Page is loading ...

NSF International requires the following water connection:

1. A quick disconnect or additional coiled tubing (at least 2x the depth of the unit) so that the machine

can be moved for cleaning underneath.

2. Thisequipmentistobeinstalledwithadequatebackowprotectiontocomplywithapplicable

federal, state and local codes..

3. Waterpipeconnectionsandxturesdirectlyconnectedtoapotablewatersupplyshallbesized,

installed and maintained in accordance with federal, state, and local codes.

1

ISO 9001 REGISTERED

Important Safeguards/Conventions

Service Manual, TCC

This appliance is designed for commercial use. Any servicing other than cleaning and maintenance

should be performed by an authorized Wilbur Curtis service center.

•DoNOTimmersetheunitinwateroranyotherliquid

•Nevercleanwithscouringpowders,bleachorharshimplements.

Conventions:

WARNINGS–Tohelpavoidpersonalinjury ImportantNotes/Cautions

SanitationRequirements

Curtis TCC Units are Factory Pre-Set and Ready to Go… Right out of the Carton.

Generallytherewillneverbeareasontochangefactorysettings.However,shouldyouneedto

makeslightadjustmentstomeetyourteaneeds,adjustmentinstructionsareprovidedlaterinthis

manual.

System Requirements:

•WaterSource30–90PSI(MinimumFlowRateof1GPM).Ifincomingwatersupplyisgreater

than90PSI,additionalregulationisrequiredtomeettherange.

•Waterpipeconnectionsandxturesdirectlyconnectedtoapotablewatersupplyshallbe

sized,installedandmaintainedinaccordancewithfederal,state,andlocalcodes.

SETUP STEPS

Theunitshouldbelevel(lefttorightandfronttoback),locatedonasolidcountertop.Connecta

waterlinefromthewaterltertotheTCCserver.NOTE:Sometypeofwaterltrationdevicemust

beusedtomaintainatrouble-freeoperation.(Inareaswithextremelyhardwater,wesuggestthat

asedimentaryandtaste&odorlterbeinstalled.)Thiswillprolongthelifeofyoursystemand

enhanceteaquality.

INSTALLATION

1. Remove dispenser from carton.

2.Runawaterlinetotheinletttingbehindthedispenser.Flushthenewwater-

line to remove foreign particles.

3.Connecta¼”aredexibleorcopperwaterlinetothemalettingontheback

of the dispenser.

4.Locatethewatersupplyvalvebehindtheunittoverifypositionisturnedon.

CAUTION:Werecommendedthatthewatersupplyvalve,behindunit,beturnedoffduring

non-business hours.

Wi l b u r Cu r t i s Co m p a n y , in C .

WILBUR CURTIS COMPANY

Montebello, CA 90640

ModelsIncluded

•TCC1

•TCC2

•TCC3

NOTE: Water source

pressure must be a

minimum of 30 PSI

pressure at all times

toinsurethequalityof

the of the product.

5. Clean out the tea concentrate system before using the TCC server. Use a Bag-in-

Boxstylecleaningsolutiontosimplifythecleaningprocedure.AcleanerlikeBev-

Cleanbeveragelinecleanercomesina3gallonbag-in-boxthatconnectsdirectlyto

yourbag-in-boxsystemforlinecleaning(http://bevclean.com).

a.Removethequickdisconnectfromtheteaconcentratebag.

b.PlacetheBIBcleanercontainernexttotheTCCteadispenser.Pullthespout

fromthecleanerboxthroughthemarkedarea.Removethecleartravelcapfrom

spout.Don’tworryaboutcleanerspillingwhenthecapisremoved.Thecaphas

an internal seal.

c. SnaptheQCDbagconnectorontothebagspout.

OFF

ON

2

7. Carefully lift the bag and set the bag into the dispenser.

8. Rest tubing on top of the bag. Route tubing to opposite product intake

–holeonoorofdispenser(seeillustration,left).

9. Replacethetopcover.

10. Dispensebeveragefromfaucetuntildarkerproductstartstoappear

(~5seconds).

11. TheTCCserverisnowreadytodispensetea.

3. Pullofftheshipping

cap that covers the

spout on the bag.

4. PlacetheQCDnextto

the spout.

5. SlideQCDsideways,

over the bag spout.

QCDsnapsinplace.

6. PushQCDplungerinto

bag spout until plunger

topisushwithtopof

QCD.A“click”willbe

heardwhenitisfully

inserted.

LOAD PRODUCT

Bag-In-Box

1.PlaceateaconcentratebagonthecounternexttotheTCCdispenser.

2. RemovethetopcoverfromtheTCCdispenserandpulloutthehosewiththeQCD

bag connector.

d. Graspingthebagconnector(asshowninLoadProduct,step6),pushtheslidingprobeallthewayintothe

bagspout.A“click”willbeheardwhenitisfullyinserted.

e. Oncethecleaningsolutionboxisconnected,openthedispensingvalveonthedispenserandrunliquid

throughthevalveuntilthesanitizer(clearliquid)isdetected.Thedispensinglineisnowclean.

f. Disengagethebagconnectorbysnappingtheconnectorprobeoutandremovetheconnectorfromthespout.

g. ReattachtheteaconcentrateBIB.

h. Opendispensingvalveondispenseruntilteaowsfreely.

WATER PRESSURE AND MIXING VALVE

Thetamper-proofsealantonthe’adjustmentknob-to-body’threadsofthepres-

sureregulatorisafactory-calibrated,pre-setpressure‘indexmark’.Itisremov-

ableifthebrixtestdemandsabsolutepreciseness.However,thepressureregu-

latorshouldrarelybechanged.Primarytaste/brixadjustmentsshouldbedone

viathemixingvalvebyturningtherodandtastingthenishedproduct.98%of

avoradjustmentsshouldbedoneinthismanner.

Thepurposeoftheregulatoristoprovideuniformwaterpressuresotheventuri-

stylemixingdevicecanproduceastableanduniformblendofconcentrateand

waterand,alsotoprotectthehydraulicsofthedispensingunitfrom“linepres-

sure”.Itisnottheprimaryadjustmentforthebrixlevel.Fromourtesting,ithasbeenshownthatexactPSIonthe

gagedoesnotdirectlycorrelatetoabrixlevelfromunittounitandfrominstallationlocationtoinstallationlocation.

Secondarily,iftheprimaryadjustmentdoesn’tprovidetheidealbrixlevel,callCurtisCareforinstructionsonhowto

adjusttheregulator.Asarule,verylittletasteadjustmentisachievedviathepressureregulator.

3

MIXING VALVE ADJUSTMENT:

Forcustomerswhowishtoadjusttheavorofthedrink,themixingvalvechangesthewaterto

concentrateratio.Thisvalveisverysensitive.Onlyslightrotationofthemixingrodisneeded

tochangetheratio(1/16thto1/8thofaturn).Thestandardsetup,astheunitcomesfromthe

factory,isapproximately7:1ratio,whichwillgiveyoua5to8percentbrixbasedonthesweet

tea concentrate.

1.Toadjustthevalve,tiltthedispenseronit’sside.

2.Lookunderneaththeunitandlocatetheadjustingrod.

3.Turncounter-clockwiseforstrongerdrink–turnclockwiseforweakerdrink.Tastethetea

witheachadjustmenttodeterminethedesiredconsistency.

CAUTION–Donotrotateadjustingrodmorethan2fullturnsfromclosedposition.Moreturnswillcausethe

adjustmentrodtodisengagefromthemixingvalve,witharesultingleak.

TEA TIPS

1. Neverholdnisheddispensedteaformorethaneighthoursatroomtemperature.

Discardanyunusedteaaftereighthours

2. Dispenseonlyenoughteathatyoureasonablyexpecttosellwithinafewhours.

3. Toprotectteaavorandtoavoidbacterialcontaminationandgrowth,cleanand

sanitizeteabrewing,storageanddispensingequipmentatleastonceaday.

WARNING DO NOT

refrigerate unused

tea overnight for later

consumption.

CLEANING

STRAINER CLEAN-OUT

1. Turnoffthewaterowrunningfromthefacilitytothestrainer.

2. Useplierstograbthehousingofthestrainerandwithanadjustablewrench,removethecap.

3. Takeoutthewirestrainerandcleanoutthecontents.Useaspiralbristledbrushtocleaninsidethestrainer.

4. Rinse the strainer and replace it into the housing.

5. Returnthecaptothehousingandturnonthewaterline.

DAILY CLEANING

RegularcleaningoftheTCCdispenserisessentialinmaintainingthehighestqualityicedteayourequipmentis

capable of producing.

1. Wipeanyspills,dustordebrisfromtheexteriorsurfaces,withadampcloth.Applyastainlesssteelpolishto

prevent scratches.

2.Turnoffwatersupplyatvalvebehindunit.

3.Openthedispensingfaucettorelievepressureinthedispensinglines.

4.Removethetopcoverandcleanwithdetergentsolution.

5. Clean the faucet assembly.

a. Unscrewthehandleassemblyfromthefaucetandremove.

b. Clean the faucet cap and silicone seat cup.

c. Use a spiral brush to clean inside the faucet body.

6.Rinseanddrypartsthatwereremoved.Assemblethemtotheunit.

4

WEEKLY CLEANING & SANITIZING

Use a concentrated cleaning solution to simplify the cleaning procedure. This procedure requires a one gallon container of a cleaning solution

containing hot water and a granulated concentrated cleaner (a cleaner like Coffee Dispenser Cleaner Corporation #12580, Urnex or equivalent)

and a one gallon container of clean hot water.

1. Turn on water supply to the dispenser.

2. Remove the quick disconnect from the tea

concentrate bag.

3. Pull the cap off of the QCD (see detail drawing)

and place this end of the line into the container

containing the cleaning solution.

4. Place a large empty container under the

dispenser faucet.

5. Open the front faucet and dispense at least

half of the cleaning solution.

6. Allow the dispenser to sit overnight before

ushing cleaning solution.

7. Flush the system by lling a one gallon

container with clean hot water (no cleaning

solution) and open the faucet and dispense at

least one gallon of the hot water or until all the cleaning solution has been ushed

from the system.

8. Remove the QCD from the ushing container and replace the cap. Reconnect the QCD to

the Bag in the Box tea concentrate and dispense several cups to prime the concentrate line or

until consistency of the product is correct.

SANITIZING

UseaBag-in-Boxstylecleaningsolutiontosimplifythesanitizingprocedure.AproductlikeBevClean(http://bevclean.

com)beveragelinesanitizercomesina3gallonbag-in-boxthatconnectsdirectlytoyourbag-in-boxsystemforline

sanitizing.

1.Removethequickdisconnectfromtheteaconcentratebag.

2. PlacetheBIBsanitizercontainernexttotheTCCteadispenser.Pullthespoutfromthesanitizerboxthroughthe

markedarea.Removethecleartravelcapfromspout.Don’tworryaboutspillingsanitizerwhenthecapisre-

moved. The cap has an internal seal.

3. SnaptheQCDbagconnectorontothebagspout.

4. Graspingthebagconnector(asshowninLoadProduct,step6),pushtheslidingprobeallthewayintothebag

spout.A“click”willbeheardwhenitisfullyinserted.

5. Oncethecleaningsolutionboxisconnected,openthedispensingvalveonthedispenserandrunliquidthrough

thevalveuntilthesanitizer(clearliquid)isdetected.

DONOTFLUSH.Allowthesanitizingsolutiontositinthetealinesovernightbeforeproceeding

withlineushingsteps6through8,below.

6. RemovetheQCDfromtheBIBcleaner.Unsnaptheconnectorprobe,pullingoutandremovingtheconnectorfrom

the spout.

7. Flushthelinewithwarmwatertoremoveanycleaningsolution.

7. ReattachtheteaconcentrateBIBproduct.

8. Openthedispensingfaucetinfrontofthedispenserandallowwatertorunoutuntilteaowsfromthefaucet.

9. Repeattheprocessforanyadditionalfaucetsondispenser.

Note:Muliti-outletmanifoldsareavailableforsanitizinguptoeightbeveragelineswithonebag-in-boxsanitizer.This

allowsyoutocleanallsystemsatonetime.

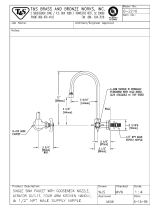

8.875”

(22.5 cm)

24”

(61.0 cm)

8.875”

(22.5 cm)

18.25”

(46.4 cm)

12.875”

(32.7 cm)

10”

(25.4 cm)

9.25”

(23.5 cm)

11.25”

(28.6 cm)

2.125”

(5.4 cm)

8.875”

(22.5 cm)

24”

(61.0 cm)

8.875”

(22.5 cm)

18.25”

(46.4 cm)

12.875”

(32.7 cm)

2.125”

[5.4 cm]

3.75”

(9.5 cm)

11.25”

(28.6 cm)

10”

(25.4 cm)

9.25”

(23.5 cm)

ROUGH-IN

DRAWINGS

TCC1

TCC2

TCC3

5

ILLUSTRATED PARTS LIST.

TCC1(single)isshownonpage6.Thetwin(TCC2)hastwofaucet/mixingvalvesystemsandtwoQDCconnectors.

Partsarecommonbetweenbothunitsexceptwherenotedbelow.TCC3IllustratedPartsListisshownonpage7.

1

2

3

4

5

6

7

8

9

10

WC-8653*

WC-14022

WC-53120*

WC-43002

WC-2615

WC-2508

WC-29078

WC-870P-101

WC-1045

WC-810-103*

QCD, LIQUID BOX BAG CONNECTOR

CLAMP,TUBING15.3-18.5mmSSOETIKER

TUBING,3/8”IDX9/16”ODCLEARPVC

CLAMP,HOSESNAPNYLON.525/.605

CONNECTOR, 1/4 FLARE X 1/4 NPT PLTD

ELBOW, 1/4 NPT PLATED TCC

NIPPLE,HEX1/4”X1/4MNPTPLATED

VALVE,BALL1/4FPTX1/4MTPPLT’D

STRAINER, ¼ FNPT 90º FLOW PATH PLTD

VALVE,CHECK1/4X1/4BARBPLATEDTCC

DESCRIPTIONPART NºITEM Nº

11

12

13

14

15

16

16A

17

18

19

WC-2435

WC-811-103*

WC-14021

WC-53113*

WC-2219

WC-5683

WC-5683-101

WC-894*

WC-1903

WC-1906

ELBOW,1/4”MNPTX1/4BARBNYLON

REGULATOR,PRESSURE1/4”NPT0-25PSI

CLAMP,TUBING14.2-706RTCC

TUBING,.25”IDX.50”ODBRAIDSILICONE

Y’FITTINGBARB¼x¼x¼ WHT NYLON

LIDASSY,TCOBLACKPLASTIC

LID ASSY, BLUE PLASTIC (OPTIONAL)

MIXINGVALVE

NUT,UNI0NSHANK

C’RING.917X.760X.090

DESCRIPTIONPART NºITEM Nº

PartsListContinuedonPage6...

3.5”

(8.8 cm)

7”

(17.5 cm)

24”

(61.0 cm)

13”

(33.0 cm)

10”

(25.4 cm)

9.25”

(23.5 cm)

2.125”

(5.4 cm)

13.25”

(33.7 cm)

8.875”

(22.5 cm)

11.25”

(28.6 cm)

14”

(35.6 cm)

6

ILLUSTRATED PARTS

TCC1 SHOWN, TCC2 COMPONENTS

ARE SIMILAR

1

4

3

8

9

12

16

17

18

19

20

21

22

25

23

24

15

29

10

13

11

26

27

28

29

30

WC-37288*

WC-37293

WC-53117-101

WC-29079

WC-8654

KIT,CHECKVALVE,CLAMPS&INSTR

KIT,CHECKVALVE(2VALVES&INSTR)

TUBE, BOTTLE ADAPTER (OPTIONAL

NIPPLE,HEX1/4”NPTX1/4NPTNYLON

CONNECTOR,SCHOLLEL’(ICEDCOF)

DESCRIPTIONPART NºITEM Nº

*RecommendedPartstoStock

20

21

22

23

24

25

WC-4320

WC-1829

WC-37222*

WC-43084*

WC-37312*

DTP-08

O’RING,.487IDX.103CS

FAUCET ASSY, TCC

KIT,FAUCETWIREREINFORCEDCUP

O-RING,.070”IDX.070”WBUNA-N

KIT,ADJUSTINGROD&O-RINGTCC

DRIPTRAY,8”

DESCRIPTIONPART NºITEM Nº

26

4

2

27

5

6

7

14

ICED COFFEE CON-

CENTRATE ONLY

30

7

ILLUSTRATED PARTS

TCC3

ALLPARTSAREIDENTICALTOTCC1&

TCC2,EXCEPTWHERENOTED

1

4

3

16

26

27

2

5

6

7

8

9

29

10

12

11

13

14

15

17

18

19

20

21

22

23

24

25

28

DOs and DON’Ts

INSTALLATION

1. Doconnectdispensertoalteredwater-

line.

2. Doushltersbeforeconnectingtodis-

penser.

3.Dosamplenisheddrinkbeforemaking

adjustments.

4. Domakeveryslightdrinkadjustments

then sample.

5. Don’tforgettoushltersbeforeinstalla-

tion.

6. Don’tmakeanypressureregulatoradjust-

mentsonurn(DoNOTattempttoadjust

theurnregulator.Ifaregulatoradjustment

isrequiredcallCURTISCARE).

7. Don’t forget to get sample approval from

customer.

OPERATION

1. Dofullyactivatefaucethandlewhendis-

pensing drinks.

2. Do clean & sanitize dispensing assembly

monthly.

3.Dokeepdispenserprimedwithconcen-

trate at all times.

4. Doreloadimmediatelywhenoutofcon-

centrate.

5. Doushandcleanlinesregularly.

6. Don’t forget to clean & sanitize faucet seat

cup

7. Dofollowallcleaningandsanitizingproce-

dures,removeandstoreconcentrateifurn

willnotbeusedforanextendedperiodof

time;ie:morethantwodays.

8

SYMPTOM POSSIBLECAUSE SOLUTION

TROUBLESHOOTING GUIDE

DifcultyprimingtheTCCtea

dispenser.

Adjustingrodonmixingvalve

is turned in too far.

Openupthevalve1/4turn

counterclockwise.

Tea does not dispense from

faucet.

Water line is turned off.

Turnonwaterlinevalve.

Onlywaterowingfromfau-

cet,notea.

1.TeaconcentrateBIBisout

of product.

2.TheteaBIBlineiskinked.

3.TheteaBIBlineis

clogged.

4. The check valve in the tea

concentrate line may be

stuck closed.

5.Theadjustmentscrew

may be turned in or

closed.

1. Replace the tea concen-

trateBIB.

2. Trace the tea line and

straighten out kinked hose.

3.Blowouthosetoclean

blockageorreplacewitha

newhose.

4. Loosen the clamps and

remove the check valve.

Clean or replace it.

5.Openthemixingvalveto

resumeproductow.

Faucetisdrippingconstantly. 1. The faucet seat cup may

have hardened particles

keeping the faucet from

sealing.

2. There may be a tear or cut

in the seat cup.

3.Waterpressuremaybe

too high.

1.Disassembleandclean

theseatcup(seecleaning

section).

2. Replace the seat cup.

3.CallCURTISCAREfor

instructionsonadjusting

thewaterregulator.

Finishedteaisweak.

1.Themixingvalveisoutof

adjustment.

2. The product check valve

may be stuck.

1.Openthemixingvalveto

increase tea concentrate

ow.

2. Remove and clean the

checkvalve.Makesure

check valve is installed

withcorrectowdirection.

9

SYMPTOM POSSIBLECAUSE SOLUTION

TROUBLESHOOTING GUIDE

Productowingfromthefau-

cet is too foamy or bubbly.

1. The clamps at the check

valve may not be tight.

2. TheclampontheQCD

connector may be loose.

3. Teaconcentrateproduct

mayhaveairintheBIB.

4.TheO-ringontheQCDis

wornout.

1. Reconnect tubing and

tighten clamps.

2.Makesurethebarbed

endoftheQCDttingis

pushed in on the hose and

the clamp is tight.

3.TurntheBIBsothetting

facesupwardandopen

the faucet until all the

bubbles are released.

4.ReplacethewornO-ring

orinstallanewQCD.

10

11

Printed in U.S.A. 2/09 F-3480 Rev K

WILBUR CURTIS CO., INC.

6913AccoSt.,Montebello,CA90640-5403USA

Phone:800/421-6150 Fax:323-837-2410

TechnicalServicePhone:800/995-0417(M-F5:30A-4:00PPST) E-Mail:[email protected]

WebSite:www.wilburcurtis.com

FOR THE LATEST SPECIFICATION INFORMATION GO TO WWW.WILBURCURTIS.COM

Product Warranty Information

TheWilburCurtisCompanycertiesthatitsproductsarefreefromdefectsinmaterialandworkmanshipundernormal

use.Thefollowinglimitedwarrantiesandconditionsapply:

2Years,Parts,fromOriginalDateofPurchaseonallttingsandtubing.

1Year,Labor,fromOriginalDateofPurchaseonallttingsandtubing.

StainlessSteelcomponentsarewarrantedfortwo(2)yearsfromdateofpurchaseagainstleakingorpittingandreplacementparts

arewarrantedforninety(90)daysfromdateofpurchaseorfortheremainderofthelimitedwarrantyperiodoftheequipmentinwhich

the component is installed.

Allin-warrantyservicecallsmusthavepriorauthorization.ForAuthorization,calltheTechnicalSupportDepartmentat1-800-995-

0417.EffectivedateofthispolicyisApril1,2003.

Additionalconditionsmayapply.Gotowww.wilburcurtis.comtoviewthefullproductwarrantyinformation.

CONDITIONS & EXCEPTIONS

Thewarrantycoversoriginalequipmentattimeofpurchaseonly.TheWilburCurtisCompany,Inc.,assumesnoresponsibilityfor

substitutereplacementpartsinstalledonCurtisequipmentthathavenotbeenpurchasedfromthe

WilburCurtisCompany,Inc.TheWilburCurtisCompanywillnotacceptanyresponsibilityifthefollowingconditionsarenotmet.The

warrantydoesnotcoverandisvoidunderthefollowingcircumstances:

1) Improper operation of equipment: Theequipmentmustbeusedforitsdesignedandintendedpurposeandfunction.

2) Improper installation of equipment: Thisequipmentmustbeinstalledbyaprofessionaltechnicianandmustcomplywith

alllocalelectrical,mechanicalandplumbingcodes.

3) Improper voltage: Equipmentmustbeinstalledatthevoltagestatedontheserialplatesuppliedwiththisequipment.

4) Improper water supply: Thisincludes,butisnotlimitedto,excessiveorlowwaterpressure,andinadequateoructuating

waterowrate.

5) Adjustments and cleaning: Theresettingofsafetythermostatsandcircuitbreakers,programmingandtemperatureadjust-

mentsaretheresponsibilityoftheequipmentowner.Theownerisresponsibleforpropercleaningandregularmaintenance

ofthisequipment.

6) Damaged in transit: Equipmentdamagedintransitistheresponsibilityofthefreightcompanyandaclaimshouldbemade

withthecarrier.

7) Abuse or neglect (including failure to periodically clean or remove lime accumulations): The manufacturer is not

responsibleforvariationinequipmentoperationduetoexcessivelimeorlocalwaterconditions.Theequipmentmust

bemaintainedaccordingtothemanufacturer’srecommendations.

8) Replacement of items subject to normal use and wear: Thisshallinclude,butisnotlimitedto,lightbulbs,sheardisks,

“0”rings,gaskets,siliconetube,canisterassemblies,whipperchambersandplates,mixingbowls,agitationassembliesand

whipperpropellers.

9) Repairs and/or Replacements aresubjecttoourdecisionthattheworkmanshiporpartswerefaultyandthedefects

showedupundernormaluse.Alllaborshallbeperformedduringregularworkinghours.Overtimechargesaretherespon

sibilityoftheowner.Chargesincurredbydelays,waitingtime,oroperatingrestrictionsthathindertheservicetechnician’s

abilitytoperformserviceistheresponsibilityoftheowneroftheequipment.Thisincludesinstitutionalandcorrectional

facilities.TheWilburCurtisCompanywillallowupto100miles,roundtrip,perin-warrantyservicecall.

RETURN MERCHANDISE AUTHORIZATION: AllclaimsunderthiswarrantymustbesubmittedtotheWilburCurtisCompany

TechnicalSupportDepartmentpriortoperforminganyrepairworkorreturnofthisequipmenttothefactory.Allreturnedequip-

mentmustberepackagedproperlyintheoriginalcarton.Nounitswillbeacceptediftheyaredamagedintransitduetoimproper

packaging. NO UNITS OR PARTS WILL BE ACCEPTED WITHOUT A RETURN MERCHANDISE AUTHORIZATION (RMA).

RMA NUMBER MUST BE MARKED ON THE CARTON OR SHIPPING LABEL. Allin-warrantyservicecallsmustbeperformed

byanauthorizedserviceagent.CalltheWilburCurtisTechnicalSupportDepartmenttondanagentnearyou.

12

EAR 7135 . 2/12/9 . revK . ecn 10262

/