo de 24" (61 cm) entre la superficie de la estufa y el fondo del armario

4, Para los recortados menos que 22 7/

8", el electrodomestico aparecerfa

ligeramente en el exterior del armario,

Puerta

abierta

(vea la

nota 5)

A

5, Deje pot los 19 ¼" (48.9 cm) de

espacio libre para Ia profundidad de la

puerta cuandoesta abierta,

lateral

PARTE

DELANTERA

22 718" (58.1 cm) rain.

23 114" (59.05 cm) max.

Notas importantes para el lnstalador

1. Lea todas Ias instrucciones contenidas en este

manual antes de instalar Ia estufa.

Saque todo el material usado en e! e,mbalaje

det compartimiento deI homo antes de

conectar el suministro eI_ctrico o de gas a la

estufa.

3. Observe todos los codigos y reglamentos

pertinentes.

4. Deje estas instrucciones con el comprador.

Nota lmportante para el Consumidor

Conserve estas instrucciones y el Manual del

Usuario para referencia futura.

A.AL-ruRA e,ANcflOC.ANcHODEL,iDIPROFUNDIDADA

PLANCHA DE LA ERENTE DELA

' COCINAR ESTUFA

:355/8" (90.5 cm) - 30" (76,2 cm) :31Y2"(80 cm) 28 5/16" (71,9 cm)

:36'_/8" (9_ cm)

E. ANCHO

DE RECORTADO***

(cubierta y armario)

30±1/16"

(7d,2±0,I5 cm)

F; PROFUNDIDAD DE G. ALTURA DEL

RECQRTADO I MOSTRADOR

21 3/4" (55,2 cm) Min. 36 5/8" (93 cm) Max

22 1/8" (56,2 cm) Max 35 5/8" (905 c:m)rain

24" (61 cm) Min con un

protector trasero

14

[NSTRUCCIONES DE

SEGUR[DAD

InstataciOn de esta estufa debe cumplir con todos los

c0digos locates, o en ausencia de c0digos locales con el

C0digo National de Gas Combustible ANS! Z223.1--

Oltima edici0n,

El diseflo de esta estufa ha sido certificado por la CSA

International, En estecomoencualquierotroartefacto

que use gas y genere calor, hay ciertas precauciones de

seguridad que usted debeseguir. Estasser_in

encontradas en el Manual del Usuario, lea!o

cuidadosamente.

AsegQrese de que [a estufa sea instalada y

conectada a tierra en forma apropiada pot un

instalador calificado o pot un t_cnico.

Esta estufa debe set emectrkamente puesta a tierra

de acuerdo con los cbdigos locales, o en su

ausenda, con el COdigo El(_ctrko National ANSI/

NFPA No. 70, Q[tima edkibn. Vea las instrucciones

para la puesta a tierra en la p_gina 4.

La instalaciOn de aparatos diseflados para instalaciOn

en casas prefabricadas (m0viles) debe conformar con el

Manufactured Home Construction and Safety Standard,

titulo 24CFR, parte 3280 [Anteriormente e! Federal

Standard for Mobil Home Construction and Safety,

titulo 24, HUD (parte 280)] o cuando tal est_indar no se

aplica, el Standard for Manufactured Home Installation

1982 (Manufactured Home sites, Communities and

Setups), ANSI Z225,1/NFPA 501A-edici0n ma's reciente,

o con los c0digos locales.

Antes de instalar [a estufa en un Mea cuyo piso

este recubierto con Iinbleo u otto tipo de piso

sint_tko, asegurese de que estos puedan resistir

una temperatura de pot 1o menos 90°F sobre [a

temperatura ambiental sin provocar encogimiento,

deformation odecoloradOn, Noinstale laestufa

sobre una alfombra al menos que coloque una plancha

de material aislante de por Io menos 1/4 pulgada,

entre la estufa y la alfombra.

• Todas las

estufas

pueden

volcarse.

Esto podria

resultar en

lesiones

personales.

®Instale el

dispositivo

antivuelcos

que se ha

empacado

junto con

esta estufa.

Para reducir el riesgo de

que se vuelque la estufa,

hay que asegurarla

adecuadamente co!o

candole los soportes

antivuelco que se

proporcionan. Para

comprobar si estos estan

instalados y apretados en

su lugar como se debe,

ase el horde trasero

superior de la estufa y

cuidado samente incline la

hacia adelante para

asegurar que la estufa se

ancle.

15

Asegurese de que el material que recubre [as

paredes alrededor de [a estufa, pueda resistir el

calor generado pot [a estufa.

No obstruya el flujo de{ aire de combustion en [a

vent[laciOn de[ homo n[ tampoco alrededor de [a

base o debajo de[ panel inferior delantero de [a

estufa. Evite tocar lasaberturaso areascercanas de

la ventilaciOn, ya que pueden estar muy calientes

duranteelfuncionamientodel homo. Laestufa

requiere aire fresco para la combustion apropiada de

los quemadores.

_Nunca deje ni_os solos o

desatendidos en un Mea donde un artefacto est&

siendousado, Amedida que los nifloscrecen,

ensefleles el uso apropiado y de seguridad para todos los

artefactos. Nuncadeje la puerta del homoabierta

cuando la estufa est,1 desatendida.

_7_lNo se pare, apoye o siente en [as

puertas o cajones de esta estufa pues puede resultar

en serias [esiones y puede tambien causar da_o a [a

estufa.

No almacene articulos que puedan interesar a los

niffos en los gabinetes sobre [a estufa. Los niflos

pueden quemarse seriamente tratando de trepar a la

estufa para alcanzar estos art[culos.

Los gabinetes de almacenamiento sobre [a estufa

deben set evitados, para eliminar la necesidad de

tenet que pasar sobre los quemadores superiores

de [a estufa para [[egar a e{los.

Ajuste el tamaffo de [a llama de los quemadores

superiores de ta[ manera que esta no sobrepase e[

bordede los utensilios decocinar. La llama

excesiva es peligrosa.

No use el homo como espacio de almacenaje. Esto

create1 una situaci0n potencialmente peligrosa.

Nunca use [a estufa para calentar el cuarto. El uso

prolongado de la estufa sin la adecuada ventilaci0n

puede resultar peligroso.

No almacene ni utilice gasolina u otros vapores y

[iquidos inflamab[es en [a proximidad de este o de

cualquier otro artefacto etectrico. Puede provocar

incendio o explosion.

En caso de una interruption del servicio electrico, es

pasible de encender los quemadores de superficie a

mano. Para encender un quemador de suoerficie,

acerque un fOsforo encendido del cabezal del

quemador, y gire delicadamente e! bot0n de control de

superficie a LITE (encendido). Tener cuidado al

encender los quemadores a mano.

Ajuste todos los controles a la posicibn "OFF"

(apagada) despues de haber hecho una operaciOn

con tiempo programado.

PARA MODELOS AUTOLIMPIANTES:

Saque [a asadera, alimentos o cualquier otto

utensilio antes de usar el cic{o de autoIimpieza de[

homo, Limpietodoexceso de derrame dealimentos.

Siga las instrucciones de prelimpiado en el Manual del

Usuario.

]uego de Cord6n Electrko

El consumidor tiene la responsabilidad de conectar el

cord6n electrico al bloque de conexi6n ubicado detra% de

la cubierta de acceso del panel trasero.

Este electrodomestico puede ser conectado por medio de

una "conexi6n directa" de cables permanentes (cable

blindado flexible o no met_ilico recubierto de cobre), o por

medio de un ensamblaje de cord6n de suministro electrico,

Solamente un ensamblaje de cordon de suministro electrico

con regimen de 125/250 voltios minimo, 40 amperios

minimo y marcado para use con cocinas debe set utilizado

.Vea la tabla (ma's abajo) para informaci6n sobre el tamafio

de abertura de la conexi6n del ensamblaje de cord6n, E!

cord6n debe de tener 3 o 4 conductores,

Para las casas sobre ruedas, las nuevas instalaciones, en los

vehiculos de recreaci6n o en las a'reas donde los c6digos lo-

cales no permiten la conexi6n del conductor a tierra al neutro,

un ensamblaje de suministro electrico de 4 conductores para

estufas, clasificado a 125/250 voltios minimo, 40 amperios

mfnimo, debe de ser utilizado Ever la figura 4),

Los bornes a la extremidad de los alambres deben ser a cur,vas

cerradas o con extremidades de lenguetas en forma de U

abiertas y curvadas. El cord6n debe de tener una abrazadera

releva de anclaje

Ver la tabla de arriba para conexi6n de alambres de 3 o 4

conductores.

TabJa de tama_o de abertura de conexi6n de cocina

Referirse a la tabla de arriba para el tamaflo de abertura de

cormexion de codna adecuada, y la informacion sobre el regimen

de amperios del ensambhje de cordon de suministro electrico..

Vea la plata de serie de la

cocina para informad0n

sobre el regimd_n de

kilovatio

120/240 Volts 120/208 Volts

Mlnimo

regimen de

amperios

de

ensambiaje

del cordon

iDiametro (pulgadas) de

abierta de conexion de

cocina,

iEnsemblaje

idel cordon

Connect,

Directa

0-16.5 Kw 0-I 2.5 Kw 40 Amp I-3/8 pulg 1-I/8 pulg

16.6-22,5 Kw 12,6-18.5 Kw 50 Amp I-3/8 pulg 1-3/8 pulg

Figura 1

Nota: La cocina corrediza fue! dua! viene de fabrica con

un agujero d diametro 1 1/8" come muestra en la figura 3.

Si un agujero mas largo esta" necesario retire la arandela

pre'cortada.

Puede ocurrir riesgo de incendio o

choque eJOctrico si se usa un juego de cord6n de estufa

de tamaFio incorrecto, si las instrucciones de instalaci6n

no son seguidas o si no se usa el anclaje del cable (vea

Figura 3).

_.__ No desate las tuercas que sujetan et

alambraje de cocina que ha sido instaJado en la

factoria aJ bloque terminal, cuando se hate la

conexion de la cocina. Se puede ocurrir el real

funcionamiento o una interruption det suministro

etectrico.

Conexi6n Electrico de la Estufa

Este aparato se fabrica con el terminal neutro conectado

al marco,

Befiere al diagrama de alambraje en las paginas de

centro de este manual.

Riesgo de Choque El@ctrico

o Una puesta a tierra est_ requerido en este

aparato.

, No Jo conecte a la corriente electrica hasta que

el aparato haya sido puesto a tierra

permanentemente,

, Desconecte Ja corriente electrica a la caja de

empaJmes antes de hacer la conexi6n eJ_ctrica.

, Este aparato debe estar conectado con un

sistema de alambres puesto en tierra, met_Jico

y permanente o un conector de puesta a tierra

debe conectarse al terminal de puesta a tierra

o el alambre conductor en eJ aparato,

No utilice el suministro de gas para hater Ja

puesta a tierra.

La falta de hater cualquier de las cosas arriba

podria resuJtar en un incendio, choque etectrico

o Jesiones personaJes.

Conexi6n de tres alambres de conducd6n a

la estufa

(Un cord6n flexible o cable de 3 conductores debe de ser

reemplazado con un cord6n flexible o cable de 4 conducto-

res donde la conexi6n del conductor a tierra al neutro esta

prohibida en las nuevas instalaciones, las casas sobre

ruedas, los vehk:ulos de recreaci6n o otras _reas donde los

c6digos locales no permiten la conexi6n a tierra al neutro.)

Si los c6digos locales permiten la conexi6n del conductor

de tierra del marco con el alambre neutro del cord6n

electrico de cobre (yea Figura 3):

1. Quite los tres tornillos en la parte m4s baja del panel

trasero, luego levante la parte m4s baja del panel

trasero (la cubierta de acceso) exponiendo el b!oque

de conexiones de los terminales de la estufa (vea

Figura 2).

2. Quite las tres tuercas desatadas (despues de remover

la cinta de goma) sobre el bloque terminal usando

un destornillador o una

Ilave de casquil!o de 3/'

8"(0,95 cm),

3. Conecte el cable neutro

del cord6n ebctrico de

cobre al terminal de color

de plata en el centro del

bloque, y conecte los

otros cabels a los

Figura 2

LEVANTE LA PARTE MAS BAJA DEL PANEL

TRASERO AQUI PARA TENER ACCESO AL BLOQUE

DE CONEXIONES DIE LOS TIERMENALES

16

terminales laterales. Empareje los cables y los

terminales seg0n e! color (cables rojos conectados

con el terminal derecho, cables negros conectados

con el terminal izquierdo.

4. Repone las tres tuercas desatadas sobre el b!oque

terminal.

5. Baje la cubierta del terminal y reinstale los tres (3)

tornillos.

Cone×ion de 4 alambres de conduccion a la

estufa (casas moviles}

ue terminal plata

Alambre

Negro

Una arazadera

de releva provista debe de estar

instalada a esta ubicaci6n Hacia el 240 V

receptaculo

Figura 3

J/8" Dia.

Agujero de la

conexi6n directa.

Retira la arandela

pre-cortada para

1-3/8" Dia. Agujero

1. Quite los tres torni!los en la parte m_is baja del panel

trasero, luego levante la parte ma's baja del panel

trasero (la cubierta de acceso) exponiendo el bloque

de conexiones de los terminales de la estufa.

2. Quite las tres tuercas dasatadas (despues de remover

la cinta de goma) sobre el b!oque termianl usando

un destornillador o una Ilave de casqui!lo de 3/

8"(0,95 cm).

3. Quite la banda de puesta a tierra de! bloque de los

terminalesy del marco delartefacto. Retengae!

torni!lo de puesta a tierra.

4. Conecte e! alambre de puesta a tierra (verde) de!

cordon electrico de cobre al marco del artefacto con

e! tornillo de puesta a tierra, usando el agujero en e!

marco donde se quit0 el tornillo de puesta a tierra

(vea figura 4).

5. Conecte e! alambre neutro (blanco) de! cordon

electrico de cobrealtermina! de color de plataen

e! centro del bloque y conecte los otros alambres a!

los terminates laterales.

6. Repone las tres tuercas desatadas sobre el bloque

terminal.

7. Baje la cubierta de acceso y vuelva a poner los 3

tornillos.

Bloque terminal plata

Rojo

Atambre

Negro l/

1-1/8" Dia.

Agujero de ta

conexi6n

directa.Retira

ta arandeta

pre-cortada

para !-3/8" Dia.

Agujero

Una arazadera

de releva provista

debe de estar

instalada a est_

ubicaciOn

NOTA: Asegurese de quitar

ta banda de puesta a tierra provista.

Figura 4

Hacia el 240 V receptaculo

Conexi6n elOctrica directa a[ cortadrcuito, a

[a caja de fusibles o [a caja de empalmes

Si el aparato esta conectado directamente al (ortacircuito,

a la (aia de fusibles o a la cap de empalmes, use un cable

blindado flexible o no metalico recubierto de cobre (con

alambre a tierra). Provee una abrazadera releva de anclaie

homologo UL a cada extremidad del cable. A la

extremidad del electrodomOstico, el cable pase a travOs del

agujero de la conexion directa (vet figura 4) en el cordon

de la plata de montaje. El tama¢io de los alambres

(alambre de cobre soIamente) y las (onexiones deben

estar conforme al regimOn del electrodomOstico.

Donde los c6digos [ocales permitan conectar el

conductor de puesta a tierra de[ e[Octrodom_stico a[

neutral (blanco) (yea figura 5}:

(Un cordon flexible o cable de 3 conductores debe de ser

reemplazado con un (ordOn flexible o cable de 4 conducto-

res donde la conexion del conductor a tierra al neutro esta

prohibida en las nuevas instalaciones, lascasassobre

ruedas, los veh[culos de recreation o otras areasdonde los

codigos locales no permiten la conexiOn a tierra al neutro.)

1. Desconecte el suministro ele(trico.

2. En el cortacircuito, la caia de fusibles o la caja de

empalmes

a) Conecte el alambre verde (o cobre desnudo), el

alambre blanco del cable del electrodomOstico y el

alambre neutral (blanco)iuntos.

b) Conecte losdos alambres negros iuntos.

c) Conecte los dos alambres rojosjuntos.

17

Alambre

Blanco

(Neutro)

A[ambres-_._

roJo

CaMedelafuente

dea[imentaci6n

-- Alambres

negros

Figura5- Sistema e[_ctrico

(ejemp[o: caja de empa[mes)

de 3 a[ambres (a tierra

neutra[)

Alambres

desnudos

o verdes

Cable de [a

estufa

Caja de

empalmes

Alambre

Blanco

(Neutro)

Conductor de

uni6n [istado-UL

(listado-CSA)

Donde los c6digos locales NO permitan conectar el conductor de puesta a tierra de[

electrodomestico a[ neutral (blanco), o siesta conectado con un sistema a 4 alambres (vea figura 6):

1. Desconecte el suministro electrico

2. Separe el alambre verde (o cobre desnudo) y el alambre blanco del electrodomestico.

3. En el cortadrcuito, la caja de fusibles o la caja de empalmes.

a. Conecte el alambre bhnco del cable del electrodomestico al alambre neutral (bhnco).

b. Conecte los 2 alambres negros juntos.

c. Conecte los 2 alambres rqos juntos.

d. Conecte el alambre verde (o de cobre desnudo) de la puesta a tierra del alambre al alambre de

puesta a tierra del cortacircuito, de la ca]a de fusibles o de la ca]a de empalmes.

F[gura 6 - S[stema

e[_ctHco de 4 a[ambres

(ejemp[o caja de

empa[me)

Alambre Cable de la fuente Caja de

desnudo o de alimentaci6n empalmes

verde Alambre

Alambres Blanco

rojos (Neutro)

1

Alambres

negros

A[ambres

desnudos o

verdes

Cable de la

estufa

Alambre

Blanco

(Neutro)

or de

uni6n [[stado-UL

(o listado-CSA)

18

Construcdon del armario

Para eliminar el riesgo de quemaduras o de fuego tratando de alcanzar algo por encima de las zonas

calientes, evite de (olocar articulos sobre la co(ina. Si (ree necesitar este espacio, el riesgo puede disminuir si instala un

sombrerete que proteja horizontalmente un mfnimo de 5" (12.7cm) sobre la base del armario.

Preparation de[ mostrador

Las extremidades de la cocina sobrepasan el horde de su mostrador.

Si tiene un mostrador con tas extremidades cuadradas (ptanas), no se necesita ninguna preparation del

mostrador.

E[ reborde de frente de mostradores moldeados deben tenet bordes moldeados a 3/4" (I .9cm) a partir de

cada extremidad de la apertura (Figura 7).

Los mostradores enazulejos deberSn necesitar un recorte de 3/4" (I .9 cm) a partit de cada extremidad y/o un

horde redondeado aplanado (Fiqura 7).

(81 cm)

o enazulejo recortado

3/4" (1.9 cm) hada arras en las esquinas de

Si el ancho de Ja abertura del mostrador es m_s grande que 30 1/16" (76,4 cm}, ajuste alas dimensiones

como para el 3/4" (I .9).

Para ta Anchura existente del Recorte de eJ29"(73.7 cm) (Figura 8):

2 3/!6"

2 3/16" (5.56 cm)

"_ (5.56cm)

_3i7 Quite el 2 3/16" de

material de frente a la

parte posteriora.

cm)

11/4"

41/2,oMin. (3.2 cm)

(3.2 cm)

Mostrador mo[deado o enazu[ejo

recortado 3/4" (1.9 cm) hada atr&s

en tas esquinas de frente de ta

abertura del mostrador.

E[ mostrador deber set hive[ado. Coloque un nivelador sobre el mostrador, primero de lado a lado y luego del

frente hacia atras. Si el mostrador no esta nivelado, la cocina no estar5 nivelada. El homo debe ser nivelado para

tener resultados satisfactorios al hornear. Lasextremidades de la plancha de la cocinar sobrepasan los hordes de la

abertura del mostrador.

19

lnstalacion de la alimentadon de gas

Esta unidad ha sido ajustada para operar con un m01tiple

de admisi0n para gas natural de 4"(10,16 cm) (1,0 kPa),

Un regulador de presiOn convertible esta conectado a la

wilvula distribuidora y DEBE ser conectado en serie con

la tuberia de suministro de gas.

Para [a operad6n apropiada, la ma_xima presiOn de

entrada al regulador no debe exceder la presiOn de una

columna de agua de 14 pulgadas (3,5 kPa),

La presiOn de entrada al regulador debe ser pot !o

menos 1 pulgada m4s grande que la v&lvula distribuidora

(,25 kPa), E! regulador ha sido ajustado para gas natural

a 4 pulgadas de presi6n para la v41vula distribuidora (1,0

kPa). La presi6n de entrada debe ser pot Io menos de 5

pulgadas (1,25 kPa), Para propano liquido a 10 pulgadas

de presiOn para la va'lvula distribuidora (2.5 kPa) la

presi6n de entrada debe ser pot Io menos de 11

pulgadas (2.75 kPa),

La tuberfa deberia ser equipada con una valvula de

cierre aprobada(vea Figura 11). Estawilvula debe

ubicarse en la misma habitaci0n que la estufa en un

lugar que permita una una facilidad de abrir y cerrar,

No bloqueeel acceso a lavalvula de cierre, Lavalvula

es para abrir o cerrar el suministro de gas al aparato.

Abra la va'lvula de cierre en la linea de suministro de

gas. Espere unos minutos a que el gas se mueva pot e!

tubo,

El suministro de gas entre la va'lvula de cierre y el

regulador se puede conectar con tuberia rfgida o con

tuberia flexible union met31ica conectada y aprobada por

la AGA/CGA donde los cOdigos locales permiten,

La tuberia del suministro de gas puede pasar por la

pared lateral del armario derecho, El armario lateral

derecho es un lugar ideal para la va'lvula de cierre

pincipal.

Conecte el Regulador de Presi6n

El regulador de presion esta ya instalada para la estufa.

No haga que la conexi0n este

demadiadoapretada, El reguladorest_i fundidoa

troque!, Apret3ndo!odemasiado podria romper el

regulador resultando en escape de gas y posiblemente

un incendio o explosi6n,

Vatvula de FLUJO DEL GAS Regulador

_'_ de presi6n

cierre Uni6n Uni6n

manual

( ) k,_ Boquilla Conector Boquill_

Apagado flexible Tapa de

(off) entrada

Todas las conexiones deben ser apretadas con una Ilave

inglesa

Figura 10

ReOnael conector flexible del tubo del suministro de gas al

regulador de la presi6n en Jaorden siguiente:

1. V_ilvuJadecierremanual (noincluido)

2. Boquilla de 1/2" (noincluido)

3. 1/2" Adaptador deunion (noincluido)

4. Conectorflexible (noincluido)

5. 1/2" Adaptador deuniOn (noincluido)

6. Boquilla de 1/2" (no incluido)

7. reguladorde presiOn (incluido)

La tuberia de suministro de gas debe ser de 1/2 "(I ,27 cm) o

3/4"(1,9 cm) D,L

El consumidor debe saber la posici0n de la wilvula

principal de cierre y tener acceso fa'cil a ello.

Cuando se usa un conducto flexible en la estufa, permita

suficiente flojedad como para sacar la estufa fuera del

recortado para la limpieza y el servicio,

NOTA: No permita quee!conductose pellizqueentre la

pared ylaestufa, Paraverlo, saqueelcajOn,

Use un compuesto para junturas de tuberfa hecho para

uso con gas natural y de LP/Propano para sellar todas las

conexionesdel gas, Sise usan Iosconectores flexibles

aseg0rese de que no estOn enroscados.

Figura 9

UBICACION DEL REGULADOR DE PRESION

V lvula de cierre o

Abierta

Figura 11

La Ilnea del suministro se debe de set equipada de una

valvula de cierre manual aprobada. Esta v_lvula se debe

Iocalizar en el mismo cuarto que la estufa y debe estar

en una Iocalizacion que permita la facilidad de la

abertura y del cierre. No bloquee el acceso a la valvula.

La valwJla es para encender o apagar el gas del aparato.

2O

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

-

13

13

-

14

14

-

15

15

-

16

16

-

17

17

-

18

18

-

19

19

-

20

20

-

21

21

-

22

22

-

23

23

-

24

24

-

25

25

-

26

26

-

27

27

-

28

28

Kenmore Elite 79046623502 Installation guide

- Category

- Cookers

- Type

- Installation guide

Ask a question and I''ll find the answer in the document

Finding information in a document is now easier with AI

in other languages

Related papers

-

Kenmore Elite 79042559315 Installation guide

-

Kenmore Elite 79075503207 Installation guide

Kenmore Elite 79075503207 Installation guide

-

Kenmore Elite 79046822100 Installation guide

Kenmore Elite 79046822100 Installation guide

-

Kenmore Elite 79046709603 Installation guide

-

Kenmore Elite 79036723604 Installation guide

Kenmore Elite 79036723604 Installation guide

-

Kenmore Elite 79046712602 Installation guide

-

Kenmore Elite 79042753514 Installation guide

Kenmore Elite 79042753514 Installation guide

-

Kenmore Elite 79031043800 Installation guide

-

Kenmore Elite 79041043801 Installation guide

Kenmore Elite 79041043801 Installation guide

-

Kenmore Elite 79031043800 Installation guide

Kenmore Elite 79031043800 Installation guide

Other documents

-

Electrolux Home Products EW30IS80RS Installation guide

-

Frigidaire FGES3065PWA User manual

-

Frigidaire FFES3026TB Installation guide

-

Sears Kenmore Pro 79079523605 Installation guide

-

Electrolux EW30IS80RS Installation guide

-

Electrolux EW30ES80RS Installation guide

-

Frigidaire CPCS389EC4 Installation guide

-

Electrolux Range Operating instructions

-

Frigidaire 1133867 Installation guide

-

Frigidaire 1133867 Installation guide