PERGO Outlast+ Install Instructions

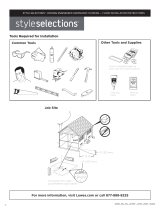

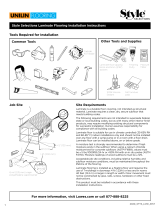

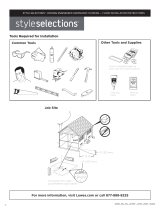

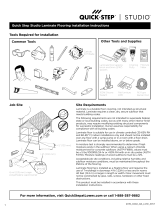

Tools Required for Installation

Common Tools

Wood

Glue

Carbide

40T Blade

Other Tools and Supplies

M

A

D

E

I

N

T

H

E

U

S

A

1

F

L

O

Z

(

3

3

.

5

m

l

)

PREMIUM

SYSTEM

COMPONENT

S

P

E

C

I

A

L

L

Y

D

E

V

E

L

O

P

E

D

F

O

R

L

A

M

I

N

A

T

E

F

L

O

O

R

I

N

G

Finishing

Putty

PREMIUM

SYSTEM

COMPONENT

Finishing

Putty

SILICONE

CAULK

SILICONE

CAULK

SILICONE

CAULK

100% Silicone

Sealant

Felt furniture

pads

Moisture

Meter

ON

Non Destructive Moisture

dlfwej dtra

djflsv

dlfwe vtra

alskdjf

vmwjc

Concrete

Encounter

Plus

0

1

2

3

4

5

6

0

50

100

150

200

250

Moisture

Meter

S

p

a

c

e

r

s

5

m

m

S

p

a

c

e

r

s

5

m

m

Laminate floor tapping

block and 5mm (

3

/16")

spacers

10' (3 m)

> 5" (130 mm)

6 mil (0.15 mm) virgin

polyethelene vapor barrier

ground

> 8" (200 mm)

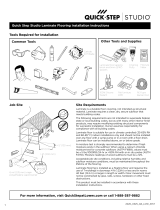

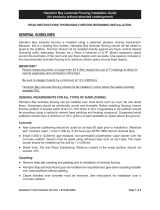

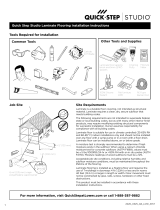

Job Site

Site Requirements

Laminate is a durable oor covering, not intended as structural material.

Laminate requires a clean, dry, secure suboor that meets building codes.

The following requirements are not intended to supersede federal, state or

local building codes, but as with many other interior nish products, may

require modifying existing structural components for successful installation.

Owner assumes responsibility for compliance with all building codes.

Laminate oor is suitable for use in climate controlled (35-65% RH and 60-

85° F) indoor installations only and should not be installed in rooms with oor

drains or sump pumps. Laminate oor can be installed above, on or below

grade.

A moisture test is strongly recommended to determine if high moisture exists

in the suboor. When using a calcium chloride moisture test for concrete

suboors (ASTM F1869), values must be ≤ 5 lbs/1000ft²/24-hr or <80% RH

with an in-situ probe (ASTM F2170). Moisture readings of wood suboors

must be ≤ 12%.

Acceptable job site conditions, including relative humidity and suboor

moisture conditions, must be maintained throughout the lifetime of the

ooring.

Laminate ooring is installed as a oating oor and requires the use of

T-moldings in doorways 4 ft (1.22m) or less and in rooms 40 feet (12.2 m) or

larger in length or width. Floor movement must not be constrained by glue,

nails, screws, hardware or other xed obstructions.

This product must be installed in accordance with these installation

instructions.

For more information, call 1-800-33-PERGO

PE Foam

Backer Rod

2019_03_OP_UNI

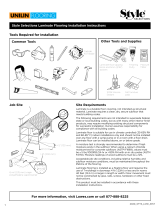

Site and Material Preparation

A.) Remove carpet and padding. Also remove any wood ooring installed on concrete. Do not remove products unless

they are asbestos-free.

B.) Undercut door frame and wallbase. Slide the ooring at least 1/4” underneath the door frame and wallbase. Also

leave a concealed 3/8” minimum expansion space under each.

C.) Remove bumps or peaks in suboor and ll depressions with oor leveling compound to ensure no more than 3/16”

unevenness per 10-foot span.

D.) Acclimate unopened product before installation. If there is no time for acclimation, there should be no more than

a difference of 25° F and 20% relative humidity between the stocking/transportation environment of the

ooring and the nal installation environment of the ooring.

E.) Clean debris from suboor before installation.

F.) For concrete suboors, install vapor barrier with overlapped seams of 8” or more.

G.) For planks without attached underlayment, install over single layer of underlayment appropriate for laminate

oors. For planks with attached underlayment, it is acceptable to install Pergo FloorMate™ underlayment prior to

ooring installation if desired. Make sure to follow the Pergo FloorMate™ installation instructions, taking special care

to seal all foam edges with sealing tape and repair all rips and perforations in the underlayment vapor barrier prior to

ooring installation. A separate vapor barrier should not be used in conjunction with Pergo FloorMate™.

PERGO Outlast+ Install Instructions

Site and Material Preparation

A

Door

Frame

Cutting Line

Wallbase

Casing

1 inch

(2,5 cm)

B

%

48 hours

60° – 85° F

15° – 29° C

35% – 65% RH

C

D

G

subfloor

6 mil (0.15 mm) virgin

polyethelene vapor barrier

> 8" (200 mm)

E F

2019_03_OP_UNI

14

15 16

WOOD

GLUE

17

10

11

13

12

7

8

9

1

2

3

4

4

PERGO Outlast+ Install Instructions

5

1 3 5 5

2

4

6

5

6

6

> 6 in

> 15 cm

6

2

3

1

Left

Right

2019_03_OP_UNI

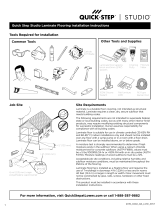

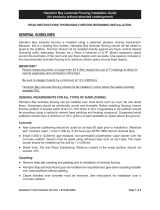

Flooring Installation

1. Inspect each plank. Floor should be installed blending planks from several cartons at the same time to ensure good

color and shade mixture throughout the installation.

2. For the rst row along straight walls, remove the tongue on all long side joints and on the short side of the 1st plank

only.

3. For uneven walls, trace contour on tongue-side of plank and cut.

4. Assemble the rst row tongue side toward wall. Insert the end tongue into the end groove and rotate downward to

assemble. Keep the planks aligned and the joints closed.

5. Two spacers thick side to thick side = 3/8”.

6. Provide a 3/8” space for expansion on all sides. First piece must be at least 8” long. Start new rows with pieces

trimmed from previous row. Ensure at least a 6” end joint offset.

7. At a slight angle, insert the tongue of plank 2 into the groove of plank 1 until the laminate edges meet, and then rotate

down until the joints lock.

8. Join the short end of the plank rst. There will be a gap on the long side joints when the plank is rotated down.

9. Raise the outside edge of the plank upward approximately 1”. Maintain this angle as you push the plank in until

the laminate edges meet. Rotate downward on the plank until the joint locks. Repeat these steps to complete the

installation. Installation Tip: Place a carton of planks across the end of the row being installed to keep installed

planks in place during installation.

10. Alternate Tap Method: Align the tongues into the grooves of the long and short sides of the planks. Install the long

side rst by placing a tapping block no closer than 8” from either end and tap lightly along the long side until the joint

is closed tightly. Then tap the end using the tapping block into a locked position. Note: Uneven tapping or use of

excessive force may damage the joint.

11. Ensure there will be a 3/8” gap (after the joint is closed) to the wall for expansion.

12. For the last row, align the plank to be used on top of the 2nd to last row. Using a full width plank as a spacer, trace wall

contour and cut plank.

13. For the last row, install the long side tongue into the groove with the end joint aligned. Using a pull bar and hammer,

work evenly along the length of the plank and lightly tap the joint closed.

14. After tapping the long side joint closed, tap the short side closed, using a tapping block or a pull bar.

Installation Under Doorway Frames

15. Slide plank under pre-cut door frame.

16. Tap the long side joint closed rst. Then tap the end joint closed.

Installation Around Fixed Objects (such as Pipes)

17. Allow 3/8” expansion space around pipes or other xed objects.

Finishing the Installation

18. Remove all spacers.

19. Create a watertight seal by applying exible 100% silicone sealant to the entire perimeter of the installation. DO NOT

use acrylic sealant.

• First ll all expansion spaces with 3/8” compressible PE foam backer rod and cover with silicone sealant.

• Prior to installing the moldings, apply silicone sealant to the portion of the molding or transition that will contact

directly with the laminate ooring surface.

• Install moldings and immediately wipe away any excess silicone sealant.

• Apply silicone sealant at connections to doorframes or any other xed objects.

PERGO Outlast+ Install Instructions

18

PE foam backer rod

Molding

Silicone sealant

19

Silicone sealant

PE foam backer rod

Molding

Silicone sealant

2019_03_OP_UNI

Care and Cleaning

Place felt oor protectors under legs of moveable furniture. Chair casters should be rubber – not plastic or metal. Place walk-

off mats at entrances. Dust mop as primary cleaning method. Occasionally wet mop with water only, using a well wrung out

mop; DO NOT pour liquid directly on oor or use an excessively wet mop that will puddle or leave moisture standing on the

oor. If needed, use a solution of 1 cup of vinegar per gallon of water OR 1/3 cup non-sudsing ammonia per gallon of water.

DO NOT use detergents, abrasive cleaners, soaps, waxes or polishes. Use correct hard surface vacuum tools. DO NOT

use rotating beater bars, oor scrubbers, steamers, jet mops or similar products. Wipe up spills immediately. DO NOT allow

topical moisture to remain on the oor longer than the time specied in the product warranty.

A

B

C

PERGO Outlast+ Install Instructions

2019_03_OP_UNI

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

Ask a question and I''ll find the answer in the document

Finding information in a document is now easier with AI

Related papers

-

Pergo LF000336 Installation guide

-

Pergo LF000336 Operating instructions

-

Pergo LF000312 Operating instructions

-

Pergo LF000497 Installation guide

-

Pergo LF000772 Operating instructions

-

Pergo LF000772 Operating instructions

-

Pergo LF000878 Installation guide

-

Pergo 04704 Operating instructions

-

Pergo Outlast Plus Operating instructions

-

Pergo LF000890P Operating instructions

Other documents

-

TrafficMASTER 360831-27096 User guide

-

allen+roth #367622-00209 Burnished Autumn Maple Laminate Flooring Lowe’s User manual

-

Style Selections LWCSS352 Installation guide

Style Selections LWCSS352 Installation guide

-

QuickStep QS902 Installation guide

QuickStep QS902 Installation guide

-

Pennsylvania Traditions 367841-00239 Installation guide

Pennsylvania Traditions 367841-00239 Installation guide

-

QuickStep LWCQS318 Installation guide

QuickStep LWCQS318 Installation guide

-

Style Selections LWCAR306 Installation guide

Style Selections LWCAR306 Installation guide

-

QuickStep QS907 Installation guide

QuickStep QS907 Installation guide

-

TrafficMASTER 368501-00264 Installation guide

-

Hampton Bay 367501-00195 Installation guide

Hampton Bay 367501-00195 Installation guide