Page is loading ...

Instructions-Parts

E-Flo® E-Flo®

E-Flo®

DC DC

DC

4–Ball 4–Ball

4–Ball

Piston Piston

Piston

Pumps Pumps

Pumps

3A2096D

EN

Electric Electric

Electric

drive drive

drive

piston piston

piston

pumps pumps

pumps

for for

for

low low

low

to to

to

medium medium

medium

volume volume

volume

paint paint

paint

circulation circulation

circulation

applications. applications.

applications.

For For

For

professional professional

professional

use use

use

only. only.

only.

Important Important

Important

Safety Safety

Safety

Instructions Instructions

Instructions

Readallwarningsandinstructionsinthismanual.

Save Save

Save

these these

these

instructions. instructions.

instructions.

See Technical Data, page 29, for

Maximum Working Pressure.

See page 3 for model part numbers and

approvals information.

PROVENQUALITY.LEADINGTECHNOLOGY.

Contents Contents

Contents

Models...............................................................3

RelatedManuals................................................3

Warnings...........................................................4

Installation..........................................................8

Location......................................................8

MountthePump..........................................8

PowerSupplyRequirements.........................8

ConnectthePowerSupply...........................10

Grounding...................................................11

FluidLineAccessories.................................12

FillWithOilBeforeUsingEquipment.............12

FlushBeforeUsingEquipment......................12

ControlModuleAccessory............................12

Operation...........................................................13

Startup........................................................13

Shutdown....................................................13

PressureReliefProcedure............................13

Maintenance......................................................14

PreventiveMaintenanceSchedule................14

ChangetheOil.............................................14

CheckOilLevel...........................................14

BearingPre-Load.........................................14

Flushing......................................................14

Troubleshooting..................................................15

Repair................................................................16

Disassembly................................................16

Reassembly................................................16

ReassembletheCouplingAdapterandTie

RodstotheMotor...........................17

Parts..................................................................18

PumpAssembly...........................................18

PumpMatrix................................................20

Dimensions........................................................22

MountingHolePatterns.......................................23

PerformanceCharts............................................25

TechnicalData...................................................29

GracoStandardWarranty....................................30

2

3A2096D

Models

Models Models

Models

The The

The

part part

part

number number

number

for for

for

your your

your

equipment equipment

equipment

is is

is

printed printed

printed

on on

on

the the

the

equipment equipment

equipment

identication identication

identication

label label

label

(L). (L).

(L).

The The

The

part part

part

number number

number

includes includes

includes

digits digits

digits

from from

from

each each

each

of of

of

the the

the

following following

following

categories, categories,

categories,

depending depending

depending

on on

on

the the

the

conguration conguration

conguration

of of

of

your your

your

equipment. equipment.

equipment.

See See

See

Pump Pump

Pump

Matrix Matrix

Matrix

, ,

,

page page

page

20 20

20

for for

for

a a

a

complete complete

complete

list list

list

of of

of

pump pump

pump

part part

part

numbers. numbers.

numbers.

E E

E

- -

-

Flo Flo

Flo

DC DC

DC

Pump Pump

Pump

(EC) (EC)

(EC)

Lower Lower

Lower

Pump Pump

Pump

Size Size

Size

(1, (1,

(1,

2, 2,

2,

3, 3,

3,

or or

or

4) 4)

4)

Motor Motor

Motor

and and

and

Controls Controls

Controls

(1, (1,

(1,

2, 2,

2,

3, 3,

3,

or or

or

4) 4)

4)

Pump Pump

Pump

Type Type

Type

and and

and

Fittings Fittings

Fittings

(1, (1,

(1,

2, 2,

2,

or or

or

3) 3)

3)

Mounting Mounting

Mounting

Type Type

Type

(0, (0,

(0,

1, 1,

1,

or or

or

2) 2)

2)

1=750cc1=1

Horsepower,

Basic

1=Hard

Chrome,

NPT

0=None

2=1000cc2=1

Horsepower,

Advanced

2=Hard

Chrome,

Tri-Clamp

1=Stand

3=1500cc3=2

Horsepower,

Basic

3=Maxlife,

Tri-Clamp

2=WallBracket

EC

4=2000cc4=2

Horsepower,

Advanced

The The

The

following following

following

approvals approvals

approvals

apply apply

apply

to to

to

Basic Basic

Basic

models models

models

only only

only

(Part (Part

(Part

Nos. Nos.

Nos.

EC11xx, EC11xx,

EC11xx,

EC21xx, EC21xx,

EC21xx,

EC23xx, EC23xx,

EC23xx,

EC33xx, EC33xx,

EC33xx,

and and

and

EC43xx). EC43xx).

EC43xx).

NOTE: NOTE:

NOTE:

SeetheE-FloDCMotormanualformotorapprovalsinformation.

Related Related

Related

Manuals Manuals

Manuals

Manual Manual

Manual

No. No.

No.

Description Description

Description

3A2526Instructions-Parts

Manual,E-FloDCMotor

3A2527Instructions-Parts

Manual,forE-FloDC

ControlModuleKit

332013Instructions-Parts

Manual,forAdvanced

DisplayControlModule

(ADCM)

3A0539Instructions-Parts

Manual,4–BallLowers

3A2096D 3

Warnings

Warnings Warnings

Warnings

Thefollowingwarningsareforthesetup,use,grounding,maintenance,andrepairofthisequipment.The

exclamationpointsymbolalertsyoutoageneralwarningandthehazardsymbolsrefertoprocedure-specic

risks.Whenthesesymbolsappearinthebodyofthismanualoronwarninglabels,referbacktothese

Warnings.Product-specichazardsymbolsandwarningsnotcoveredinthissectionmayappearthroughout

thebodyofthismanualwhereapplicable.

WARNING WARNING

WARNING

FIRE FIRE

FIRE

AND AND

AND

EXPLOSION EXPLOSION

EXPLOSION

HAZARD HAZARD

HAZARD

Flammablefumes,suchassolventandpaintfumes,inwork work

work

area area

area

canigniteorexplode.Tohelp

preventreandexplosion:

•Useequipmentonlyinwellventilatedarea.

•Eliminateallignitionsources;suchaspilotlights,cigarettes,portableelectriclamps,and

plasticdropcloths(potentialstaticarc).

•Keepworkareafreeofdebris,includingsolvent,ragsandgasoline.

•Donotplugorunplugpowercords,orturnpowerorlightswitchesonoroffwhenammable

fumesarepresent.

•Groundallequipmentintheworkarea.SeeGrounding Grounding

Grounding

instructions.

•Useonlygroundedhoses.

•Holdgunrmlytosideofgroundedpailwhentriggeringintopail.Donotusepaillinersunless

theyareantistaticorconductive.

•Stop Stop

Stop

operation operation

operation

immediately immediately

immediately

ifstaticsparkingoccursoryoufeelashock,Donotuse

equipmentuntilyouidentifyandcorrecttheproblem.

•Keepaworkingreextinguisherintheworkarea.

Staticchargemaybuilduponplasticpartsduringcleaningandcoulddischargeandignite

ammablevapors.Tohelppreventreandexplosion:

•Cleanplasticpartsonlyinwellventilatedarea.

•Donotcleanwithadrycloth.

•Donotoperateelectrostaticgunsinequipmentworkarea.

ELECTRIC ELECTRIC

ELECTRIC

SHOCK SHOCK

SHOCK

HAZARD HAZARD

HAZARD

Thisequipmentmustbegrounded.Impropergrounding,setup,orusageofthesystemcan

causeelectricshock.

•Turnoffanddisconnectpoweratmainswitchbeforedisconnectinganycablesandbefore

servicingorinstallingequipment.

•Connectonlytogroundedpowersource.

•Allelectricalwiringmustbedonebyaqualiedelectricianandcomplywithalllocalcodes

andregulations.

BURN BURN

BURN

HAZARD HAZARD

HAZARD

Equipmentsurfacesanduidthat’sheatedcanbecomeveryhotduringoperation.Toavoid

severeburns:

•Donottouchhotuidorequipment.

4

3A2096D

Warnings

WARNING WARNING

WARNING

MOVING MOVING

MOVING

PARTS PARTS

PARTS

HAZARD HAZARD

HAZARD

Movingpartscanpinch,cutoramputatengersandotherbodyparts.

•Keepclearofmovingparts.

•Donotoperateequipmentwithprotectiveguardsorcoversremoved.

•Pressurizedequipmentcanstartwithoutwarning.Beforechecking,moving,orservicing

equipment,followthePressure Pressure

Pressure

Relief Relief

Relief

Procedure Procedure

Procedure

anddisconnectallpowersources.

PRESSURIZED PRESSURIZED

PRESSURIZED

EQUIPMENT EQUIPMENT

EQUIPMENT

HAZARD HAZARD

HAZARD

Fluidfromtheequipment,leaks,orrupturedcomponentscansplashintheeyesoronskin

andcauseseriousinjury.

•FollowthePressure Pressure

Pressure

Relief Relief

Relief

Procedure Procedure

Procedure

whenyoustopspraying/dispensingandbefore

cleaning,checking,orservicingequipment.

•Tightenalluidconnectionsbeforeoperatingtheequipment.

•Checkhoses,tubes,andcouplingsdaily.Replacewornordamagedpartsimmediately.

TOXIC TOXIC

TOXIC

FLUID FLUID

FLUID

OR OR

OR

FUMES FUMES

FUMES

Toxicuidsorfumescancauseseriousinjuryordeathifsplashedintheeyesoronskin,

inhaled,orswallowed.

•ReadMSDSstoknowthespecichazardsoftheuidsyouareusing.

•Storehazardousuidinapprovedcontainers,anddisposeofitaccordingtoapplicable

guidelines.

PERSONAL PERSONAL

PERSONAL

PROTECTIVE PROTECTIVE

PROTECTIVE

EQUIPMENT EQUIPMENT

EQUIPMENT

Wearappropriateprotectiveequipmentwhenintheworkareatohelppreventseriousinjury,

includingeyeinjury,hearingloss,inhalationoftoxicfumes,andburns.Thisequipmentincludes

butisnotlimitedto:

•Protectiveeyewear,andhearingprotection.

•Respirators,protectiveclothing,andglovesasrecommendedbytheuidandsolvent

manufacturer.

3A2096D 5

Warnings

WARNING WARNING

WARNING

EQUIPMENT EQUIPMENT

EQUIPMENT

MISUSE MISUSE

MISUSE

HAZARD HAZARD

HAZARD

Misusecancausedeathorseriousinjury.

•Donotoperatetheunitwhenfatiguedorundertheinuenceofdrugsoralcohol.

•Donotexceedthemaximumworkingpressureortemperatureratingofthelowestrated

systemcomponent.SeeTechnical Technical

Technical

Data Data

Data

inallequipmentmanuals.

•Useuidsandsolventsthatarecompatiblewithequipmentwettedparts.SeeTechnical Technical

Technical

Data Data

Data

inallequipmentmanuals.Readuidandsolventmanufacturer’swarnings.Forcomplete

informationaboutyourmaterial,requestMSDSfromdistributororretailer.

•Donotleavetheworkareawhileequipmentisenergizedorunderpressure.

•TurnoffallequipmentandfollowthePressure Pressure

Pressure

Relief Relief

Relief

Procedure Procedure

Procedure

whenequipmentisnotinuse.

•Checkequipmentdaily.Repairorreplacewornordamagedpartsimmediatelywithgenuine

manufacturer’sreplacementpartsonly.

•Donotalterormodifyequipment.Alterationsormodicationsmayvoidagencyapprovals

andcreatesafetyhazards.

•Makesureallequipmentisratedandapprovedfortheenvironmentinwhichyouareusingit.

•Useequipmentonlyforitsintendedpurpose.Callyourdistributorforinformation.

•Routehosesandcablesawayfromtrafcareas,sharpedges,movingparts,andhotsurfaces.

•Donotkinkoroverbendhosesorusehosestopullequipment.

•Keepchildrenandanimalsawayfromworkarea.

•Complywithallapplicablesafetyregulations.

6 3A2096D

Installation

Installation Installation

Installation

Installationofthisequipmentinvolvespotentially

hazardousprocedures.Onlytrainedandqualied

personnelwhohavereadandwhounderstand

theinformationinthismanualshouldinstallthis

equipment.

Location Location

Location

Whenselectingthelocationfortheequipment,keep

thefollowinginmind:

•Theremustbesufcientspaceonallsidesof

theequipmentforinstallation,operatoraccess,

maintenance,andaircirculation.

•Ensurethatthemountingsurfaceandmounting

hardwarearestrongenoughtosupporttheweight

oftheequipment,uid,hoses,andstresscaused

duringoperation.

•Theremustbeastart/stopcontrol(C)withineasy

reachoftheequipment.SeeFig.1.

Mount Mount

Mount

the the

the

Pump Pump

Pump

SeeMountingHolePatterns,page23.

SecurethestandtotheoorwithM19(5/8in.)

boltswhichengageatleast152mm(6in.)intothe

concreteoortopreventthepumpfromtipping.

Levelthepumpasrequired,usingshims.

Power Power

Power

Supply Supply

Supply

Requirements Requirements

Requirements

Improperwiringmaycauseelectricshockorother

seriousinjuryifworkisnotperformedproperly.

Haveaqualiedelectricianperformanyelectrical

work.Besureyourinstallationcomplieswithall

National,StateandLocalsafetyandrecodes.

SeeTable1forpowersupplyrequirements.The

systemrequiresadedicatedcircuitprotectedwitha

circuitbreaker.

Table Table

Table

1 1

1

. .

.

Power Power

Power

Supply Supply

Supply

Specications Specications

Specications

Model Model

Model

Voltage Voltage

Voltage

Phase Phase

Phase

Hz Hz

Hz

Current Current

Current

EM0011

EM0012

100–250

Vac

150/6020A

EM0021

EM0022

200–250

Vac

150/6020A

Hazardous Hazardous

Hazardous

Area Area

Area

Cabling Cabling

Cabling

and and

and

Conduit Conduit

Conduit

Requirements Requirements

Requirements

Explosion Explosion

Explosion

Proof Proof

Proof

Allelectricalwiringinthehazardousareamustbe

encasedinClassI,DivisionI,GroupDapproved

explosion-proofconduit.FollowallNational,State,

andLocalelectriccodes.

Aconduitseal(D)isrequiredwithin18in.(457mm)

ofthemotorfortheUSandCanada.SeeFig.3.

Allcablesmustberatedat70°C(158°F).

Flame Flame

Flame

Proof Proof

Proof

(ATEX) (ATEX)

(ATEX)

Useappropriateconduit,connectors,andcable

glandsratedforATEXII2G.FollowallNational,

State,andLocalelectriccodes.

Allcableglandsandcablesmustberatedat70°C

(158°F).

8 3A2096D

Installation

NON NON

NON

- -

-

HAZARDOUS HAZARDOUS

HAZARDOUS

AREA AREA

AREA

HAZARDOUS HAZARDOUS

HAZARDOUS

AREA AREA

AREA

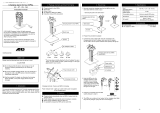

Figure1TypicalInstallation

Key Key

Key

for for

for

Fig. Fig.

Fig.

1 1

1

A

ElectricalSupply(mustbesealedconduit

approvedforuseinhazardouslocations)

B

FusedSafetySwitch,withlock

CStart/StopControl(mustbeapprovedfor

useinhazardouslocations)

D

ExplosionProofConduitSeal.Required

within18in.(457mm)ofthemotorforthe

USandCanada.

Key Key

Key

for for

for

Fig. Fig.

Fig.

1 1

1

E

FluidPressureGauge

F

FluidShutoffValve

GPumpGroundWire.Twogroundterminals

areprovidediflocalcoderequiresredundant

groundingconnections.

HFluidDrainValve

3A2096D 9

Installation

Connect Connect

Connect

the the

the

Power Power

Power

Supply Supply

Supply

Improperwiringmaycauseelectricshockorother

seriousinjuryifworkisnotperformedproperly.

Haveaqualiedelectricianperformanyelectrical

work.Besureyourinstallationcomplieswithall

National,StateandLocalsafetyandrecodes.

1.Ensurethatthefusedsafetyswitch(B,Fig2)is

shutoffandlockedout.

Figure2LockedOutFusedSafetySwitch

2.SeeFig.3.Installastart/stopcontrol(C)inthe

electricalsupplyline(A),withineasyreachof

theequipment.Thestart/stopcontrolmustbe

approvedforuseinhazardouslocations.

3.Opentheelectricalcompartment(S)onthe

motor.

4.Bringthepowerwiresintotheelectrical

compartmentthroughthe3/4–14npt(f)inletport.

Connectthewirestotheterminals,asshown.

Torquetheterminalnutsto25in-lb(2.8N•m)

maximum.Do Do

Do

not not

not

over-torque. over-torque.

over-torque.

5.Closetheelectricalcompartment.Torquethe

coverscrewsto15ft-lb(20.3N•m).

Figure3ConnectthePowerWires

Notes Notes

Notes

for for

for

Fig. Fig.

Fig.

3 3

3

Tightenallterminalnutsto25in-lb(2.8N•m)

maximum.Do Do

Do

not not

not

over over

over

- -

-

torque. torque.

torque.

Tightencoverscrewsto15ft-lb(20.3N•m).

Aconduitseal(D)isrequiredwithin18

in.(457mm)ofthemotorfortheUSand

Canada.

10 3A2096D

Installation

Grounding Grounding

Grounding

Thisequipmentmustbegroundedtoreducethe

riskofstaticsparkingandelectricshock.Electric

orstaticsparkingcancausefumestoigniteor

explode.Impropergroundingcancauseelectric

shock.Groundingprovidesanescapewireforthe

electriccurrent.

1.Pump: Pump:

Pump:

SeeFig.4.Loosenthegroundscrewand

attachagroundwire.Tightenthegroundscrew

securely.Connecttheotherendoftheground

wiretoatrueearthground.

NOTE: NOTE:

NOTE:

Advancedmodelsrequireinstallation

ofthe24P822ControlModule.Allpumps

connectedtoacommoncontrolmodulemustbe

groundedtothesamegroundpoint.Different

groundpoints(unequalpotential)maycause

currenttoowthroughcomponentcables,

causingincorrectsignals.

Figure4GroundWire

2.Fluid Fluid

Fluid

hoses: hoses:

hoses:

Useonlyelectricallyconductive

hoseswithamaximumof500ft.(150m)

combinedhoselengthtoensuregrounding

continuity.Checktheelectricalresistanceof

hoses.Iftotalresistancetogroundexceeds25

megohms,replacehoseimmediately

3.Fluid Fluid

Fluid

supply supply

supply

container: container:

container:

Followyourlocalcode.

3A2096D

11

Installation

Fluid Fluid

Fluid

Line Line

Line

Accessories Accessories

Accessories

Installthefollowingaccessoriesintheordershown

inFig.1,usingadaptersasnecessary.Alluid

linesandaccessoriesmustberatedtothemaximum

workingpressureof400psi(2.8MPa,28.0bar).

•Fluid Fluid

Fluid

drain drain

drain

valve valve

valve

(D): (D):

(D):

requiredinyoursystem,to

relieveuidpressureinthehoseandcirculation

system.

•Fluid Fluid

Fluid

pressure pressure

pressure

gauge gauge

gauge

(E): (E):

(E):

formoreprecise

adjustmentoftheuidpressure.

•Fluid Fluid

Fluid

shutoff shutoff

shutoff

valve valve

valve

(F): (F):

(F):

shutsoffuidow.

Fill Fill

Fill

With With

With

Oil Oil

Oil

Before Before

Before

Using Using

Using

Equipment Equipment

Equipment

SeeFig.5.Beforeusingtheequipment,openthell

cap(P)andaddGracoPartNo.16W645ISO220

silicone-freesyntheticgearoil.Checktheoillevelin

thesightglass(K).Filluntiltheoillevelisnearthe

halfwaypointofthesightglass.Theoilcapacityis

approximately1.5quarts(1.4liters).Do Do

Do

not not

not

overll. overll.

overll.

NOTE: NOTE:

NOTE:

Two1quart(0.95liter)bottlesofoilare

suppliedwiththeequipment.

Figure5SightglassandOilFillCap

Flush Flush

Flush

Before Before

Before

Using Using

Using

Equipment Equipment

Equipment

Thepumpuidsectionwastestedwithlightweight

oil,whichisleftintheuidpassagestoprotectparts.

Toavoidcontaminatingyouruidwithoil,ushthe

equipmentwithacompatiblesolventbeforeusing

theequipment.

Control Control

Control

Module Module

Module

Accessory Accessory

Accessory

TheControlModuleAccessoryisrequiredwith

AdvancedE-FloDCmotorstoprovidetheinterface

foruserstoenterselectionsandviewinformation

relatedtosetupandoperation.SeetheControl

ModuleAccessoryKitmanualforinstallationand

operationinformation.

12

3A2096D

Operation

Operation Operation

Operation

Startup Startup

Startup

Tooperatethepump,followtheStartupinstructions

fortheBasicorAdvancedmotorintheMotormanual.

TheAdvancedE-FloDCmotorsrequireinstallationof

the24P822ControlModuleAccessoryKittoprovide

theinterfaceforuserstoenterselectionsandview

informationrelatedtosetupandoperation.Seethe

ControlModuleAccessoryKitmanualforinstallation

andoperationinformation.

Runthepumpataslowspeeduntiltheuidlinesare

primedandallairisforcedoutofthesystem.

Shutdown Shutdown

Shutdown

FollowthePressureReliefProcedure,page13.

Pressure Pressure

Pressure

Relief Relief

Relief

Procedure Procedure

Procedure

Thisequipmentstayspressurizeduntilpressureis

manuallyrelieved.Tohelppreventseriousinjury

fromsplashinguidandmovingparts,followthe

PressureReliefProcedurewhenyoustopspraying

andbeforecleaning,checking,orservicingthe

equipment.

1.Disengagethestart/stopcontrol(C).SeeFig.1.

2.Shutoffandlockoutthefusedsafetyswitch(B).

3.Opentheuiddrainvalve(D),havingawaste

containerreadytocatchdrainage.Leaveopen

untilyouarereadytopressurizesystemagain.

3A2096D 13

Maintenance

Maintenance Maintenance

Maintenance

Preventive Preventive

Preventive

Maintenance Maintenance

Maintenance

Schedule Schedule

Schedule

Theoperatingconditionsofyourparticularsystem

determinehowoftenmaintenanceisrequired.

Establishapreventivemaintenancescheduleby

recordingwhenandwhatkindofmaintenanceis

needed,andthendeterminearegularschedulefor

checkingyoursystem.

Change Change

Change

the the

the

Oil Oil

Oil

NOTE: NOTE:

NOTE:

Changetheoilafterabreak-inperiodof

200,000–300,000cycles.Afterthebreak-inperiod,

changetheoilonceayear.

1.SeeFig.6.Placeaminimum2quart(1.9liter)

containerundertheoildrainport.Removethe

oildrainplug(25).Allowalloiltodrainfromthe

motor.

2.Reinstalltheoildrainplug(25).Torqueto25–30

ft-lb(34–40N•m).

3.SeeFig.7.Openthellcap(P)andaddGraco

PartNo.16W645ISO220silicone-freesynthetic

gearoil.Checktheoillevelinthesightglass(K).

Filluntiltheoillevelisnearthehalfwaypointof

thesightglass.Theoilcapacityisapproximately

1.5quarts(1.4liters).Do Do

Do

not not

not

overll. overll.

overll.

4.Reinstallthellcap.

Figure6OilDrainPlug

Check Check

Check

Oil Oil

Oil

Level Level

Level

SeeFig.7.Checktheoillevelinthesightglass(K).

Theoillevelshouldbenearthehalfwaypointofthe

sightglasswhentheunitisnotrunning.Iflow,open

thellcap(P)andaddGracoPartNo.16W645ISO

220silicone-freesyntheticgearoilasrequired.The

oilcapacityisapproximately1.5quarts(1.4liters).

Do Do

Do

not not

not

overll. overll.

overll.

Figure7SightglassandOilFillCap

Bearing Bearing

Bearing

Pre Pre

Pre

- -

-

Load Load

Load

SeeFig.7.Thebearingpre-loads(R)arefactory

setandarenotuseradjustable.Donotadjustthe

bearingpre-loads.

Flushing Flushing

Flushing

•Flushbeforechanginguids,beforeuidcandry

intheequipment,attheendoftheday,before

storing,andbeforerepairingequipment.

•Flushatthelowestpressurepossible.Check

connectorsforleaksandtightenasnecessary.

•Flushwithauidthatiscompatiblewiththeuid

beingdispensedandtheequipmentwettedparts.

14

3A2096D

Troubleshooting

Troubleshooting Troubleshooting

Troubleshooting

NOTE: NOTE:

NOTE:

Checkallpossibleremediesbeforedisassemblingthepump.

NOTE: NOTE:

NOTE:

TheLEDonthemotorwillblinkifanerrorisdetected.SeeError Error

Error

Code Code

Code

Troubleshooting Troubleshooting

Troubleshooting

inthemotor

manualforfurtherinformation.

Problem Problem

Problem

Cause Cause

Cause

Solution Solution

Solution

Inadequatepowersupply.

SeePowerSupplyRequirements,

page8.

Exhausteduidsupply.Rellandreprimepump.

Cloggeduidoutletline,valves,

etc.

Clear.

Pumpoutputlowonbothstrokes.

Wornpistonpacking.

Replace.Seelowermanual.

Heldopenorwornballcheck

valves.

Checkandrepair.Seelower

manual.

Pumpoutputlowononlyone

stroke.

Wornpistonpacking.

Replace.Seelowermanual.

Nooutput.Improperlyinstalledballcheck

valves.

Checkandrepair.Seelower

manual.

Exhausteduidsupply.Rellandreprimepump.

Heldopenorwornballcheck

valves.

Checkandrepair.Seelower

manual.

Pumpoperateserratically.

Wornpistonpacking.

Replace.Seelowermanual.

Inadequatepowersupply.

SeePowerSupplyRequirements,

page8.

Exhausteduidsupply.Rellandreprimepump.

Cloggeduidoutletline,valves,

etc.

Clear.

Pumpwillnotoperate.

Fluiddriedonpistonrod.Disassembleandcleanpump.

Seelowermanual.Infuture,stop

pumpatbottomofstroke.

3A2096D 15

Repair

Repair Repair

Repair

Disassembly Disassembly

Disassembly

1.Stopthepumpatthebottomofitsstroke.

2.Relievethepressure.Seethe

PressureReliefProcedure,page13.

3.Disconnectthehosesfromthelowerandplug

theendstopreventuidcontamination.

4.Removethe2-pieceshield(12)byinsertinga

screwdriverstraightintotheslot,andusingitas

alevertoreleasethetab.Repeatforalltabs.Do Do

Do

not not

not

usethescrewdrivertoprytheshieldsapart.

5.Loosenthecouplingnut(11)andremovethe

collars(10).Removethecouplingnutfromthe

pistonrod(R).Unscrewthelocknuts(8)fromthe

tierods(6).Separatethemotor(3)andlower

(7).SeeFig.7.

6.Torepairthelower,seethelowermanual.

7.Therearenouser-serviceablepartsinthe

motor.ContactyourGracorepresentativefor

assistance.

Reassembly Reassembly

Reassembly

NOTE: NOTE:

NOTE:

Ifthecouplingadapter(9)andtierods

(6)havebeendisassembledfromthemotor,see

ReassembletheCouplingAdapterandTieRodsto

theMotor,page17.

1.SeeFig.8.Assemblethecouplingnut(11)to

thepistonrod(R).

2.Orientthelower(7)tothemotor(3).Positionthe

loweronthetierods(6).Lubricatethethreadsof

thetierods.Screwthetierodlocknuts(8)onto

thetierods.Tightenthelocknutsandtorqueto

50-60ft-lb(68-81N•m).

3.Insertthecollars(10)intothecouplingnut

(11).Tightenthecouplingnutontothecoupling

adapter(9)andtorqueto90–100ft-lb(122–135

N•m).

4.Installtheshields(12)byengagingthebottom

lipswiththegrooveinthewet-cupcap.Snapthe

twoshieldstogether.

5.Flushandtestthepumpbeforereinstalling

itinthesystem.Connecthosesandush

thepump.Whileitispressurized,checkfor

smoothoperationandleaks.Adjustorrepair

asnecessarybeforereinstallinginthesystem.

Reconnectthepumpgroundwirebefore

operating.

16 3A2096D

Repair

Reassemble Reassemble

Reassemble

the the

the

Coupling Coupling

Coupling

Adapter Adapter

Adapter

and and

and

Tie Tie

Tie

Rods Rods

Rods

to to

to

the the

the

Motor Motor

Motor

NOTE: NOTE:

NOTE:

Usethisprocedureonlyifthecoupling

adapter(9)andtierods(6)havebeendisassembled

fromthemotor,toensureproperalignmentofthe

motorshafttothepistonrod(R).

1.SeeFig.7.Screwthetierods(6)intothemotor

(3)andtorqueto50-60ft-lb(68-81N•m).

2.Screwthecouplingadapter(9)intothemotor

shaftandtorqueto90–100ft-lb(122–135N•m).

3.Reassemblethepumptothemotor,asexplained

inReassembly,page16.

Figure8PumpAssembly

Notes Notes

Notes

for for

for

Fig. Fig.

Fig.

8 8

8

Torqueto50–60ft-lb(68–81N•m).

Torqueto90–100ft-lb(122–135N•m).

3A2096D

17

Parts

Ref Ref

Ref

Part Part

Part

Description Description

Description

Qty Qty

Qty

1

SeePumpMatrix,page20

KIT,mountingbracket,pump;includesitems

4and5;seemanual311619

1

2

SeePumpMatrix,page20STAND,oor

1

3

SeePumpMatrix,page20MOTOR;BasicorAdvanced;seemotor

manual;includesitems3aand3b

1

3a▲16M130LABEL,warning1

3b16W645

OIL,gear,synthetic;ISO220silicone-free;

1quart(0.95liter);notshown

2

4

SeePumpMatrix,page20WASHER

4

5

SeePumpMatrix,page20BOLT

4

6

15G924ROD,tie

3

7

SeePumpMatrix,page20

PUMP,displacement;seelowermanual1

8108683NUT,lock,hex3

915H369ADAPTER1

10184128

COLLAR,coupling

2

11184059NUT,coupling1

1224F251

KIT,shield,coupler(includes2pieces)

1

▲ReplacementDangerandWarninglabels,tags,

andcardsareavailableatnocost.

3A2096D 19

Parts

Pump Pump

Pump

Matrix Matrix

Matrix

Pump Pump

Pump

Part Part

Part

No. No.

No.

Pump Pump

Pump

Series Series

Series

Mounting Mounting

Mounting

Bracket Bracket

Bracket

(Ref (Ref

(Ref

1) 1)

1)

Floor Floor

Floor

Stand Stand

Stand

(Ref (Ref

(Ref

2) 2)

2)

Motor Motor

Motor

(Ref (Ref

(Ref

3) 3)

3)

Washer Washer

Washer

(Ref (Ref

(Ref

4) 4)

4)

Bolt Bolt

Bolt

(Ref (Ref

(Ref

5) 5)

5)

Lower Lower

Lower

Pump Pump

Pump

(Ref (Ref

(Ref

7) 7)

7)

EC1110

AEM001124F413

EC1111

A255143256193EM001110013310010124F413

EC1112

A255143EM001110013310010124F413

EC1210

AEM001224F413

EC1211

A255143256193EM001210013310010124F413

EC1212

A255143EM001210013310010124F413

EC2110

AEM001124F424

EC2111

A255143256193EM001110013310010124F424

EC2112

A255143EM001110013310010124F424

EC2210

AEM001224F424

EC2211

A255143256193EM001210013310010124F424

EC2212

A255143EM001210013310010124F424

EC2310

AEM002124F424

EC2311

A255143256193EM002110013310010124F424

EC2312

A255143EM002110013310010124F424

EC2410

AEM002224F424

EC2411

A255143256193EM002210013310010124F424

EC2412

A255143EM002210013310010124F424

EC2320

AEM002124F426

EC2321

A255143256193EM002110013310010124F426

EC2322

A255143EM002110013310010124F426

EC2420

AEM002224F426

EC2421

A255143256193EM002210013310010124F426

EC2422

A255143EM002210013310010124F426

EC2330

AEM002124F427

EC2331

A255143256193EM002110013310010124F427

EC2332

A255143EM002110013310010124F427

EC2430

AEM002224F427

EC2431

A255143256193EM002210013310010124F427

EC2432

A255143EM002210013310010124F427

EC3310

AEM002124F432

EC3311

A255143256193EM002110013310010124F432

EC3312

A255143EM002110013310010124F432

20 3A2096D

/